Aqueous fluid for surface treatment of zinc-plated steel sheets and zinc-plated steel sheets

A technology of galvanized steel sheet and treatment liquid, which is applied in the direction of metal material coating process, anti-corrosion coating, coating, etc., can solve the problems that cannot be used or have not been solved, and achieve the effect of excellent grounding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

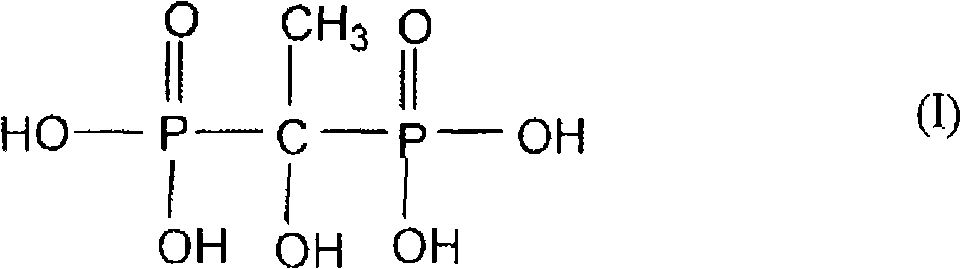

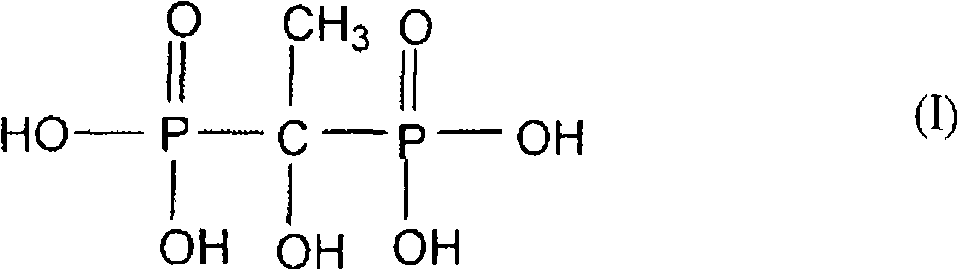

Method used

Image

Examples

Embodiment

[0066] Fabrication of surface-treated galvanized steel sheets as test panels

[0067] In the following examples, galvanized steel sheets (GI, GA, EG: GI, GA, and EG with a size of 200mm×300mm and a thickness of 0.8mm were prepared respectively) were subjected to alkaline degreasing to wash off the antirust oil, and washed with water. Rinse off the degreasing solution, rinse with pure water, and then dry with warm air, and use the resulting material as a test panel. Evaluation tests described later were performed using, as test panels, surface-treated galvanized steel sheets in which a film was formed on the surface of the test panel by various aqueous treatment solutions.

[0068] Components used in aqueous treatment fluids

[0069] Component (A): commercially available ammonium zirconium carbonate (as ZrO 2 Counted as 20% by mass)

[0070] ingredient (B)

[0071] B-1: Vanadium(IV) oxalate

[0072] B-2: Vanadyl(IV) sulfate

[0073] B-3: Vanadyl(IV) acetylacetonate

...

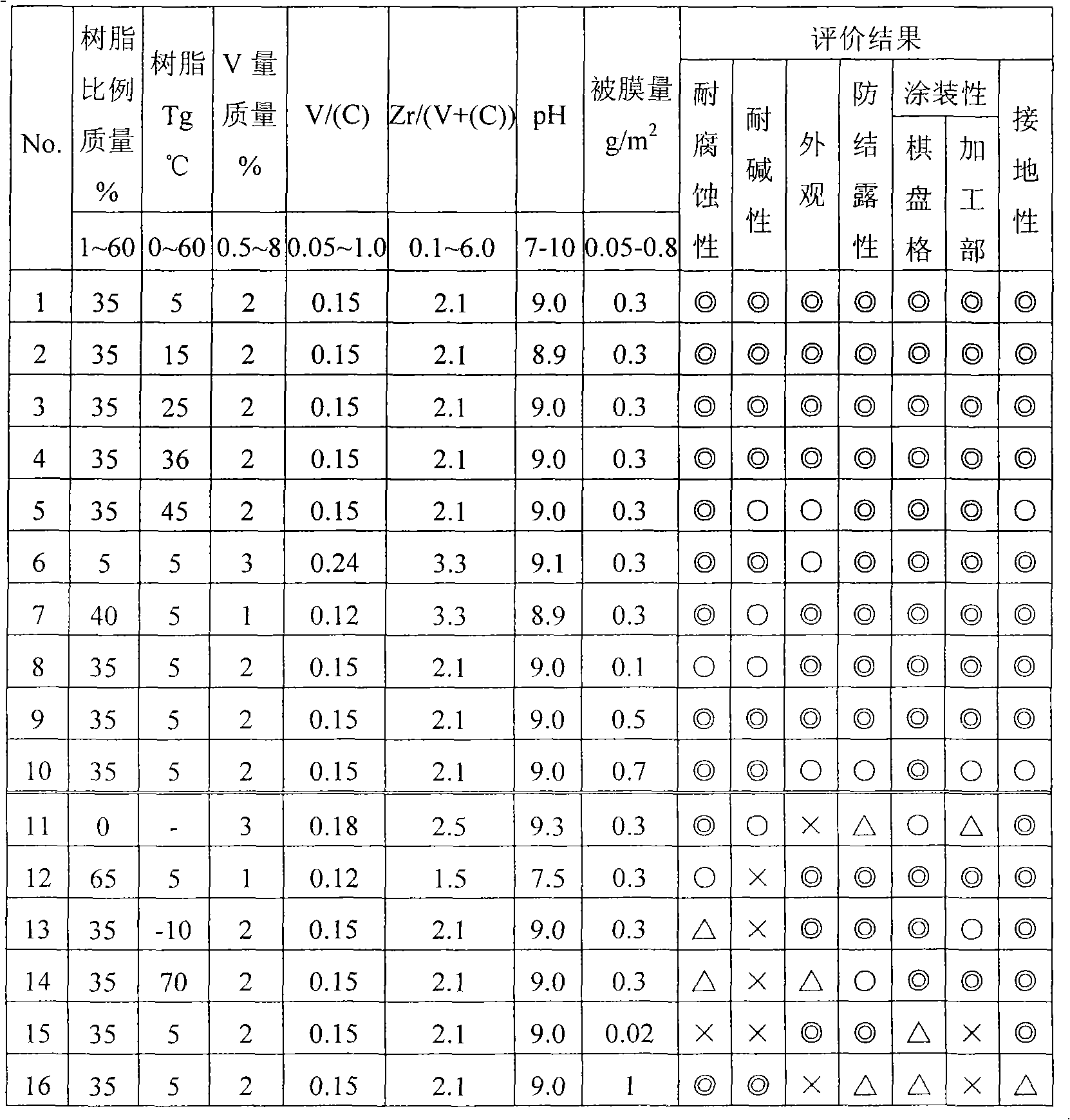

Embodiment 1

[0134] For No.1 in Table 1 below, 6.2 g of B-1 (vanadium (IV) oxalate) was dissolved in pure water and 22 g of (C) organic phosphonic acid, and the pH was raised to 8. Then, (A) 213 g of ammonium zirconium carbonate was added, and 175 g of D-1 water-dispersible acrylic resin was added, stirred and dissolved, G-11 g was added as an antifoaming agent, and pure water was added to make the total amount 1 kg. The pH of this aqueous treatment liquid was 9.0, and the solid content was 10% by mass. Other aqueous treatment liquids having the compositions shown in Table 1 were prepared in the same procedure (all dry solids adjusted to 10% by mass). At this time, the same components as No. 1 were used except for the water-dispersible acrylic resin.

[0135] Here, a treatment solution obtained by adding 3 g of (E) guanidine carbonate to the treatment solutions of No. 1 and No. 7 was also prepared, and the treatment solution with (E) added and the treatment solution without (E) added wer...

Embodiment 2

[0142] For No. 17 in Table 2, 3.3 g of B-1 (vanadium (IV) oxalate) was dissolved in pure water and (C) 15 g of organic phosphonic acid, and the pH was raised to 8 with 28% by mass of ammonia water. Then, add (A) 224g of ammonium zirconium carbonate, then add 200g of D-1 water-dispersible acrylic resin, further add (E) 5g of guanidine carbonate, stir and dissolve, then add G-21g as a defoamer, add water to make the total amount It is 1kg. The pH of this aqueous treatment liquid was 9.5, and the solid content was 10% by mass. Other aqueous treatment liquids having the compositions shown in Table 2 were prepared in the same procedure (all dry solids were adjusted to 10% by mass). At this time, the same thing as No. 17 was used for each component, and the addition amount of each of (E) and G-2 was the same as No. 17.

[0143] The water-based treatment solutions prepared above are poured onto the surface of the galvanized steel sheet (GI) to wet the entire surface, and then the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com