Grinding process of sealing surface of ball valve

A grinding process and sealing surface technology, which is applied in the field of valve manufacturing, can solve the problems of poor finish and fit, reduce the friction coefficient between the valve seat and the ball, and achieve the effect of cleaning, increasing mirror effect, and convenient grinding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is specifically described below by the embodiment, only for further illustrating the present invention, can not be interpreted as the limitation of protection scope of the present invention, the technical engineer of this field can make some non-essential improvements and improvements to the present invention according to the content of the above-mentioned invention Adjustment.

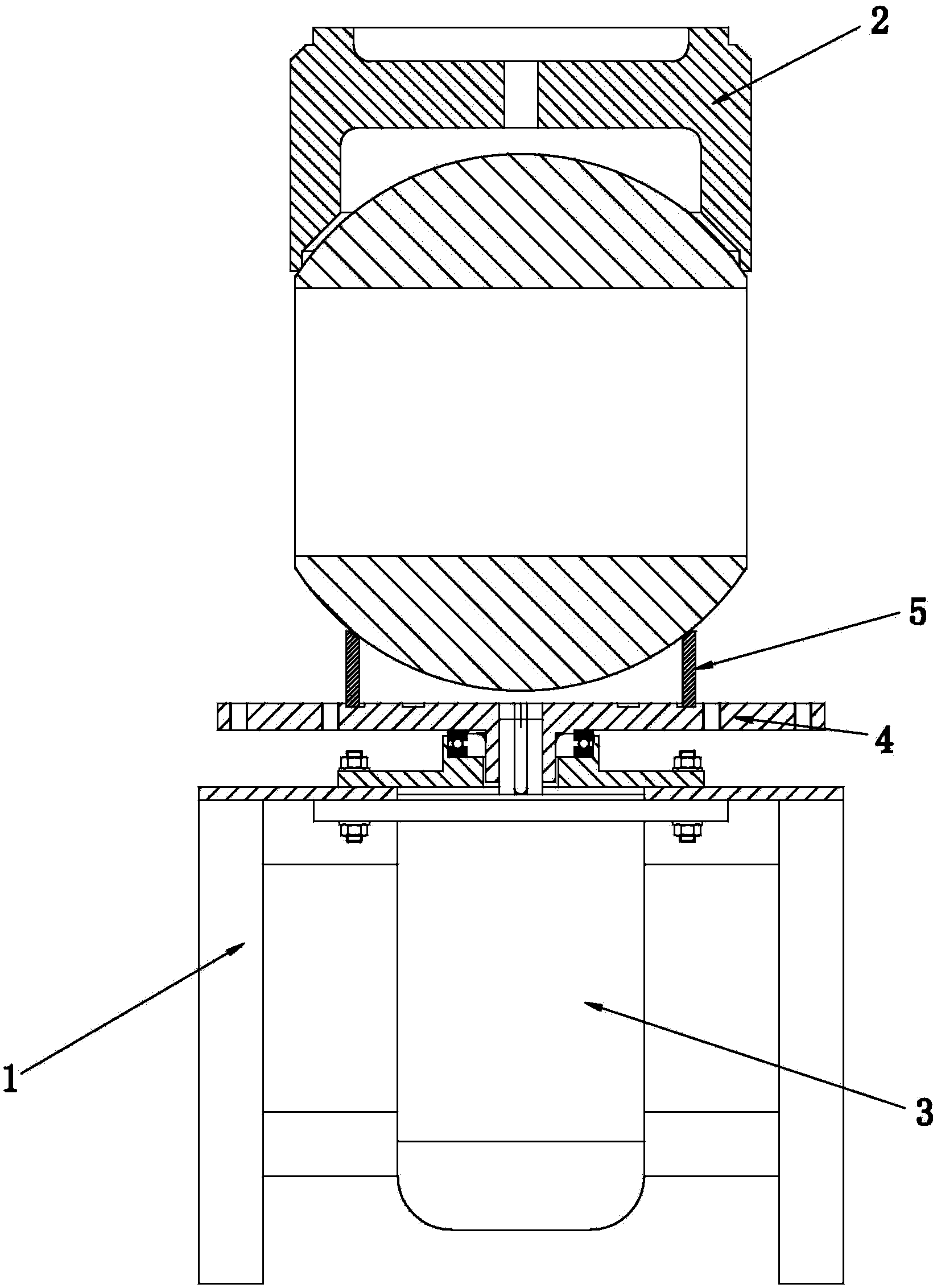

[0017] The spheres are placed on a grinding device, which is a technique well known to those of ordinary skill in the art, such as figure 1 Its general structure is as follows: including a frame 1 and a cup-shaped grinding tool 2, a driving motor 3 is installed on the frame 1, the output of the driving motor 3 is connected to a rotating disk 4, and a washer 5 for placing a sphere is fixed on the rotating disk 4, The ball is placed on the washer 5 and driven to rotate by the driving motor 3. The grinding tool 2 is used for grinding the ball. The output speed of the driving ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com