Multifunctional automobile chassis component test bench

A technology of automobile chassis and components, applied in the field of test benches, can solve the problems of inconvenient up and down adjustment and inability to adjust accurately, and achieve the effects of convenient adjustment, improved precision, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

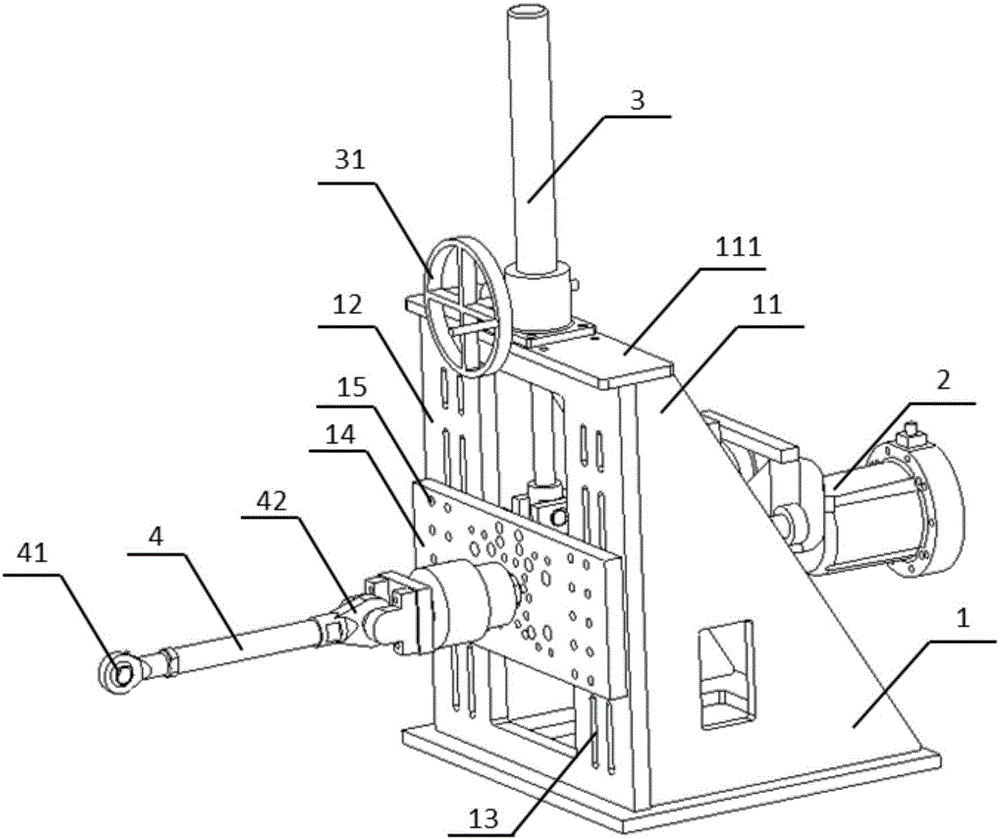

[0050] figure 1 It is a structural schematic diagram of a multifunctional automobile chassis parts test bench according to an embodiment of the present invention.

[0051] In this embodiment, the test bench for multifunctional automobile chassis components may include: a basic fixing bracket 1 , an actuator 2 , a lifting mechanism 3 and a connecting rod 4 .

[0052]The basic fixed support 1 is used to support the whole actuator 2, and it has a door frame type support 11, and one end surface of the door frame type support 11 is provided with a fixed plate 12 along its longitudinal direction, and the fixed plate 12 is arranged along its The waist hole 13 that length direction is provided with. The actuator 2 is installed at the base fixing bracket 1 for providing driving force to the test bench. The lifting mechanism 3 is detachably installed on the top 111 of the door frame-shaped support 11 and passes through the top 111 and is connected with the actuator 2 for driving the a...

Embodiment 2

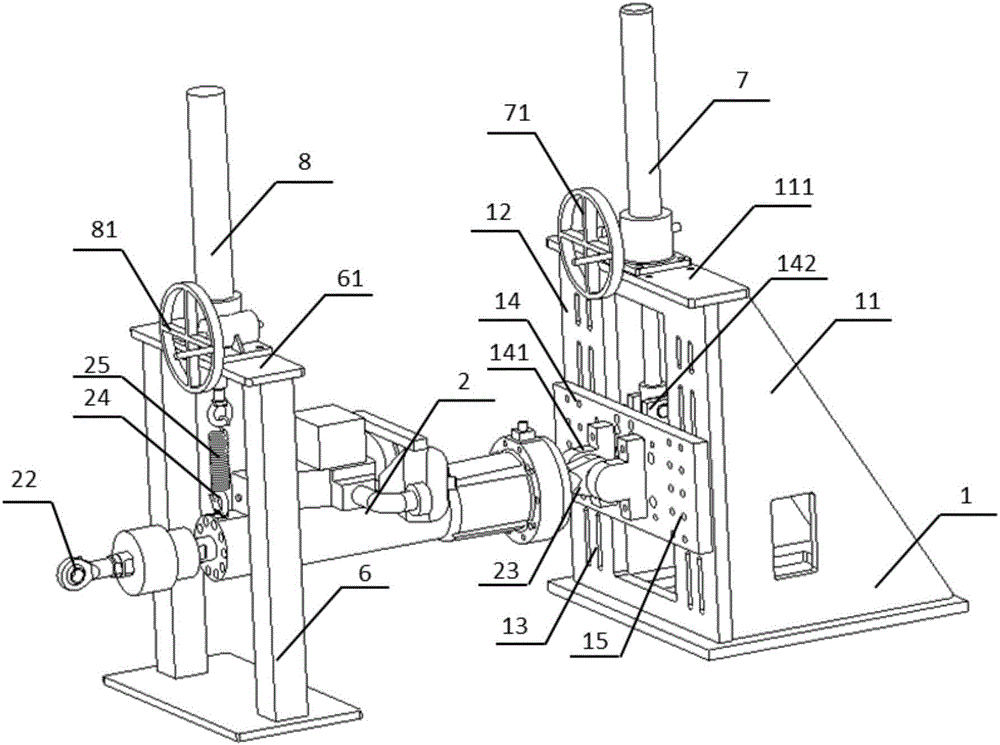

[0066] figure 2 It is a structural schematic diagram of a multifunctional automobile chassis parts test bench according to another embodiment of the present invention. In this embodiment, the multifunctional automobile chassis parts test bench may include: a basic fixed support 1 , a fixed support 6 , an actuator 2 , a first lifting mechanism 7 and a second lifting mechanism 8 .

[0067] The basic fixed support 1 is used to support the whole actuator 2, and it has a door frame type support 11, and one end surface of the door frame type support 11 is provided with a fixed plate 12 along its longitudinal direction, and the fixed plate 12 is arranged along its The waist hole 13 that length direction is provided with. The fixed bracket 6 is arranged in front of the basic fixed bracket 1 along the transverse axis thereof, and is used to support the entire actuator 2 together with the basic fixed bracket 1 . The actuator 2 is installed between the base fixing bracket 1 and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com