Capacitance type pressure sensing conversion device and method of achieving capacitance type pressure sensing on low-end singlechip

A conversion device, capacitive technology, applied in the direction of measuring devices, measuring force, instruments, etc., can solve the problems of expensive pressure sensing parts, high power consumption, increased manufacturing costs, etc., achieve excellent anti-interference effect and reduce power consumption , the effect of reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

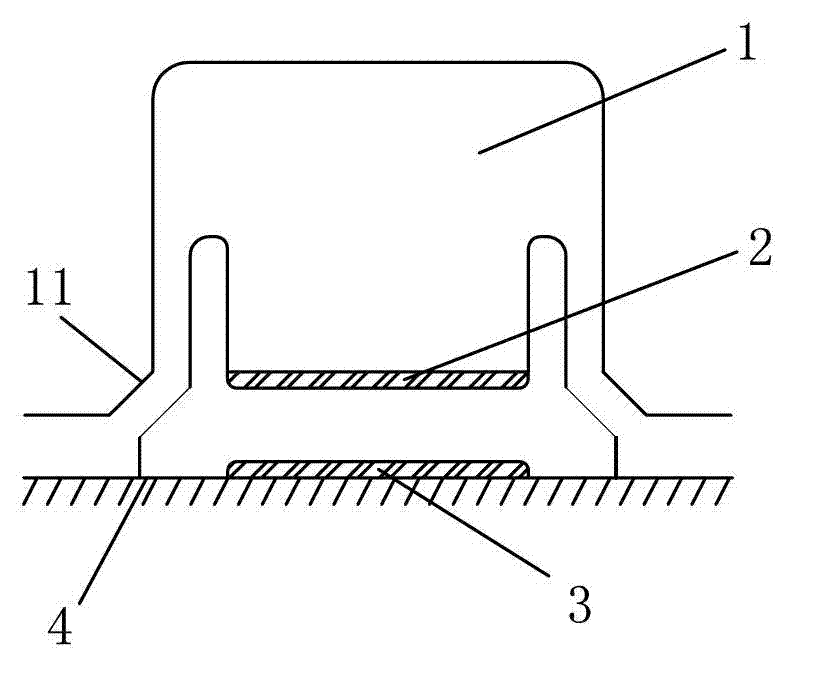

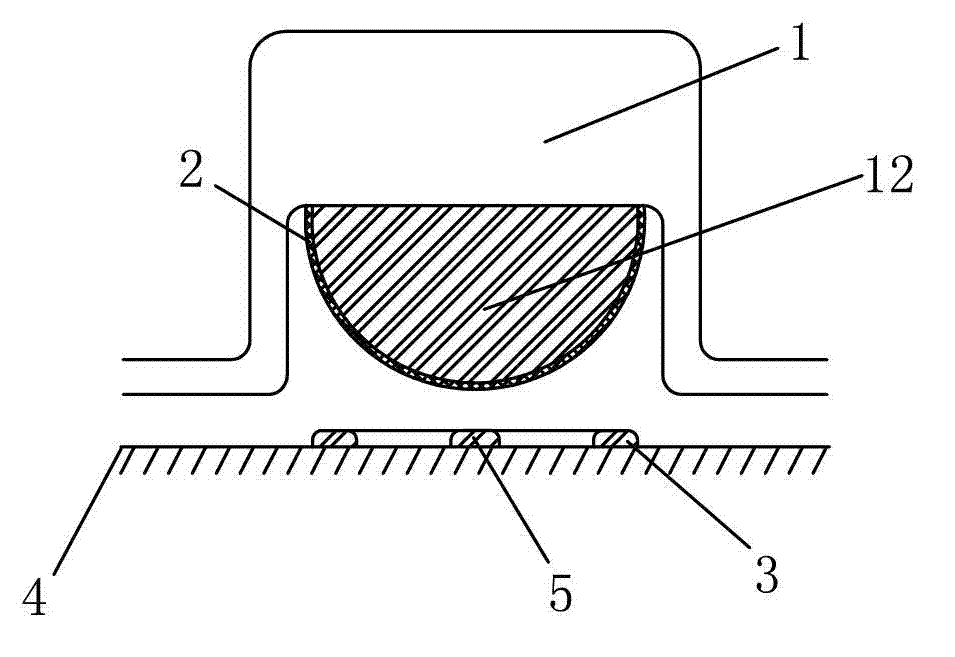

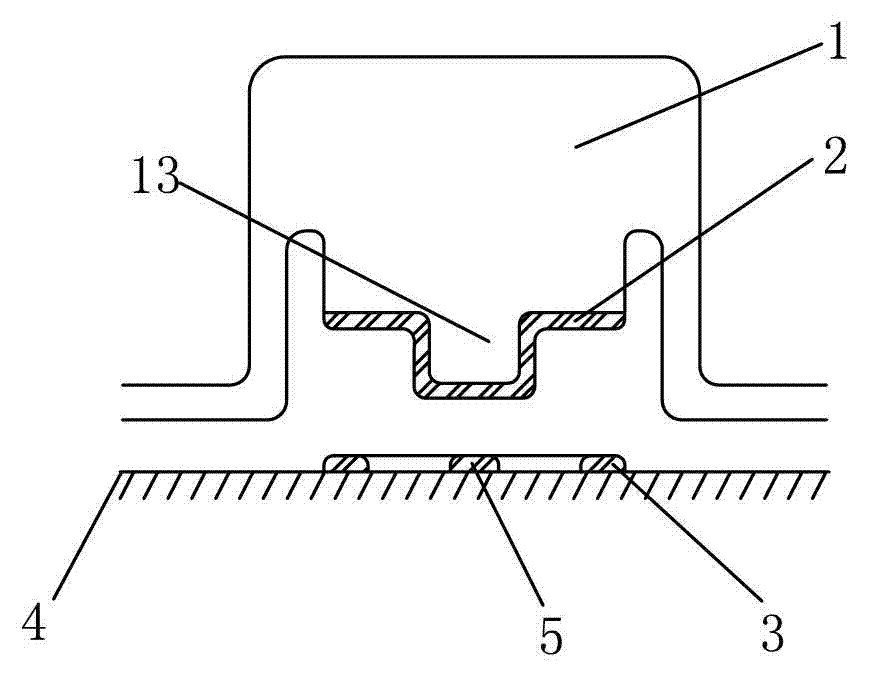

[0031] Such as figure 1 In the first embodiment shown, the elastic button 1 adopts a square shape, and the elastic rubber sheet 11 extending downward along the periphery of the square shape to the PCB substrate 4 is used as a support, and the support is used to maintain a capacitance detection distance between the two PCB substrates. Press the elastic button to change the distance value of the capacitance detection interval, and generate a conversion output between the pressing force and the capacitance change. The bottom surface of the elastic button is opposite to the conductive copper foil circuit 3 on the PCB substrate 4, and the bottom surface is coated with a conductive coating 2, the conductive coating 2 is connected to the ground wire, and the conductive coating 2 can be a carbon coating layer. The conductive coating and the conductive copper foil lines form the two poles of the capacitor. In addition, it is also possible to use sponge rubber as a supporting member be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com