Patents

Literature

96results about How to "Smooth acceleration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

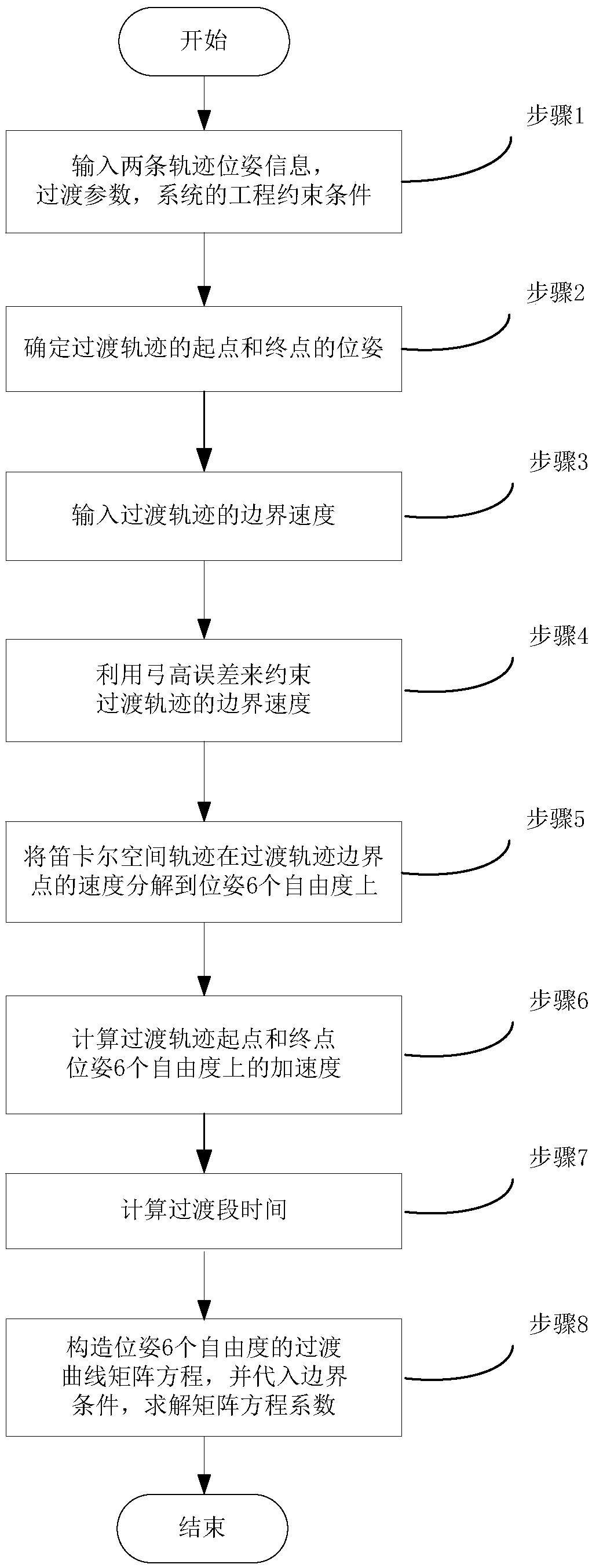

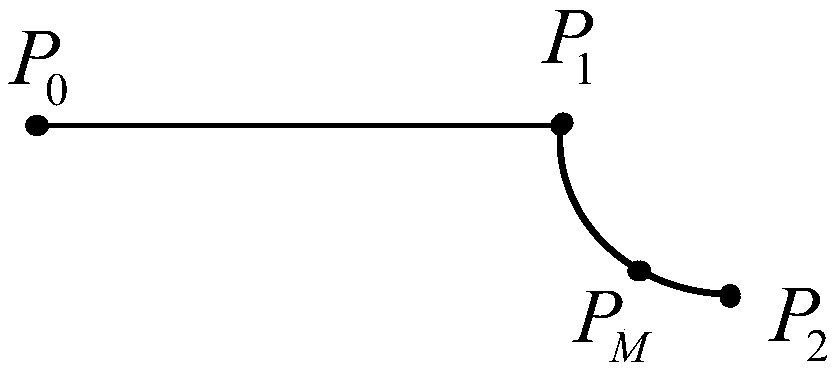

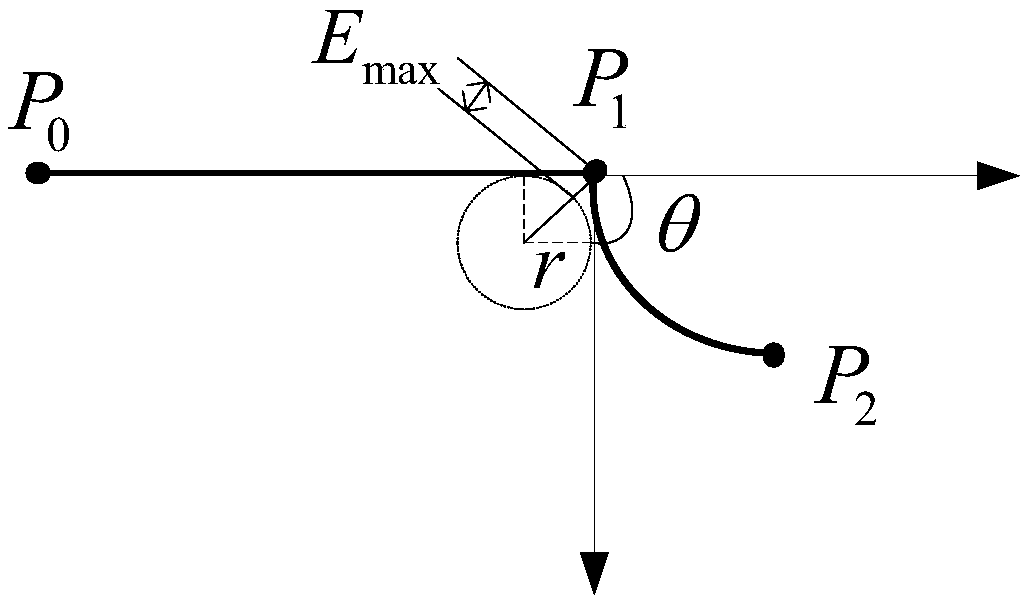

Transitional track planning method applied by industrial robot

ActiveCN105500354AAvoid multiple solutionsIntuitive curveProgramme-controlled manipulatorCurve shapeRotation velocity

The invention discloses a transitional tracking planning method applied by an industrial robot, which can realize the transition between a joint space track and a cartesian space track, and the transition between two tracks of the cartesian space, the transitional track between different movement tracks are planned under the cartesian space, and has an intuitive shape; by adopting the algorithm that two parabolas are fused into one transitional curve, the smoothness of the track, speed and acceleration can be ensured, and the curve shape is controllable; the transitional track is formed by six independent curves, and the transition can be realized on the track with only posture change without position change; from the engineering application angle, the path velocity of transitional track boundary is restrained by utilizing the included angle between the tracks and the system allowable chord error, the boundary posture rotation speed is restrained by the similar mode, so that the large impact on a mechanical system caused by overhigh engagement speed can be prevented.

Owner:埃斯顿(广东)机器人有限公司

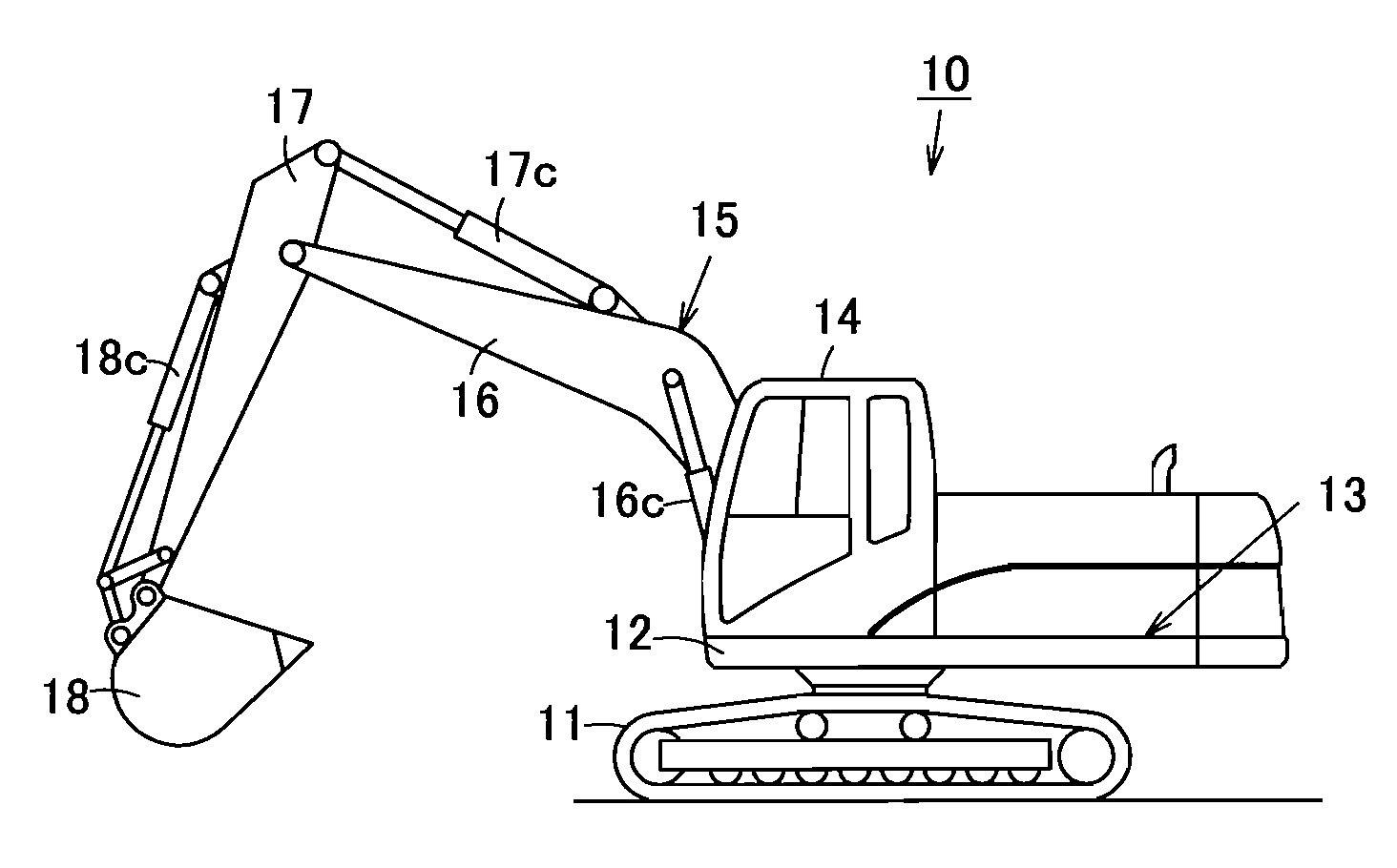

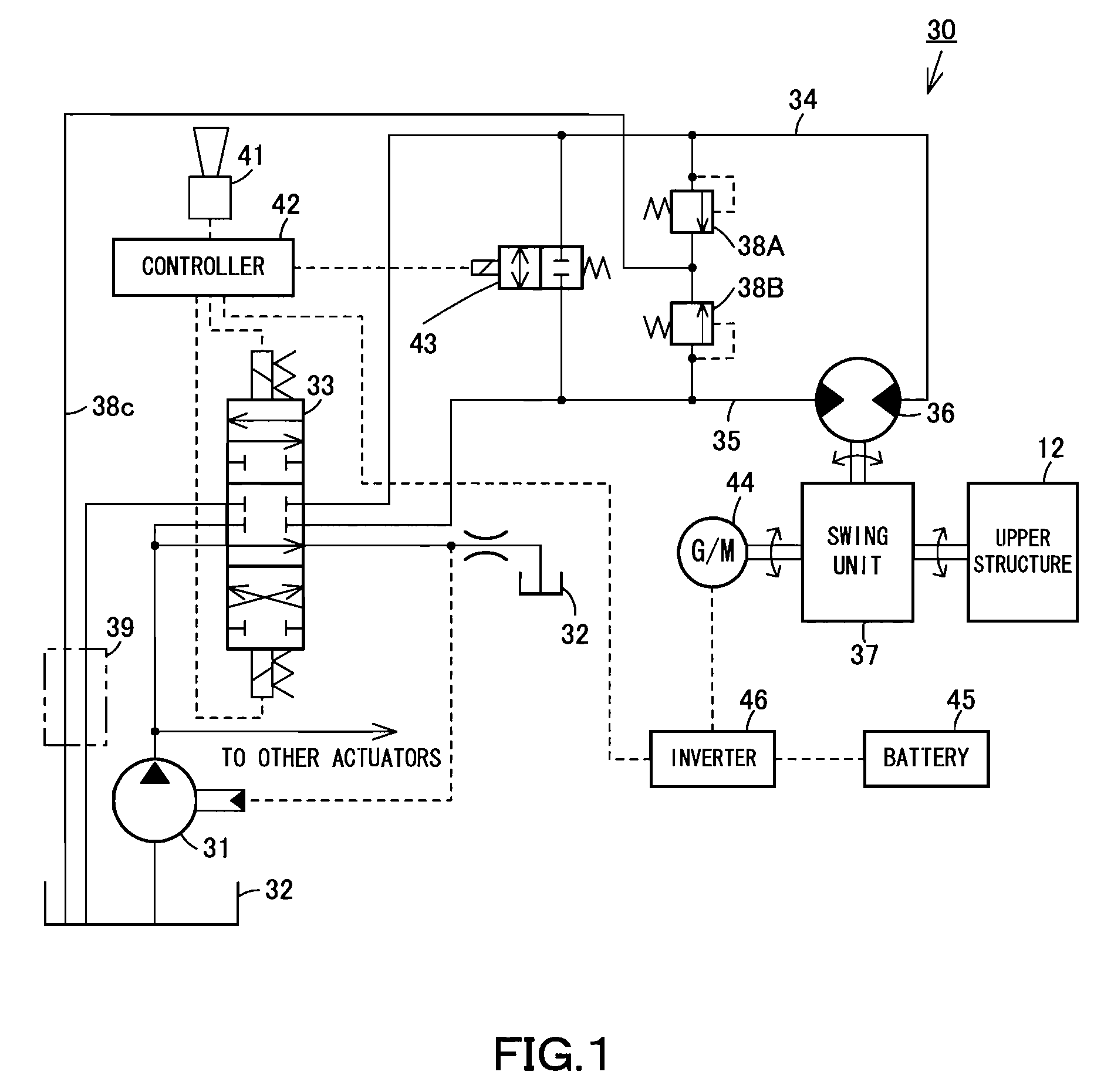

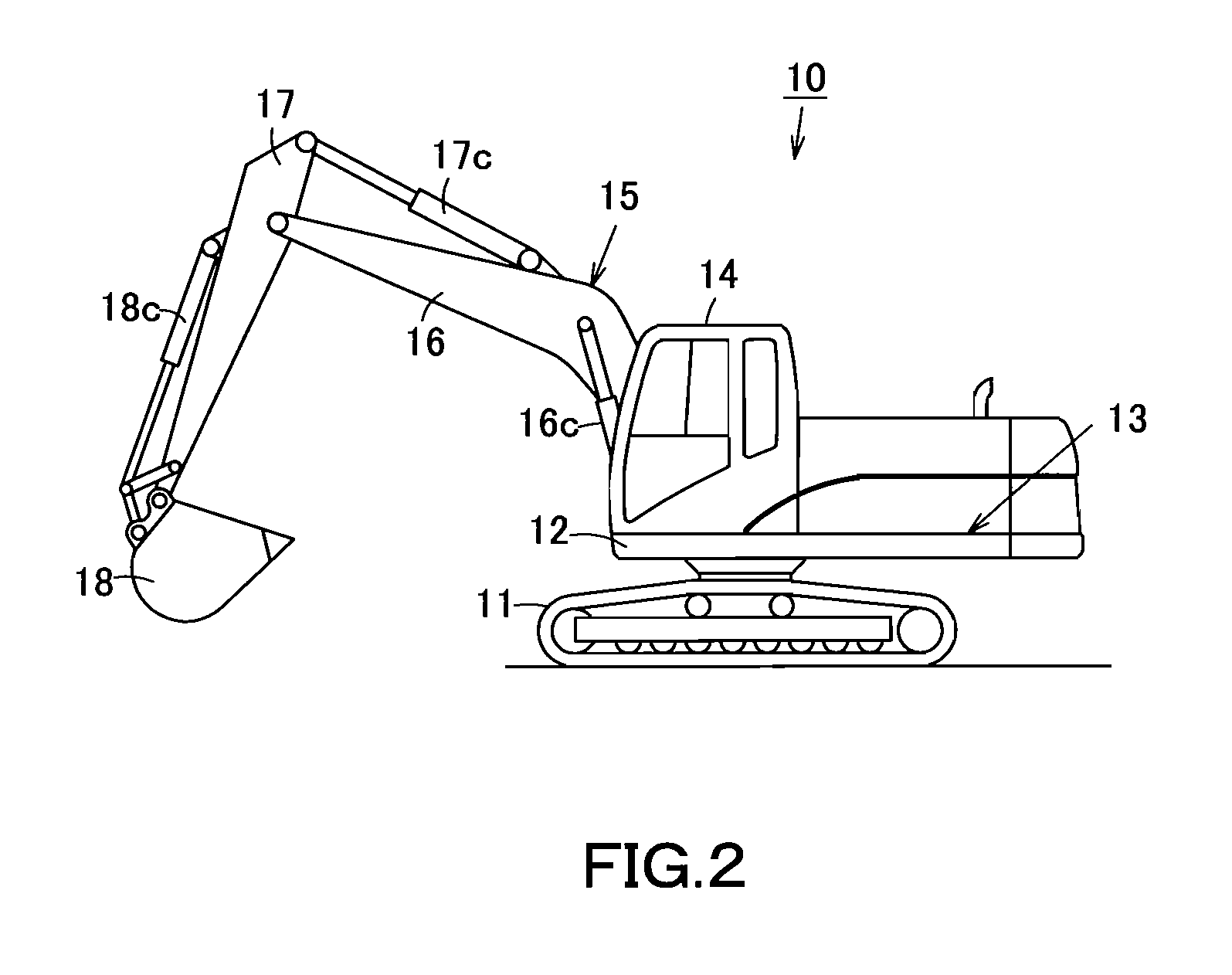

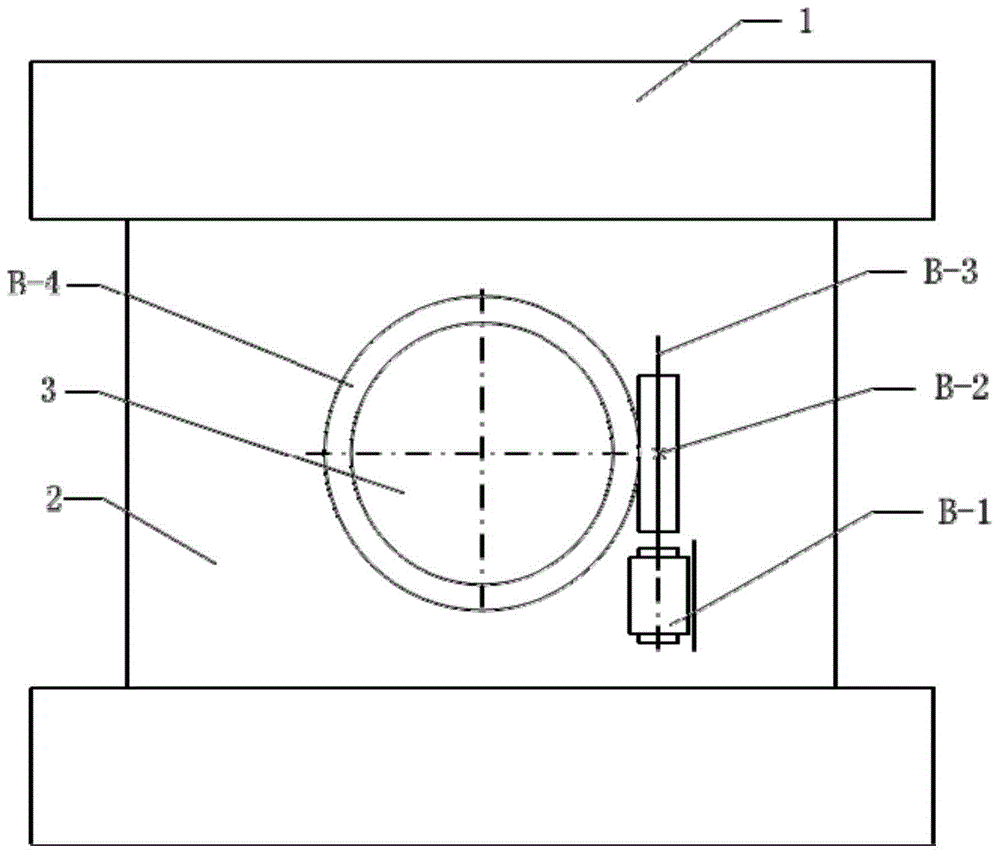

Swing Drive Device and Work Machine

InactiveUS20080317574A1Smoothly acceleratedLoss of hydraulic energyLifting devicesServometer circuitsThermal energyEngineering

The invention provides a swing drive device that is capable of energy conservation by limiting loss of hydraulic fluid pressure energy resulting from discharge of the hydraulic fluid pressure energy as thermal energy into the air during acceleration or deceleration of swinging action and transforming motion energy to electric energy during deceleration of swinging action, and also enables cost reduction by making components and parts compact.

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

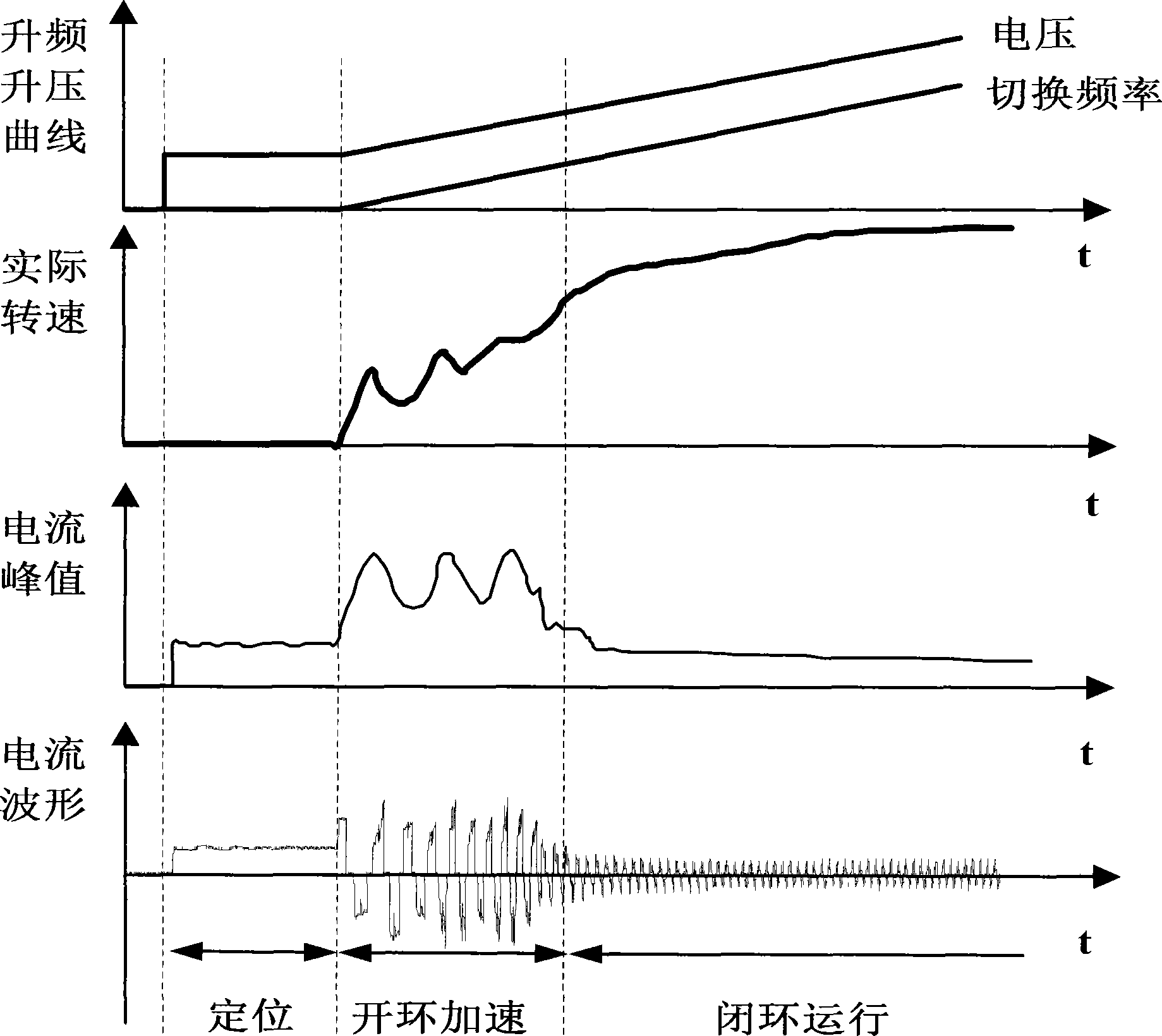

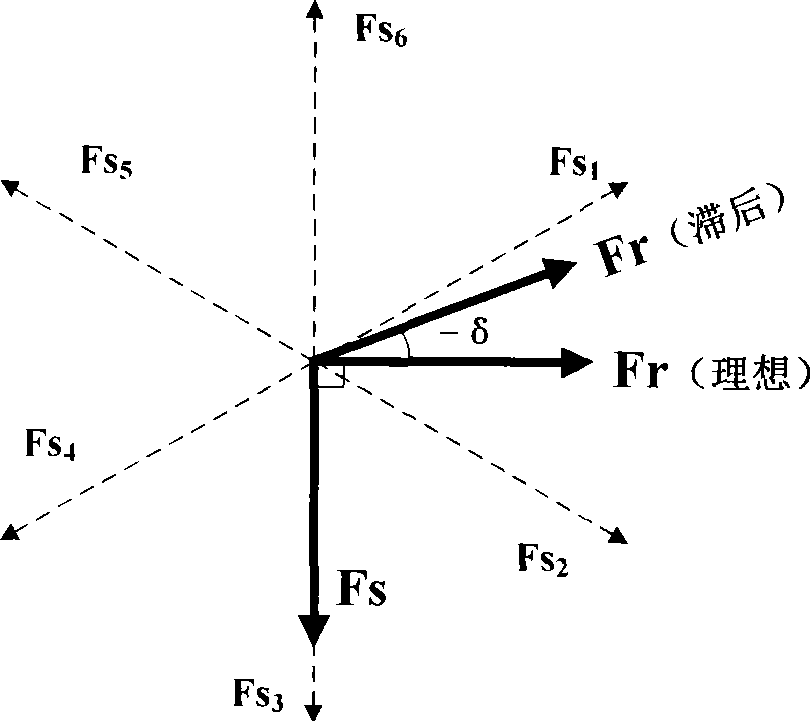

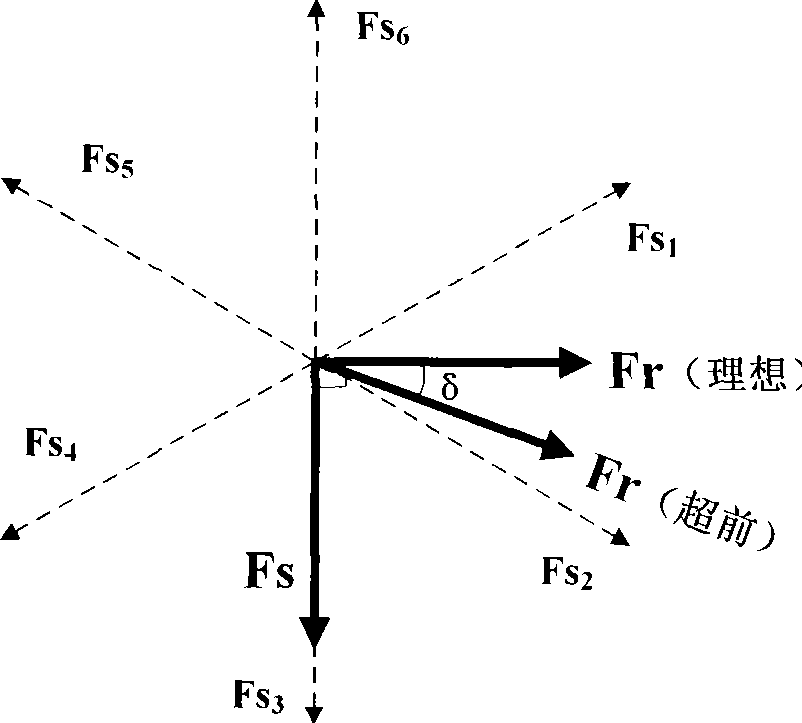

Starting method for brushless DC motor without position sensor based on current feedback

InactiveCN101478281AEasy to startImprove stabilityDynamo-electric machine testingStarter arrangementsPhase currentsClosed loop

The invention discloses a starting method of a brushless, position sensor- free DC motor based on current feedback. The method comprises the steps as follows: a rotor is pre-positioned; the direction changing and the current converting are carried out; a preset voltage value is calculated according to a pressure-raising curve and is output in the form of PWM; the direction changing and the current converting are carried out when detection shows that a phasing current value I exceeds a predetermined value IH, and the preset voltage value in the next step is calculated at the same time according to the pressure-raising curve; and an electric motor is switched over to closed-loop operation when the current converting frequency is greater than the predetermined value, that is, rotational speed is high enough to obtain a back-EMF signal. Based on the real-time detection on the starting current, the technical proposal of the starting method obtains better starting performance compared with a traditional three-step starting method, ensures the stability and controllability of Delta during the whole accelerating process, leads the starting current to be more stable, enables the accelerating process to be smoother, automatically reduces the rotational speed and the Delta so as to obtain greater electromagnetic torque without desynchronizing when meeting with load disturbance, and does not need to add extra hardware or timers, thereby being simpler and more reliable.

Owner:浙江精雷电器股份有限公司

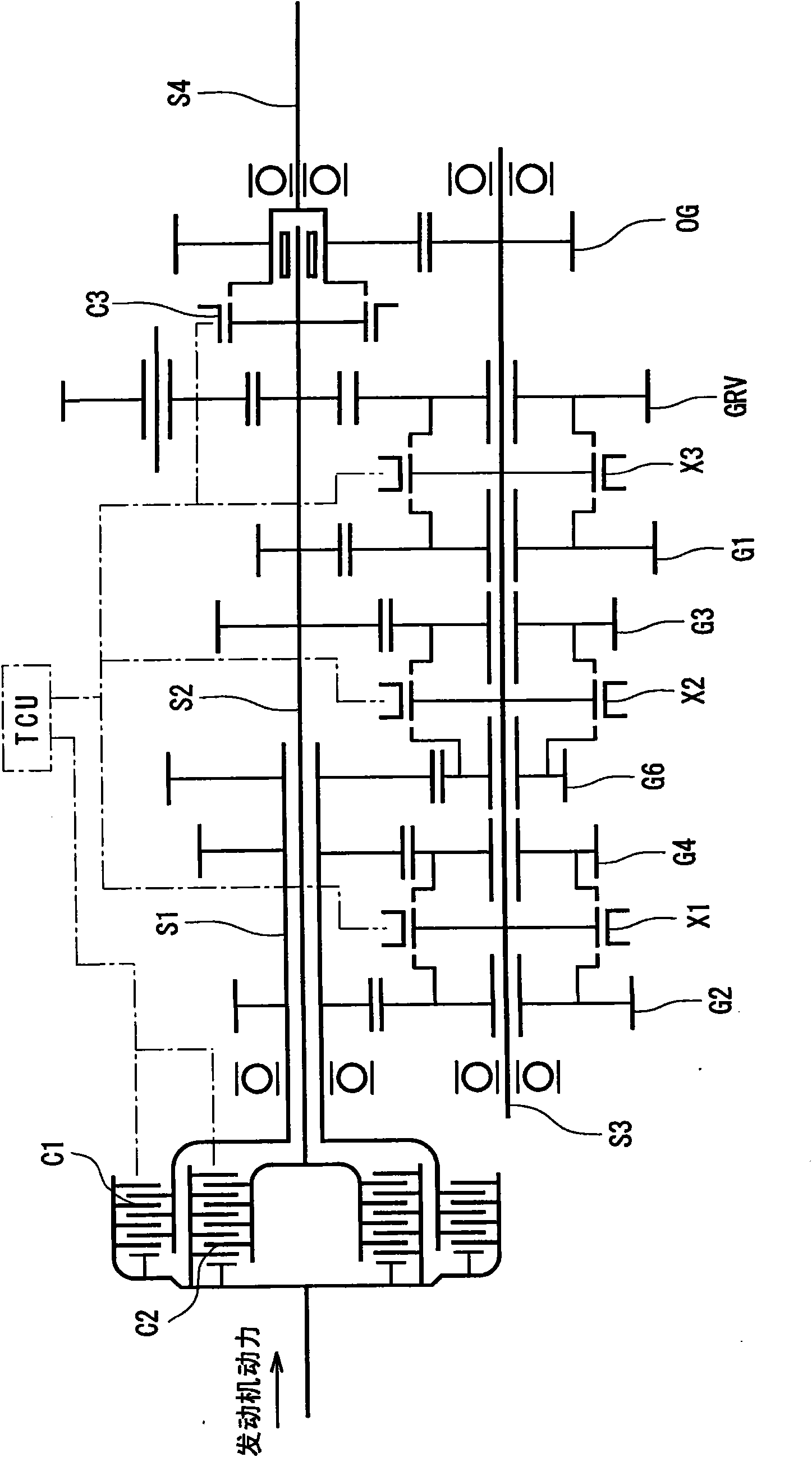

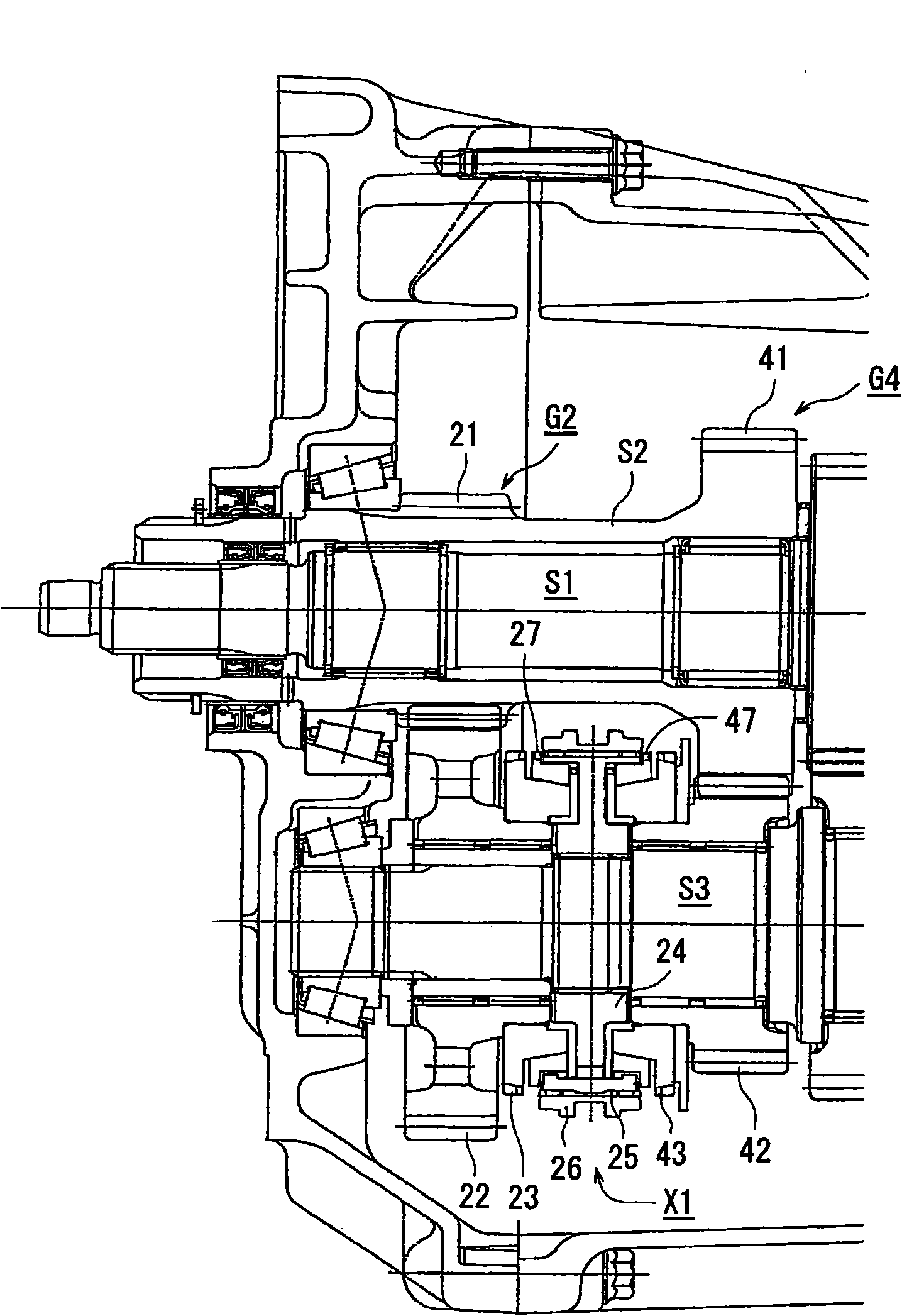

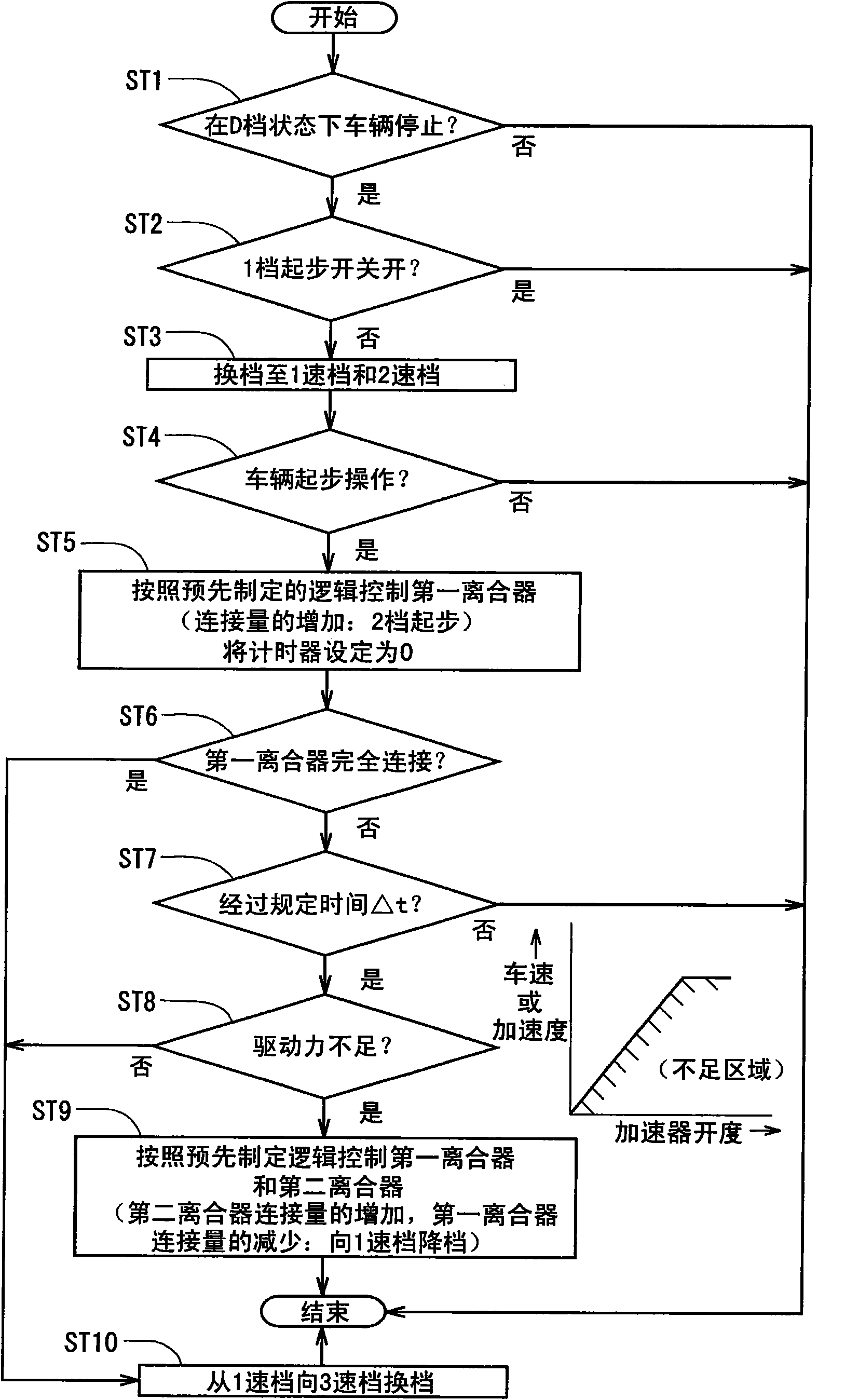

Acceleration control apparatus for automobile dual-clutch transmission

ActiveCN101978188ASmooth accelerationIncrease connection volumeClutchesGearing controlGear trainControl theory

The present invention provides an acceleration control apparatus, at the start of a freight vehicle mounting a dual clutch type transmission in an ordinary condition, a smooth start is accomplished with the second speed, but the transmission is quickly shifted to the first speed when the vehicle is to start moving on the way of uphill road. At the start of the freight vehicle, first, the two input shafts of the dual clutch type transmission are set to a state of being shifted to the first speed and to the second speed and in this state, the amount of connection of the friction clutch coupled to the gear train of the second speed is increased to execute the second-speed start. After the passage of a predetermined period of time, the accelerator opening degree and the vehicle speed are detected to judge the excess or insufficiency of the driving force. If the driving force is not insufficient, the start with the second speed is continued to quickly accelerate the vehicle. If the driving force is judged to be insufficient, the friction clutch coupled to the gear train of the first speed is readily connected. The transmission has been shifted already to the gear train of the first speed. Therefore, the transmission is shifted down in a short period of time avoiding unexpected occurrence such as moving back of the vehicle even on an uphill road vehicle.

Owner:ISUZU MOTORS LTD

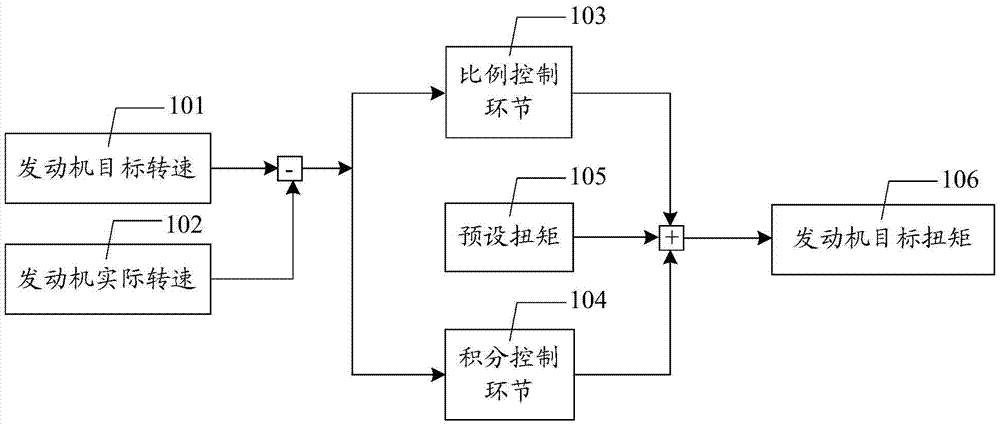

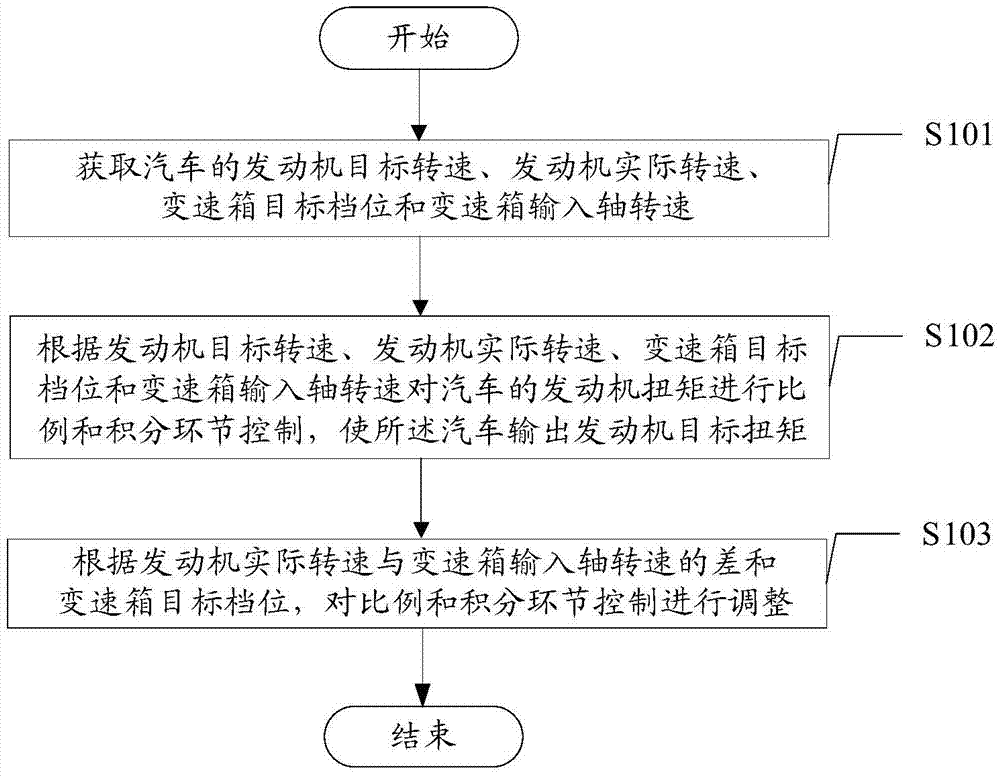

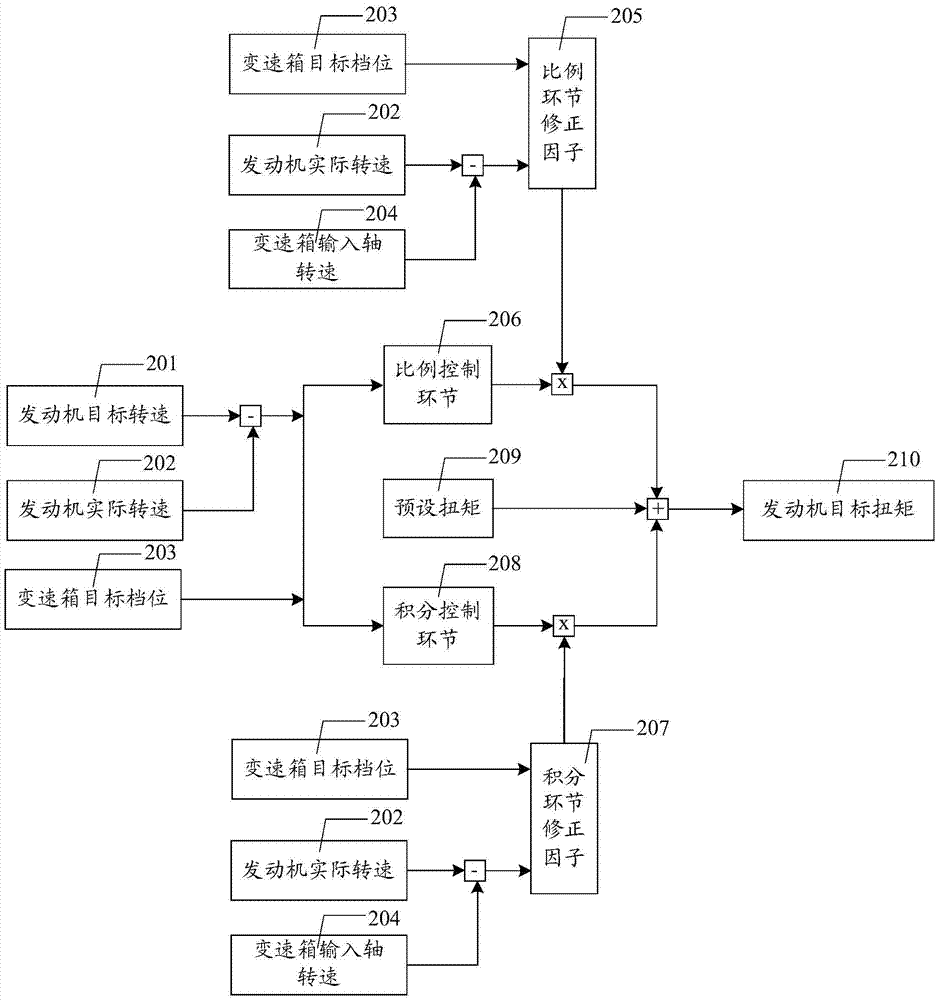

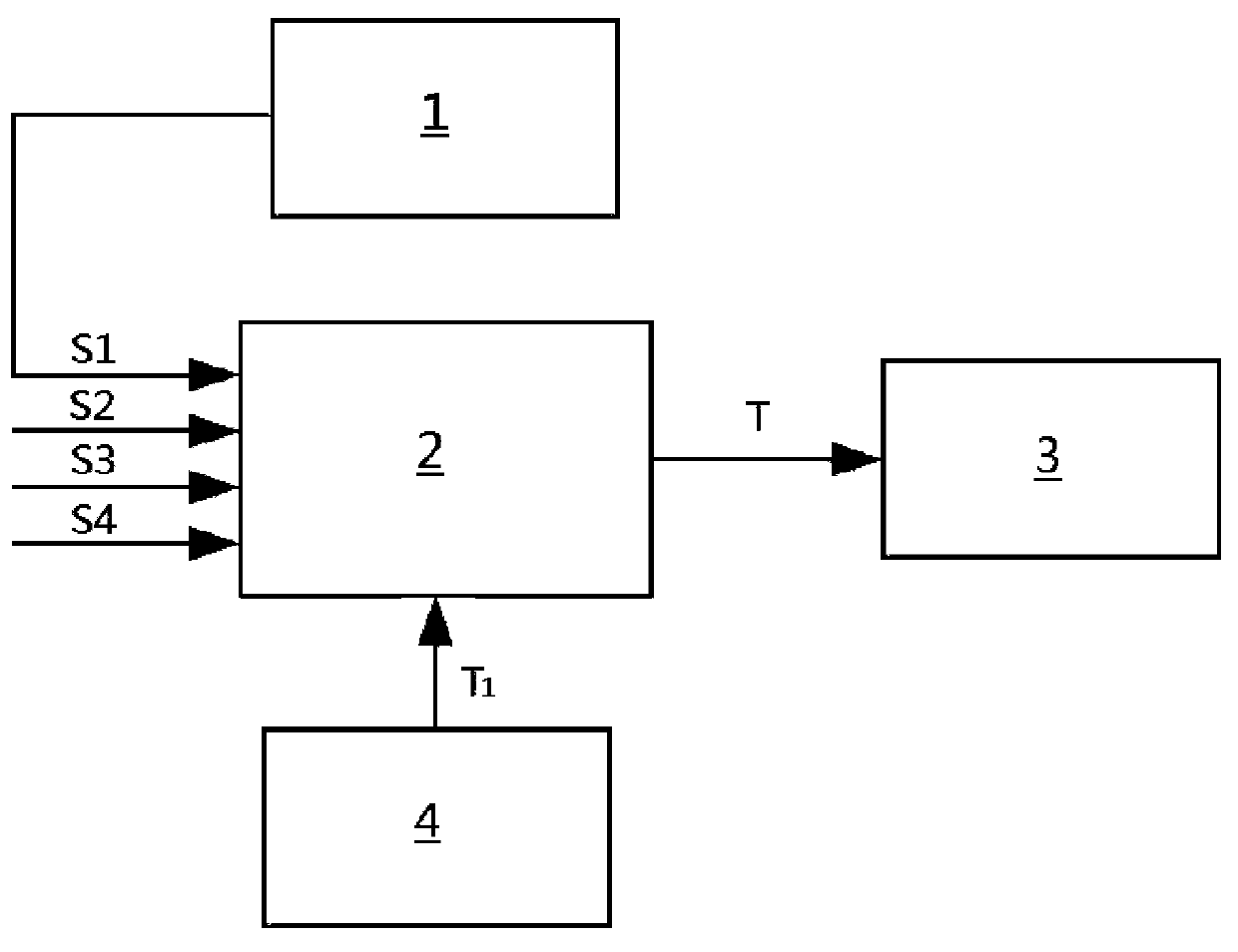

Engine torque control method and automobile

ActiveCN106907481ASolve the problem of non-linear speed changeImprove bindingGearing controlEngineeringAcceleration Unit

The invention discloses an engine torque control method suitable for an automobile adopting a dry clutch. The engine torque control method comprises the steps that the target engine rotating speed, the actual engine rotating speed, the target transmission gear and the transmission input shaft rotating speed of the automobile are acquired; the engine torque of the automobile is subjected to proportional element and integral element control according to the actual engine rotating speed, the target transmission gear and the transmission input shaft rotating speed of the automobile, so that the automobile outputs the target engine torque; and proportional element and integral element control is adjusted according to the difference between the actual engine rotating speed and the transmission input shaft rotating speed, and the target transmission gear. According to the scheme aiming at the automobile adopting the dry clutch, under the starting work condition of the automobile at a neutral gear sliding to be accelerated to the first or second gear, stable acceleration of the automobile is ensured through impaction generated in the rotating speed synchronous process of the engine and the clutch.

Owner:SAIC MOTOR

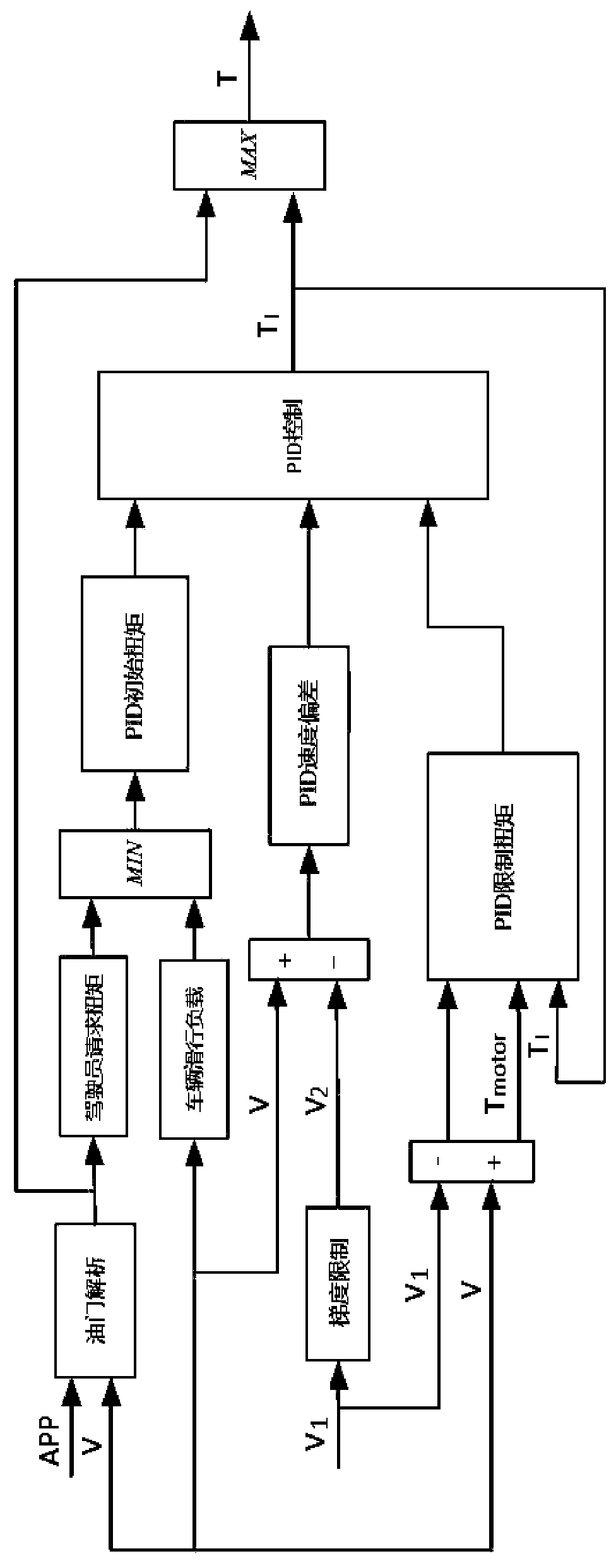

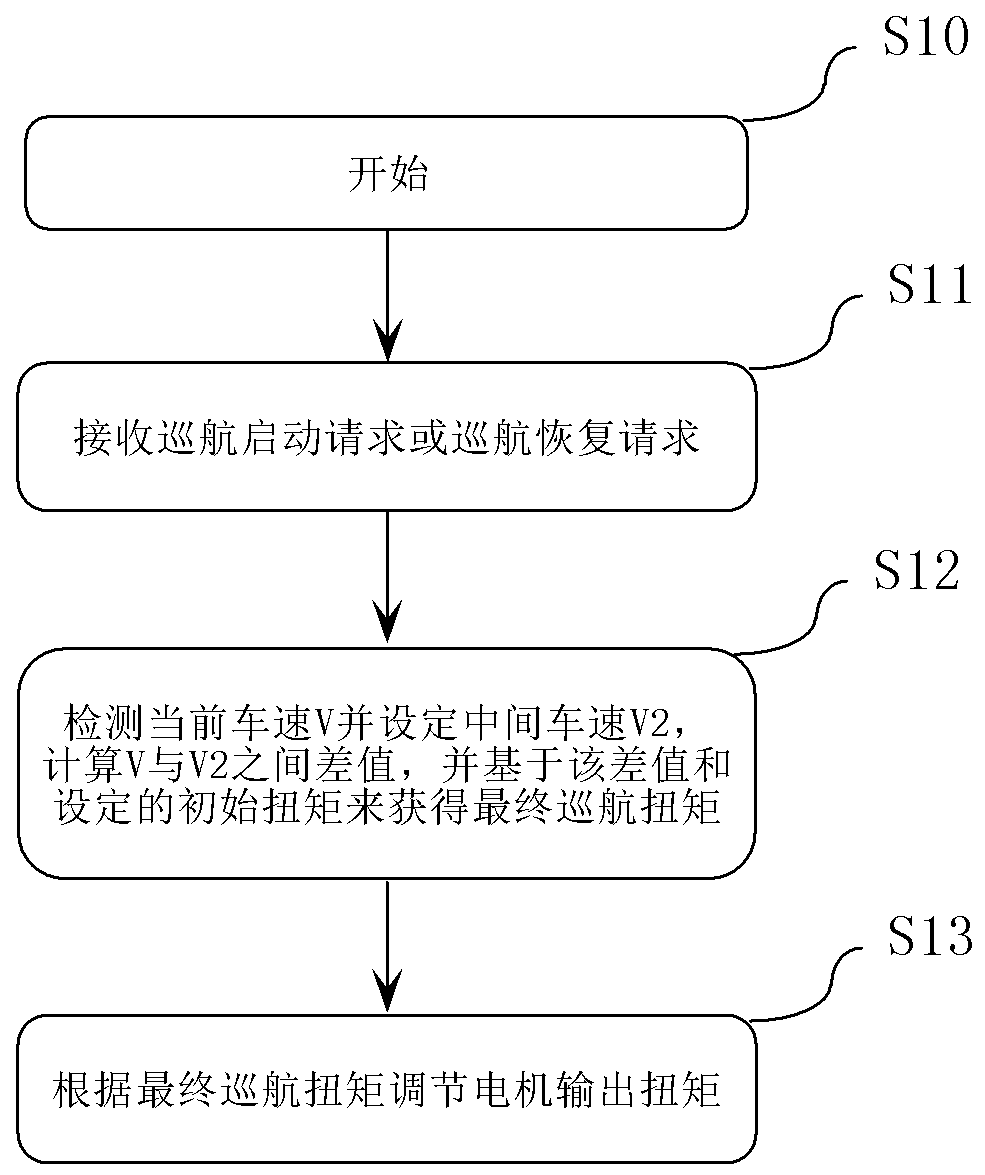

Electric vehicle cruise control method and system, vehicle, controller and storage medium

ActiveCN109835335AReduce calibration workloadSmooth cruiseSpeed controllerElectric devicesCruise controlElectric vehicle

The invention relates to an electric vehicle cruise control method and system, a vehicle, a controller and a storage medium. The method comprises the following steps: receiving a cruise starting request or a cruise recovery request, wherein the cruise starting request comprises a cruise target vehicle speed V1; if the vehicle conforms to the cruise setting condition, detecting a current vehicle speed V, setting an intermediate vehicle speed V2 between the cruise target vehicle speed V1 and the current vehicle speed V according to the cruise target vehicle speed V1 and the current vehicle speedV, then calculating a difference value between the current vehicle speed V and the intermediate vehicle speed V2, and obtaining a final cruise torque based on the difference value and a set initial torque; and adjusting the motor output torque of the electric vehicle according to the final cruise torque to drive the vehicle to cruise. The cruise control torque can be effectively prevented from fluctuating, it is guaranteed that cruise driving of the whole vehicle is smoother, and the driving experience of a user is improved.

Owner:NIO ANHUI HLDG CO LTD

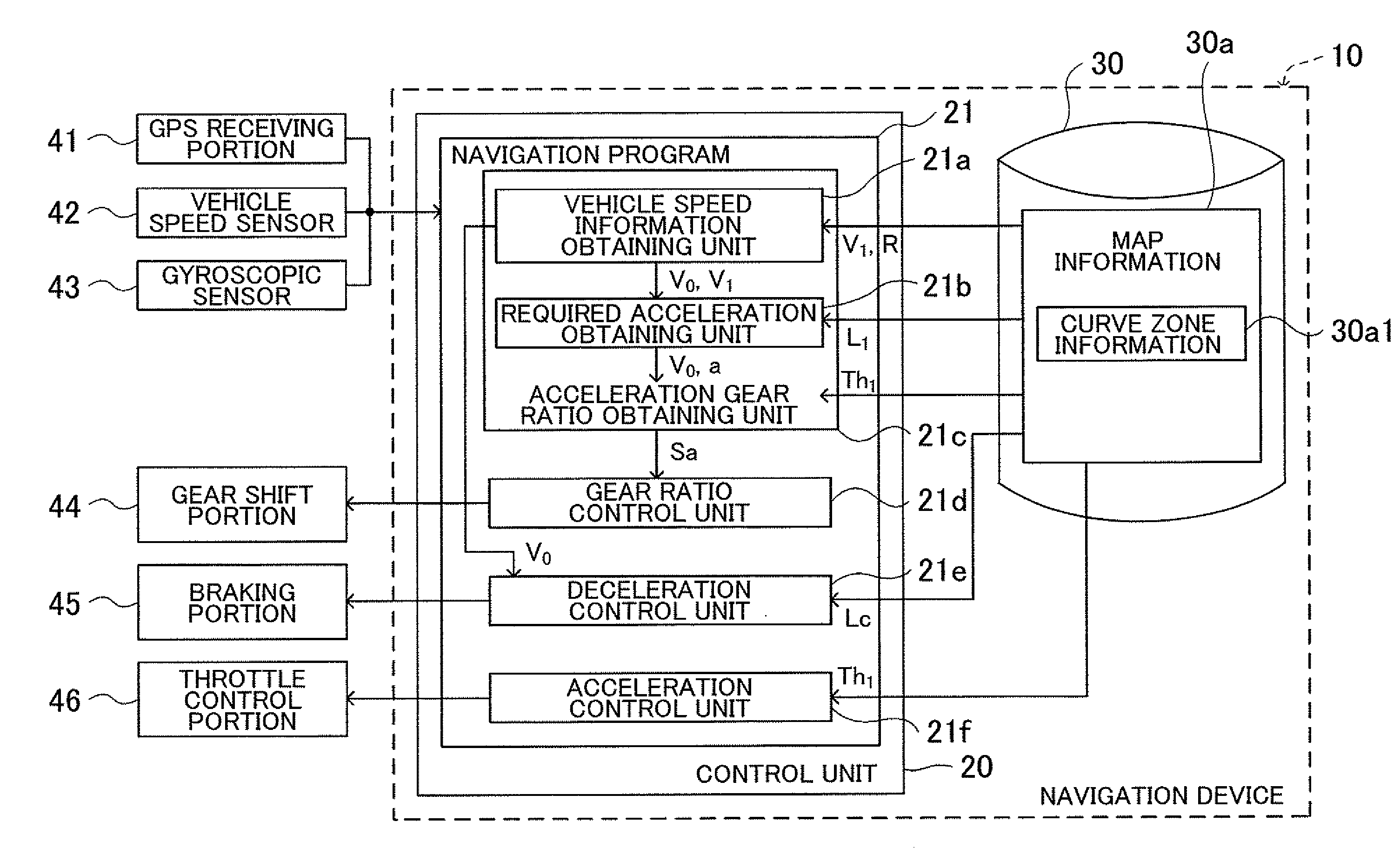

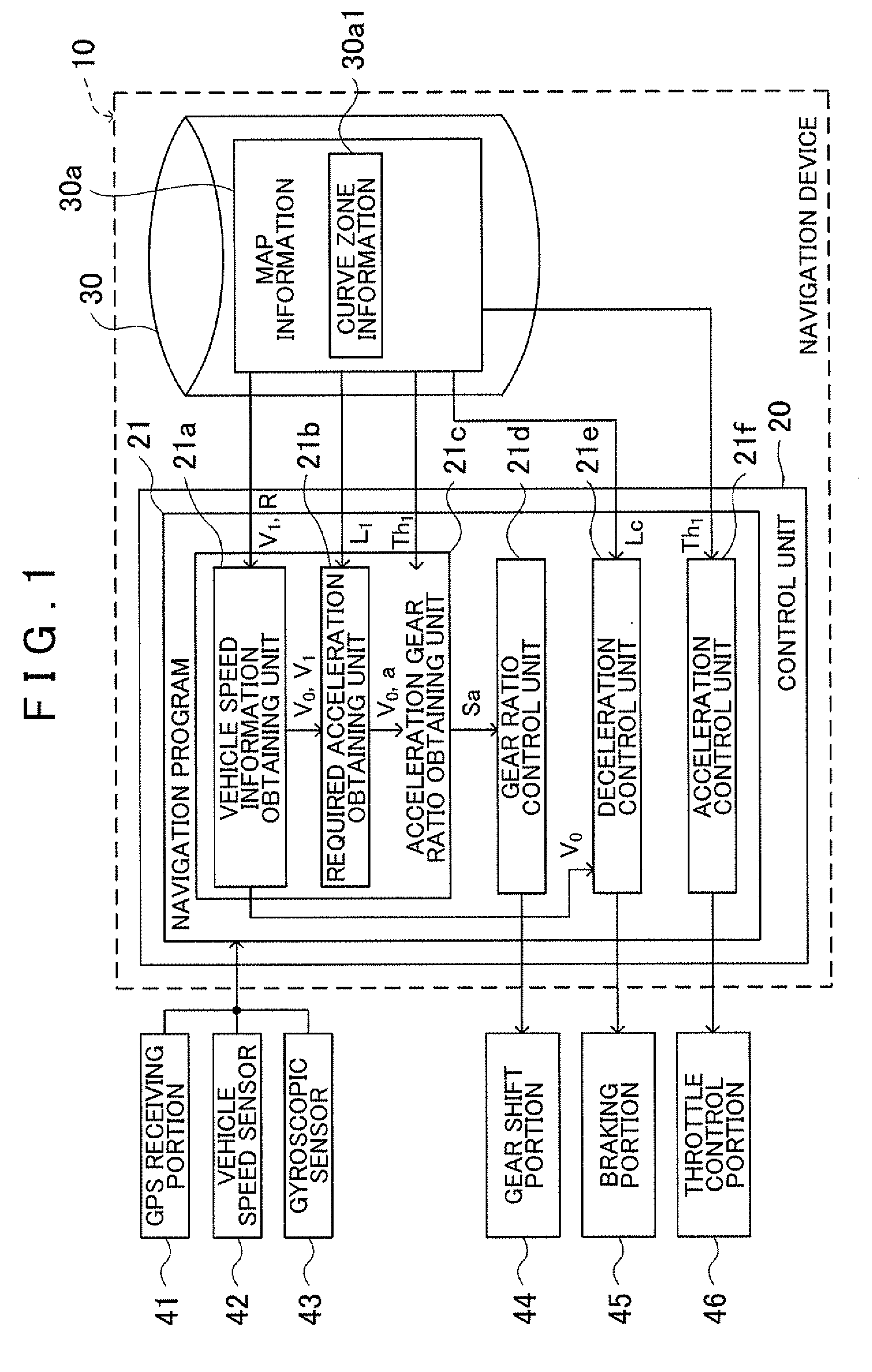

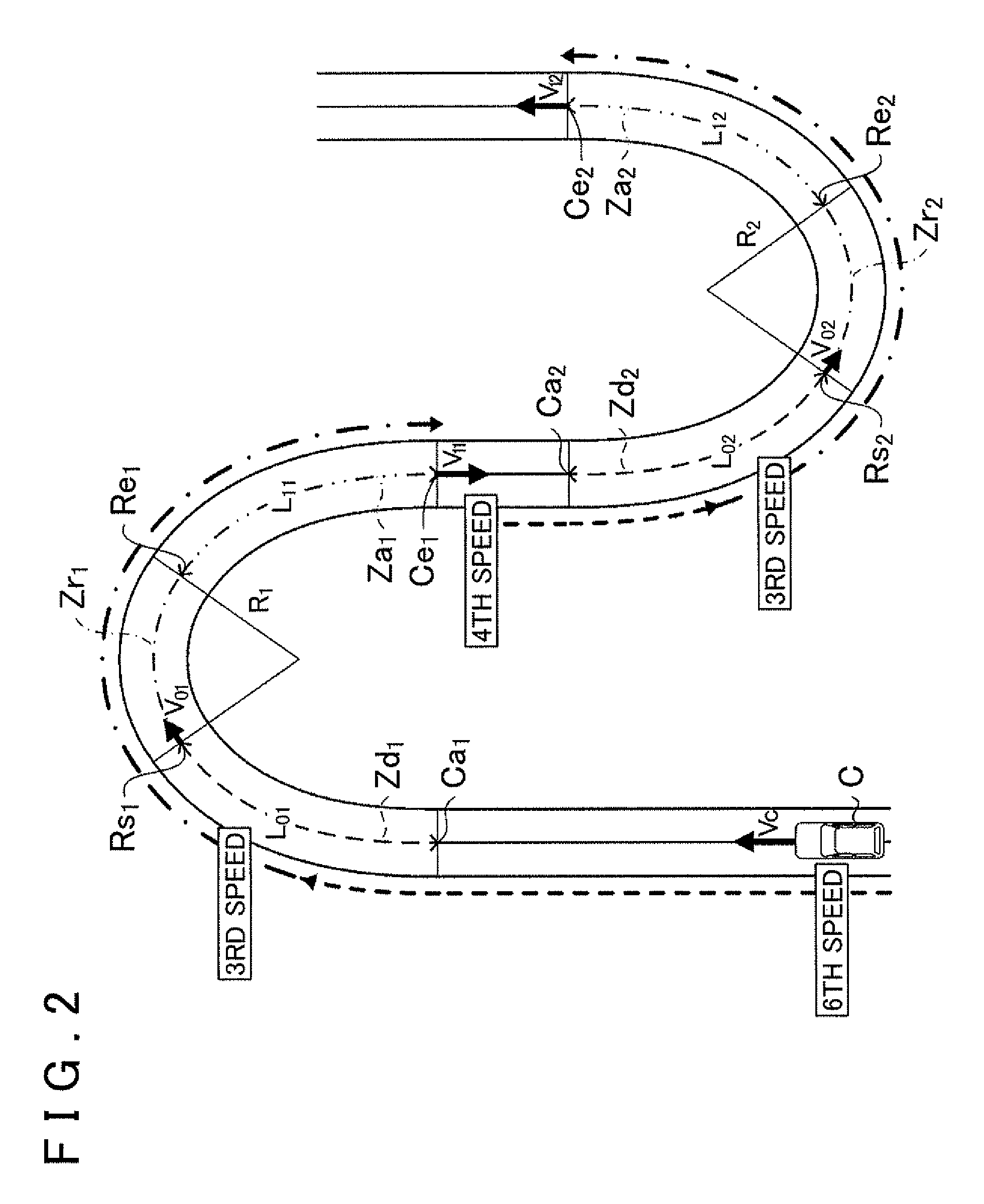

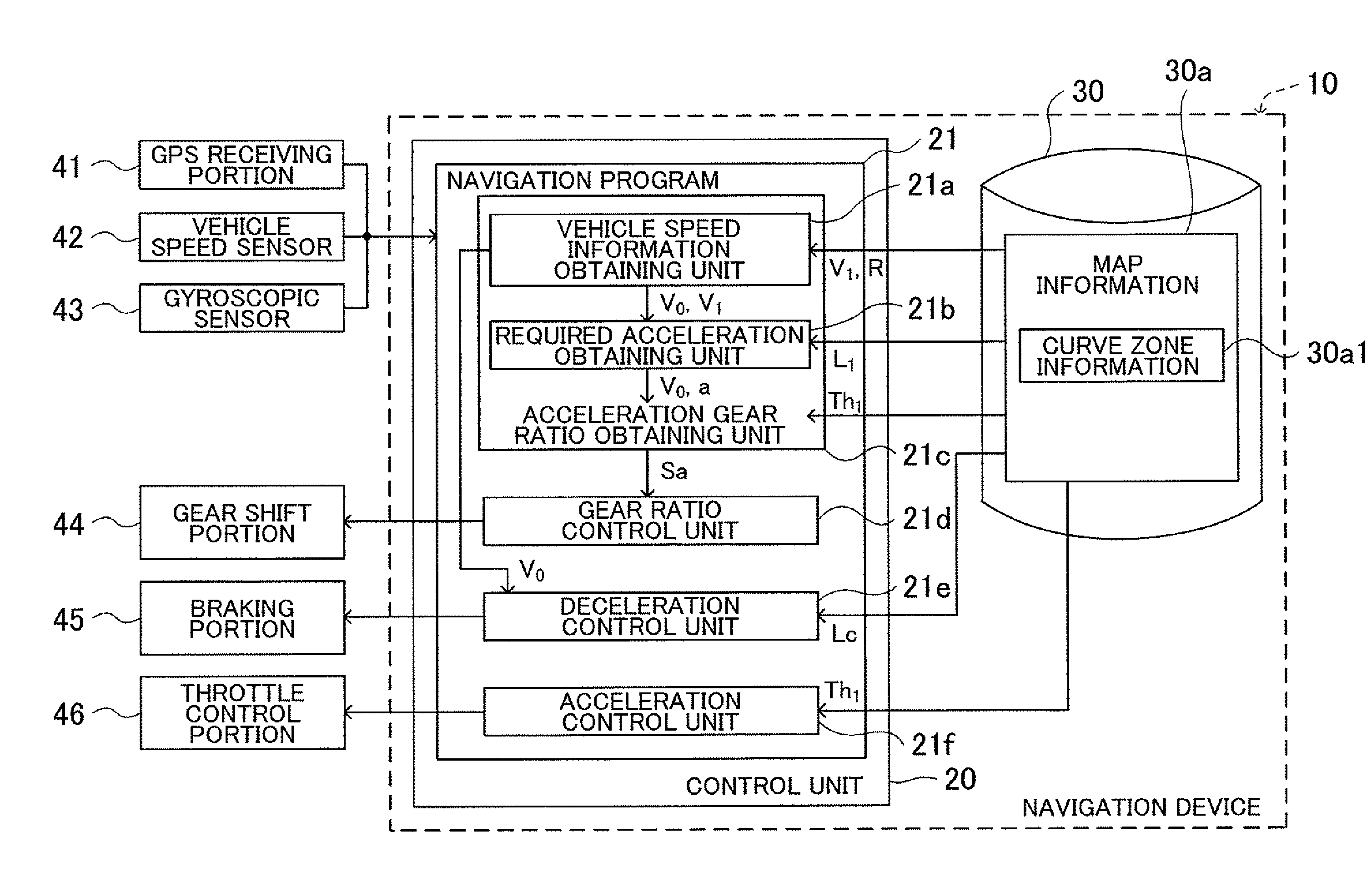

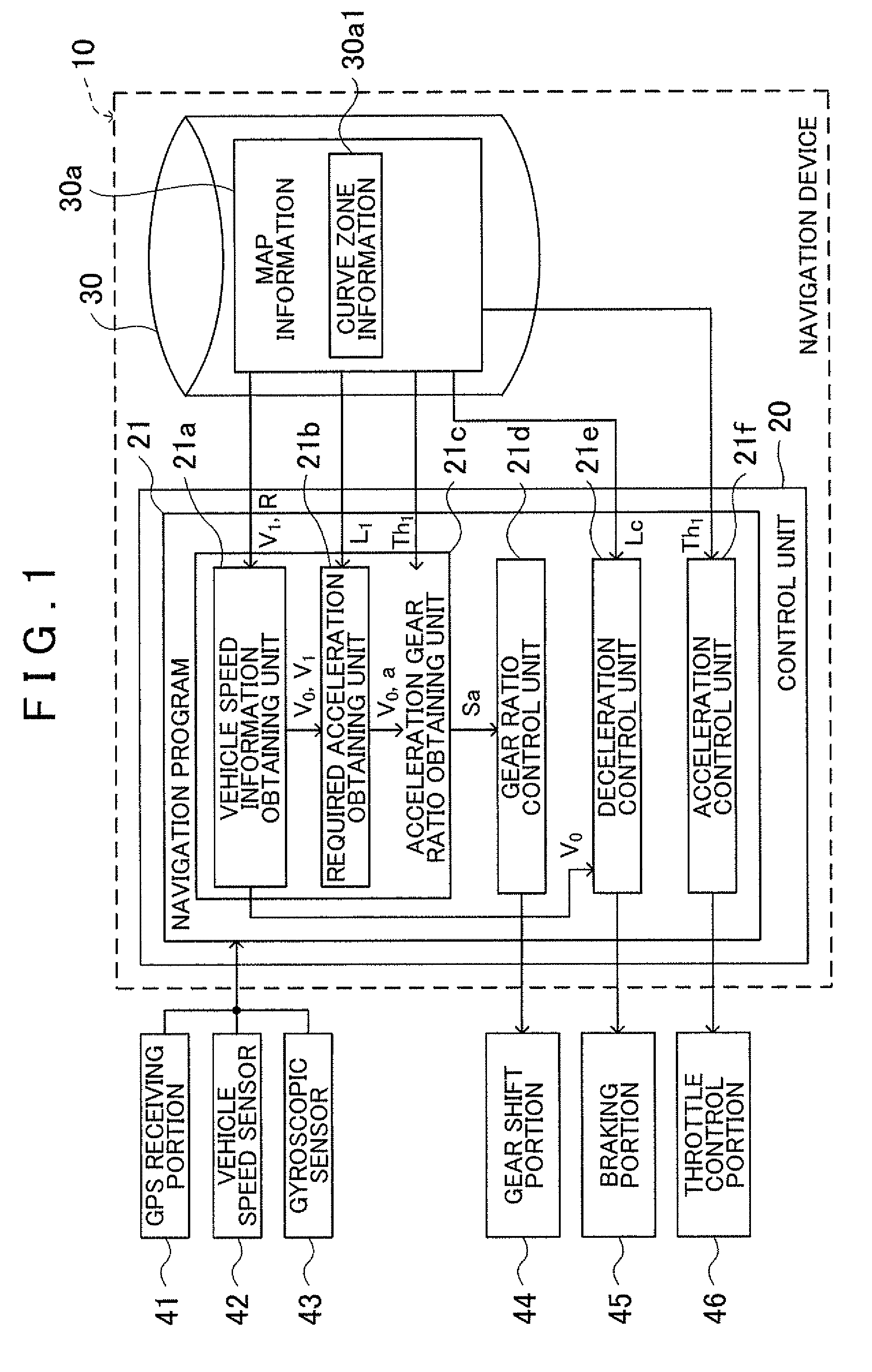

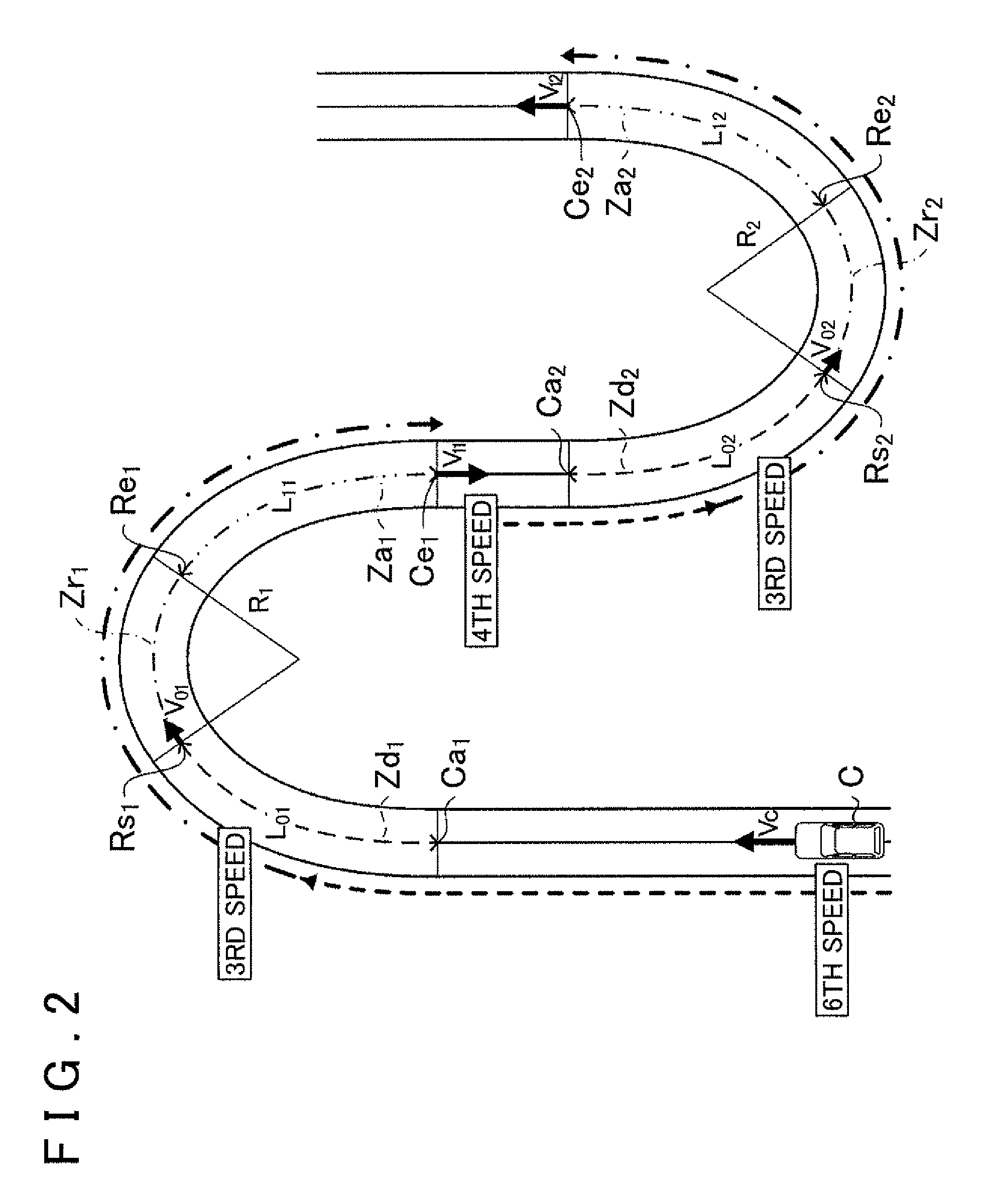

Driving support device, driving support method and driving support program

InactiveUS20090319139A1Smooth travelSmoothly acceleratedAnalogue computers for trafficAnti-collision systemsEngineeringAcceleration Unit

Information pertaining to a first zone set ahead of a host vehicle and a second zone farther ahead than the first zone is acquired. Based on the information, if a distance between an end point of the first zone and a start point of the second zone is shorter than a distance within which the host vehicle can be slowed at a predetermined deceleration to a second target vehicle speed for traveling the second zone at the start point of the second zone, a second acceleration gear ratio is acquired for accelerating the host vehicle in a second acceleration zone following the second zone. The gear ratio of the host vehicle is set to the second acceleration gear ratio in a first deceleration zone for slowing the host vehicle before reaching the first zone.

Owner:AISIN AW CO LTD

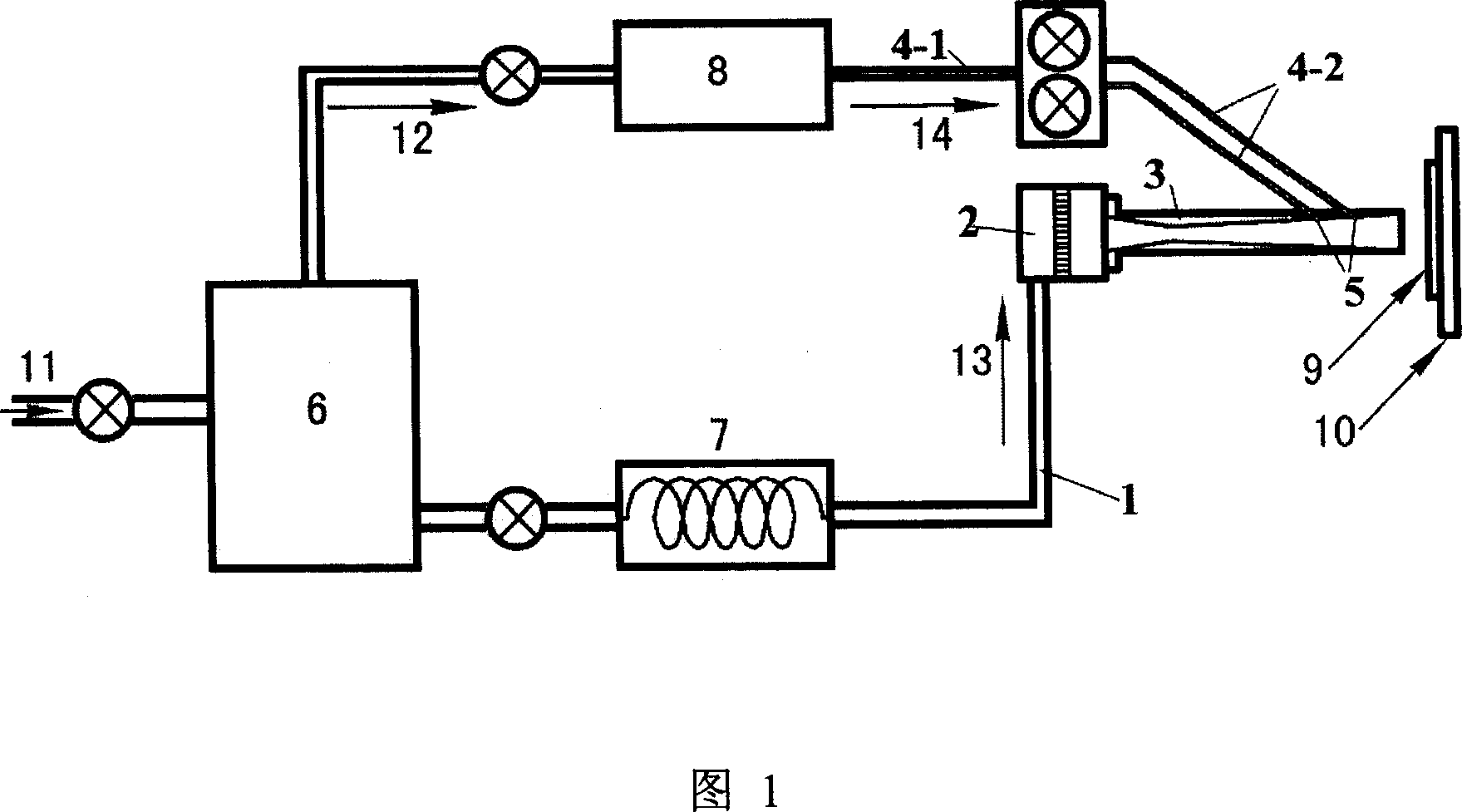

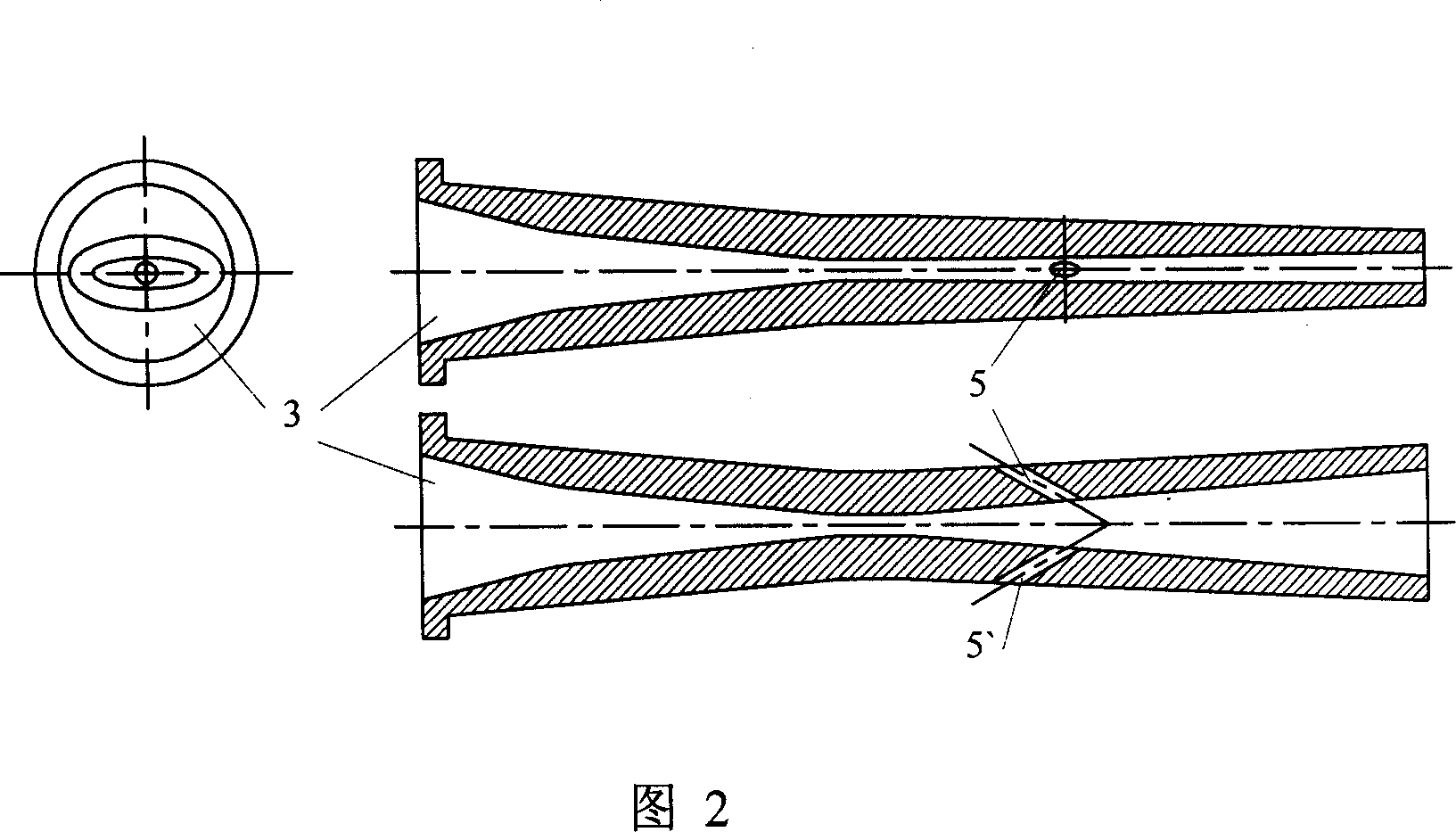

Cold air dynamical spray-painting method and apparatus of delivering powder through down stream

InactiveCN1958171AMelting point does not causeTemperature controlLiquid surface applicatorsLiquid spraying apparatusCold airMetallurgy

A cold-pneumatic spray coating method and apparatus by feeding powder at downstream is disclosed. Said method includes such steps as heating the working gas, delivering it to upstream of the flow channel in Laval nozzle, using the carrying gas to deliver the metallic powder to be sprayed to the downstream divergent segment via powder delivering tube, accelerating it by working gas, and spraying it. The cross-section the flow channel in divergent segment is elliptical or the combination of ellipse and rectangle. Its advantage is no pollution and blocking of nozzle throat.

Owner:BAOSHAN IRON & STEEL CO LTD

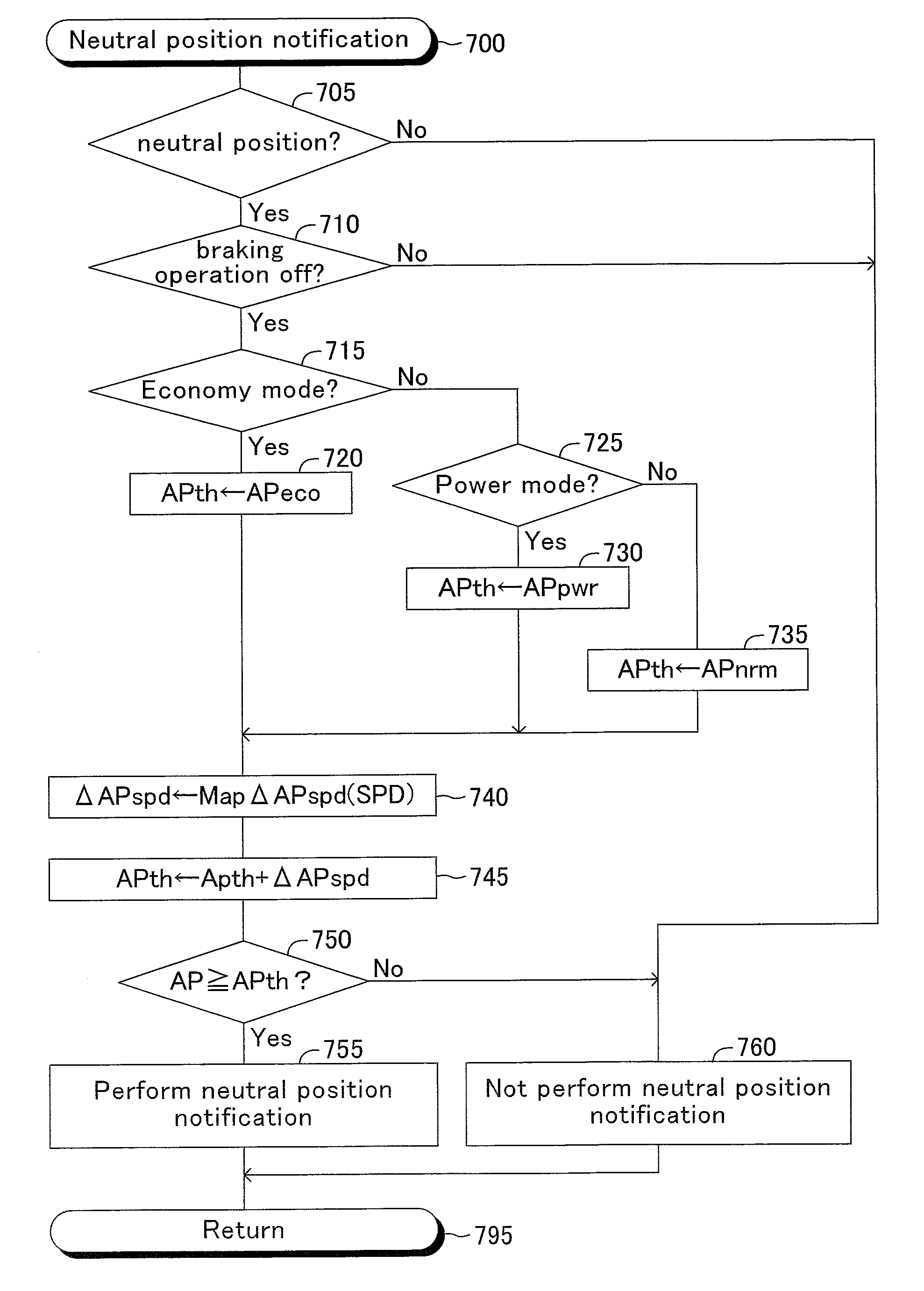

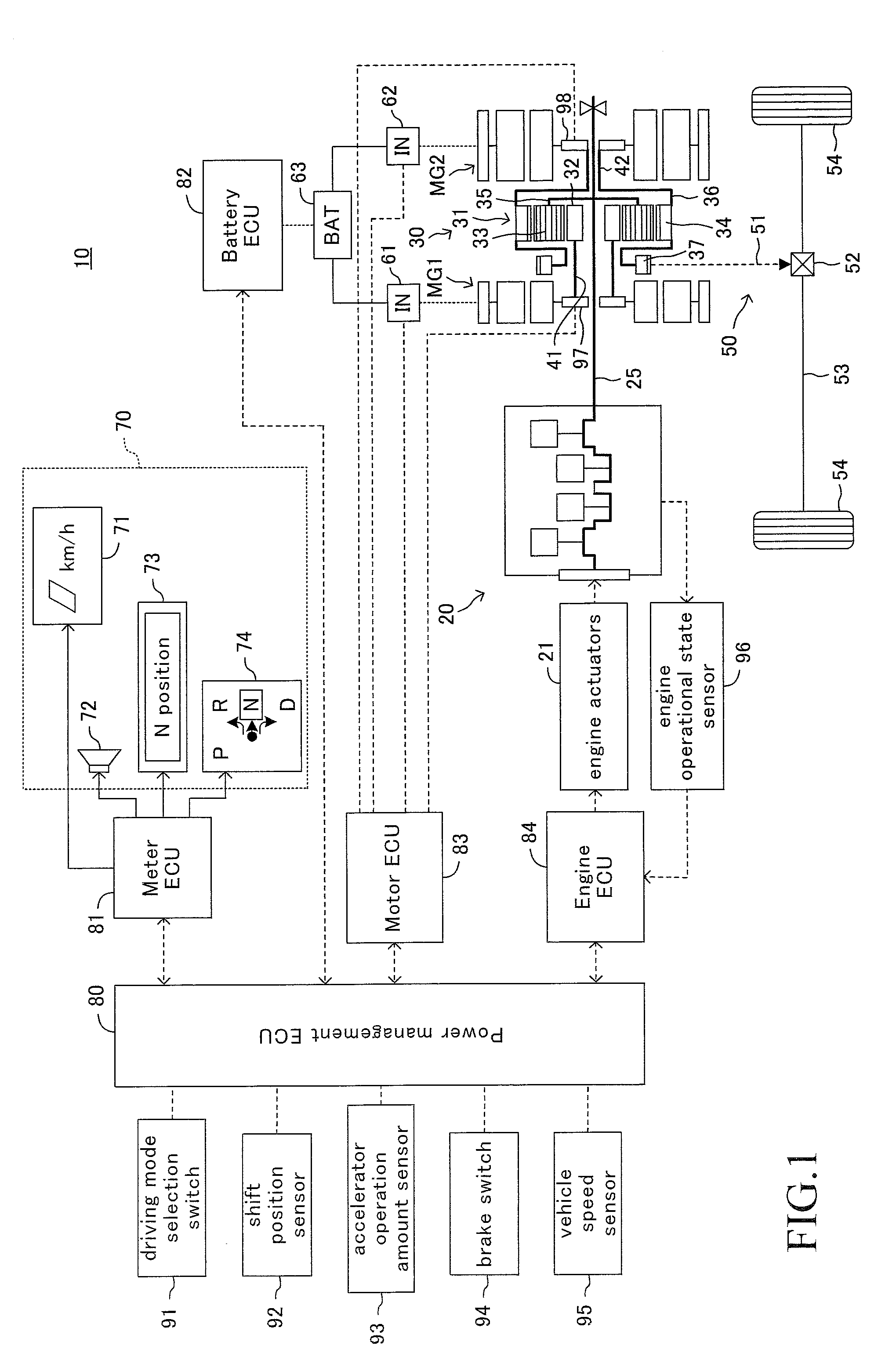

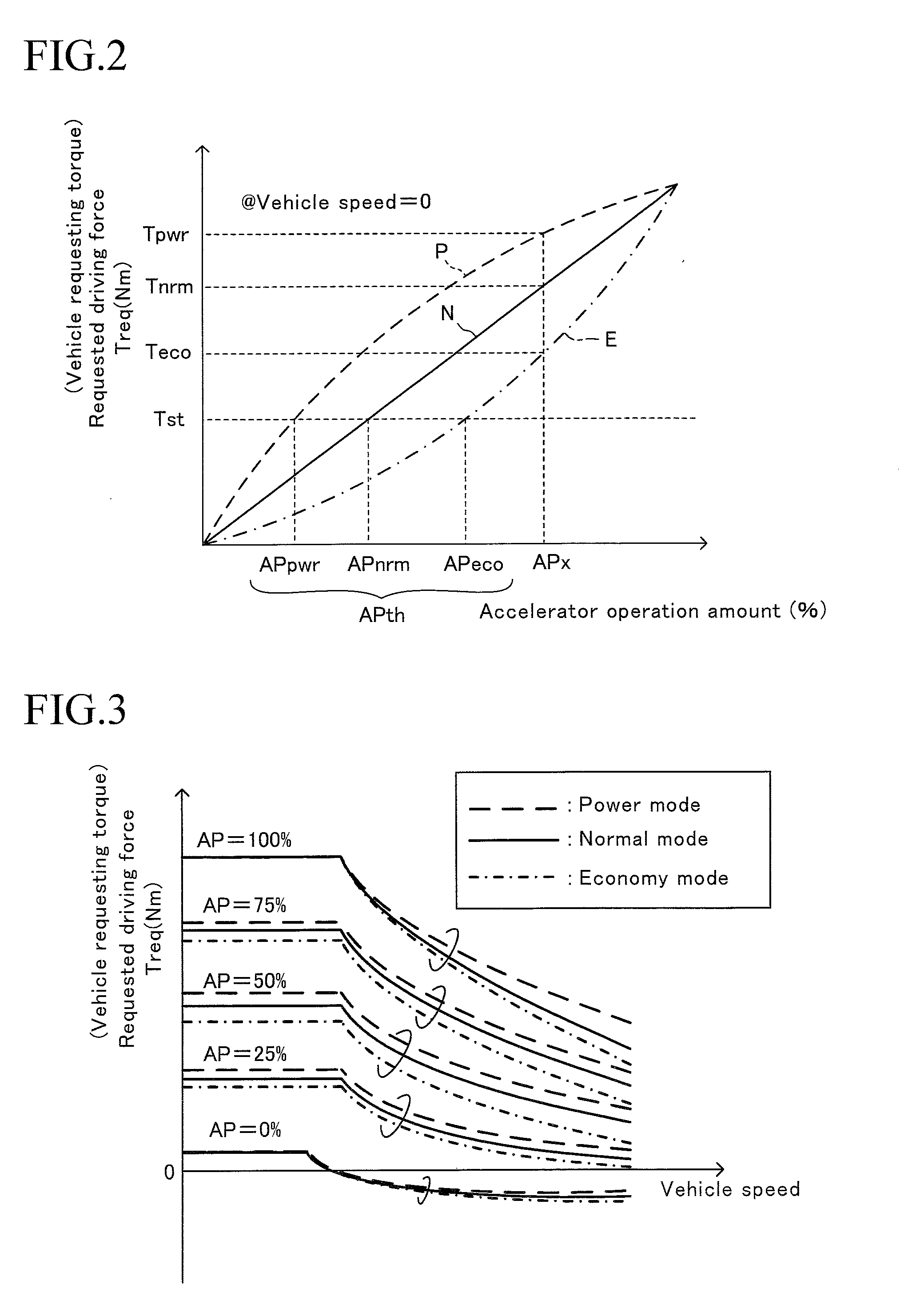

Hybrid vehicle

InactiveUS20140288757A1Large amount of operationSmooth startHybrid vehiclesDigital data processing detailsPower modeNormal mode

A hybrid vehicle according to one of embodiments of the present invention generates a driving torque using an internal combustion engine, an motor generator, and the like when a shift position is a driving position, the driving torque being determined based on a selected driving mode (e.g., a power mode to give priority to the power, and a normal mode to give priority to fuel consumption) and an accelerator operation amount. On the other hand, when the shift position is a neutral position, the vehicle maintains a rotational speed of the engine at a constant speed (including zero when the engine is stopped) regardless of the accelerator operation amount. When the accelerator operation amount becomes equal to or larger than an accelerator operation amount threshold while the neutral position is selected, the vehicle supplies information indicating that the neutral position is selected to a driver. The accelerator operation amount threshold is determined based on the driving mode.

Owner:TOYOTA JIDOSHA KK

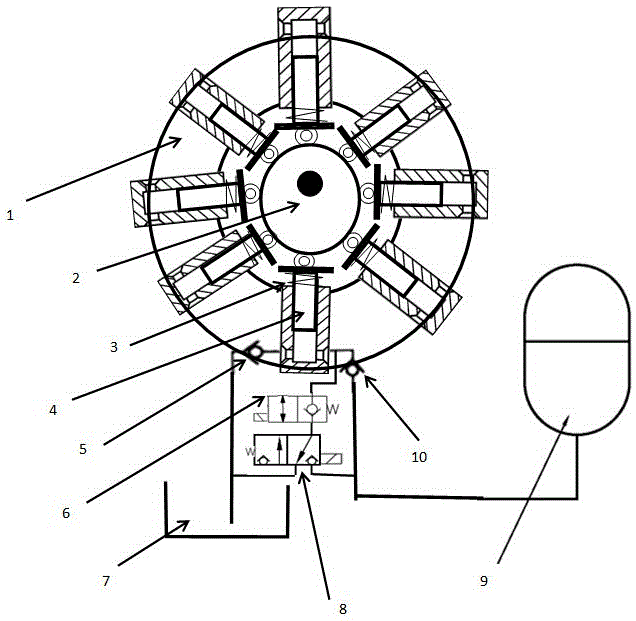

Automobile kinetic energy conversion and recovery device

ActiveCN105059274AImprove efficiencyIncrease energy densityHybrid vehiclesBraking element arrangementsHydraulic motorRadial motion

The invention discloses an automobile kinetic energy conversion and recovery device. The automobile kinetic energy conversion and recovery device is used for storing energy during subway braking and recovering kinetic energy during starting. The automobile kinetic energy conversion and recovery device mainly comprises an eccentric wheel, hydraulic plungers and a corresponding hydraulic loop. During subway braking, the eccentric wheel and an axle rotate synchronously, so that the built-in hydraulic plungers conducts reciprocating radial motion; hydraulic oil is pressed into an energy accumulator through the hydraulic plungers on the basis of the design of the corresponding hydraulic loop, and therefore kinetic energy of the automobile is converted into hydraulic energy to be stored. During subway starting, the device is used as a low-speed large-torque hydraulic motor on the basis of switching control over an electromagnetic valve to push a subway to achieve kinetic energy recovery. According to the automobile kinetic energy conversion and recovery device, the hydraulic mode is utilized for energy storage, braking energy is not converted into electric energy and is just stored as hydraulic energy, and the efficiency is much higher than that of the existing energy storage mode.

Owner:王林翔

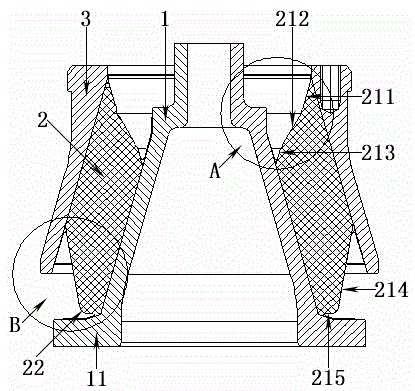

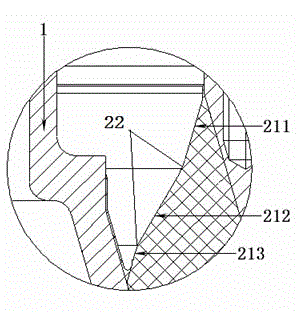

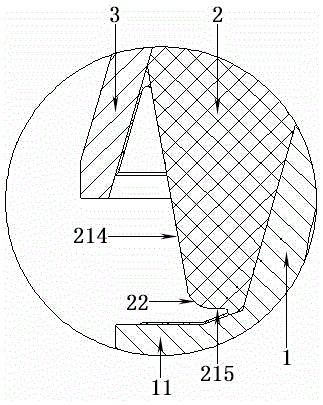

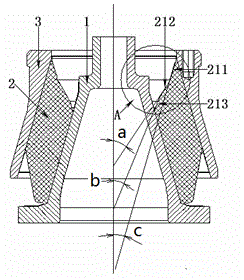

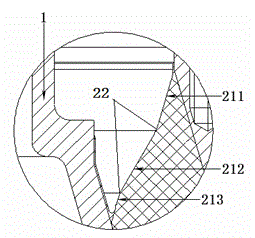

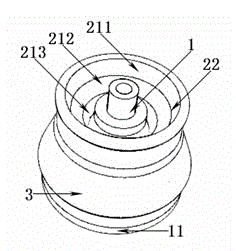

Conical spring stiffness changing and wrinkle and cracking prevention method, and product

ActiveCN106032831APrevent derailmentAvoid Inverse S-CurvesSpringsAxle-boxes mountingWrinkle skinEngineering

Provided are a conical spring stiffness changing and wrinkle and cracking prevention method, and a product. A conical spring comprises an inner cone, a rubber body, and an outer cone. The rubber body surrounds the inner cone. The outer cone surrounds the rubber body. The rubber body, and the inner cone and the outer cone form a rubber metal spring arranged in a conical manner. The conical spring is characterized in that a rubber body upper rubber profile and a rubber body lower rubber profile of the conical spring use a multisection structure form. The rubber body upper rubber profile is a multisection downhill structure, and the rubber body lower rubber profile is a multisection uphill structure. Through changing the shape, slope, and length of each section, and the number of sections in the multisection downhill structure of the rubber body upper rubber profile and the multisection uphill structure of the rubber body lower rubber profile, the size of stiffness changing and the position of stiffness changing of the conical spring are adjusted, and adjustment of multiple stiffness changing is realized through controlling the number of multisection.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

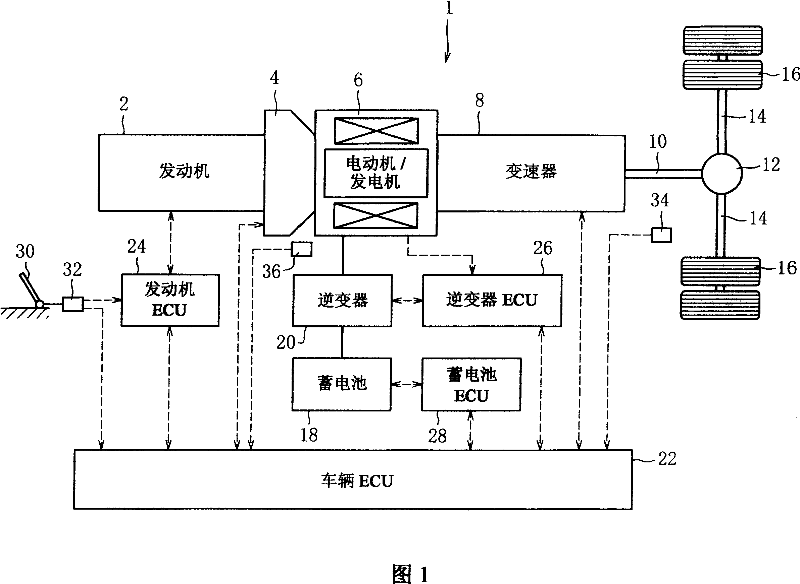

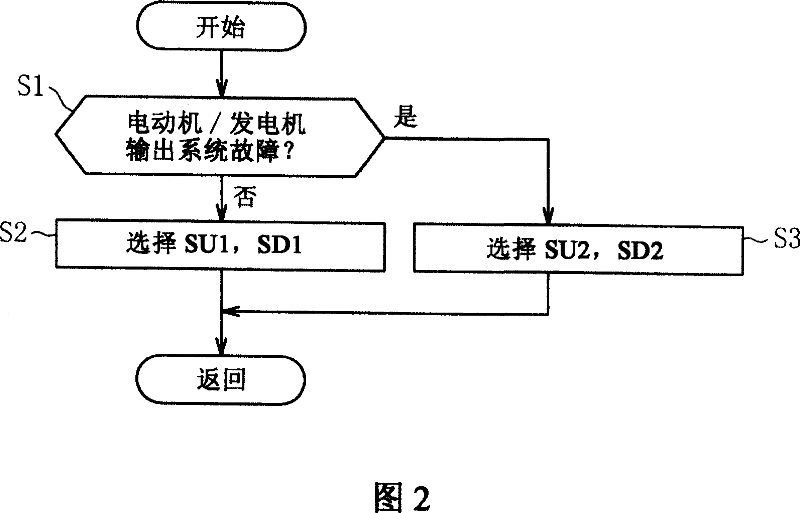

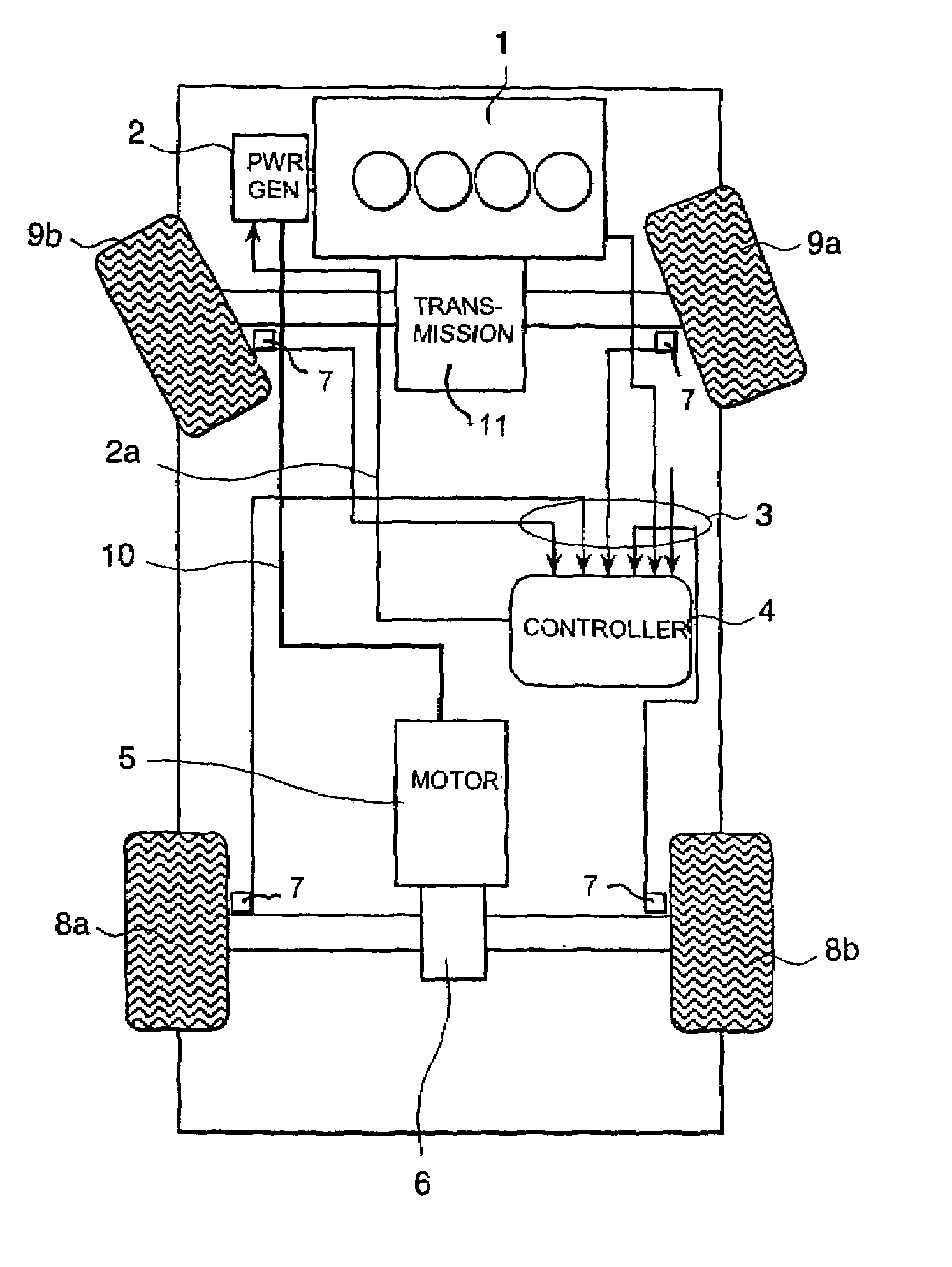

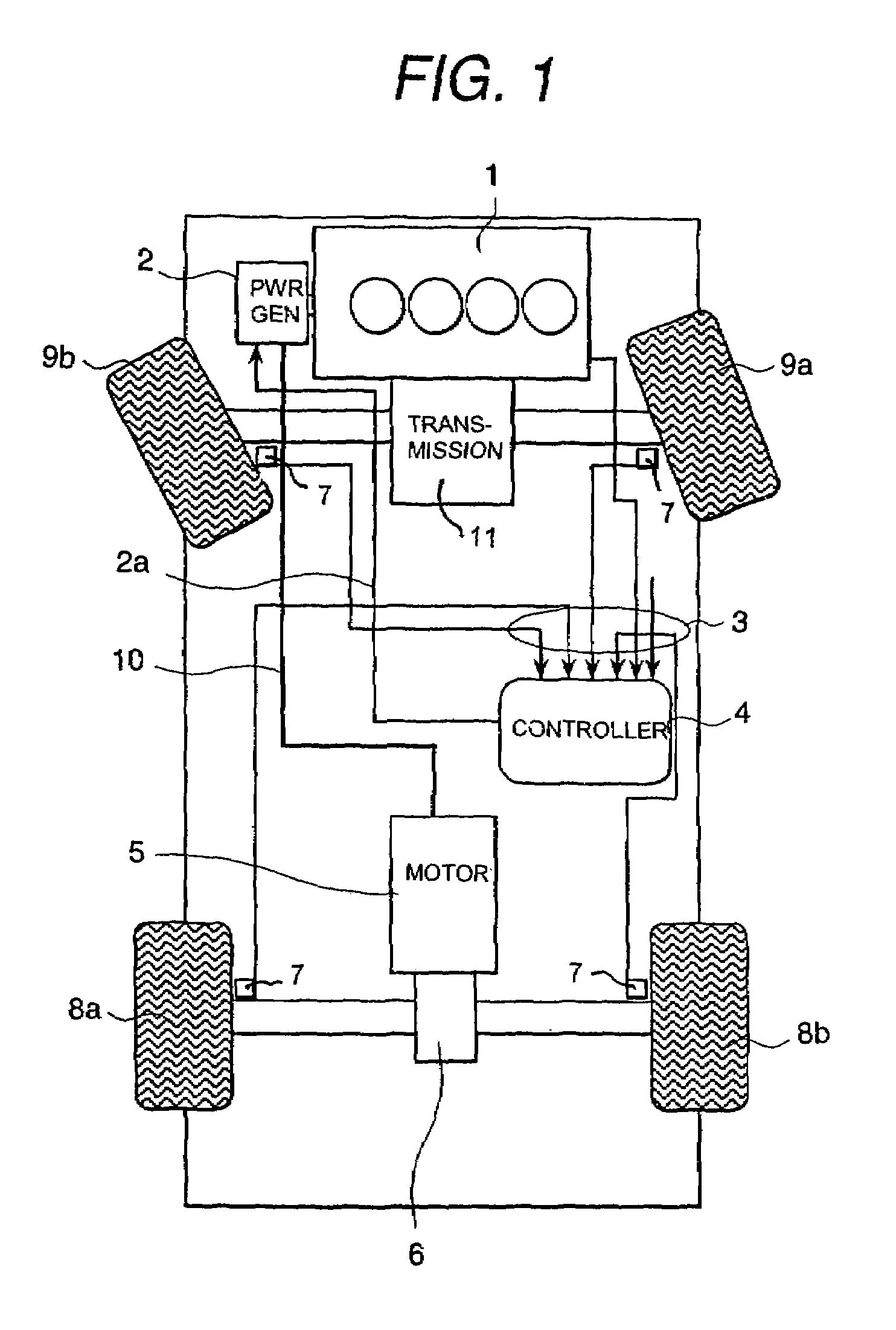

Control device for a hybrid electric vehicle

InactiveCN101038031ASmooth startSmooth accelerationSpeed controllerElectric devicesDrive wheelLow speed

A hybrid electric vehicle is equipped with an engine output system that makes the engine generate a driving force and outputs the driving force of the engine and a motor output system that makes an electric motor generate a driving force and outputs the driving force of the electric motor, and is capable of transmitting to driving wheels the driving forces outputted from the respective systems. If a failure of the motor output system is not detected, a vehicle ECU sets the gear of an automatic transmission for start-up of the vehicle to a first gear. If the failure is detected, the vehicle ECU sets the gear of the automatic transmission for start-up the vehicle to a second gear that is lower than the first gear.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

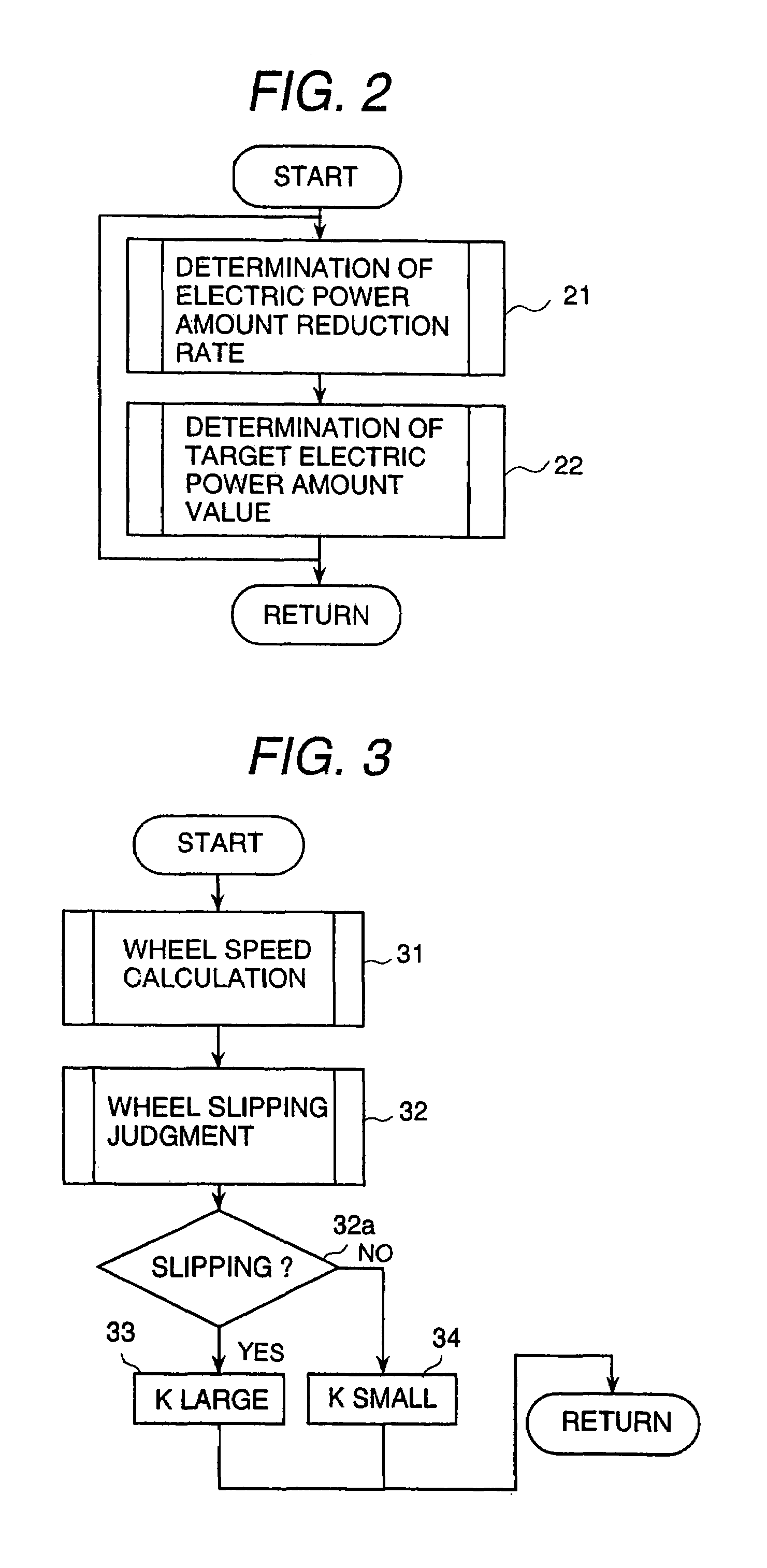

Control apparatus for vehicle-use electric power generator

InactiveUS7054726B2Stable speedSimple system configurationDigital data processing detailsSpeed sensing governorsEngineeringElectric power

It is desirable prevent the speed of an engine, that is driving an electric-power generator, from abruptly increasing when electric power generation by the electric power generator, which supplies electric power to a wheel-driving motor, is stopped. Thus, a control apparatus is provided for a vehicle electric power generator to control the amount of electric power generated by the electric power generator, which is connected to, and driven by, an engine for driving a vehicle. Wheel speed detection means is provided to detect slipping of the wheels, and the control apparatus operates to ensure that, when the amount of electric power generated is to be reduced, if the wheels are not slipping, the amount of electric power generation by the electric power generator is slowly reduced, in comparison with the case where the wheels are slipping.

Owner:HITACHI LTD

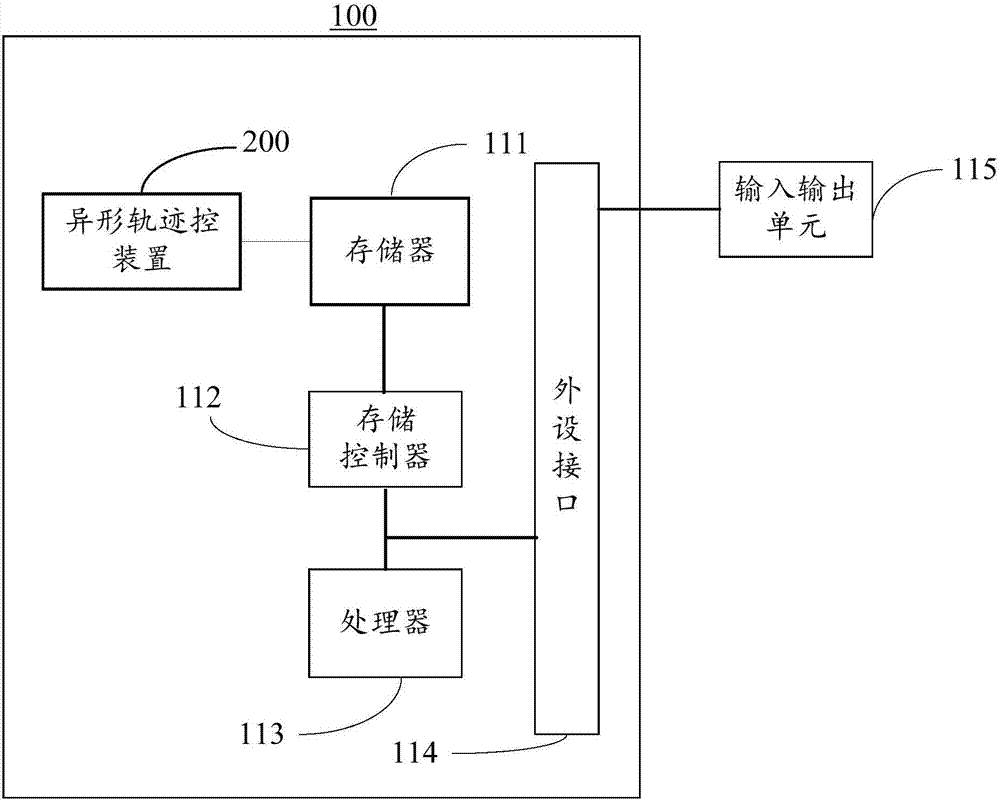

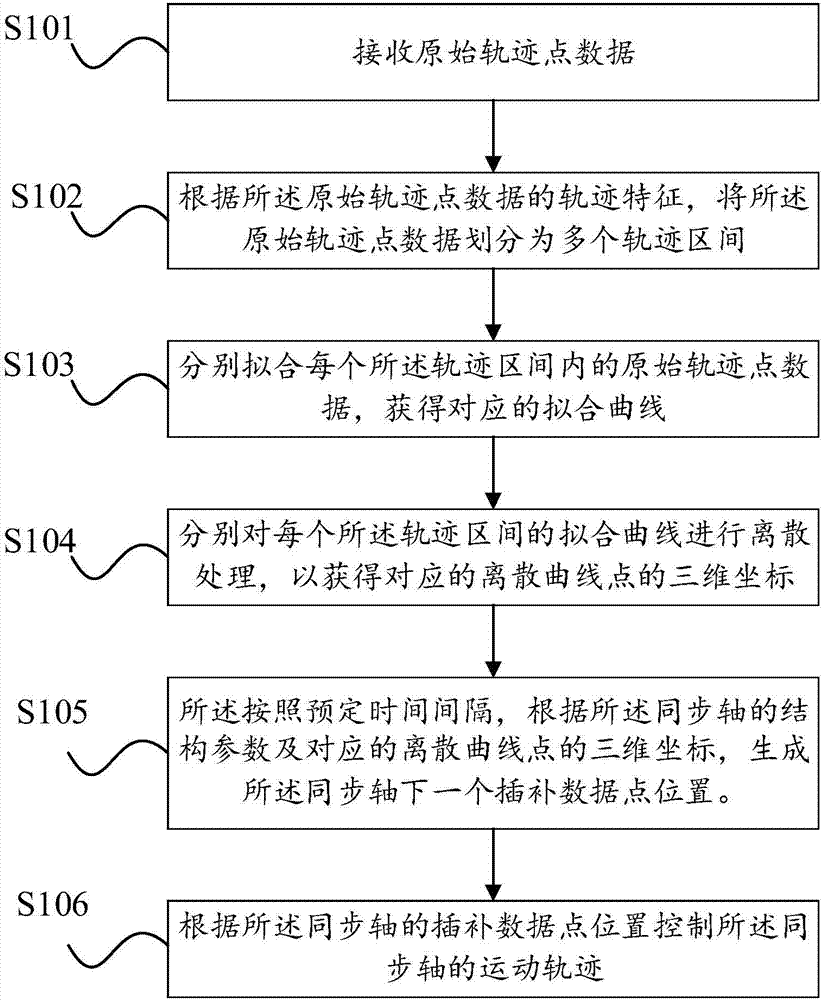

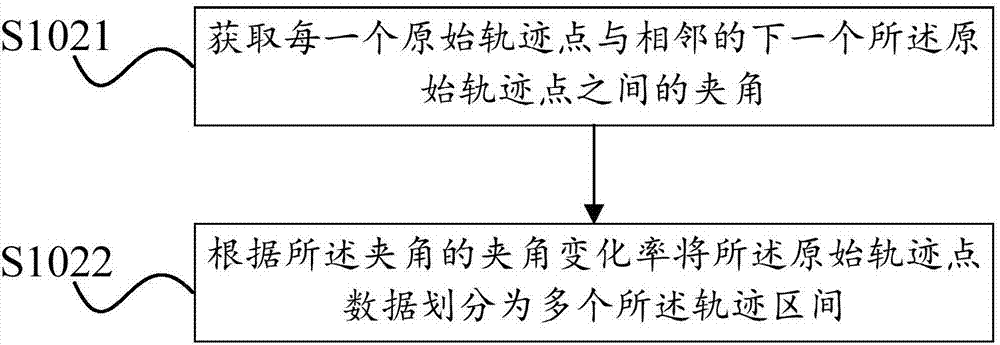

Special-shape trajectory control method and device

ActiveCN107247446AImprove stabilityImprove processing speedNumerical controlAutomatic controlDiscrete curve

The invention provides a special-shaped trajectory control method and device, relates to the field of automatic control. The method comprises a step of receiving original trajectory point data, a step of dividing the original trajectory point data into multiple trajectory intervals according to the trajectory characteristics of the original trajectory point data, a step of fitting the original trajectory point data in each trajectory interval and obtaining a corresponding fitting curve, a step of carrying out discrete processing on the fitting curve of each trajectory interval so as to obtain the 3D coordinates of a corresponding discrete curve point, a step of generating a next interpolation data point position of a synchronous axis according to a predetermined time interval and according to the structure parameters of the synchronous axis and the 3D coordinates of the discrete curve point, and a step of controlling the motion trajectory of the synchronous axis according to the interpolation data point position of the synchronous axis. Thus an acceleration process is more stable and efficient, an error rate is small, and processing equipment is protected. The accuracy is extremely high.

Owner:SHENZHEN LEAD CNC SYST

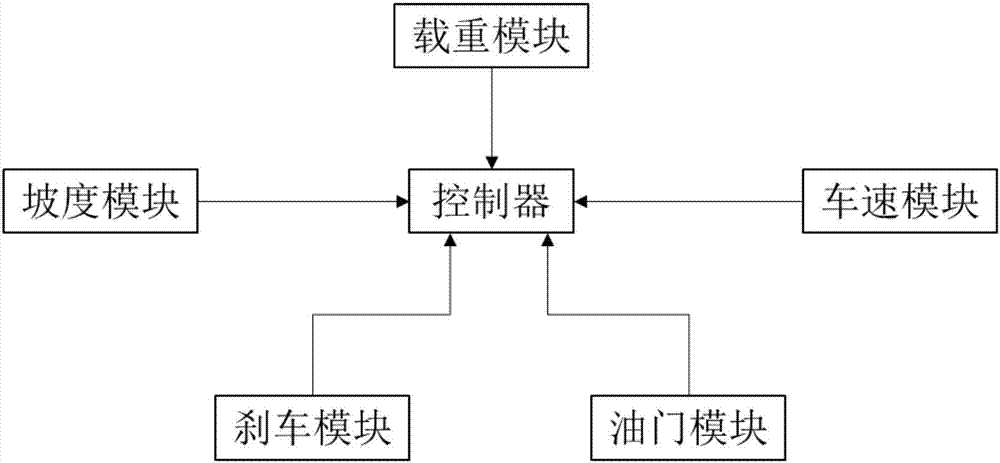

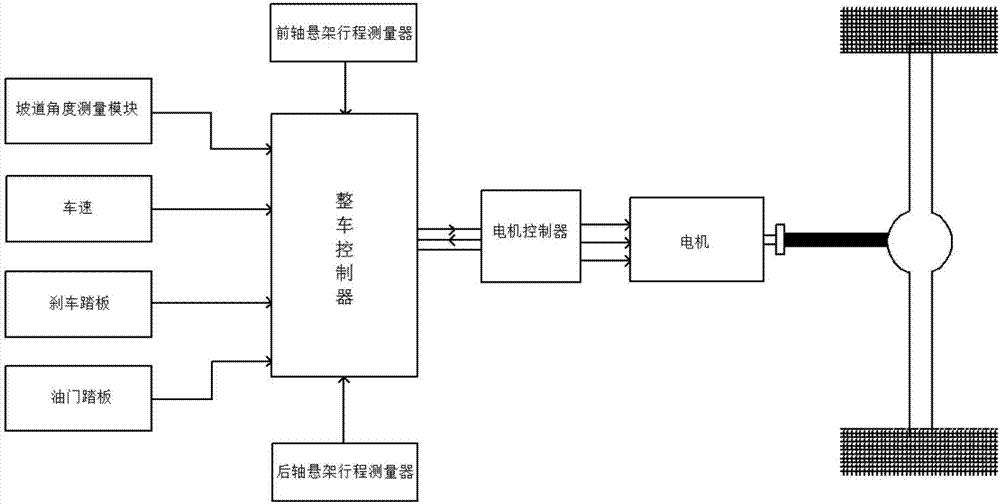

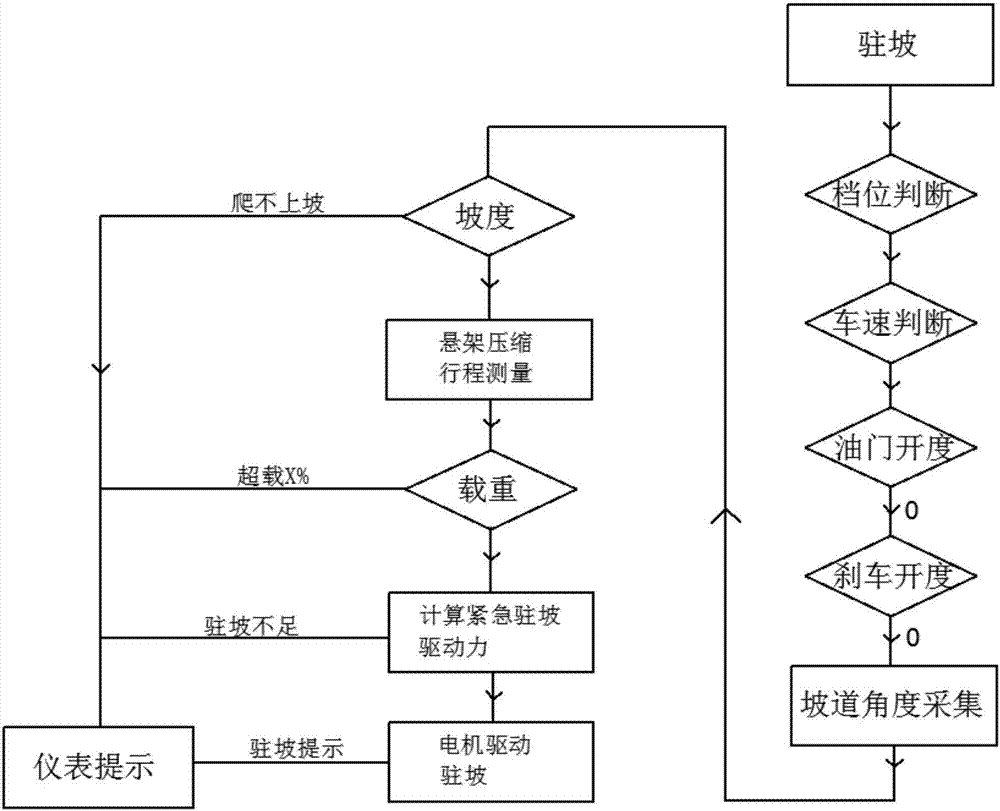

Hill-hold control system of electric vehicle

PendingCN107215240AActive Computing DriversEasy to controlSpeed controllerElectric energy managementControl systemElectric vehicle

The invention discloses a hill-hold control system of an electric vehicle. The system comprises a slope module, a vehicle speed module, a brake module, an accelerator module and a controller; the output end of the slope module is connected with a first input end of the controller, the output end of the vehicle speed module is connected with a second input end of the controller, the output end of the brake module is connected with a third input end of the controller, and the output end of the accelerator module is connected with a fourth input end of the controller; the slope module is used for obtaining slope signals of a road, the vehicle speed module is used for obtaining vehicle speed signals, the brake module is used for obtaining brake signals, the accelerator module is used for accelerator signals, the controller is used for obtaining the operating mode of the electric vehicle according to the road slope and the vehicle speed, obtaining accelerating signals according to the accelerator signals at the same time, and outputting the brake signals and the accelerating signals when the operating mode is a hill-hold start mode.

Owner:东风特汽(十堰)专用车有限公司

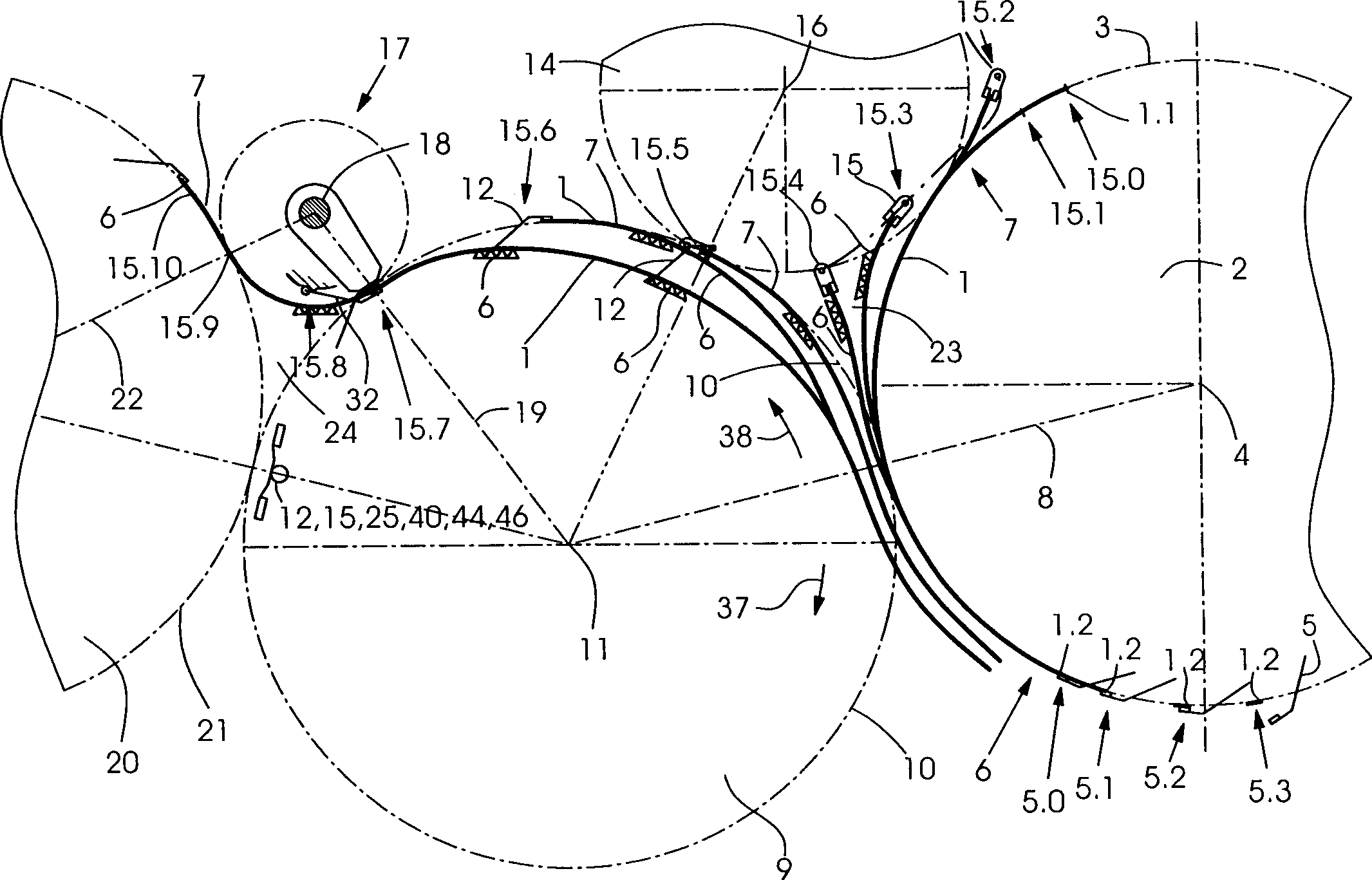

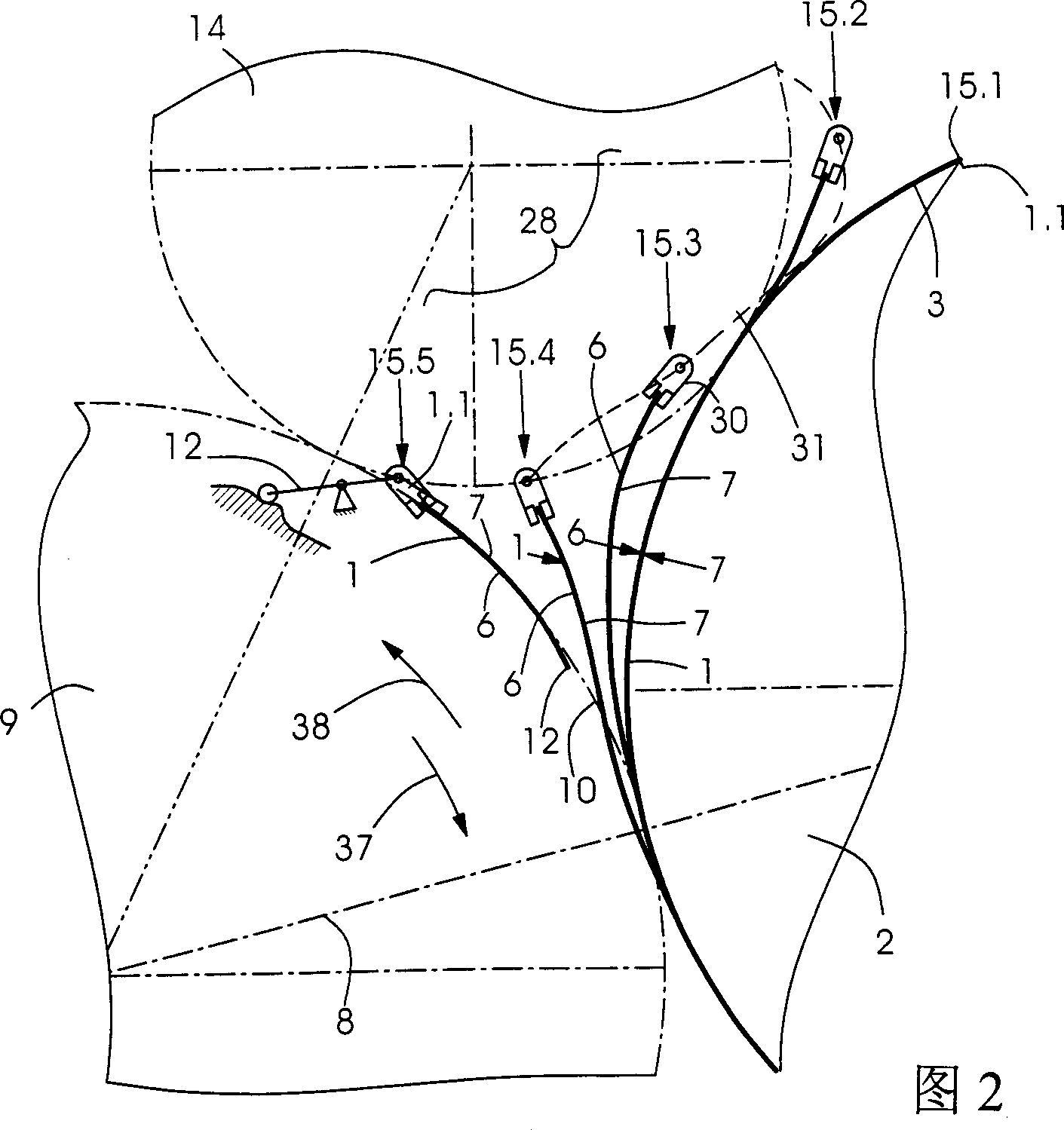

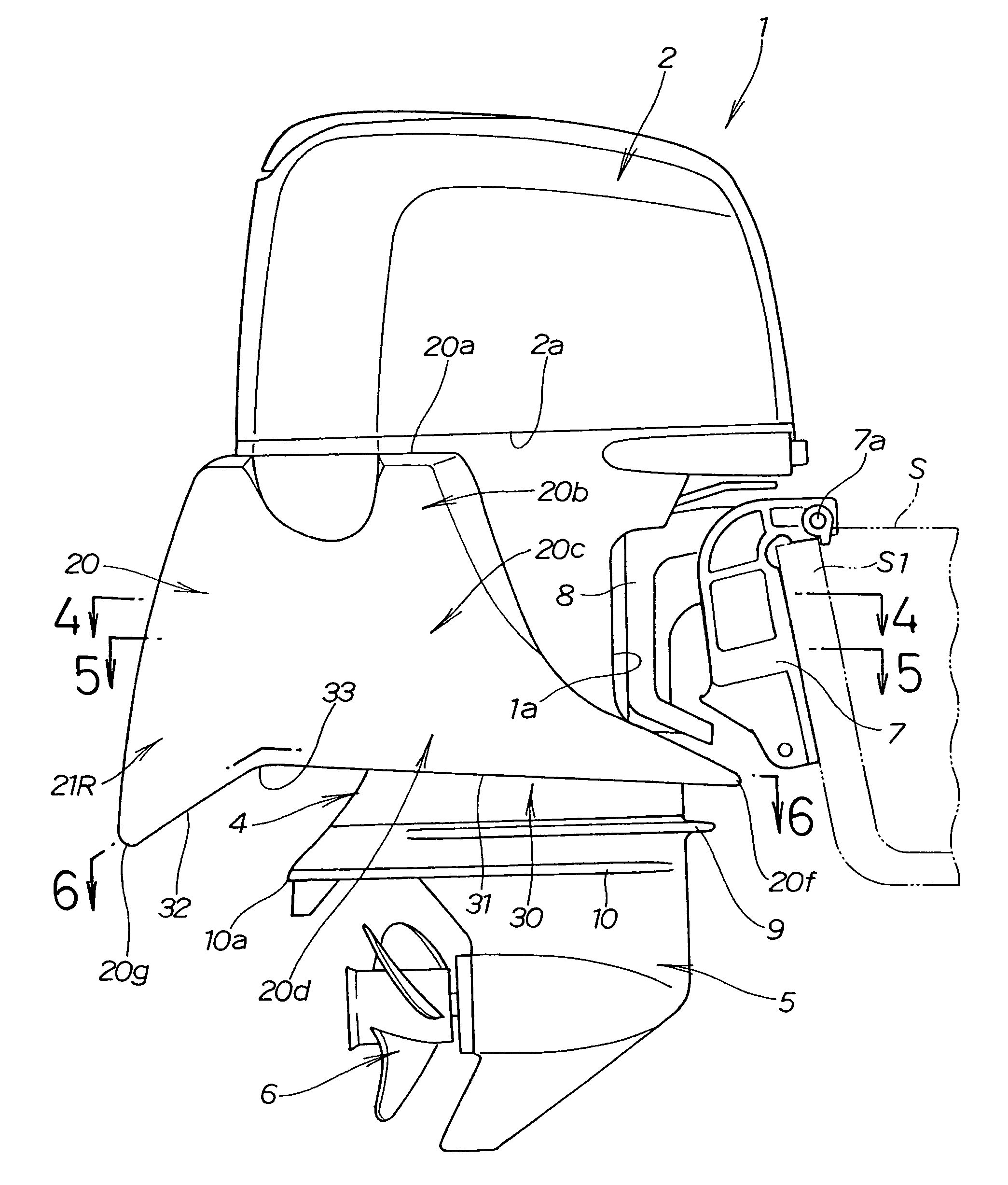

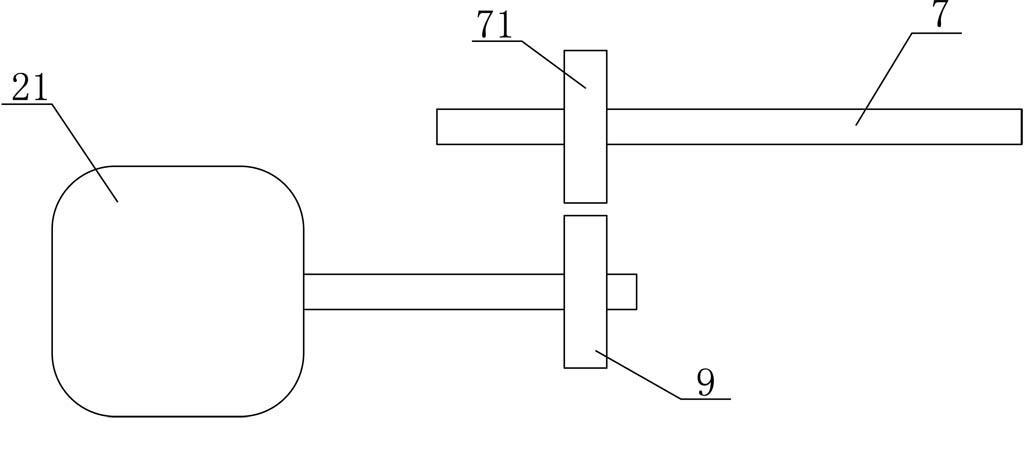

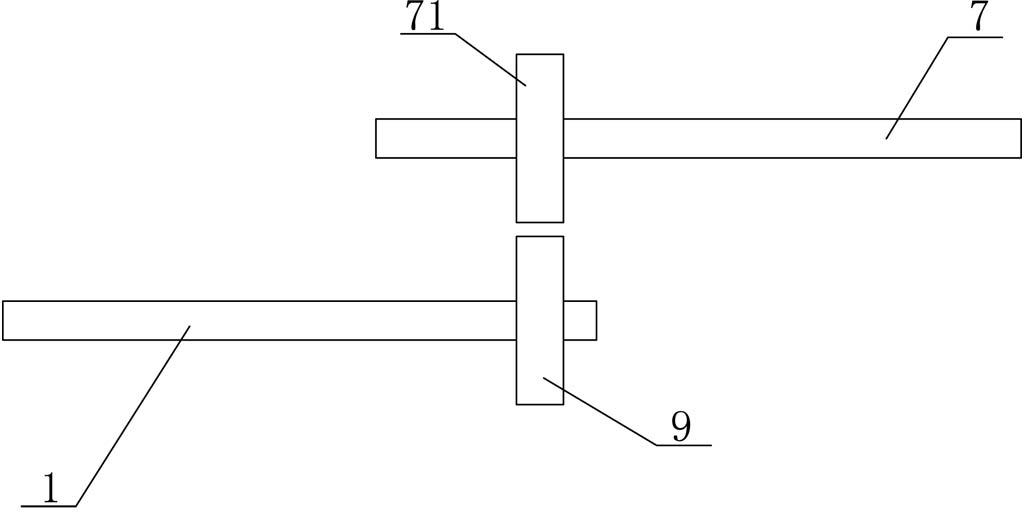

Apparatus for turning plane printed matter in half turning paper treating machine

InactiveCN1365889ASave drive energySave installation spaceArticle feedersSheet deliveryEngineeringPrinting press

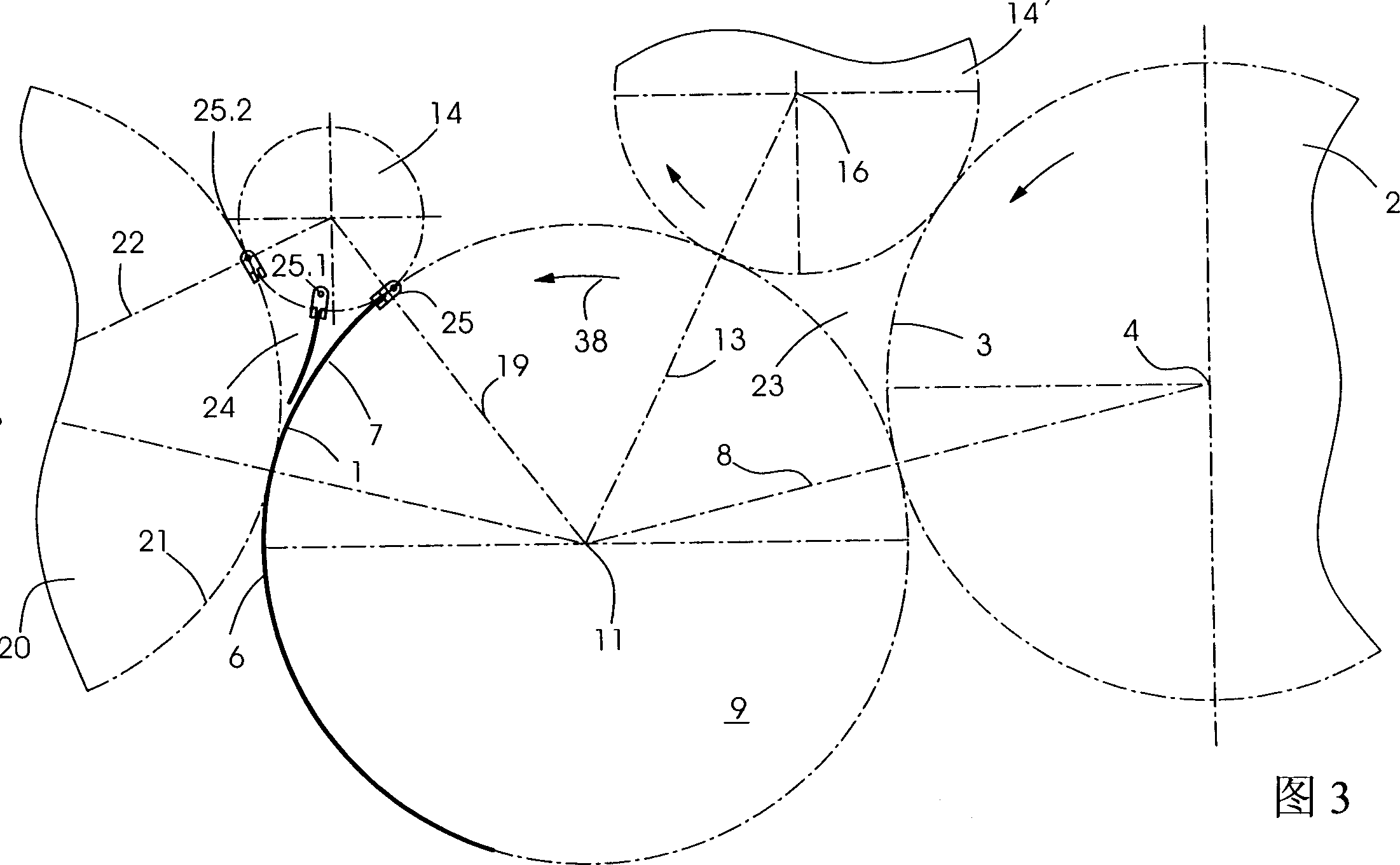

The invention relates to a device for turning over paper (1, 65) using a paper delivery roller (9), which is adjacent to two paper guide rollers (1, 20), and is equipped with a turning / turning / With storage rollers (14, 26) and an additional transport element (17), the rotary printing press for handling paper can operate in single-sided printing mode and double-sided printing mode (59, 60). When using single-sided printing mode and double-sided printing mode (59, 60), the transfer cylinder (9) can be driven in opposite directions of rotation (37, 38). A gripper system (12; 15, 25, 40, 44) that works in two rotation directions (37, 38) of the transfer roller (9) is installed on the outer shell surface (10) of the transfer roller (9). ,46).

Owner:HEIDELBERGER DRUCKMASCHINEN AG

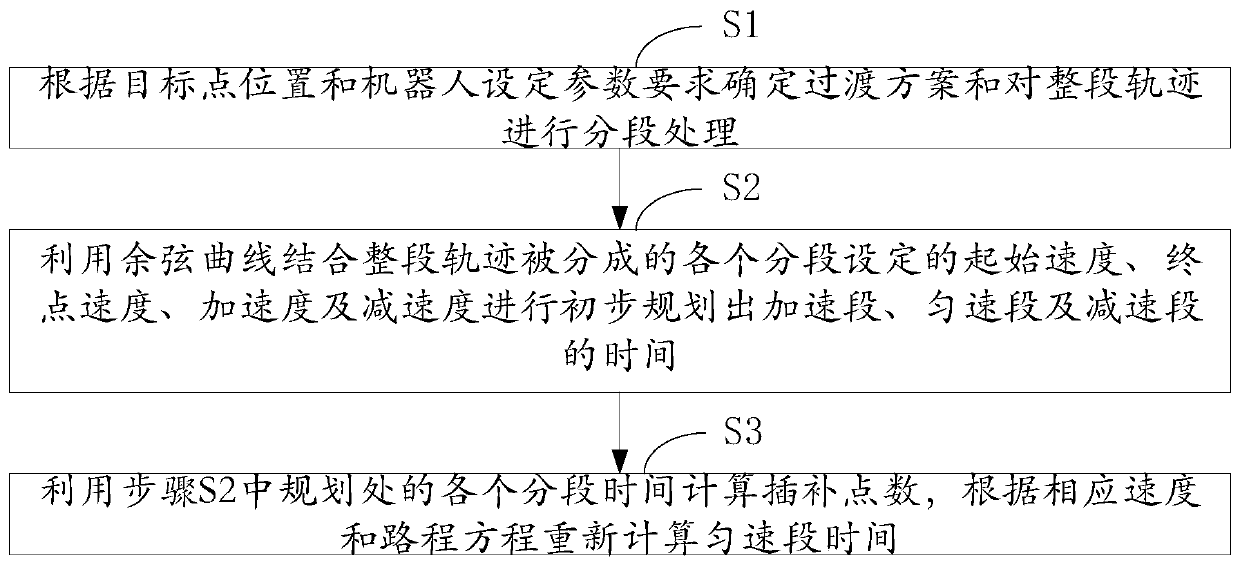

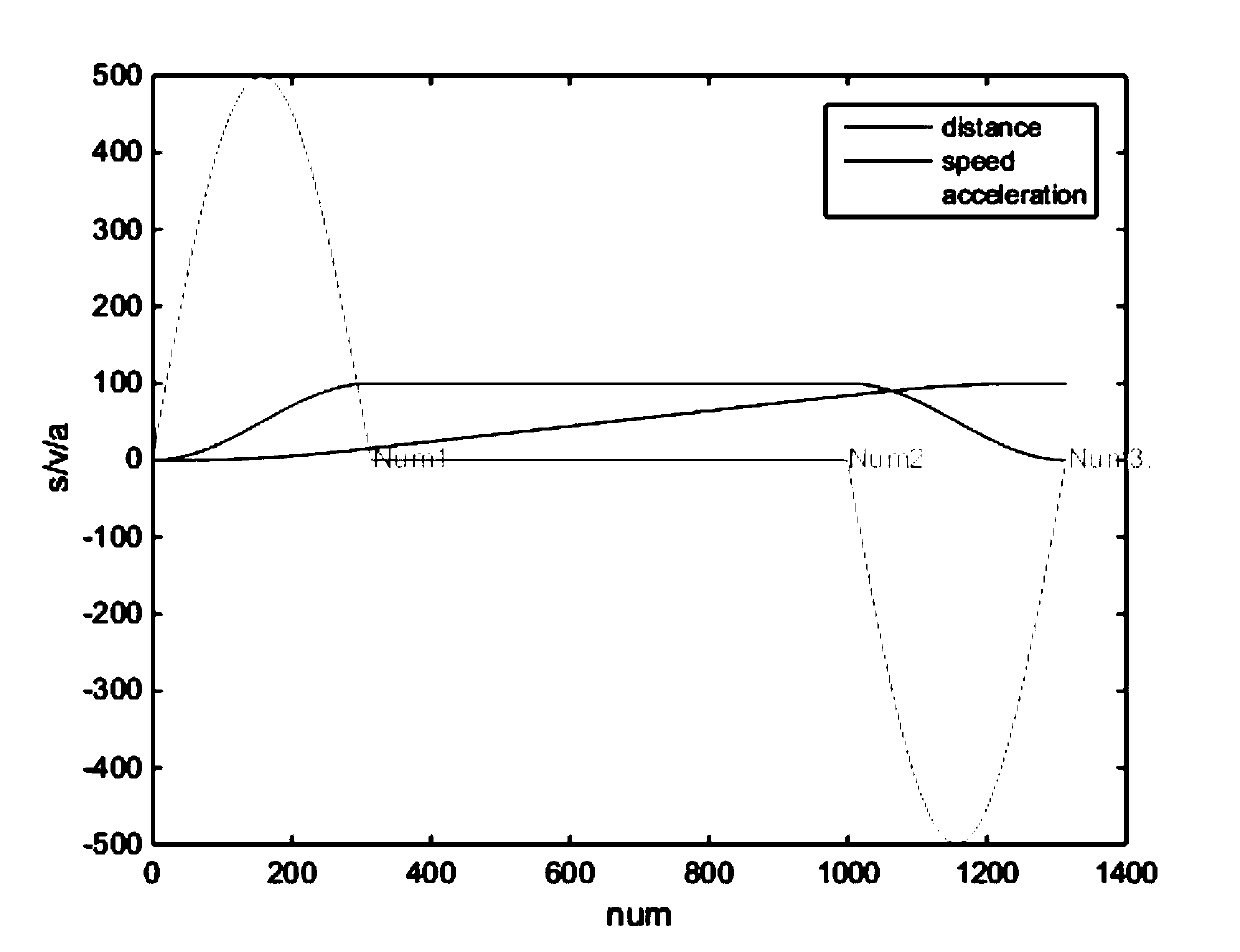

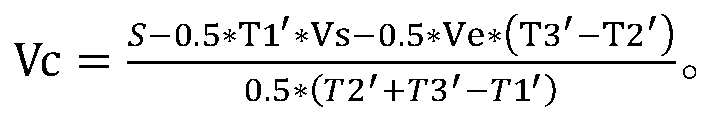

Cosine interpolation method of industrial robot under spatial linear movement

ActiveCN110147077APrevent high driving torqueTo prevent the phenomenon that the imputation cannot be completedProgramme controlComputer controlEquation of the centerThermal velocity

The invention is applied to the field of movement trajectory technology improvement, and provides a cosine interpolation method of an industrial robot under spatial linear movement. The method comprises the steps: 1, a transition scheme is determined according to the target point position and the robot setting parameter requirements, and segmentation processing is conducted on an overall trajectory; 2, times of an accelerating segment, a uniform velocity segment and a decelerating segment are preliminarily planned by combining a cosine curve with starting velocities, terminal velocities, accelerating velocities and decelerating velocities which are set for various segments obtained by segmenting the overall trajectory; and 3, the interpolation point number is calculated by means of the various segment times planned in the step 2, and the time of the uniform velocity segment is recalculated according to a corresponding velocity and journey equation. The various trajectory segments are interpolated by adopting the cosine curve interpolation method, not only does the accelerating velocities distributed in various intervals become smooth, but also the accelerating velocities become smooth.

Owner:SHENZHEN COLIBRI TECH

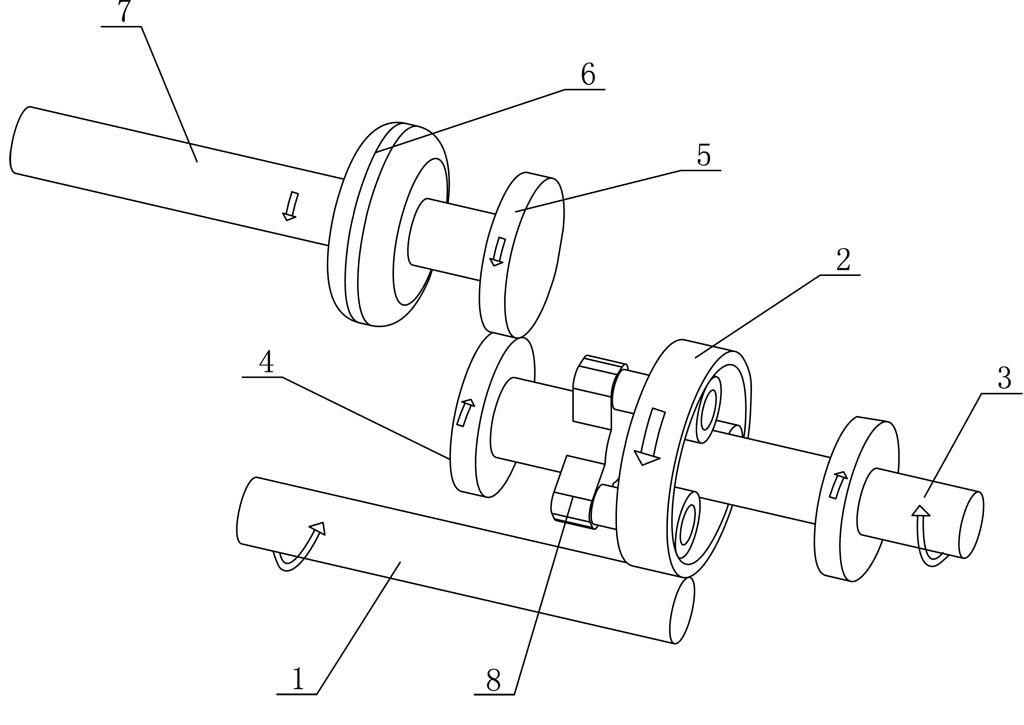

Synchronous two-stage transmission for vehicle

InactiveCN104455240AGrow fastSmooth accelerationToothed gearingsTransmission elementsLow speedControl theory

The invention provides a synchronous two-stage transmission for a vehicle. The synchronous two-stage transmission comprises an input spline shaft and an output angle gear shaft, wherein the input end of the input spline shaft is arranged on the outer side of a box; an input connecting disk is arranged at the input end of the input spline shaft; a gear hub is arranged on the outer side of the spline part on the input spline shaft; a gear sleeve is arranged on the outer side of the gear hub; the gear sleeve is turned by a shifting fork to be moved; synchronous rings are arranged on the outer sides of the gear hub and the gear sleeve; the contact surfaces of the synchronous rings are slopes; a top-gear driving gear and a low-gear driving gear respectively sleeve the two sides of the input spline shaft idly; the opposite end faces of the top-gear driving gear and the low-gear driving gear are respectively meshed with the gear hub; the top-gear driving gear is externally meshed with a high-speed driven gear; the high-speed driven gear is fixed on the angle gear shaft; the low-gear driving gear is externally meshed with a low-speed driven gear; the low-speed driven gear is fixed on the angle gear shaft; the angle gear shaft is parallel to the input spline shaft; an angle gear is arranged at the upper end of the angle gear shaft; the upper end of the angle gear shaft extends to the outer side of the box. The power is inputted by the input spline shaft, then shifts the gear through the synchronizer, and then is transmitted to the output angle gear shaft through two approaches, so as to realize two types of transmission of the tricycle.

Owner:CHONGQING XIANYOU TECH DEV

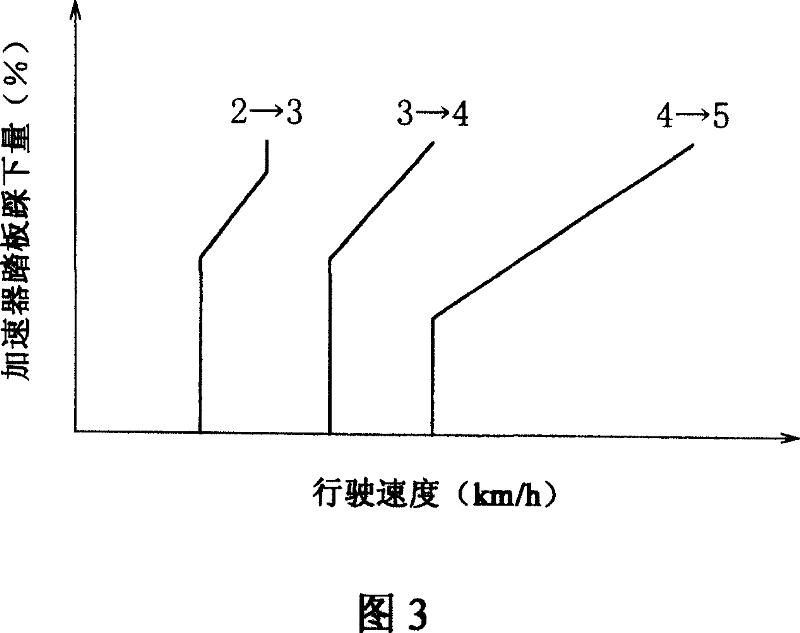

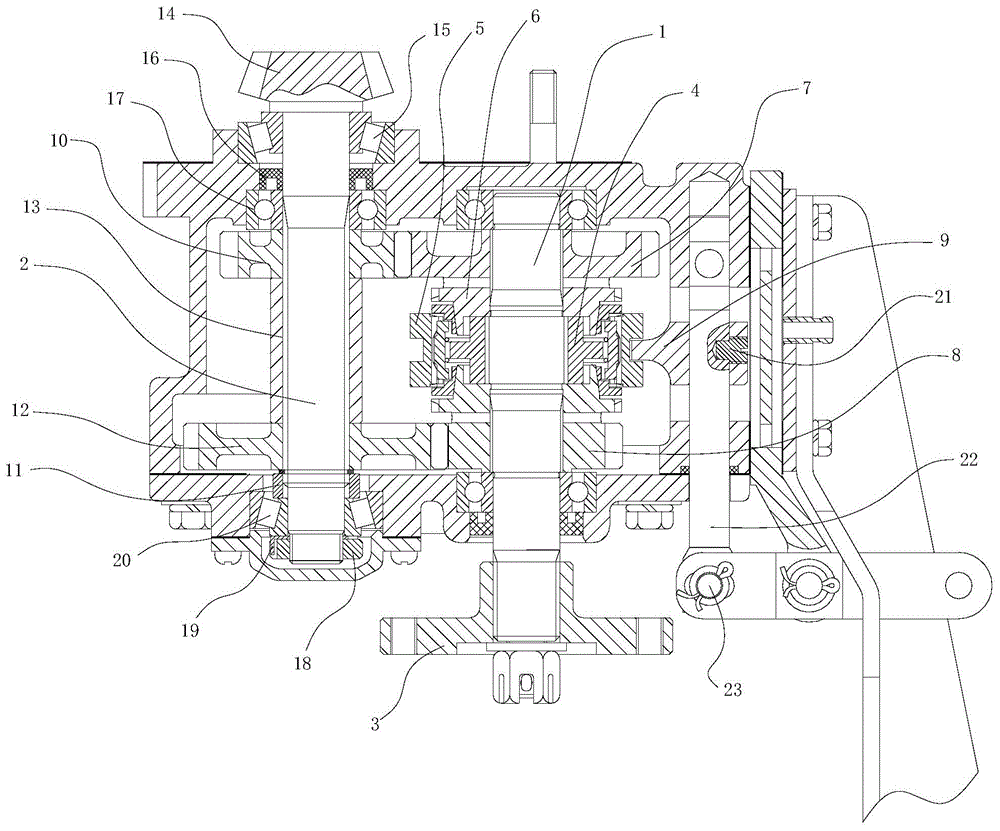

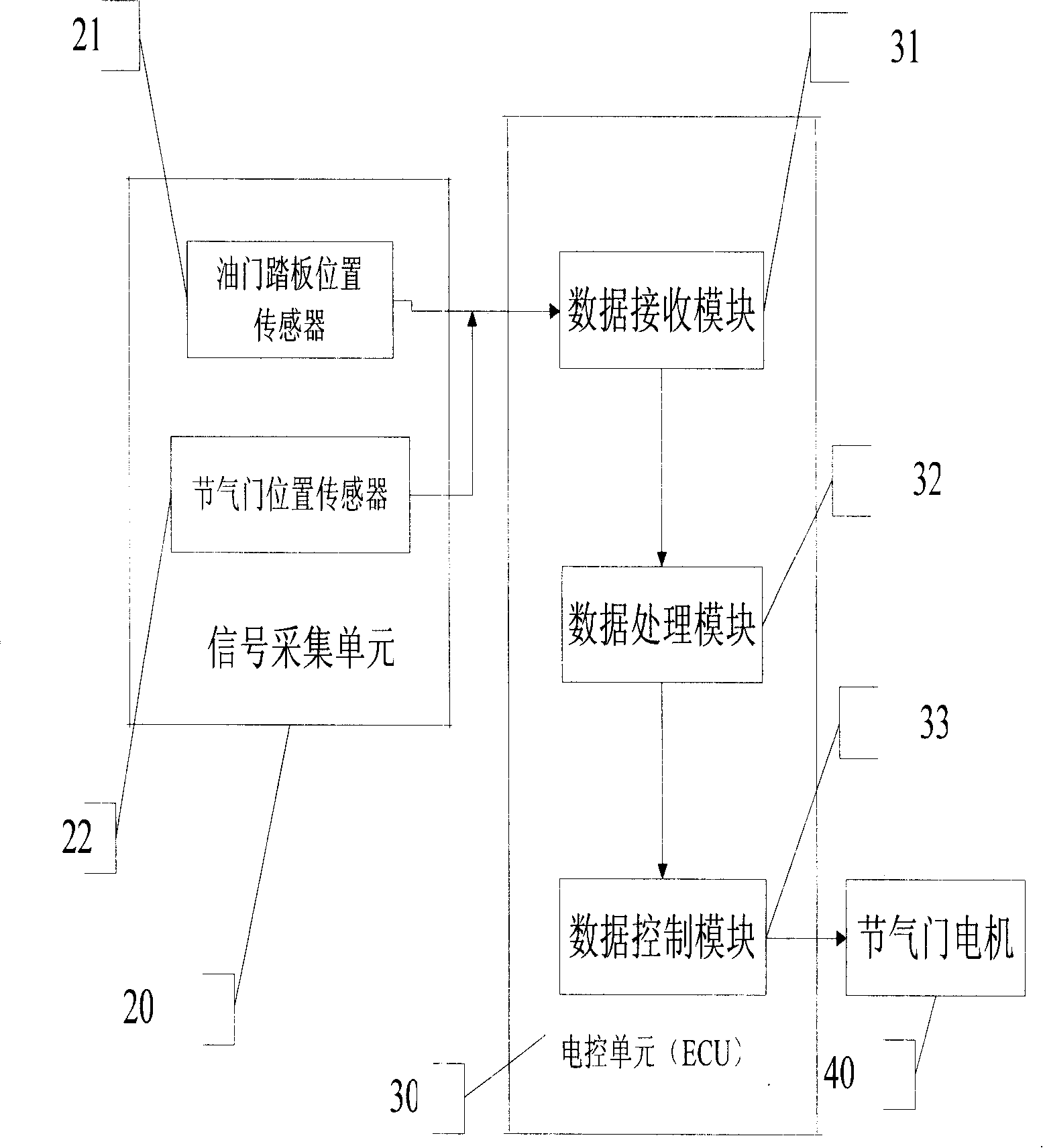

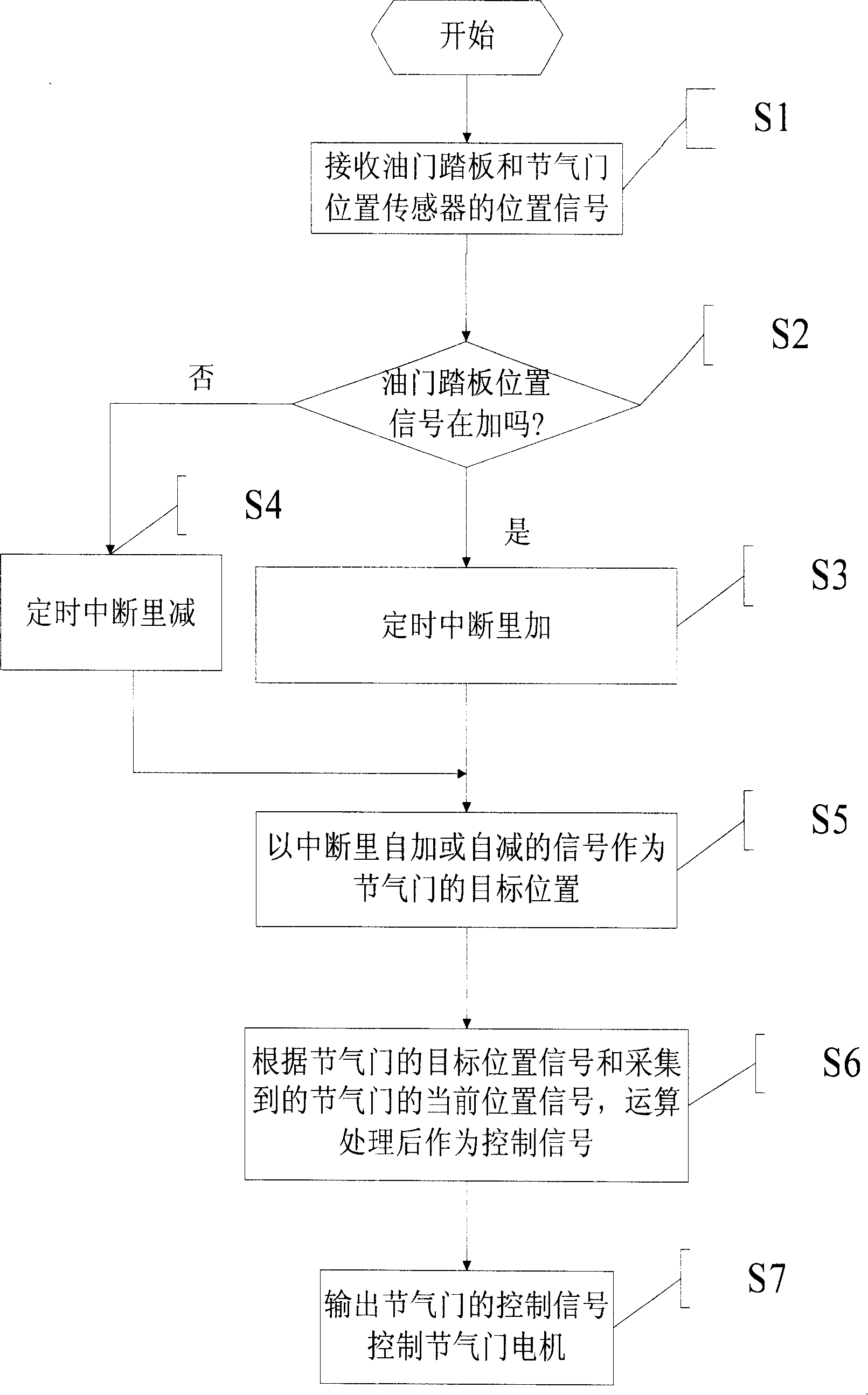

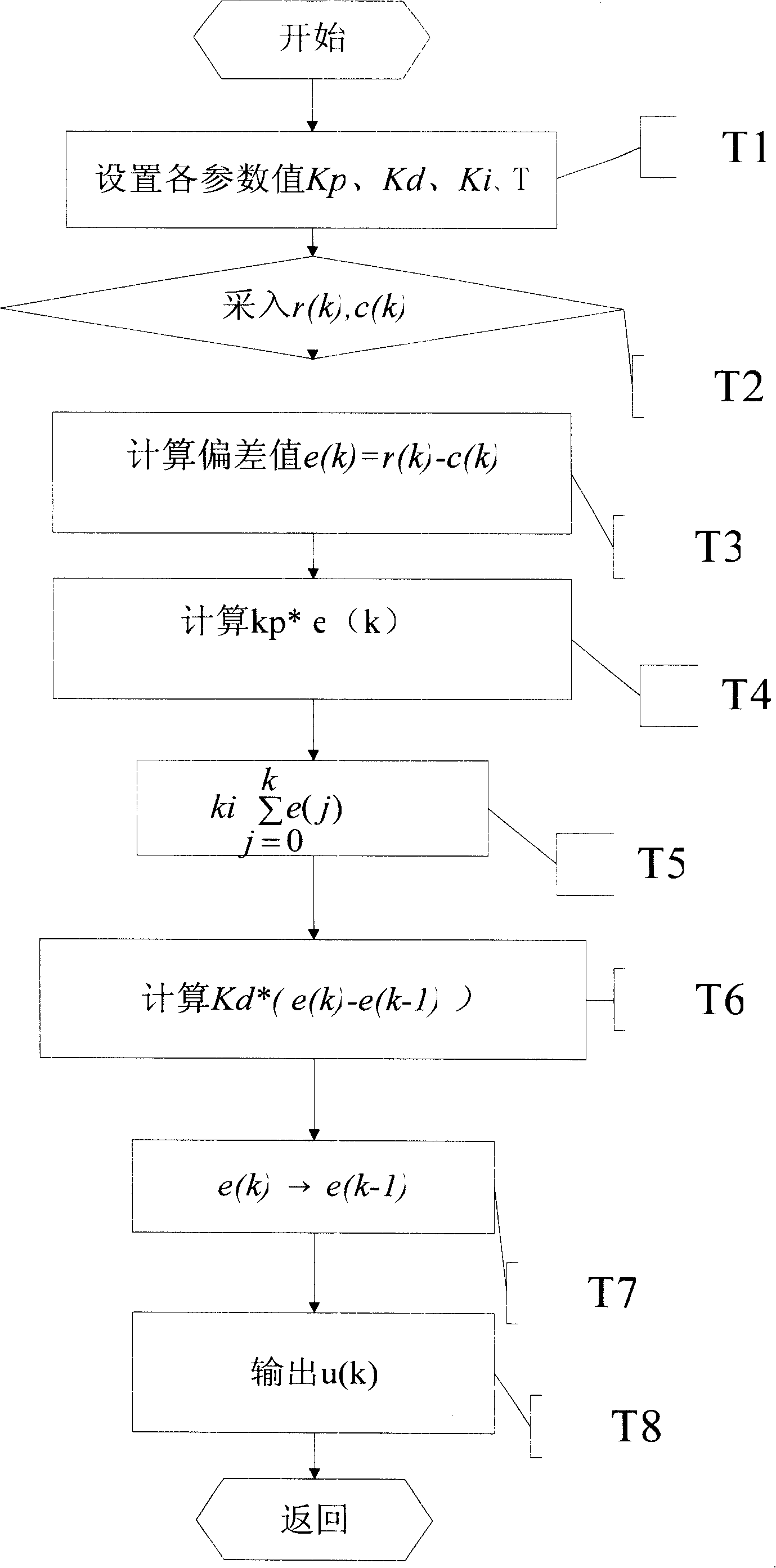

Elastic control method for automatic transmission case choke

ActiveCN101210615AMeet the use requirementsImprove stabilityGearing controlControllers with particular characteristicsThrottle controlAutomatic transmission

The invention discloses a method for controlling the elasticity of a throttle of an automatic gearbox. The method is implemented by the following steps of: collecting signals from an accelerator pedal sensor and signals from a throttle position sensor, automatically adding or subtracting signals in a timed interruption according to the opening degree of an accelerator pedal, converting the self-added or self-subtracted signals in the timed interruption into a target position of the throttle to control a motor of the throttle. Accordingly, under the conditions of sudden acceleration or deceleration of the accelerator pedal, the invention can avoid the over-high instantaneous accelerated or decelerated speed, enable the smooth acceleration or deceleration along with the operation of the accelerator pedal, and ensure the riding comfort and fuel efficiency. The inventive throttle control method has good stability, accuracy and real-time property and can meet the operating requirement of AMT.

Owner:BYD CO LTD

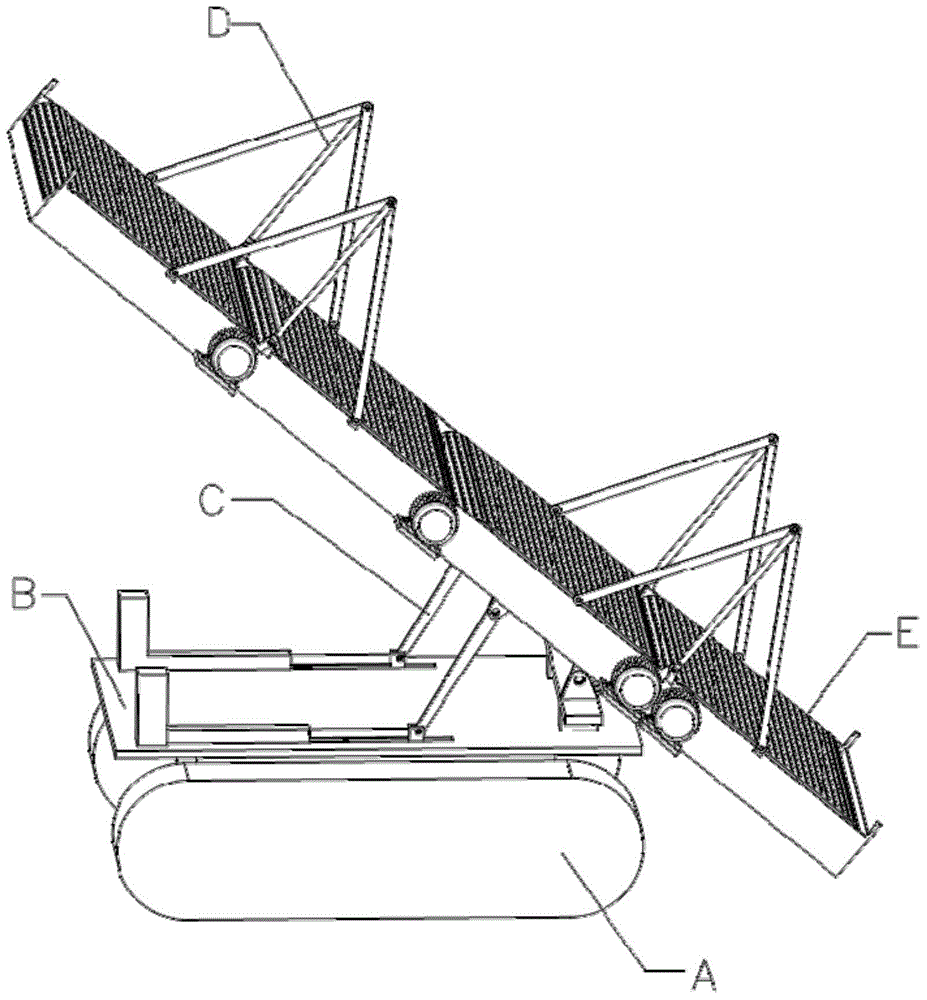

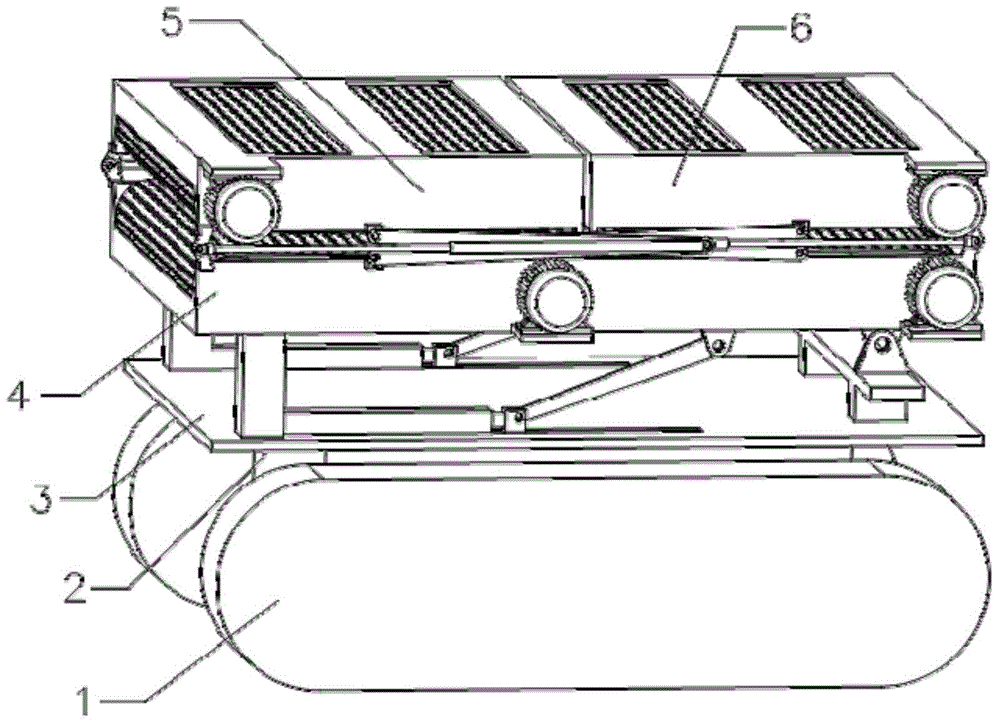

Foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine

The invention discloses a foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine. At present, a machine capable of quickly throwing sand bags is urgently needed for recover damages as far as possible during flood defense. The foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine comprises a tracked traveling device, a rotating platform steering device, a throwing platform lifting device, a foldable throwing platform unfolding device, a belt transmission device and a hydraulic system. The tracked traveling device is capable of operating in severe environment; the rotating platform steering device and the throwing platform lifting device are capable of changing sand bag throwing directions and angles at any time as needed; the foldable throwing platform unfolding device is capable of quickly and efficiently folding and unfolding the throwing platform; the sand bags are stably accelerated by a four-level variable-speed special-shaped belts of the belt transmission device; friction force between the sand bags and the belt is increased, and an acceleration process is quicker. The foldable multi-level special-shaped belt transmission type continuous flood-defense sand bag throwing machine has the advantage that operation efficiency in flood defense can be improved to reduce economic loss as far as possible.

Owner:安徽翰邦科技咨询有限公司

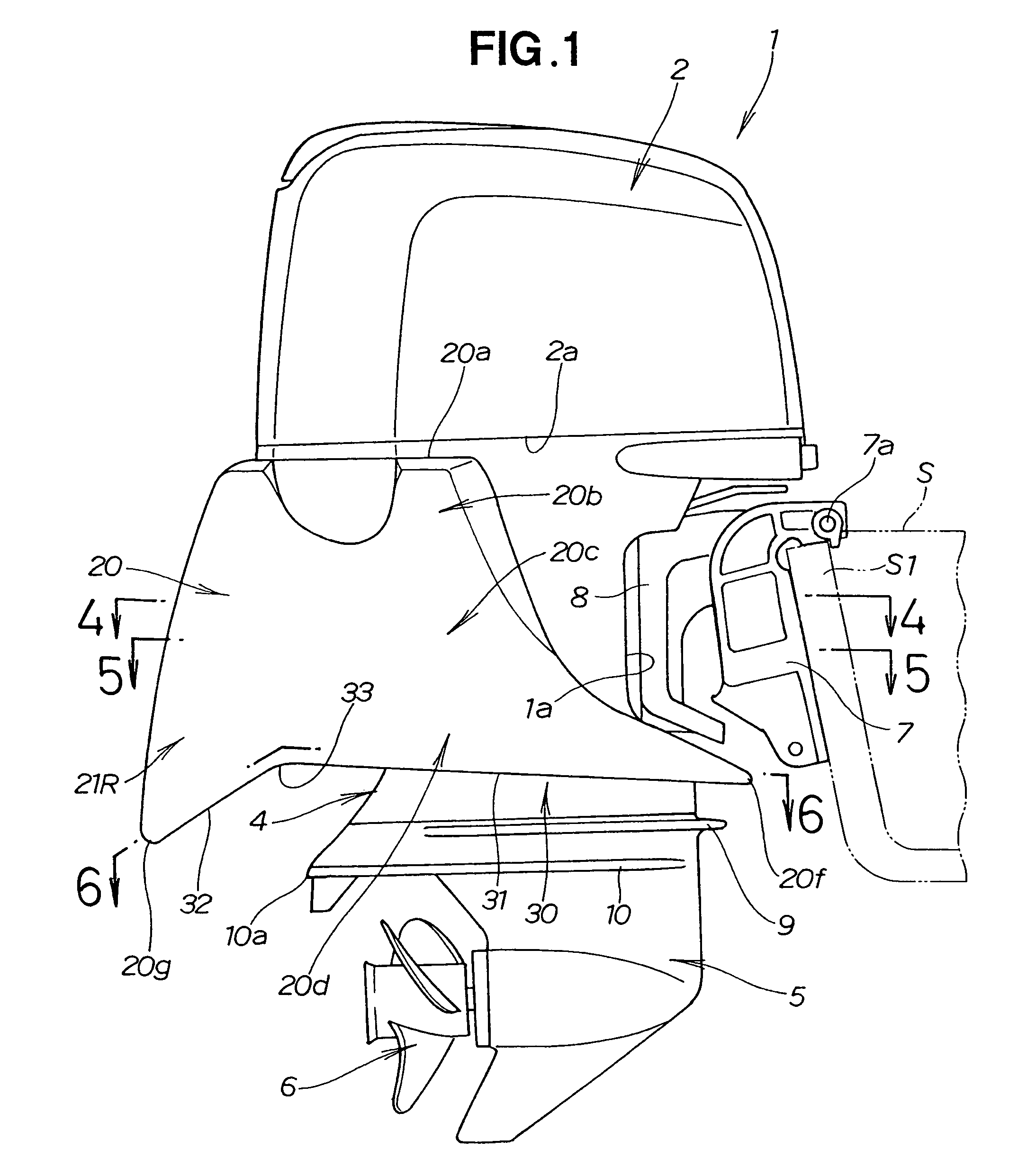

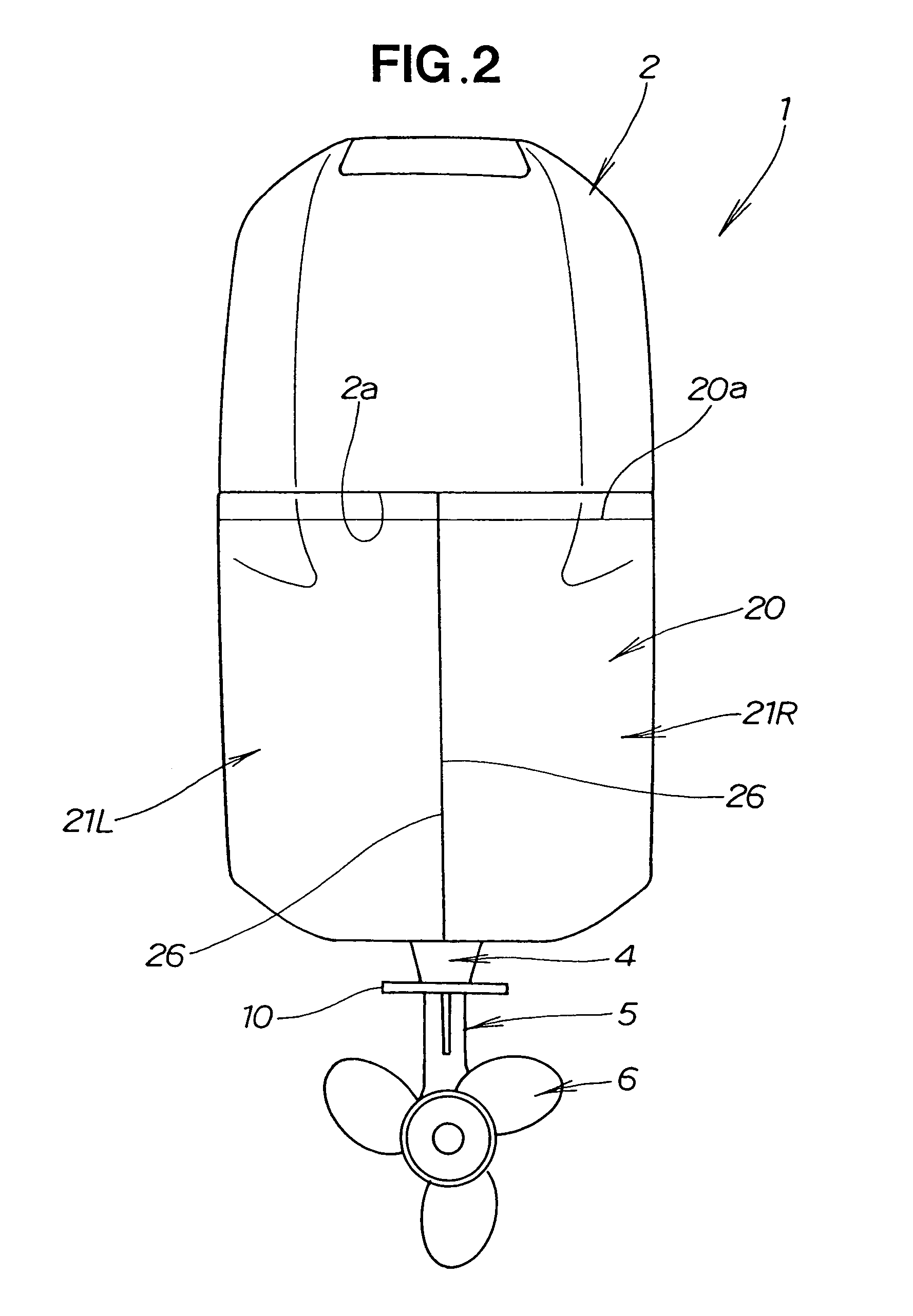

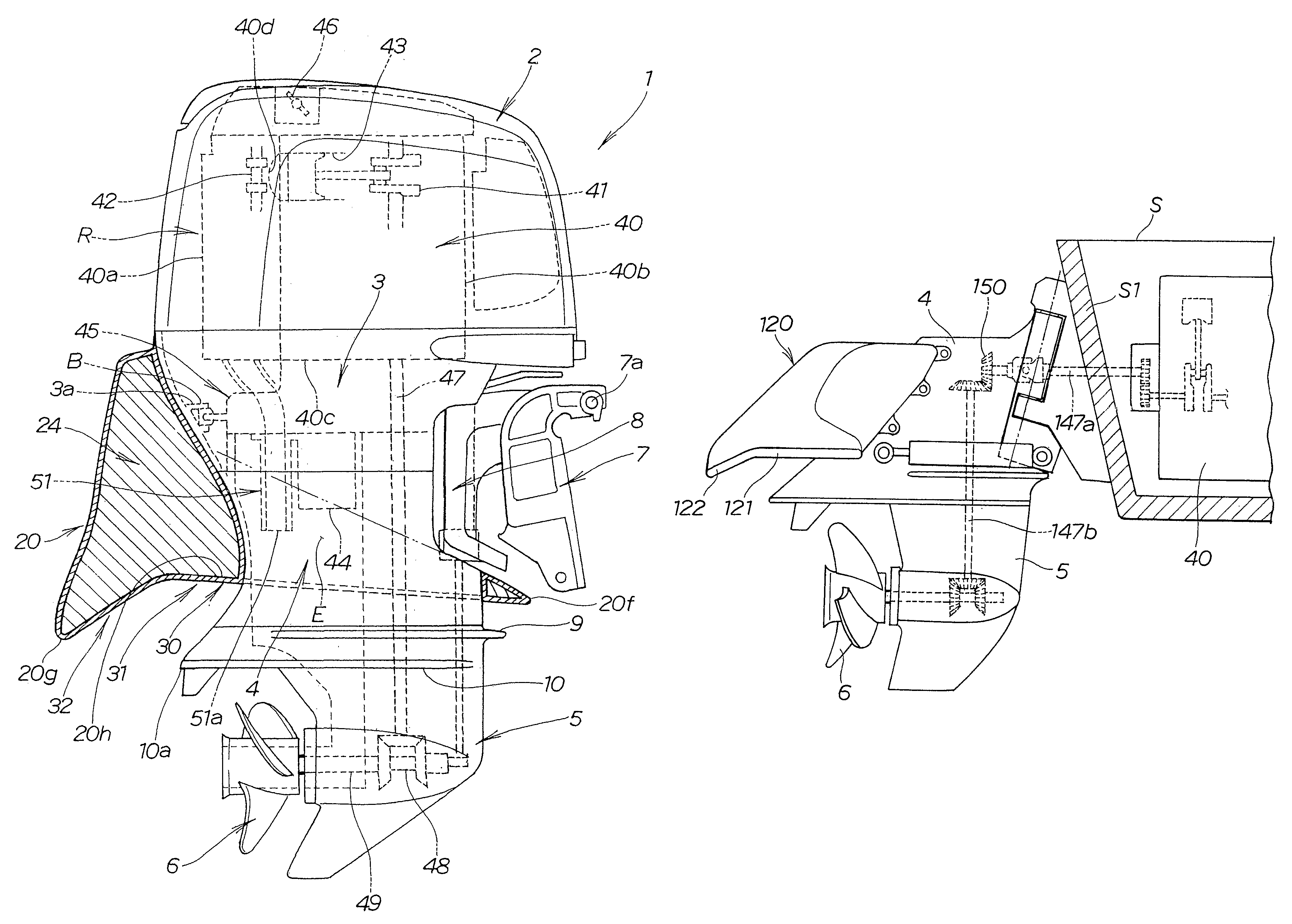

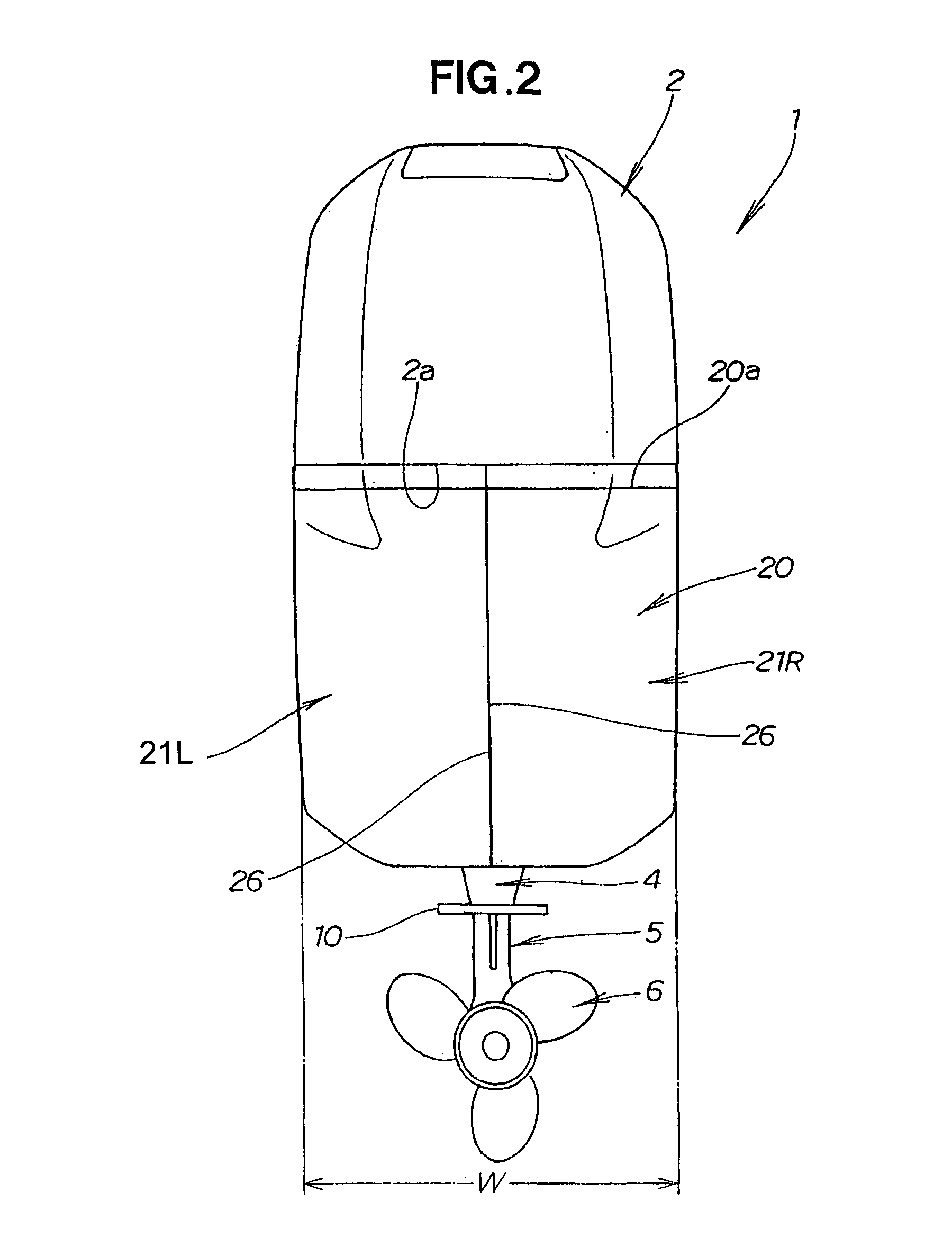

Outboard engine

ActiveUS7322866B2Time is exceededSmooth accelerationWatercraft hull designPropulsion power plantsEngineering

Owner:HONDA MOTOR CO LTD

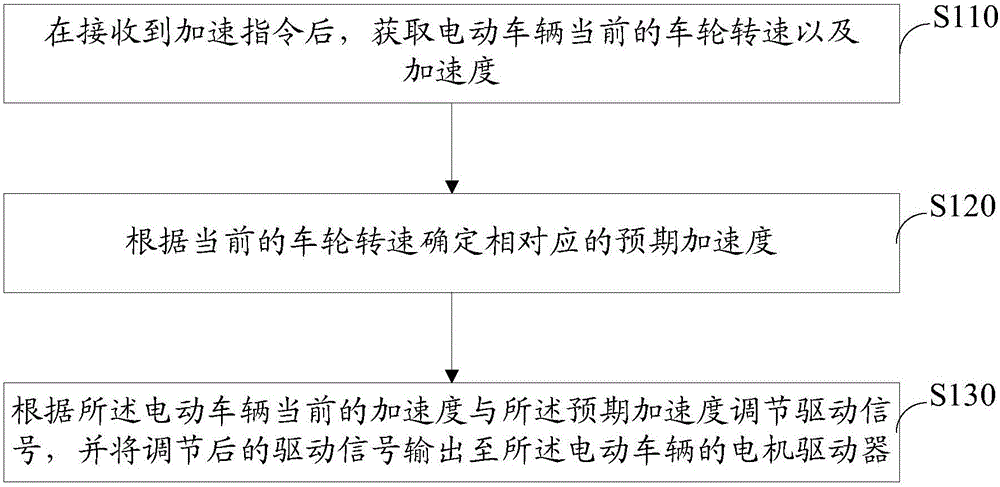

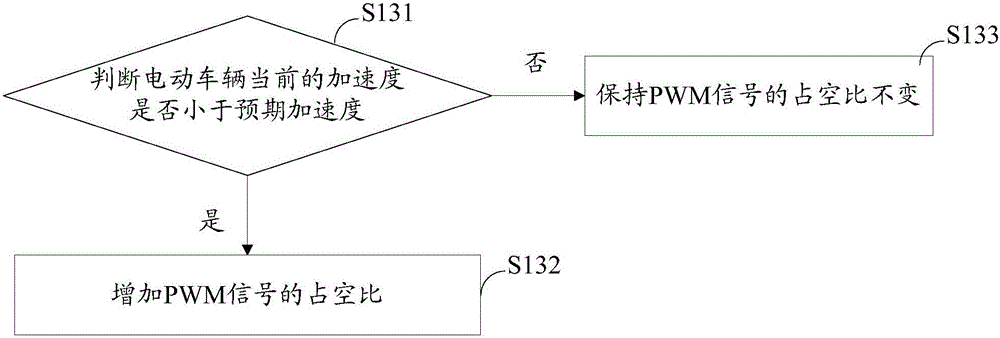

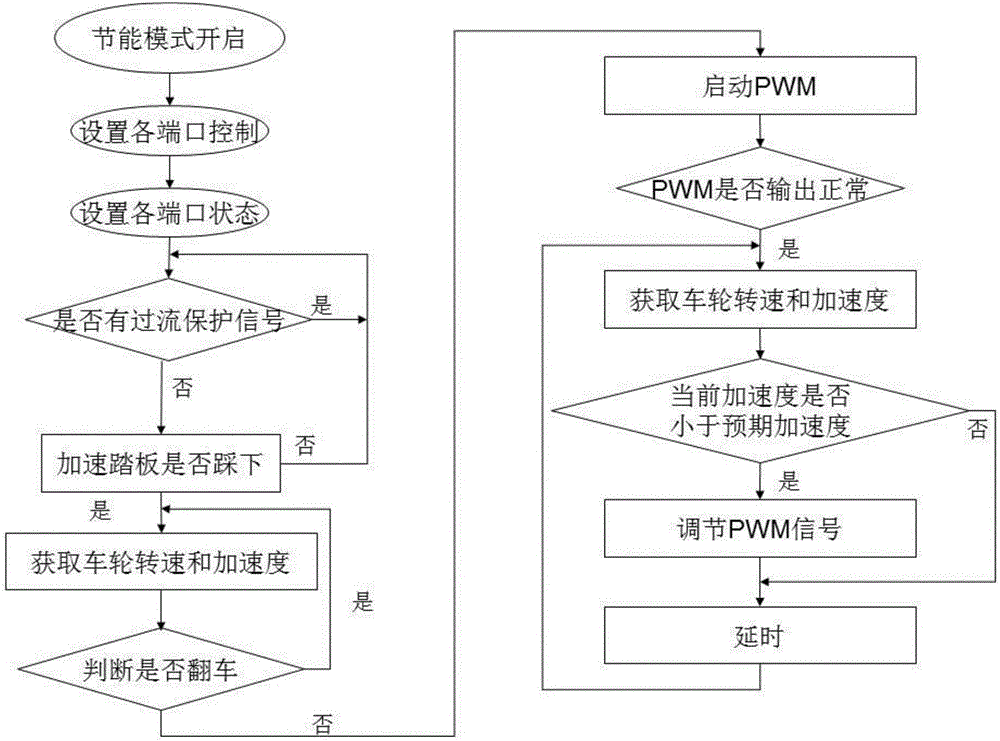

Energy-saving acceleration method and device for electric vehicle

ActiveCN105774595ASmooth accelerationImprove battery lifeSpeed controllerElectric energy managementAutomatic controlElectric machine

The invention relates to an energy-saving acceleration method and device for an electric vehicle. The method includes the following steps that after an acceleration command is received, the wheel rotation speed and the acceleration of the electric vehicle are acquired; the corresponding expected acceleration is determined according to the current wheel rotation speed of the electric vehicle; and a drive signal is adjusted according to the current acceleration and the expected acceleration of the electric vehicle, and the adjusted drive signal is output to a motor driver of the electric vehicle. By the adoption of the method and device, the drive signal is adjusted according to the real-time wheel rotation speed and the real-time acceleration of the electric vehicle, the work state of a motor is automatically controlled, the stable acceleration performance of the electric vehicle is achieved under the minimum work current, the situation that the output power of the motor is too large due to improper manual acceleration control, and consequently the electric quantity of a battery is wasted is avoided, the service life of the battery is prolonged, and the running capacity of the electric vehicle is improved.

Owner:GUANGQI HONDA

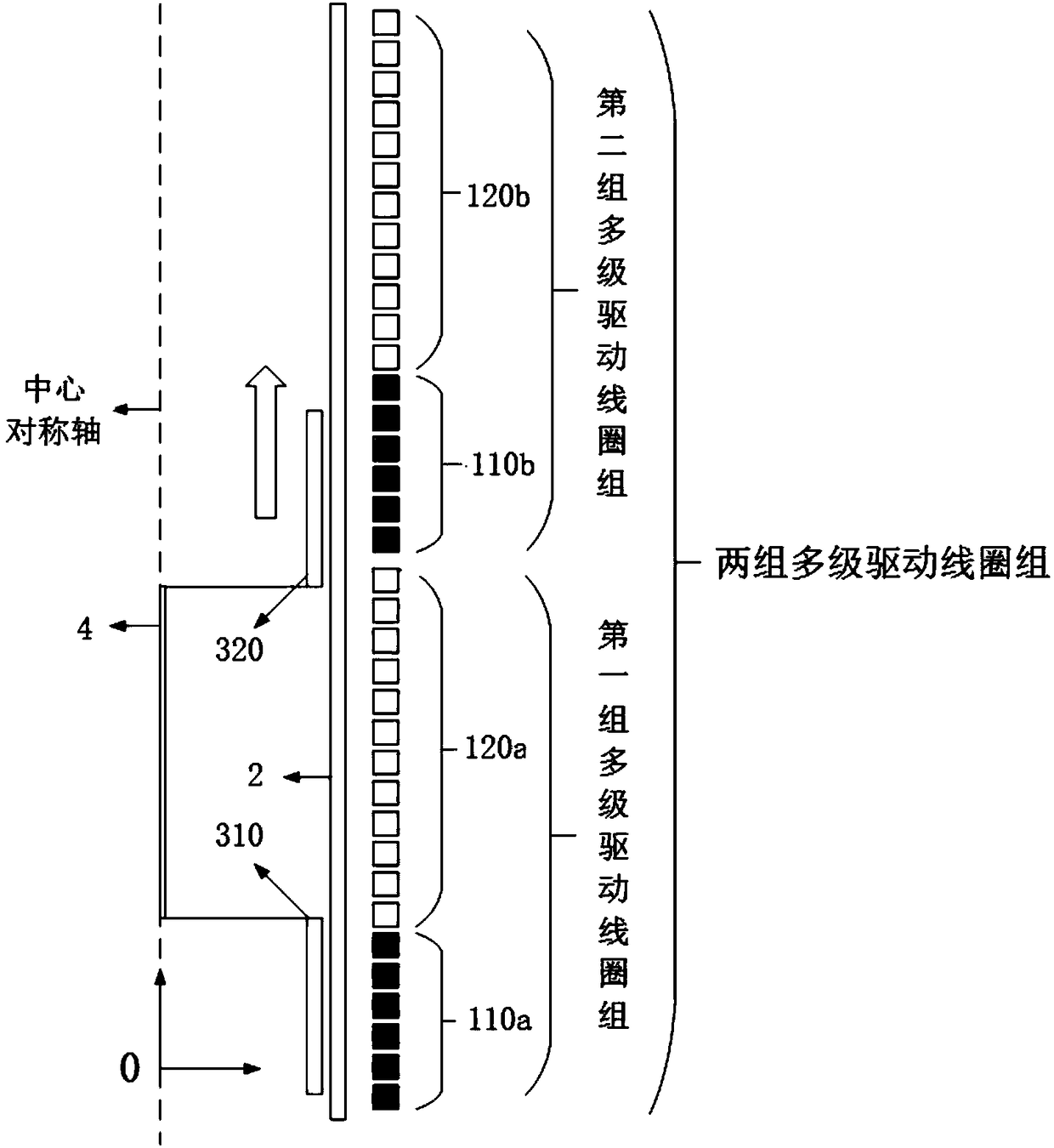

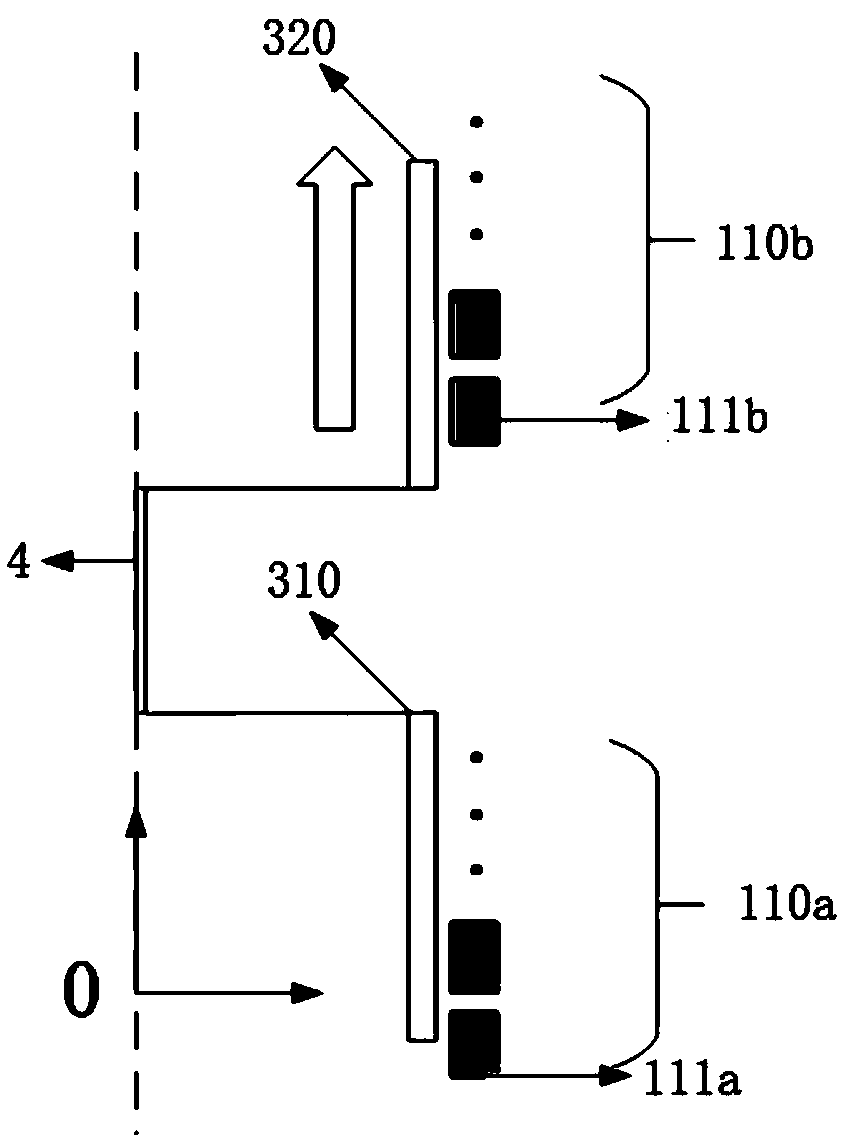

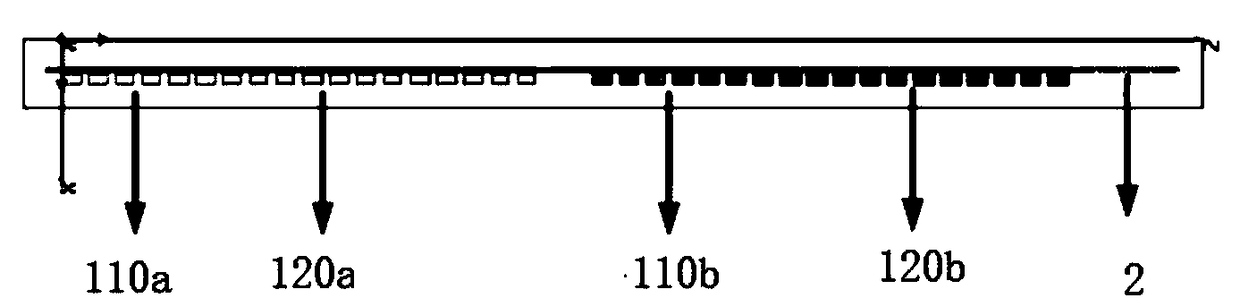

Combined asynchronous induction electromagnetic coil emitter and ignition method thereof

ActiveCN108387138AAvoid Acceleration FaultsSmooth accelerationLaunching weaponsEngineeringGun barrel

The invention discloses a combined asynchronous induction electromagnetic coil emitter and an ignition method thereof. The combined asynchronous induction electromagnetic coil emitter comprises a plurality of sets of multistage coil emitters, a gun barrel and a plurality of connectors. Each multistage coil emitter comprises a multistage driving coil set and a corresponding armature, the multistagedriving coils are sequentially wound outside the gun barrel in the axial direction of the gun barrel, the armatures are sequentially arranged in the gun barrel in the axial direction of the gun barrel, and the adjacent armatures are connected through the connectors. When the combined asynchronous induction electromagnetic coil emitter is not triggered, the armatures are located in the corresponding multistage driving coil sets. After the combined asynchronous induction electromagnetic coil emitter is triggered, the multistage driving coils provide acting force pointing to a gun opening in theaxial direction of the gun barrel for the armatures in the multistage driving coils. According to the combined asynchronous induction electromagnetic coil emitter, propulsive force of different pulsewidths, amplitudes and waveforms can be achieved, the accelerated speed faults of the armatures can be avoided, and therefore acceleration is smoother; meanwhile, stress, the emitting speed and emitting efficiency can be improved; and the combined asynchronous induction electromagnetic coil emitter is more suitable for occasions with higher requirements for thrust precision.

Owner:WUHAN UNIV

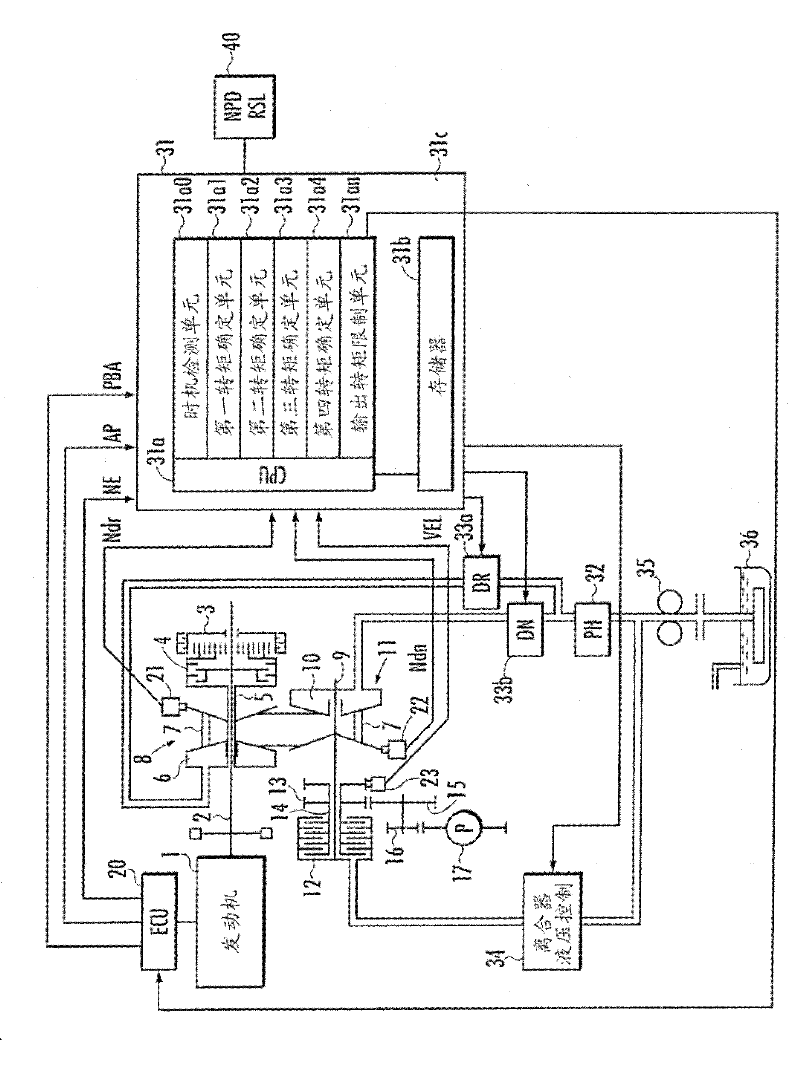

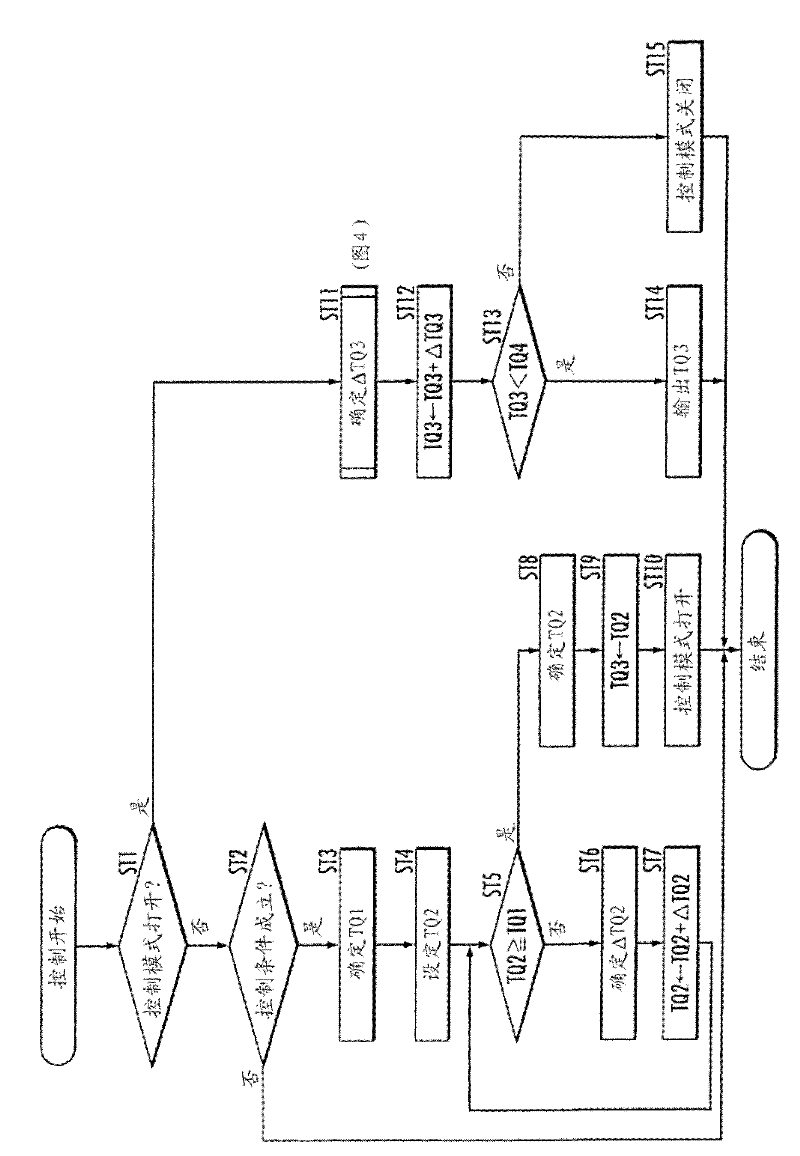

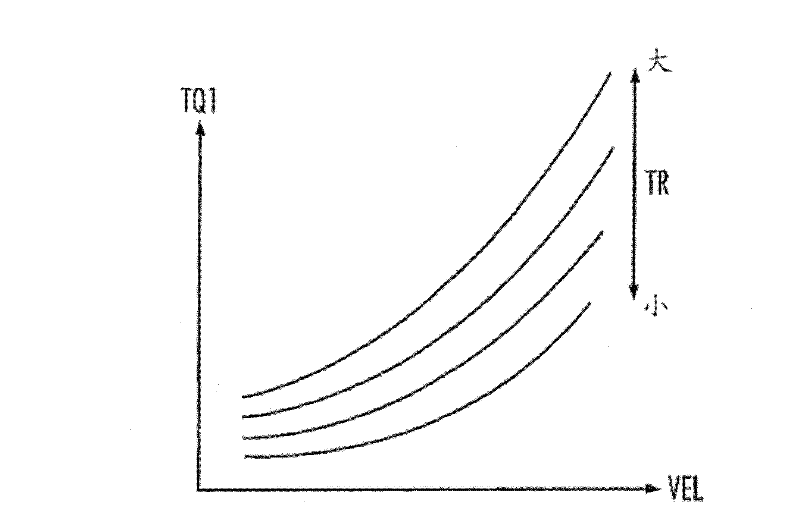

Output torque control device

InactiveCN102245886ALarge output torqueSmooth accelerationElectrical controlMachines/enginesControl theoryGear ratio

Output torque from a drive source is calculated as: a detection-timing torque which is determined when a value corresponding to the actuation of an accelerator pedal exceeds a predetermined value; a first torque which is determined on the basis of the vehicle speed and the transmission gear ratio; a second torque which is determined on the basis of the detection-timing torque and the first torque; a third torque which is determined on the basis of the control input of the accelerator pedal and the second torque; and a fourth torque which is determined on the basis of the control input of the accelerator pedal. The output torque is limited to the third torque only when the third torque is less than the fourth torque. The third torque is determined so that an increase in the third torque value is suppressed more when the detection-timing torque is larger than the first torque than when the detection-timing torque is not larger than the first torque.

Owner:HONDA MOTOR CO LTD

Driving support device, driving support method and driving support program

InactiveUS8050834B2Smooth travelSmooth accelerationAnalogue computers for trafficAnti-collision systemsEngineeringAcceleration Unit

Information pertaining to a first zone set ahead of a host vehicle and a second zone farther ahead than the first zone is acquired. Based on the information, if a distance between an end point of the first zone and a start point of the second zone is shorter than a distance within which the host vehicle can be slowed at a predetermined deceleration to a second target vehicle speed for traveling the second zone at the start point of the second zone, a second acceleration gear ratio is acquired for accelerating the host vehicle in a second acceleration zone following the second zone. The gear ratio of the host vehicle is set to the second acceleration gear ratio in a first deceleration zone for slowing the host vehicle before reaching the first zone.

Owner:AISIN AW CO LTD

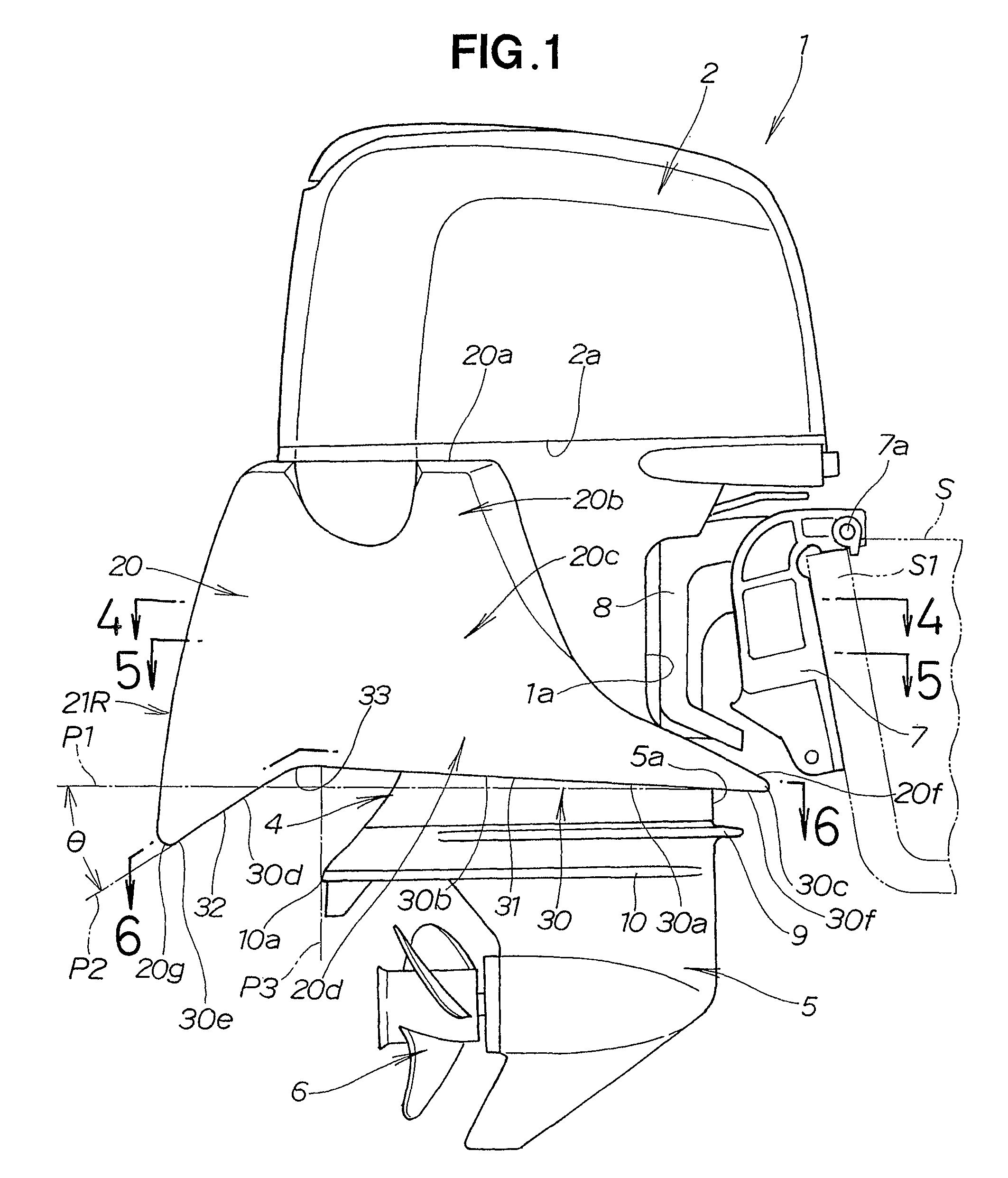

Boat propulsion engine

InactiveUS8206192B2Reduces further sinkingExtension of timeRotary propellersPropulsion power plantsDrive shaftStern

A boat propulsion engine includes a buoyant member (20) disposed on a case body that houses a drive shaft (47) in order to lift the stern. The buoyant member has a lower surface (32) that slopes downward in the rearward direction.

Owner:HONDA MOTOR CO LTD

Stepless speed change structure for planetary gears

InactiveCN102537238AChange speed ratioRealize infinitely variable speedToothed gearingsGearing detailsControl powerGear wheel

The invention discloses a stepless speed change structure for planetary gears, which has the advantages of high torque bearing capability, no slipping, simple structure, less parts, low manufacture and maintenance costs, superior long service life and wide speed change range, and can be applied to heavy-duty vehicles, large-scale vehicles and mini-type vehicles. Based on the structural characteristics of the planetary gears, the stepless speed change of power input and output speeds is realized when the revolution ratio between a gear ring and a sun gear is changed by changing the rotational speed of a planetary gear rack. The stepless speed change structure comprises the gear ring, the planetary gear rack and the sun gear, wherein the gear ring is connected with the power input shaft of a vehicle engine; the sun gear is connected with the power output shaft; the planetary gears are mounted on the planetary gear rack and are connected with a power adjusting control device capable of changing the speeds of the planetary gears; and the power adjusting control device comprises a control power input shaft and a control gear arranged at one end of the control power input shaft.

Owner:宏万兵

Upper end surface of tapered spring rubber body, and method and product for preventing folds and cracks

The invention provides an upper end surface of a tapered spring rubber body, and a method and a product for preventing folds and cracks. The upper end surface comprises an inner cone, a rubber body and an outer cone, wherein the rubber body is arranged around the periphery of the inner cone; the outer cone is arranged around the periphery of the rubber body; a rubber metal spring which is conically arranged is formed by the rubber body, the inner cone and the outer cone; the upper end surface of the rubber body is connected with the inner cone and the outer cone of the tapered spring, respectively; the rubber body has a gradual descending tendency from the connection part of the rubber body and the outer cone to the inner cone of the rubber body; the upper end surface of the tapered spring rubber body is characterized by being in a multi-section downhill combined profile structure; the upper end surface of the rubber body is formed by combining a plurality of sections of annular end surfaces with different shapes, gradients and lengths. The profile shape of the upper end surface is changed so that the variable stiffness of the tapered spring is adjusted; the upper end surface of the tapered spring rubber body is divided into more than two sections of multi-section profile combination; all sections of the profile have different shapes, gradients and lengths.

Owner:ZHUZHOU TIMES RUIWEI ANTI VIBERATION EQUIP LTD

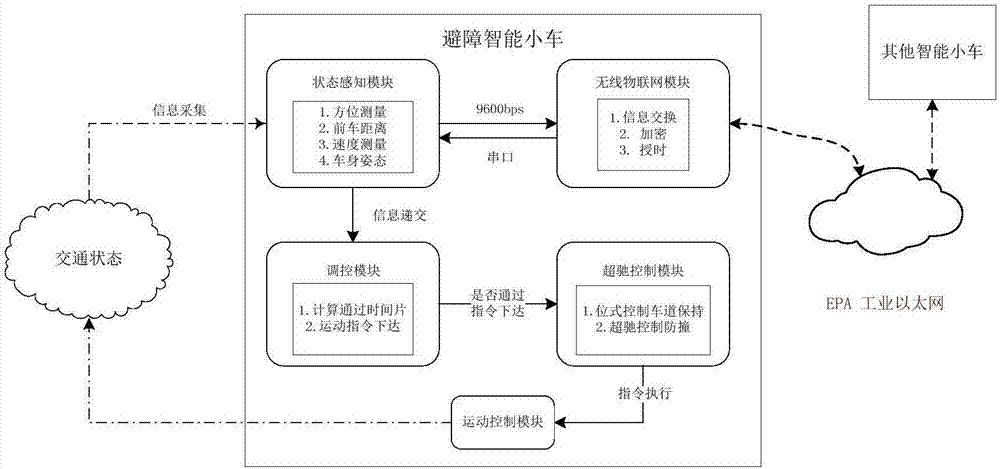

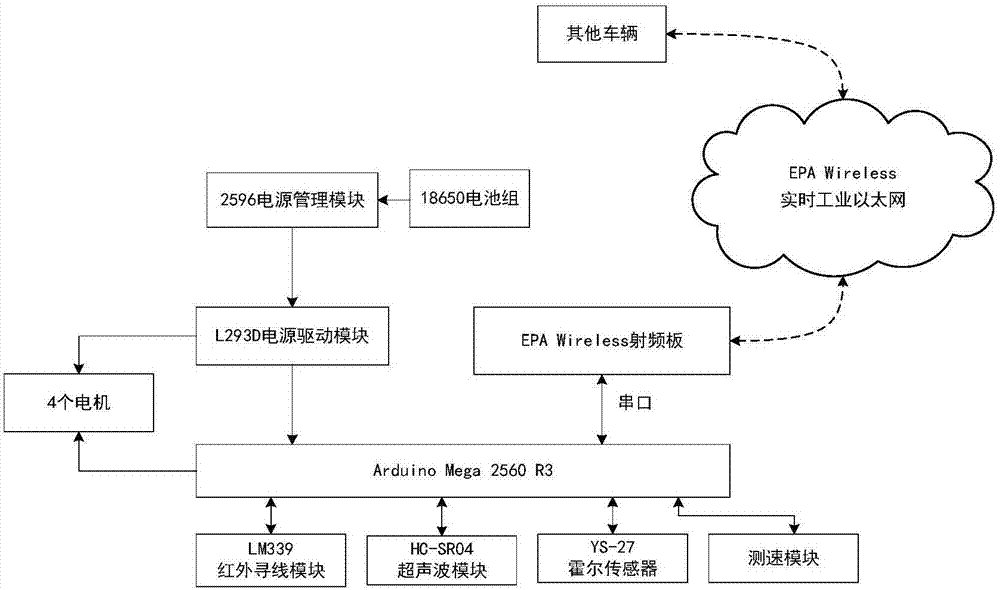

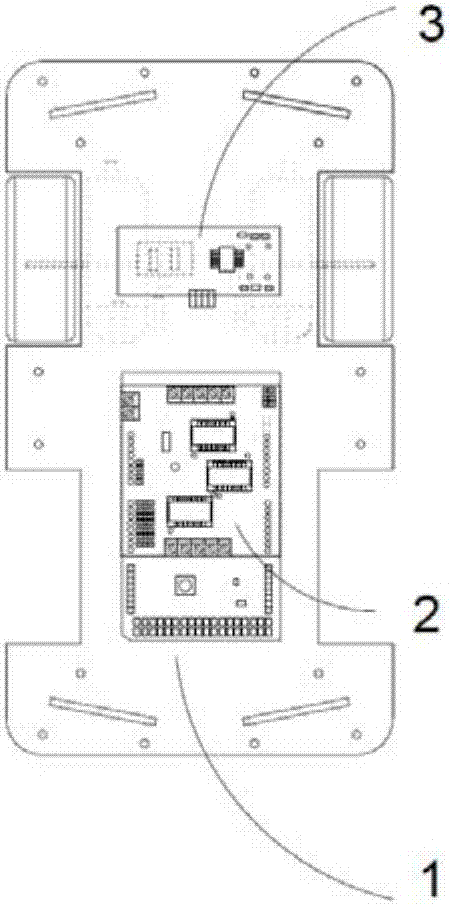

Wireless Internet-of-Things-based override control obstacle avoidance intelligent vehicle and control method therefor

ActiveCN106959692AClock synchronizationSynchronous schedulingPosition/course control in two dimensionsVehiclesEngineeringObstacle avoidance

The invention discloses a wireless Internet-of-Things-based override control obstacle avoidance intelligent vehicle and a control method therefor and belongs to the field of wireless Internet-of-Things. A state sensing module, a wireless Internet-of-Things module, a regulation and control module and an override control module are mounted on the obstacle avoidance intelligent vehicle; the obstacle avoidance intelligent vehicle is suitable for traffic conditions of a crossroad, and the obstacle avoidance intelligent vehicle is allowed to cross the crossroad in a conflict-free manner. Particularly, special conditions can be handled with smooth speed change via the override control module, and effects of timely advancing, smooth deceleration, smooth acceleration and smooth parking can be exerted; clock synchronization and dispatching synchronization of the obstacle avoidance intelligent vehicle in the Internet-of-Things are fulfilled, signal lagging of traffic dispatching and time constants of a traffic system can be greatly reduced, and simplified and unified management of a traffic system model can be facilitated.

Owner:ZHEJIANG UNIV

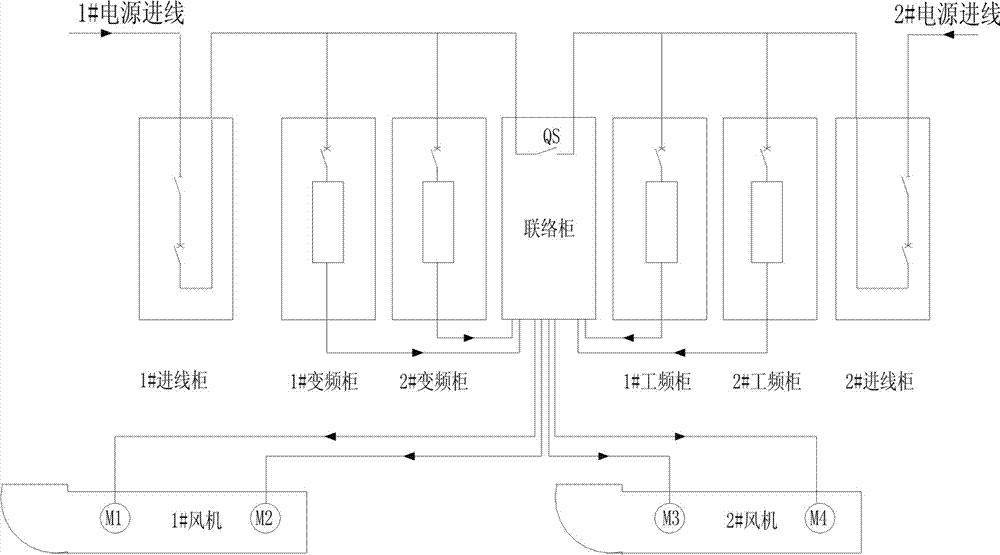

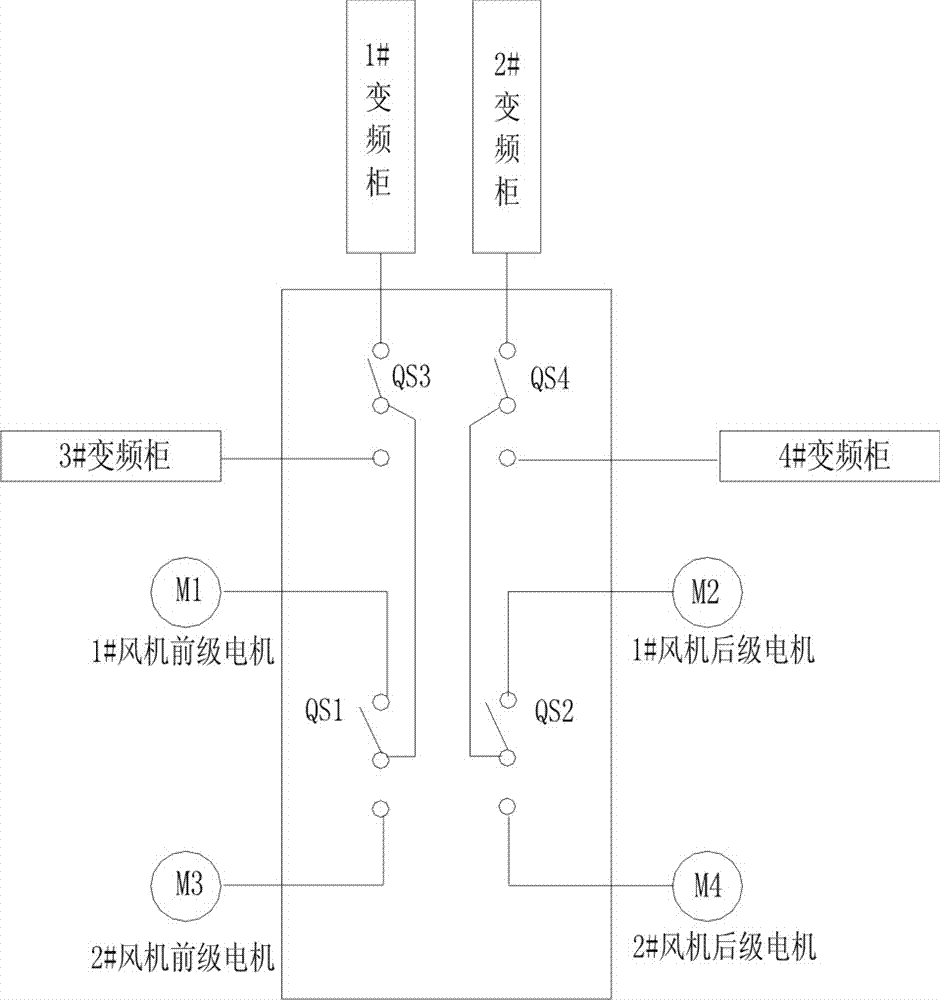

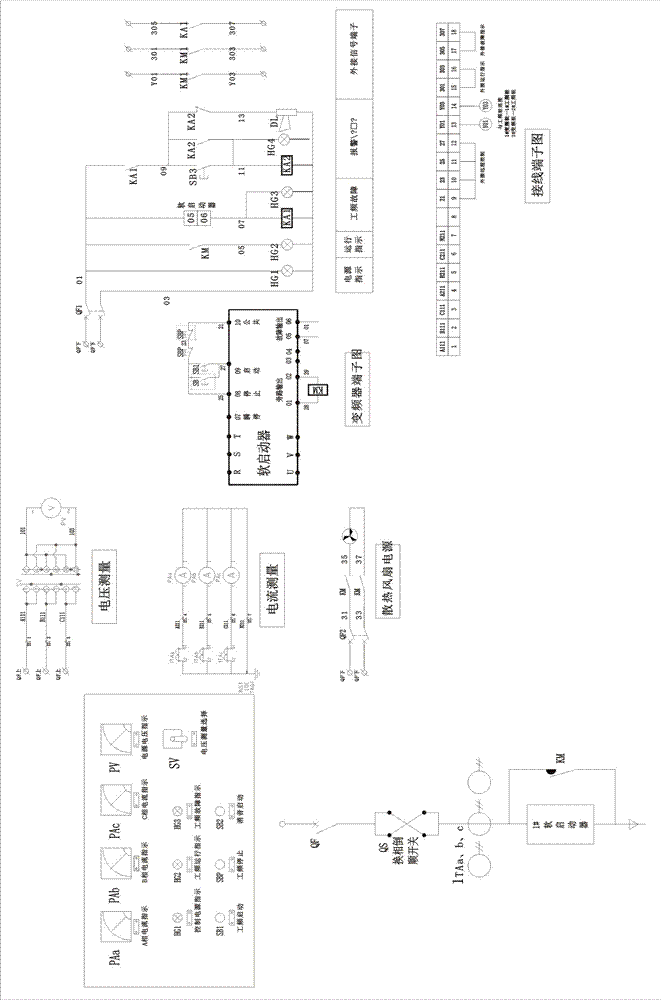

Intelligent fluid control system

InactiveCN104214126AReduced service lifeSmooth accelerationPump controlNon-positive displacement fluid enginesPower gridPower flow

The invention discloses an intelligent fluid control system. The intelligent fluid control system is characterized by sequentially comprising an incoming wire cabinet A, a variable frequency cabinet A, a variable frequency cabinet B, an outgoing wire cabinet, a power frequency cabinet A, a power frequency cabinet B and an incoming wire cabinet B from left to right, wherein the incoming wire cabinet A and the incoming wire cabinet B are used for being connected with a power incoming wire respectively; the incoming wire cabinet A is connected with the variable frequency cabinet A and the variable frequency cabinet B; the variable frequency cabinet A and the variable frequency cabinet B are connected with a contact cabinet; the incoming wire cabinet B is connected with the power frequency cabinet A and the power frequency cabinet B; the power frequency cabinet A and the power frequency cabinet B are connected with the contact cabinet; the contact cabinet is connected with a fan pre-stage motor M1, a fan post-stage motor M2, a fan pre-stage motor M3 and a fan post-stage motor M4. The intelligent fluid control system has the main advantages that the motors cannot be directly started in the starting process, and the starting process is automatically divided into three periods namely a first accelerating time period, a second accelerating time period and a third accelerating time period, so that the motors can be steadily accelerated, the starting current is greatly reduced, the service lives of the motors are guaranteed, and the impact on a power grid is relatively low.

Owner:四川川鸿电气设备有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com