Double-deck liftable stage

A stage, double-layer technology, applied in the field of lifting stage, can solve the problem that the upper and lower layers cannot be performed at the same time with diversified three-dimensional effects, etc., and achieve the effect of stable platform lifting without shaking, good synchronization, and reducing friction coefficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

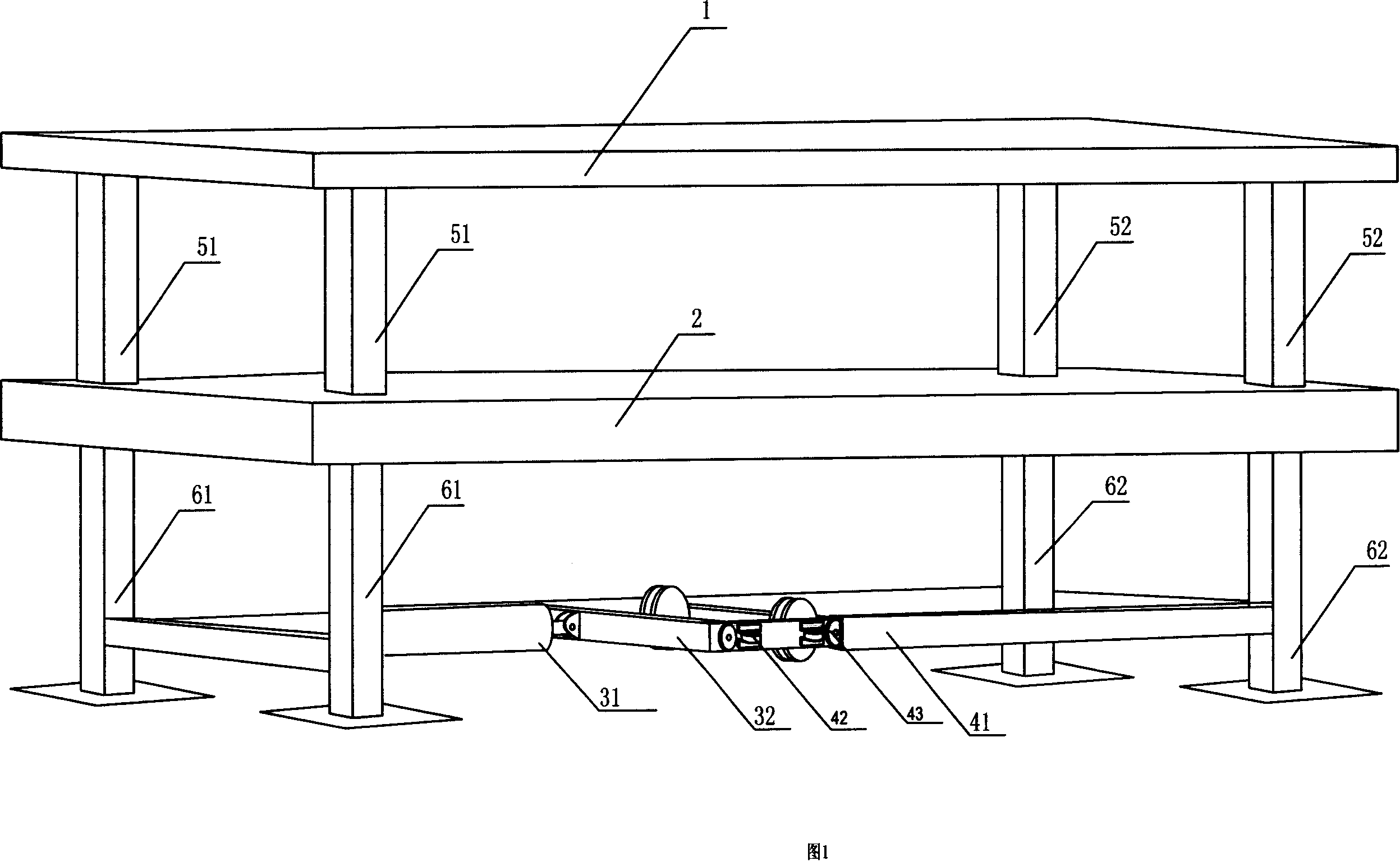

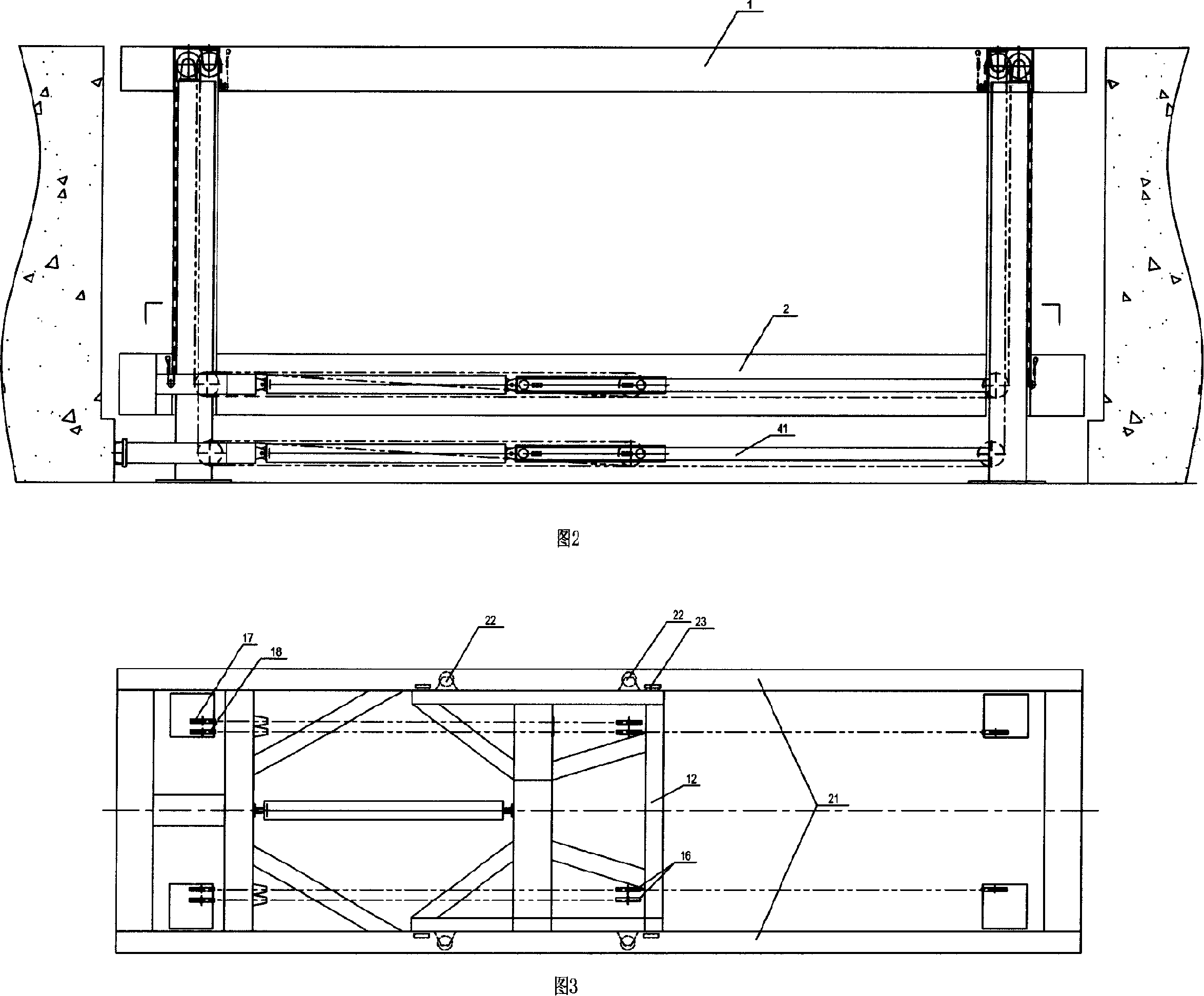

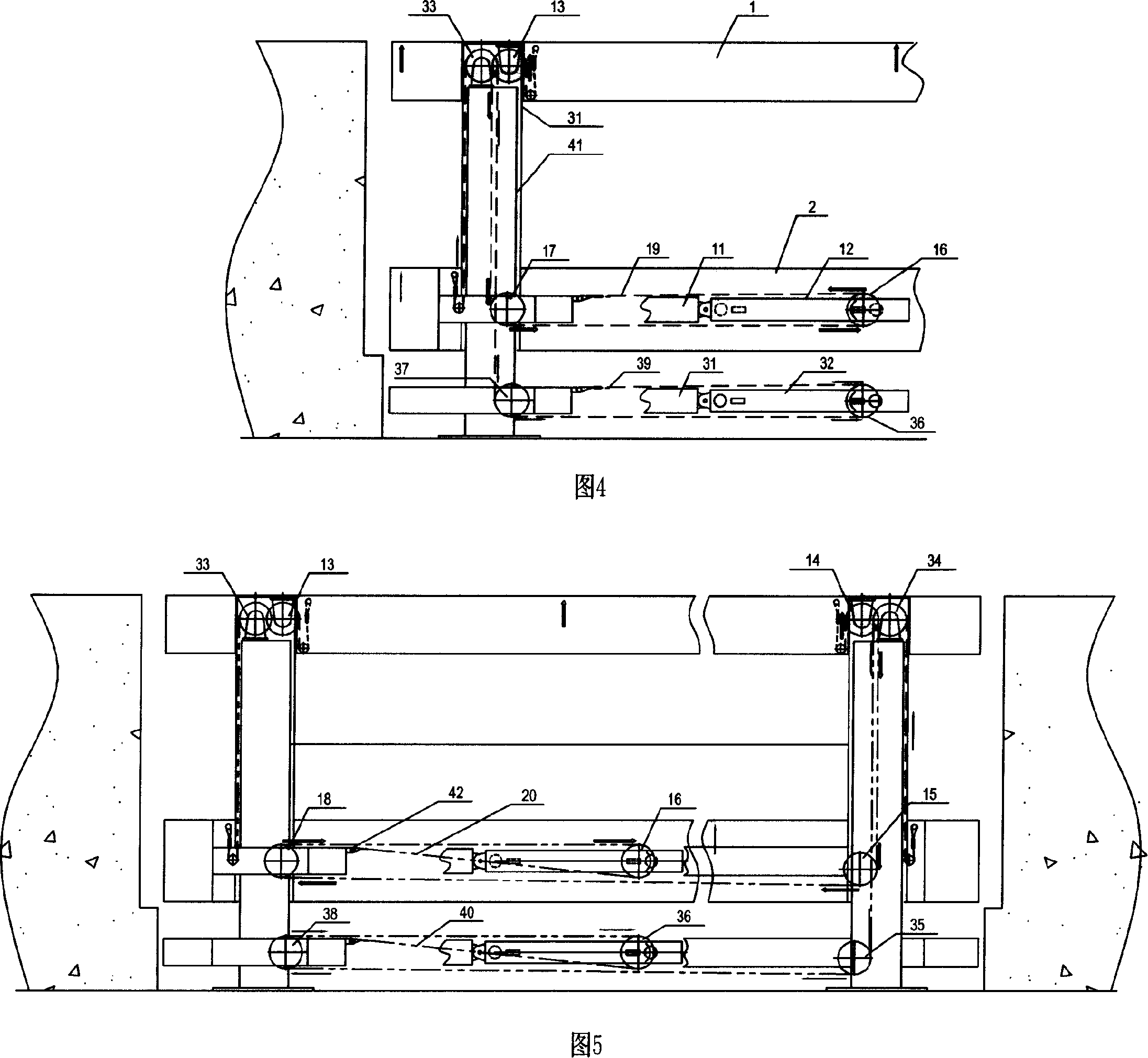

[0018] Referring to Figures 1-5, a double-deck lifting stage includes an upper table 1 and a lower table 2 arranged up and down, a first lifting drive device for driving the upper table to lift, and a second lifting drive for driving the lower table. Device; the movable lower platform is set on the lower pillars fixed to the foundation, and the lower pillars are four, including two left lower pillars 61 and two right lower pillars 62, which are respectively arranged at the four corners of the lower platform. A hollow upper pillar is fixedly connected to the position corresponding to the lower pillar above the lower platform, the inner diameter of the upper pillar is larger than the outer diameter of the lower pillar, and the movable upper stage is sleeved on the upper pillar, and the upper pillar It is four, including two left upper pillars 51 and two right upper pillars 52. With the positioning structure of four columns, the force on the table is evenly distributed, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com