Swing direct drive device and method built in solenoid coil

A solenoid coil, direct drive technology, applied to the power device inside the switch, valve operation/release device, valve device and other directions, can solve the problems of easy failure, many parts, inconvenience, etc., and achieve a wide range of applications , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

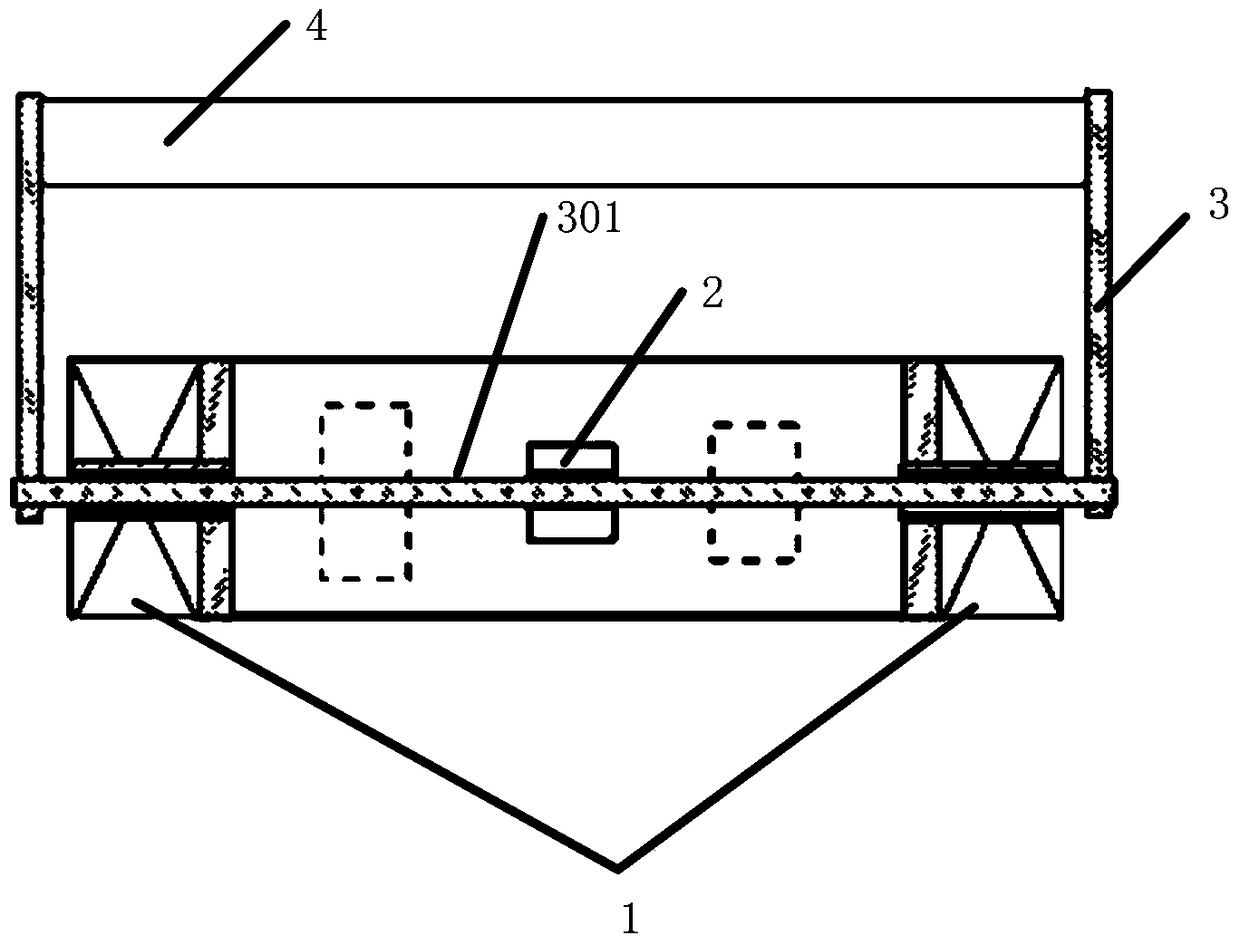

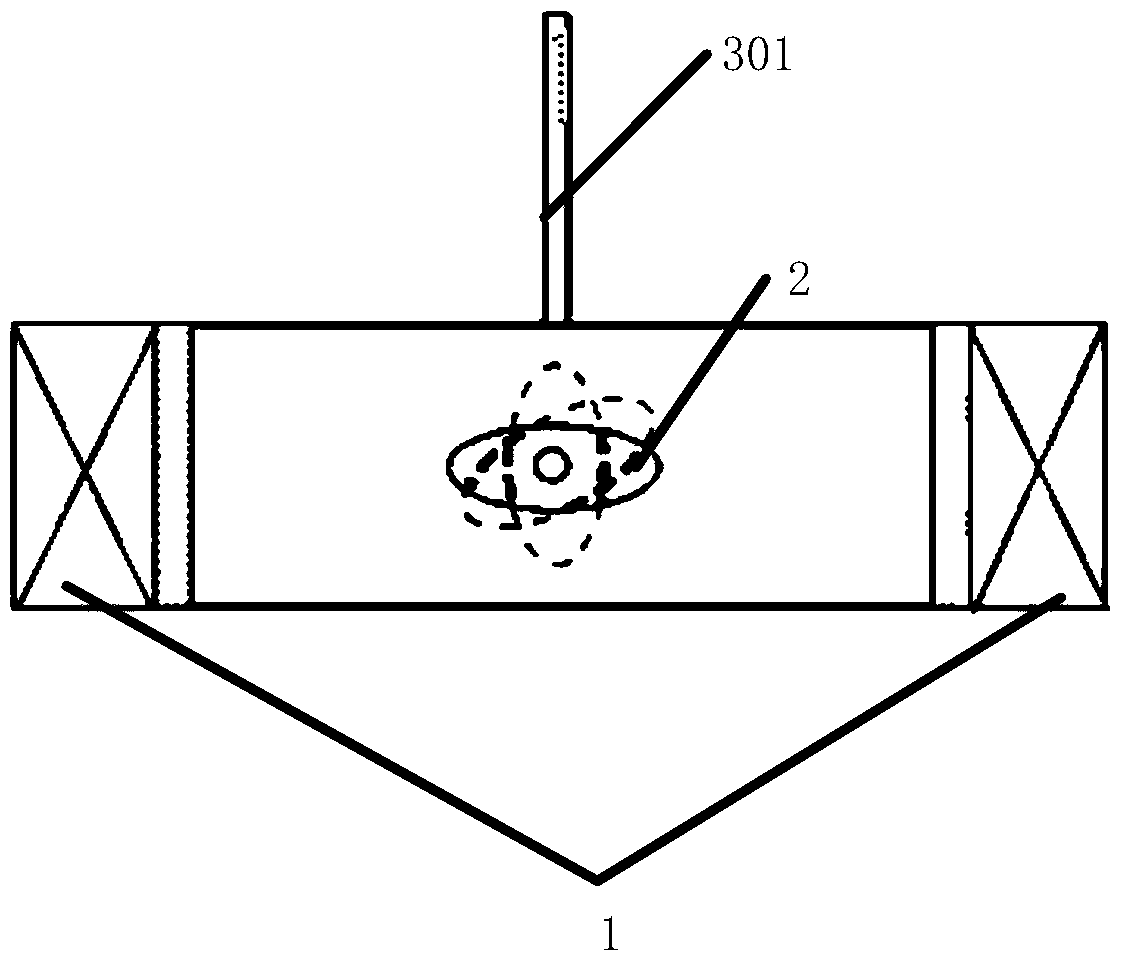

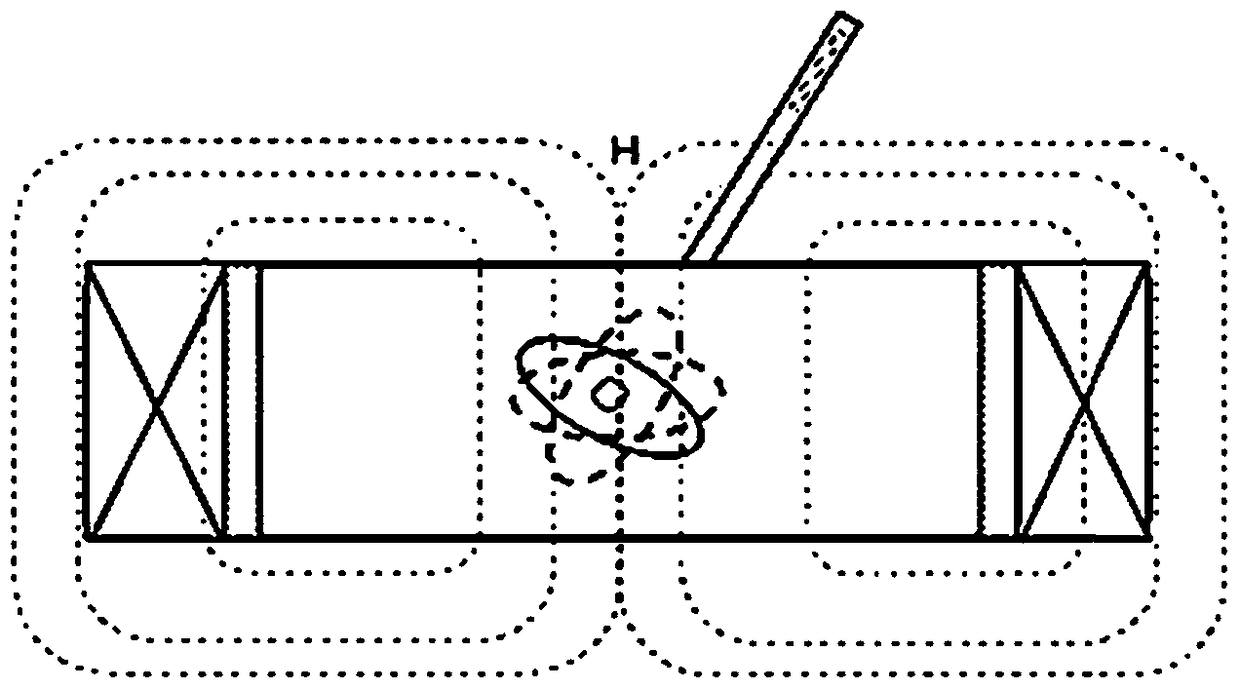

[0053] figure 1 , figure 2 , image 3 It is a structural schematic diagram of the swing direct drive device built in the solenoid coil in the first embodiment of the present invention. The first embodiment is a preferred example of the above-mentioned basic embodiment. In this embodiment, the swing direct drive device built in the solenoid coil includes a solenoid coil 1, a magnet 2, and a transmission assembly 3; the magnet 2 can be It is an electromagnet or a permanent magnet; the magnet 2 is located inside the solenoid coil 1; the magnet 2 is connected to the transmission assembly 3, and the transmission assembly 3 extends from the inside of the solenoid coil 1 to the outside of the solenoid coil 1; the solenoid coil 1 Applying a magnetic force to the magnet 2 causes the magnet 2 to rotate; the magnet 2 rotates and drives the transmission assembly 3; the number of the magnet 2 is one or more.

[0054] Among them, the solenoid coil 1 interacts with the magnet 2 to form a...

no. 2 example

[0057] Figure 4 , Figure 5 It is a structural schematic diagram of the swing direct drive device built in the solenoid coil in the second embodiment of the present invention. The second embodiment is a preferred example of the above-mentioned basic embodiment. In this embodiment, the swing direct drive device built in the solenoid coil includes a solenoid coil 1, a magnet 2, and a transmission assembly 3; the magnet 2 can be It is an electromagnet or a permanent magnet; the magnet 2 is located inside the solenoid coil 1; the magnet 2 is connected to the transmission assembly 3, and the transmission assembly 3 extends from the inside of the solenoid coil 1 to the outside of the solenoid coil 1; the solenoid coil 1 Applying a magnetic force to the magnet 2 causes the magnet 2 to rotate; the magnet 2 rotates and drives the transmission assembly 3; the number of the magnet 2 is one or more.

[0058] Among them, the solenoid coil 1 interacts with the magnet 2 to form a magnetic...

no. 3 example

[0061] Figure 6 , Figure 7 It is a structural schematic diagram of the swing direct drive device built in the solenoid coil in the third embodiment of the present invention. The third embodiment is a preferred example of the above-mentioned basic embodiment. In this embodiment, the swing direct drive device built in the solenoid coil includes a solenoid coil 1, a magnet 2, and a transmission assembly 3; the magnet 2 can be It is an electromagnet or a permanent magnet; the magnet 2 is located inside the solenoid coil 1; the magnet 2 is connected to the transmission assembly 3, and the transmission assembly 3 extends from the inside of the solenoid coil 1 to the outside of the solenoid coil 1; the solenoid coil 1 Applying a magnetic force to the magnet 2 causes the magnet 2 to rotate; the magnet 2 rotates and drives the transmission assembly 3; the number of the magnet 2 is one or more.

[0062] Among them, the solenoid coil 1 interacts with the magnet 2 to form a magnetic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com