Soft and hard double seal fixed ball valve

A fixed ball valve, double-sealing technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of low valve service life, difficulty, high hardness of metal materials, reduce operating torque, prevent damage, The effect of solving the problem of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

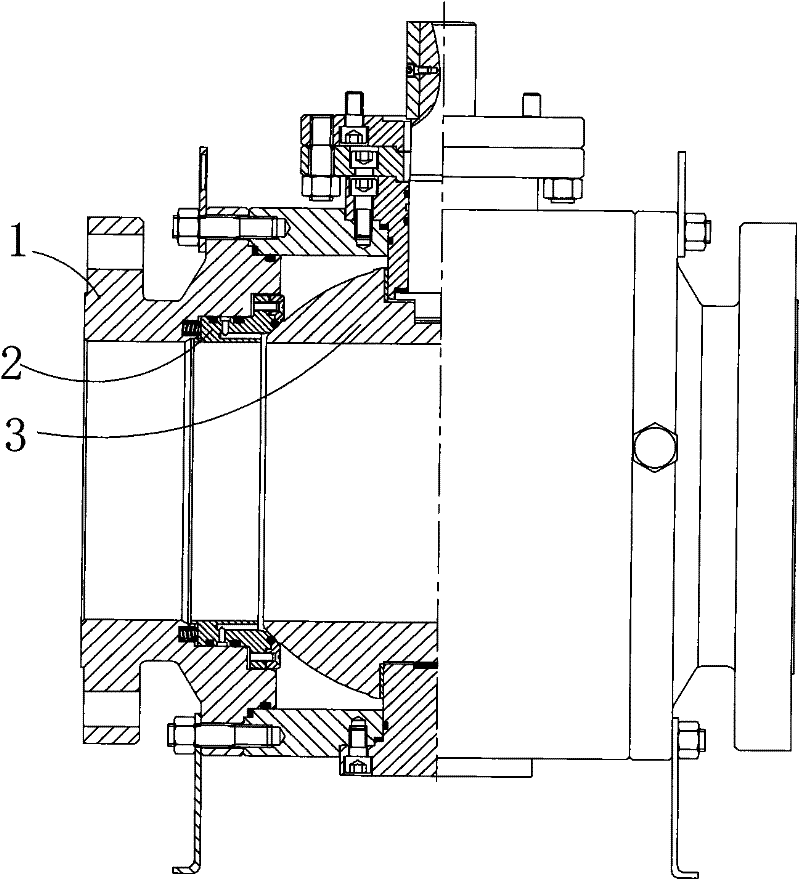

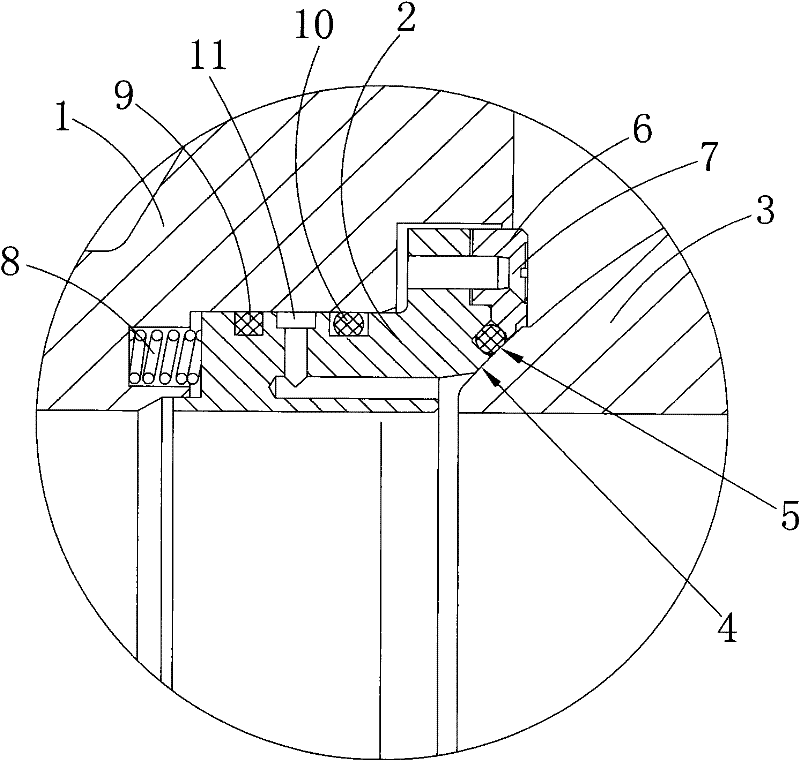

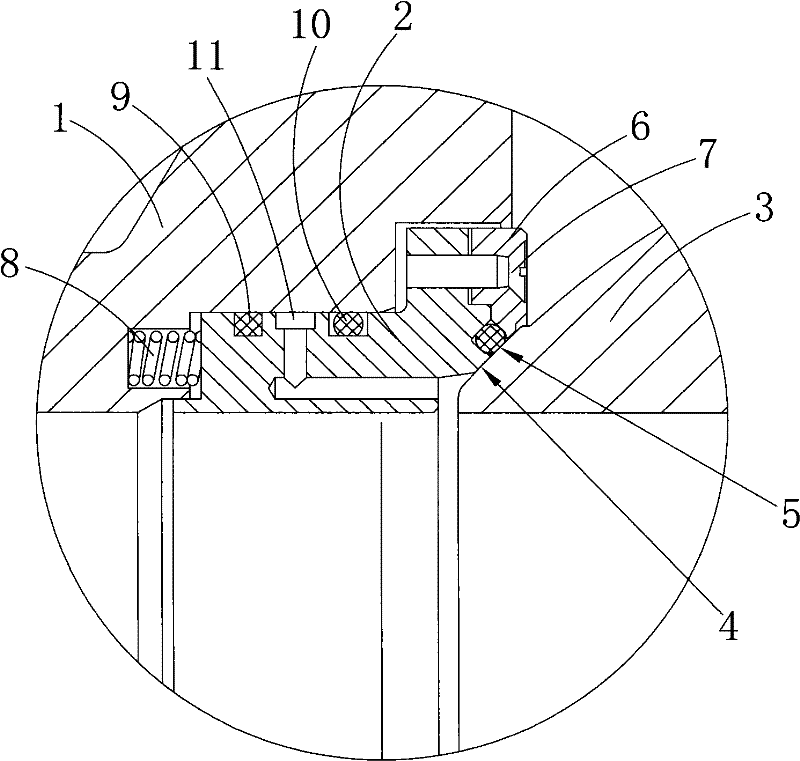

[0023] Embodiment: A soft and hard double-sealed fixed ball valve, including a valve body 1, a valve seat 2 and a spherical valve core 3, the valve seat is fixed between the flow channel port of the valve body and the spherical valve core, the valve body, the valve core Both the seat and the spherical valve core are made of metal, and the valve seat has a hard sealing surface 4, which is the surface on the valve seat in contact with the spherical valve core, and the shape of the hard sealing surface corresponds to the spherical shape. The arc surface of the spool is consistent, the hard sealing surface is in contact with the spherical spool to form a primary hard seal, and the first O-ring 5 made of rubber is fixed on the valve seat, and the first O-ring is in contact with the said first O-ring. The contact of the spherical spool constitutes a secondary soft seal.

[0024] The seal between the valve seat and the spherical valve core adopts a combination of soft and hard double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com