Conical spring stiffness changing and wrinkle and cracking prevention method, and product

A conical spring, variable stiffness technology, applied in the field of elastic shock absorption, can solve the problems of rubber body wrinkle cracking, difficulty in meeting the multiple stiffness changes of locomotives, etc., and achieve the effects of preventing cracking, good shock absorption, and preventing derailment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

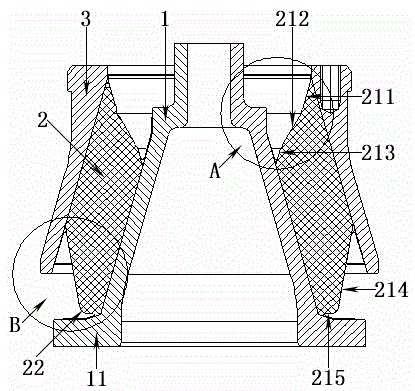

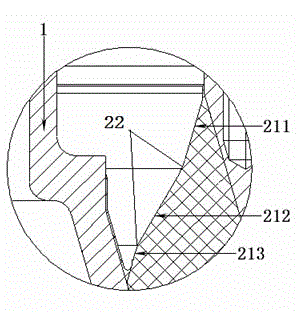

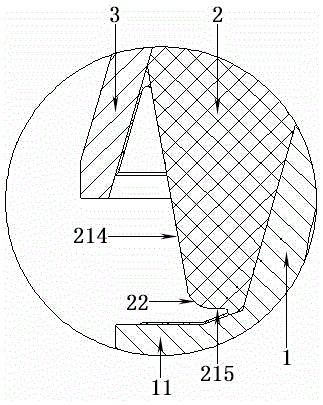

[0047] Such as Figure 1 to Figure 5 As shown, a conical spring includes an inner cone 1 , a rubber body 2 and an outer cone 3 , and the lower end of the inner cone 1 extends outward to form an annular inner cone boss 11 . Such as figure 1 with figure 2 As shown, the upper end surface 21 of the rubber body 2 is a three-section multi-section downhill structure, which are respectively the first annular straight section 211, the second annular straight section 212 and the third annular straight section 213, and every two annular flat sections The circular fillet section 22 is used for transition between the straight sections; the so-called multi-section downhill structure is that the rubber body 2 is gradually descending from the connection with the outer cone 3 to the inner cone 1 of the rubber body 2 . Such as figure 1 with image 3 As shown, the lower end surface of the rubber body 2 is a two-stage multi-stage uphill structure, which are respectively the fourth annular st...

Embodiment 2

[0061] The structure is roughly the same as that of Embodiment 1, but the upper end surface of the rubber body 2 and the lower end surface of the rubber body 2, and the transition edge 111 of the boss adopt not a gentle straight line edge transition, but a gentle curve edge transition, the upper end of the rubber body 2 There are four annular straight sections 21 and three annular rounded corner sections 22 , and the lower end of the rubber body 2 is three annular straight sections 21 and two annular rounded corner sections 22 . Changing the number of segments of the annular straight section 21 can change the number of times the conical spring becomes stiff, that is to say, the number of times of the stiffness of the conical spring can be changed by adjusting the number of ring straight segments 21 . Increasing or reducing the number of annular straight sections 21 can still make the upper and lower ends of the rubber body 2 wrinkle-free and always maintain a smooth shape when ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com