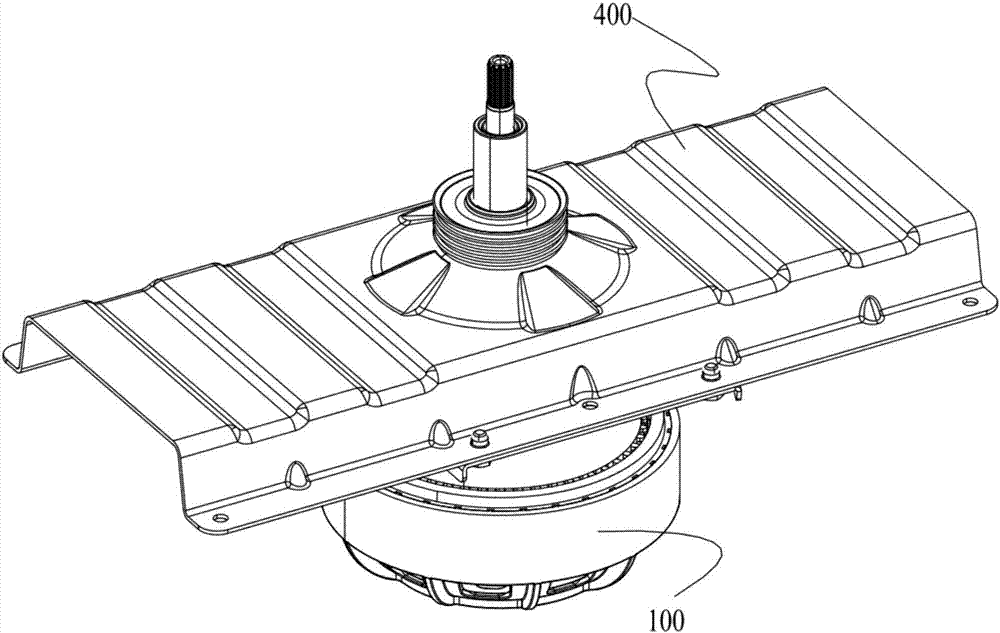

Driving clutch assembly of washing machine

A technology for a clutch assembly and a washing machine, applied in the field of washing machines, can solve the problems of cumbersome connection structure of clutch and rotor, insufficient compact structure, and high motor cost, and achieve the effects of easy batch assembly, compact structure, compact product and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

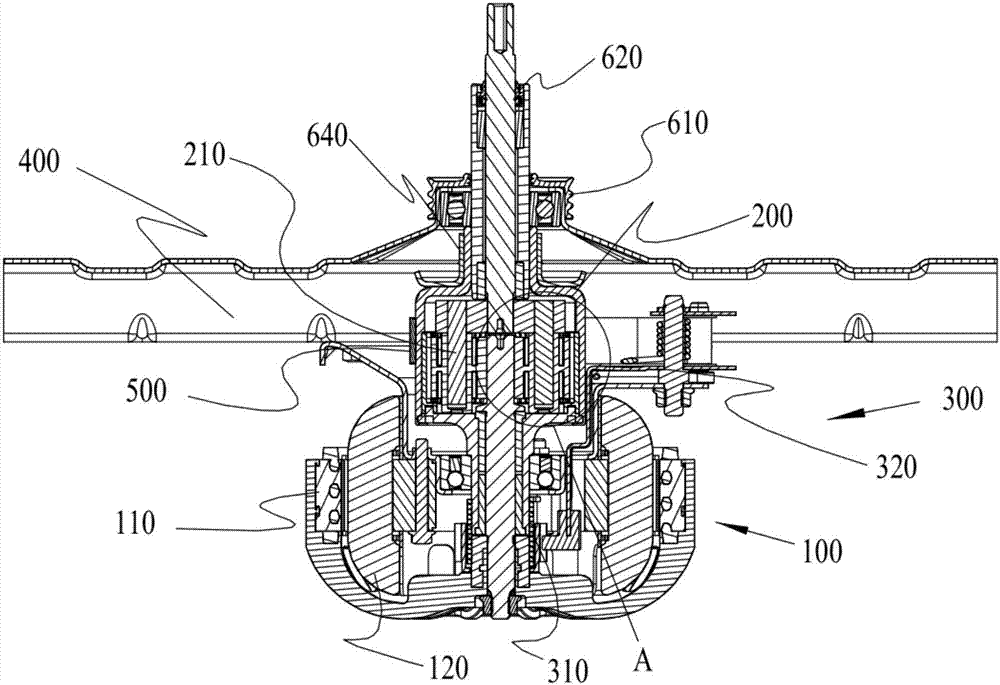

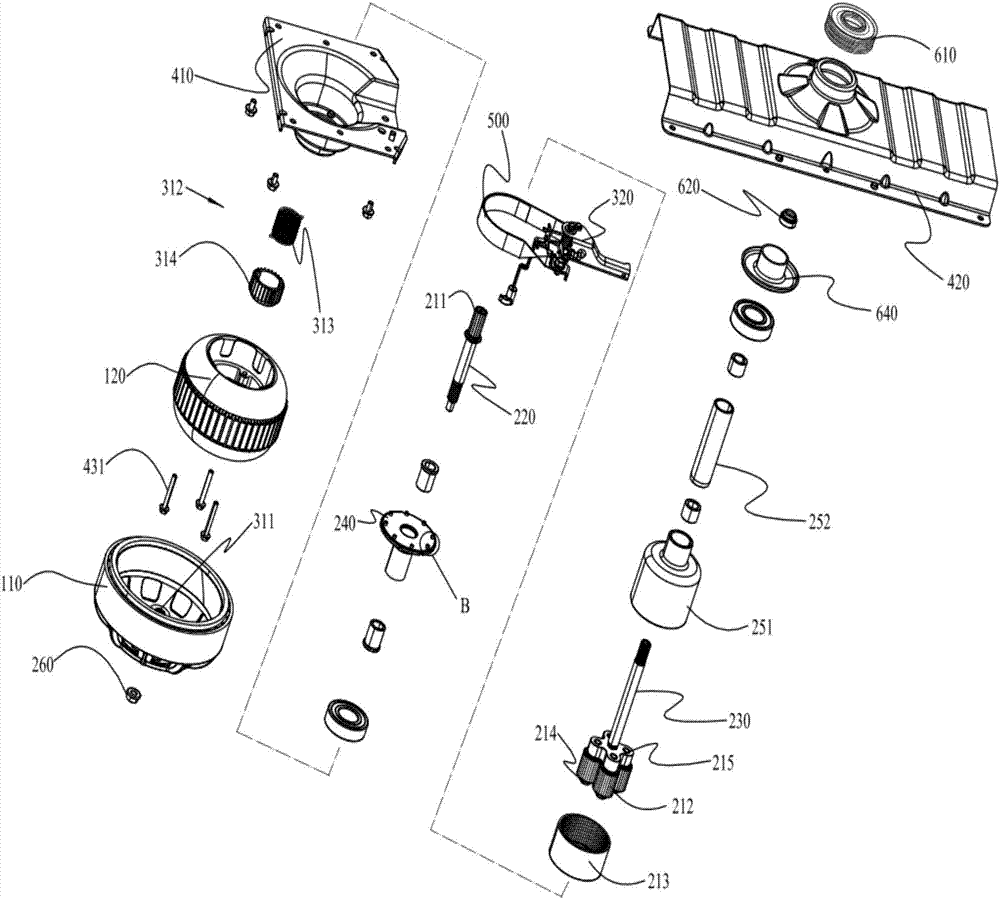

[0057] The embodiment of the invention discloses a washing machine drive clutch assembly, which includes a rotating body and a transmission device. The transmission device includes a deceleration mechanism, a clutch mechanism and an installation housing. The ground is output to the washing and dehydration executing parts of the washing machine, wherein the clutch assembly is provided with a clutch shaft sleeve and a clutch spring assembly, the clutch shaft sleeve is arranged outside the input end of the drive shaft, and is fixedly connected with the outer rotor assembly, and the clutch spring assembly covers Connected to the outside of the input end of the clutch sleeve and the drive sleeve. Preferably, the lever assembly can be relatively rotatably installed on the stator mounting plate, the inside of the stator mounting plate has a stepped surface, the stepped surface is provided with a lever socket, and the output end of the lever is inserted into the dial along the upper op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com