Two-way hard sealing butterfly valve with movable valve seat

A mobile, hard-sealed technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve problems affecting the long-term normal operation of pipelines, high production costs, and bellows are easily damaged by water immersion, and achieve good hard-sealed effects. Long service life, guarantee the effect of hard sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

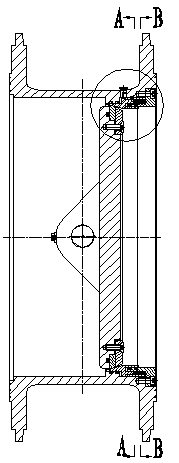

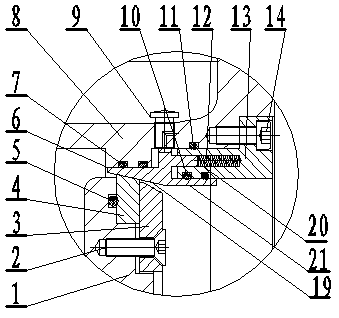

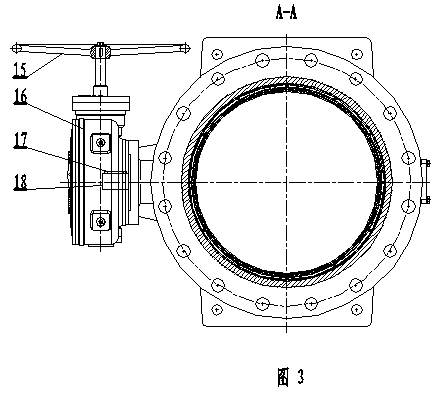

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

[0019] Such as Figure 1-Figure 6 As shown, the present invention includes a valve body 8, a valve seat 6, a butterfly plate 1, a hand wheel 15, a worm gear box 16, a key 17 and a valve shaft 18, and the butterfly plate 1 is fixedly connected with a pressure plate 3 through a pressure plate screw 2. A butterfly plate sealing ring 4 is provided between the pressure plate 3 and the butterfly plate 1, and a valve seat 6 is provided between the butterfly plate sealing ring 4 and the valve body 8, and the valve seat is divided into a clamping portion 19 extending horizontally and inversely. And the support arm part, the joint between the clamping part 19 and the top of the butterfly plate sealing ring 4 is a slope, the joint between the clamping part 19 and the valve body 8 is a plane, and the support arm part includes first The support arm 20 and the second support arm 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com