Wall polisher

A grinding machine and grinding head technology, which is applied to grinding heads, grinding machines, and machine tools suitable for grinding workpiece planes, etc., can solve the problems that circular grinding discs are not suitable for grinding walls, and the adsorption force of wall grinding machines cannot be adjusted. , to achieve the effect of stable vacuuming effect, convenient night operation and convenient assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with specific embodiments in conjunction with the drawings:

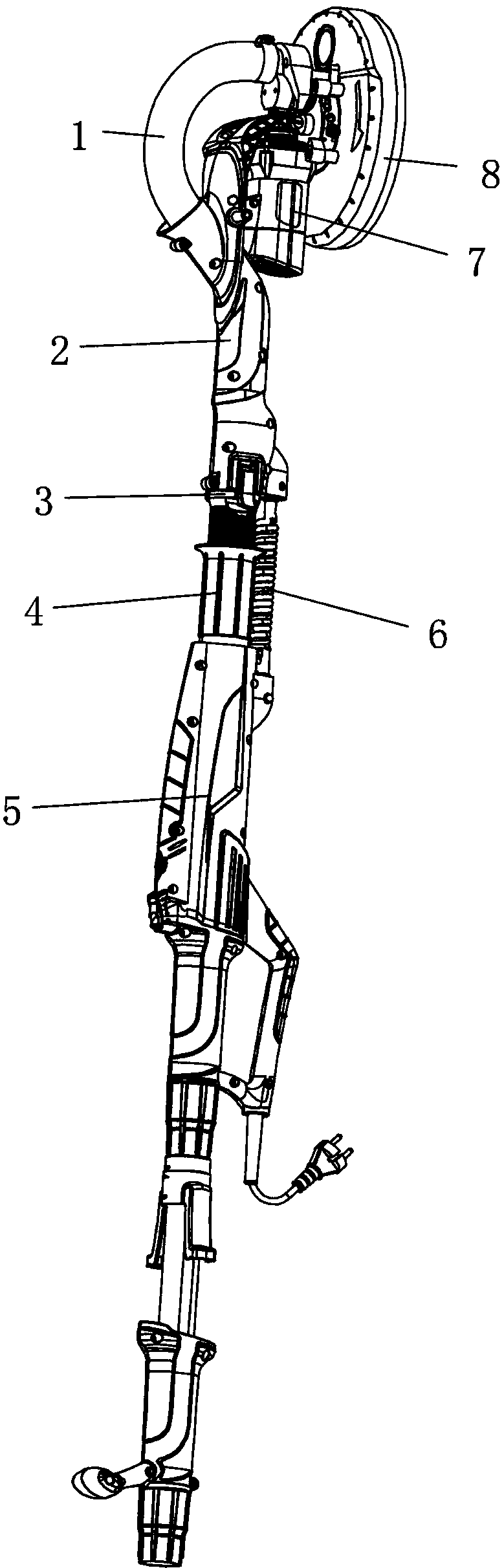

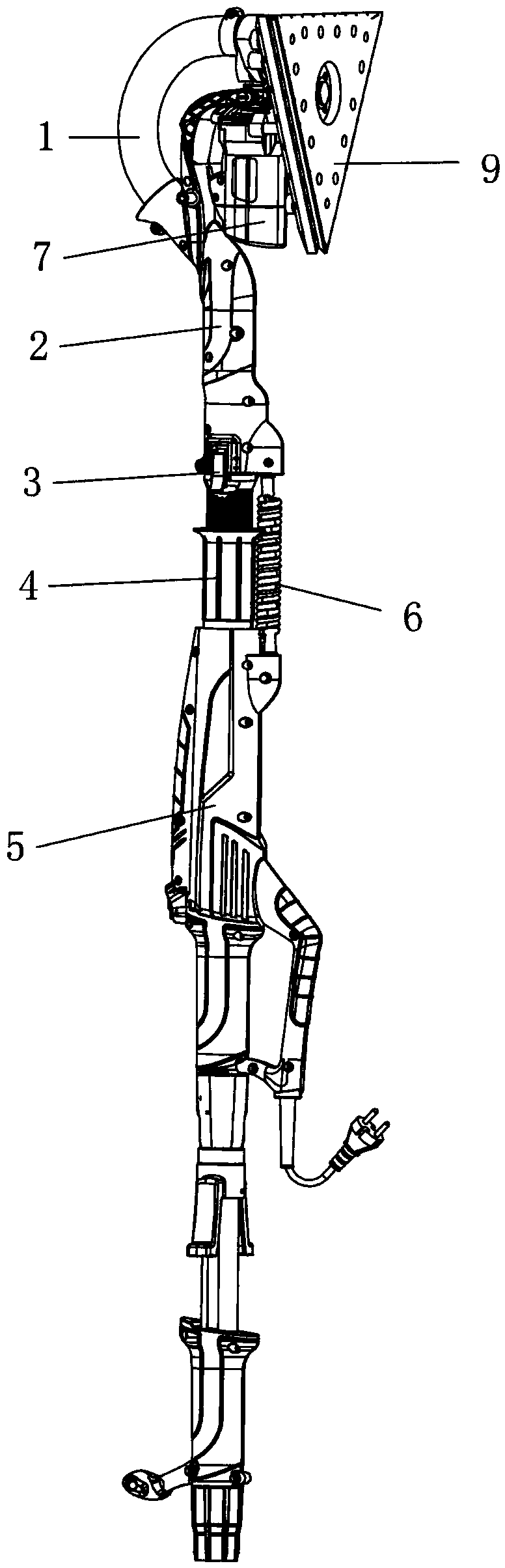

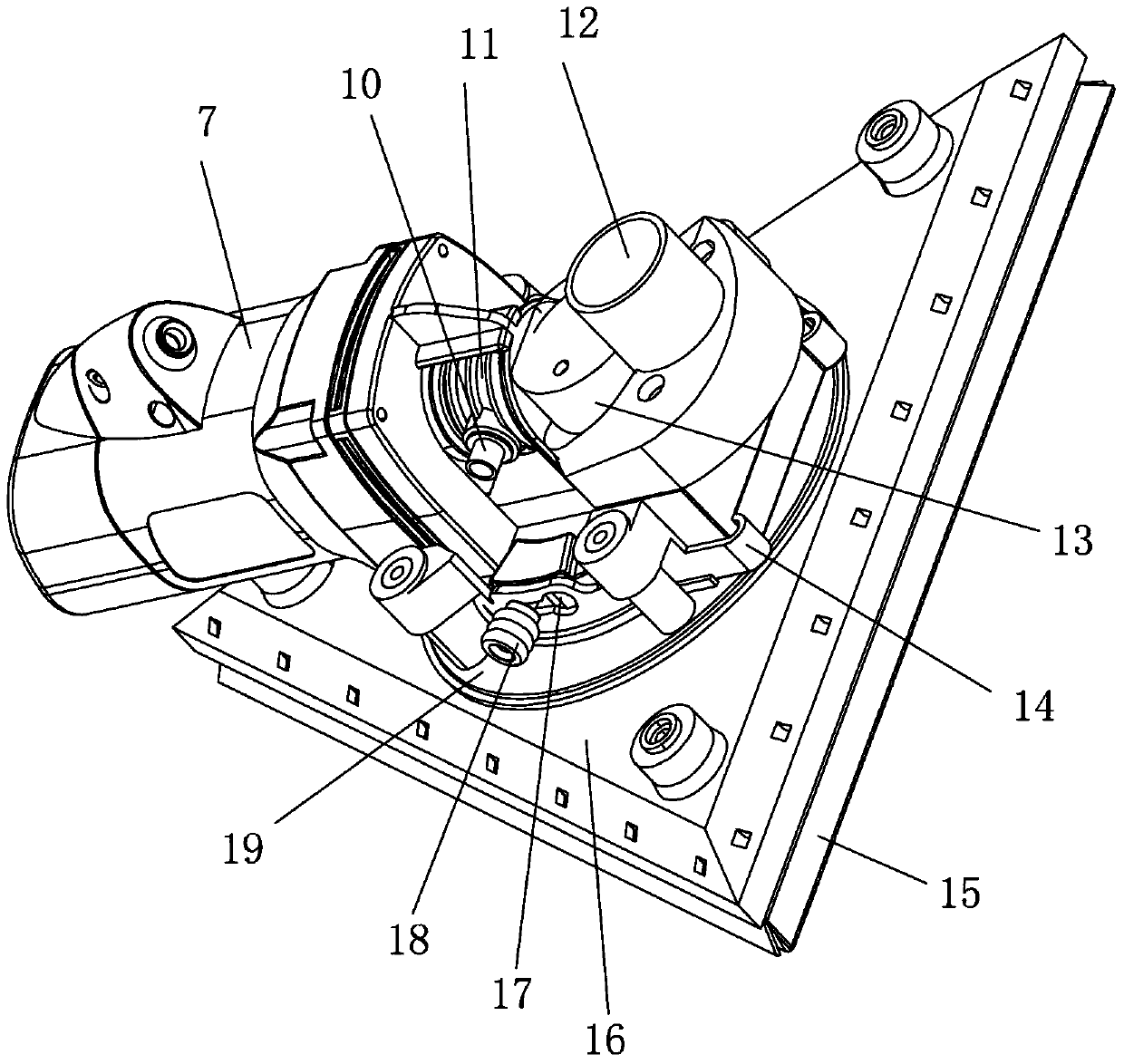

[0038] The wall grinder includes an operating handle, a motor 7, and a polishing head. The polishing head is installed at the front end of the operating handle (this installation method is an existing technology, which has been disclosed in ZL201320595632.8, and the front end of the operating handle is installed through a hinged shaft 10. On the sleeve 11, the sleeve 11 is sleeved on the horizontal axis of the top cover), the grinding head includes a top cover, a base, and a grinding disc assembly; the top cover or the base is provided with an air extraction nozzle, and an air extraction nozzle It is connected to the grinding disc assembly through the air path in the top cover; the suction pipe port is connected to the dust suction pipe in the operating handle through the air pipe 1, and the dust suction pipe is connected with the vacuum cleaner pipeline. This...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com