Video camera module

A camera and lens technology, which is applied in the field of camera modules for auto-focusing, can solve the problems of large offset of the shielding shell, positioning of the shielding shell, shaking of the shielding shell, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

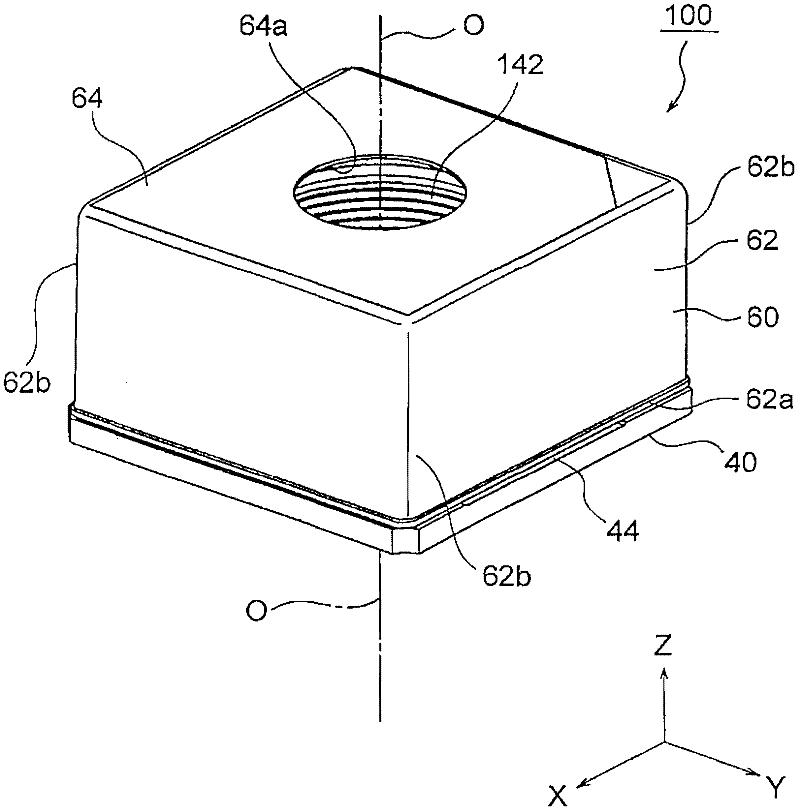

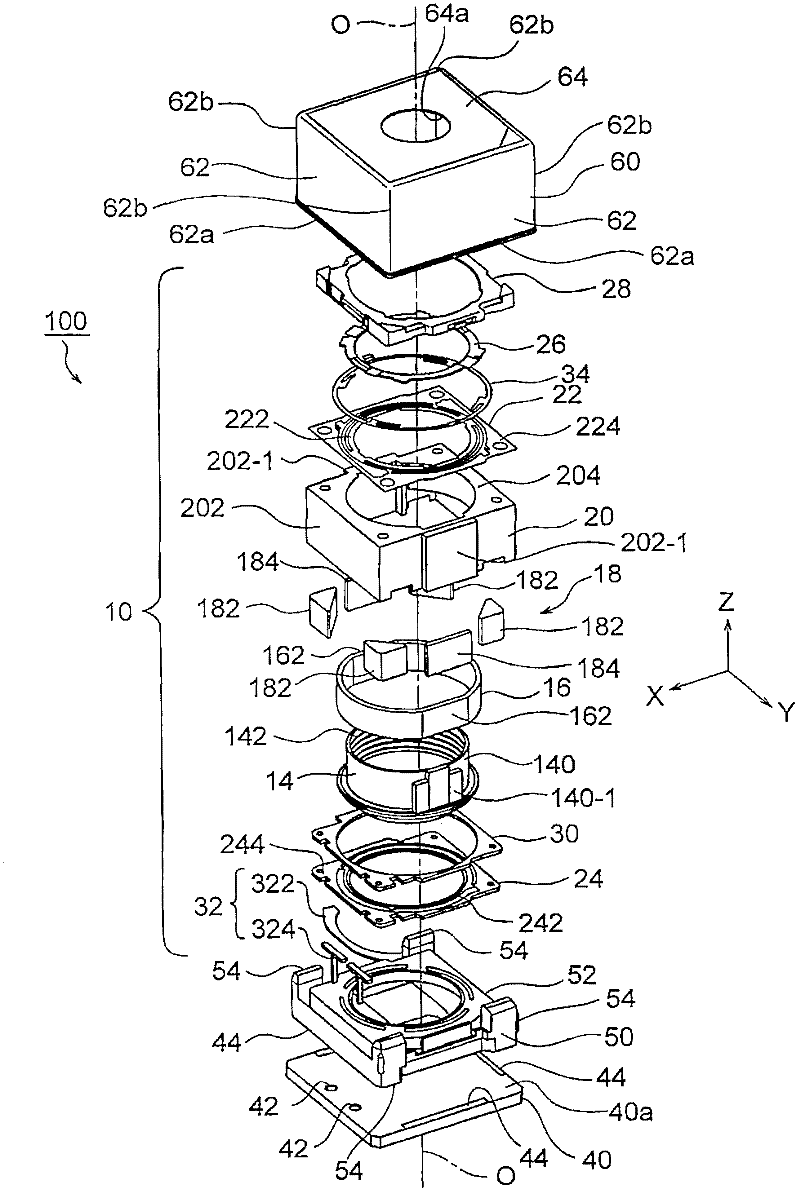

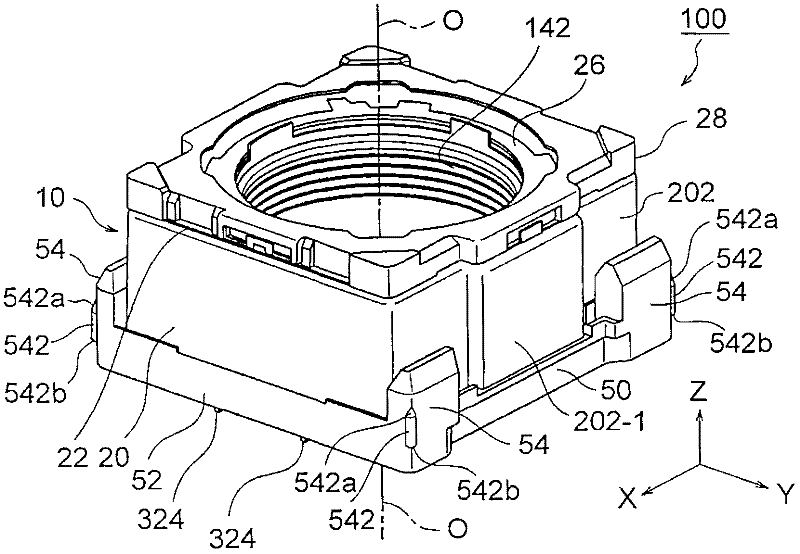

[0030] refer to Figure 1 to Figure 5 , the camera module 100 according to the first embodiment of the present invention will be described. figure 1 is a perspective view showing the appearance of the camera module 100, figure 2 is an exploded perspective view of the camera module 100 . image 3 is expressed in figure 2 In the shown camera module 100 , it is a perspective view of a state in which the driver main body 10 and the base member 50 are assembled. Figure 4 is expressed in figure 2 In the shown camera module 100 , it is a perspective view of an assembled state of the driver main body 10 , the base member 50 , and the sensor substrate 40 . Figure 5 is in figure 2 The illustrated camera module 100 is a cross-sectional view in which the sensor substrate 40 is omitted.

[0031] here, as Figure 1 to Figure 5 As shown, an orthogonal coordinate system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com