Cold air dynamical spray-painting method and apparatus of delivering powder through down stream

A cold air power spraying, downstream technology, applied in the direction of spraying device, liquid spraying device, device for coating liquid on the surface, etc., can solve the problems of complicated preparation work, turbulent flow, unfavorable coating quality, etc., to achieve operation and Complicated maintenance, good for powder delivery, high safety requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

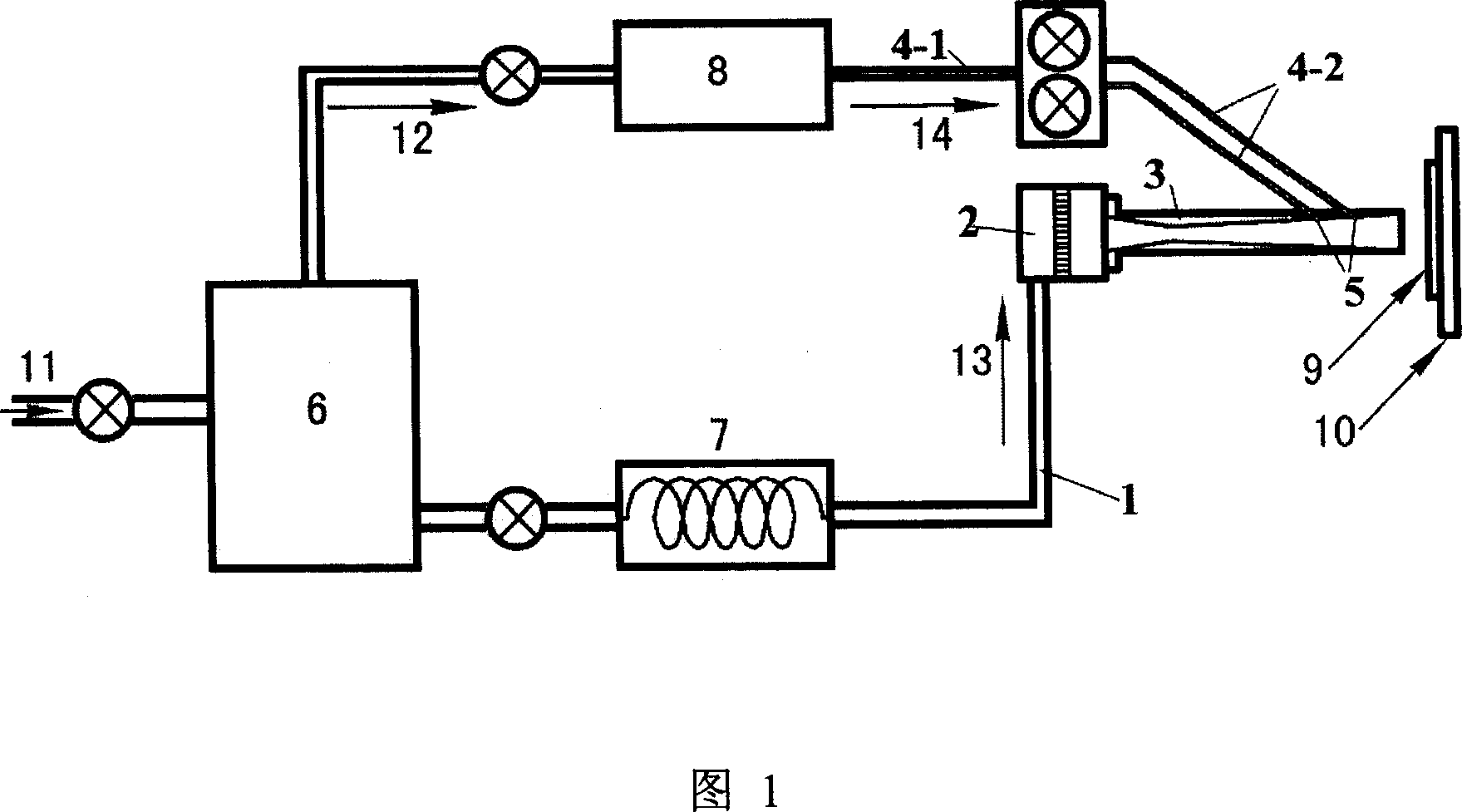

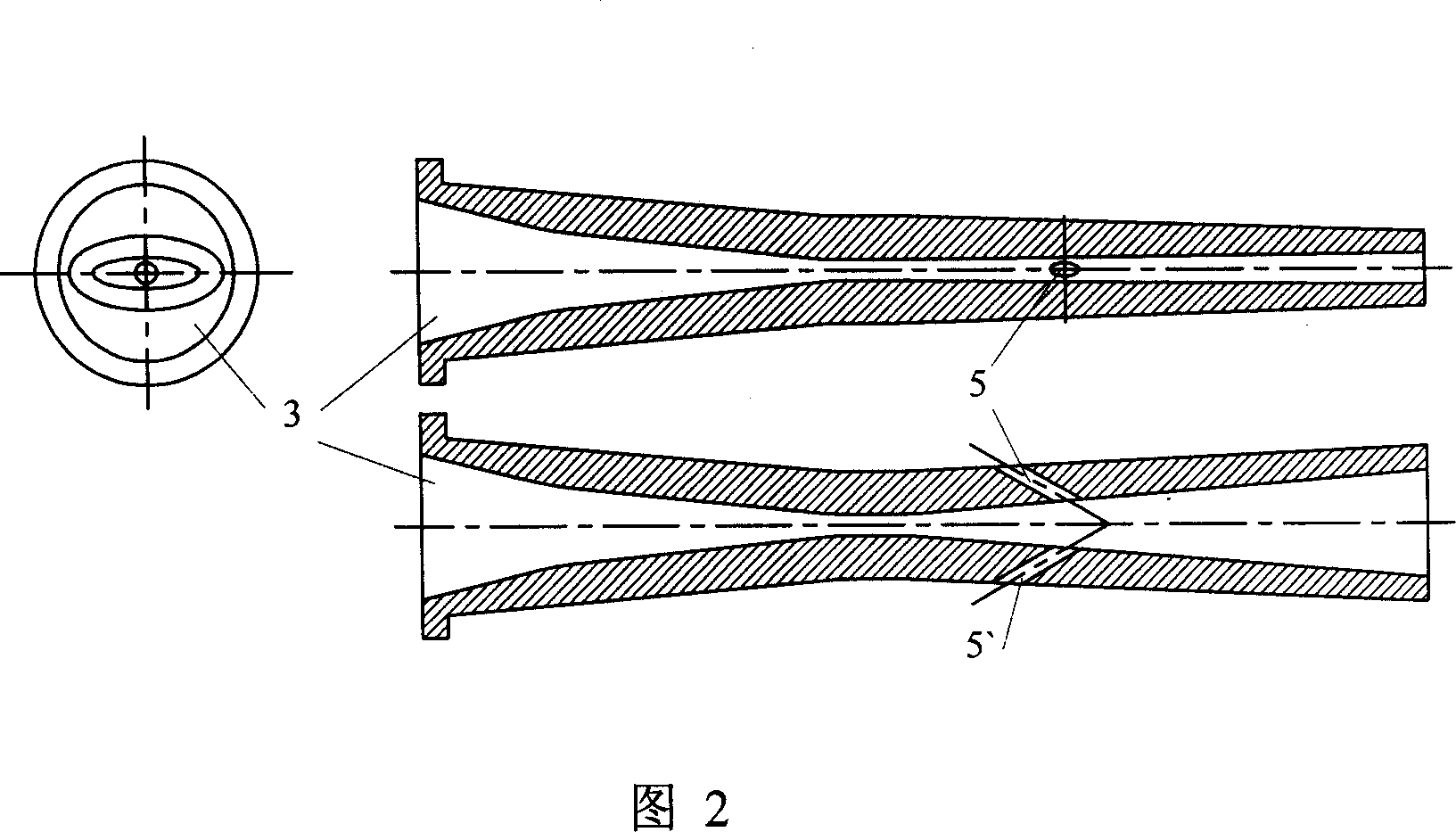

[0033] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 10 μm to 30 μm, and the substrate is an aluminum plate. The working gas pressure at the nozzle inlet is 2.5MPa and the temperature is 380°C. Using a high-pressure powder feeder, the pressure of the carrier gas is slightly higher than 2.5MPa. The form of the nozzle is shown in Figure 2. The diameter of the throat is Φ2.5mm, the outlet is elliptical, the major and minor axes of the ellipse are 14mm and 4mm respectively, and the length of the divergent section is 65mm. The side walls on both sides of the central axis of the nozzle flow channel have a pair of powder feeding holes symmetrically distributed relative to the central axis of the flow channel. The diameter of the powder feeding hole is Φ2.1mm, the axis is at an angle of 45° to the central axis of the nozzle, and the outlet is 20mm away from the throat. The result of spraying is: the deposition rate is about 75%, and ...

Embodiment 2

[0035] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 20 μm to 45 μm, and the substrate is an aluminum plate. The working gas pressure at the nozzle inlet is 3.5MPa and the temperature is 400°C. Using a high-pressure powder feeder, the pressure of the carrier gas is slightly higher than 3.5MPa. The form of the nozzle is shown in Figure 1, the diameter of the throat is Φ2.7mm, the outlet is an ellipse-rectangular combination (perfect circle-rectangular combination), and the major and minor axes of the ellipse are 6mm and 6mm (diameter of a perfect circle), respectively. The rectangular side length of the nozzle outlet inner wall profile is 3.9mm, and the length of the divergent section is 120mm. There are two powder feeding holes on the side wall on one side of the central axis of the nozzle flow channel. The diameter of the powder feeding hole is Φ2.1mm, and the axis is at an angle of 60° to the central axis of the nozzle. The...

Embodiment 3

[0037] Nitrogen is used as the working gas, the particle diameter of the copper powder to be sprayed is 50 μm to 75 μm, and the substrate is an aluminum plate. Using a conventional powder feeder, the pressure of the carrier gas is 0.4MPa. The working gas pressure at the nozzle inlet is 3.0MPa, and the temperature is 500°C. The throat diameter of the nozzle is Φ3.0mm, the outlet is elliptical, the long and short axes of the ellipse are 13.7mm and 4mm respectively, and the length of the divergent section is 200mm. There is a powder feeding hole on the side wall on the side of the central axis of the nozzle flow channel. The diameter of the powder feeding hole is Φ2.5mm, the axis and the nozzle central axis form an angle of 30°, and the outlet is 75mm away from the throat. The result of spraying is: the deposition rate is about 70%, and the coating is uniform and good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com