Patents

Literature

30results about How to "Meet the sealing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

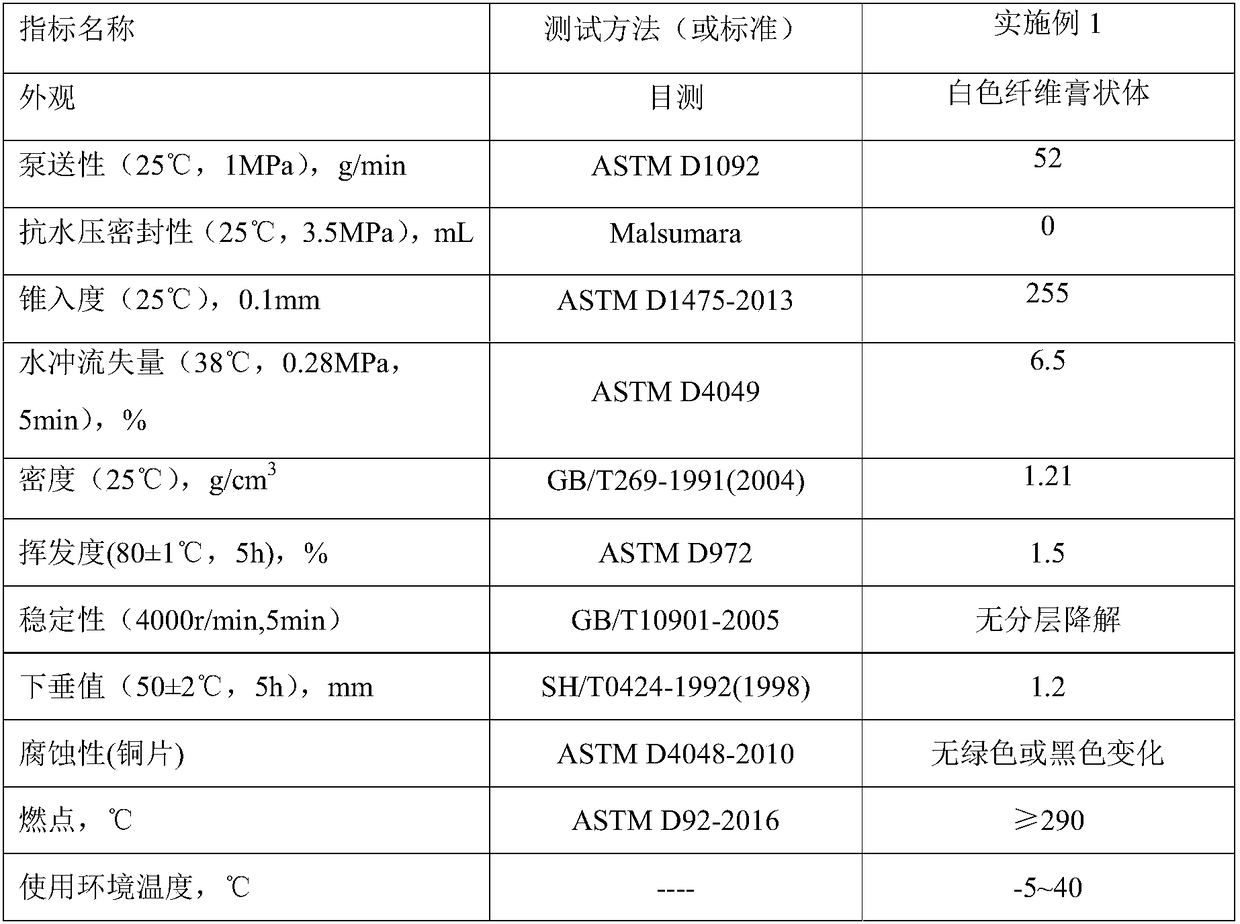

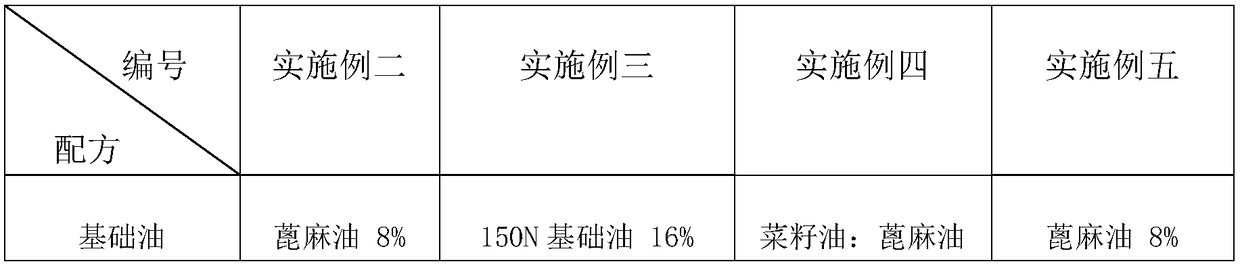

Special main bearing sealing grease for shield tunneling machine as well as preparation method and application thereof

InactiveCN108641794AGood sealing against water pressureEnhanced pumpabilityLubricant compositionAntioxidantEngineering

The invention discloses special main bearing sealing grease for a shield tunneling machine. According to the formula, the special main bearing sealing grease is prepared from the ingredients, in percentage by weight: 8-16% of base oil, 2-5% of thickener, 10-20% of fire retardant, 15-25% of tackifier, 12-20% of lubricating agent, 4-8% of reinforcing agent, 20-30% of filler, 0.5-3% of antiwear agent, 1-3% of antirust agent and 0.5-1% of antioxidant. The invention further provides a preparation method of the special main bearing sealing grease for the shield tunneling machine. The special main bearing sealing grease for the shield tunneling machine can resist the water pressure as high as 3.5MPa at the temperature of 25 DEG C in a lab, and has good water pressure resistance and airtightness.The pumping property of the special main bearing sealing grease is 30-60g / min at the temperature of -5-40 DEG C and under the pressure of 1MPa, the pumping property is excellent and not affected by the environmental temperature, and thus the construction problems that the pumping property in winter is poor, and pipes are blocked and the like. In addition, the product has the outstanding fire resistance, abrasive resistance and demulsibility.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP +1

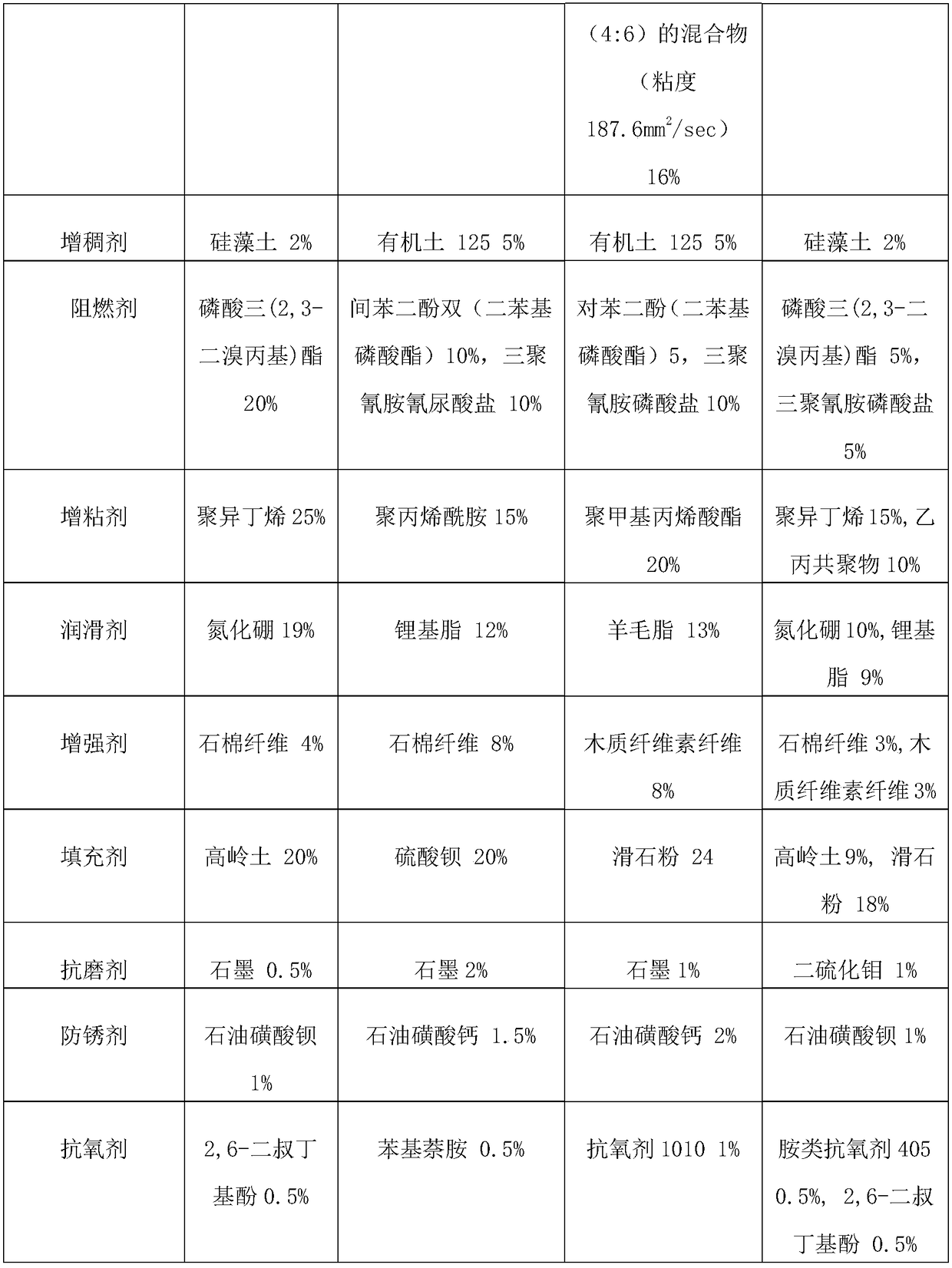

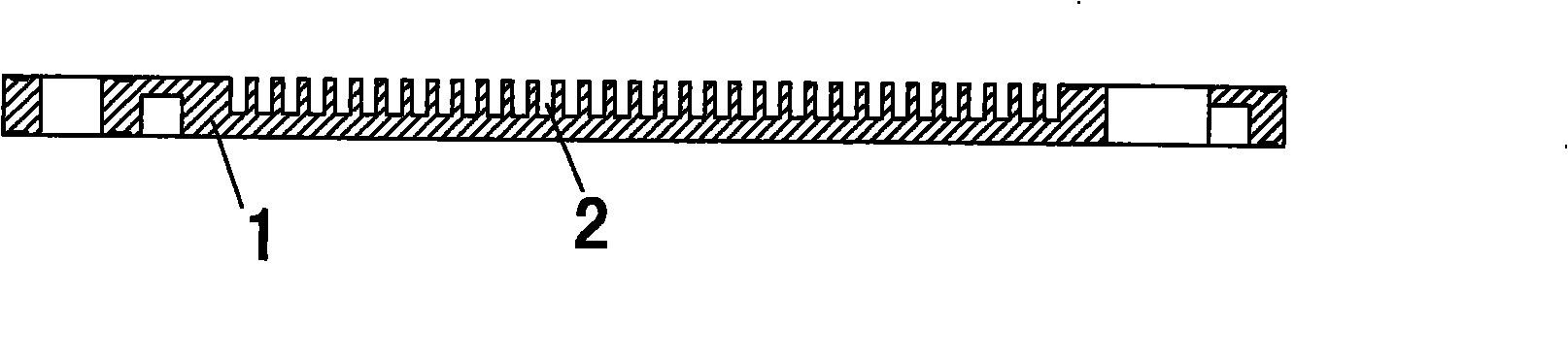

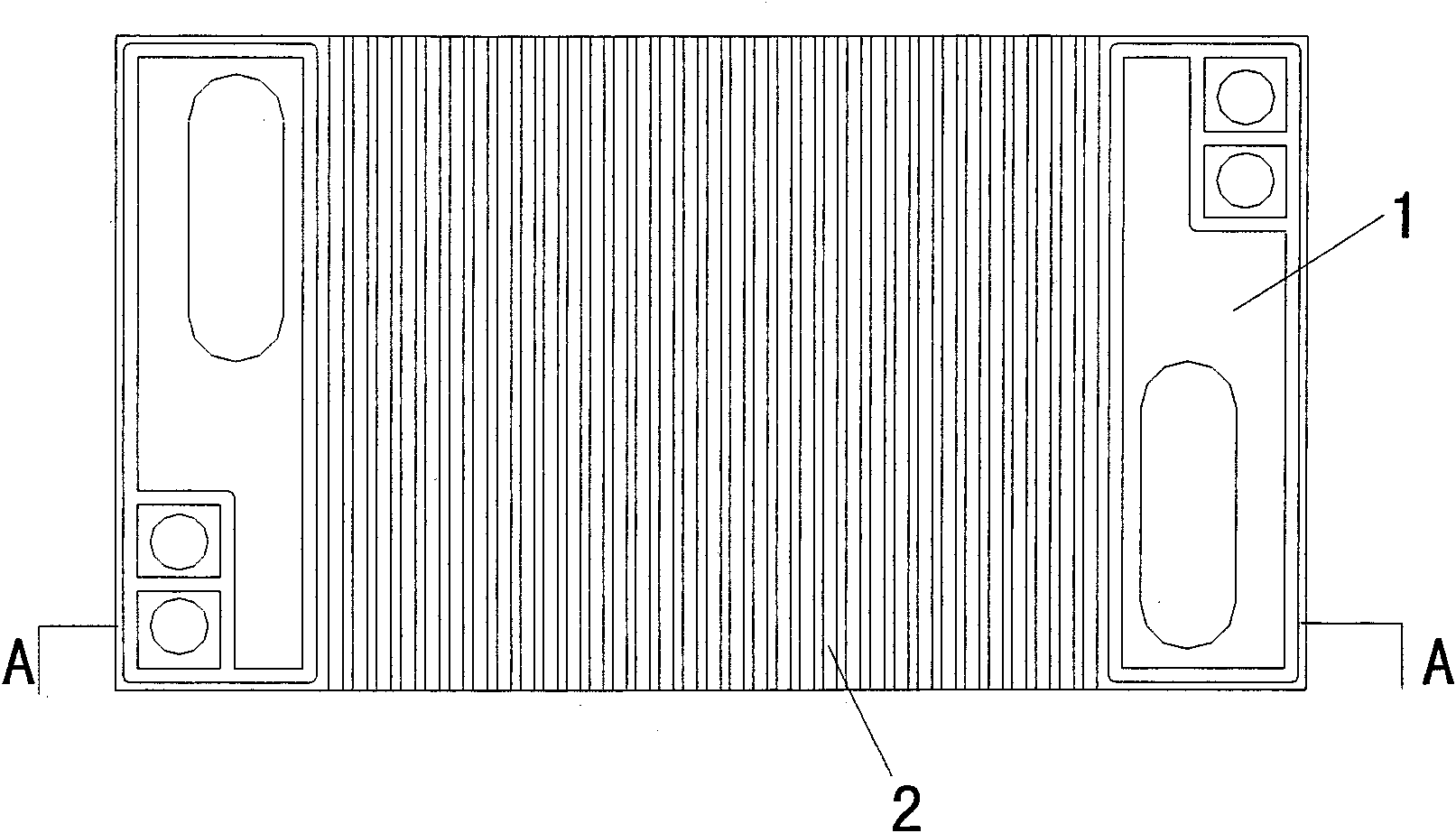

Production method for graphite bipolar plate of fuel cell

The invention provides a production method for a graphite bipolar plate of a fuel cell, which comprises the following steps of: A) taking a high-purity graphite block which is baked for one time or is soaked for one time and baked for two times as a raw material, and mechanically cutting the graphite block into bipolar plate biscuits; B) flatly grinding the bipolar plate biscuits into bipolar plate sheets; C) using a horizontal milling cutter which is formed by a plurality of parallel circular saw blades to process a straight-through flow field structure with multiple grooves which are distributed in parallel to form semi-finished bipolar plate products; and D) sealing the semi-finished bipolar plate products by using epoxy glue and conducting solidification to obtain finished bipolar plate products. Compared with the prior art, the cost of the bipolar plate of the fuel cell is greatly reduced from the aspects of the selection of the raw material, the flow field design of the graphite bipolar plate, the processing and the like, and the production method is particularly suitable for the production of the bipolar plate with deep runners.

Owner:SHANGHAI PEARL HYDROGEN POWER SOURCE TECH

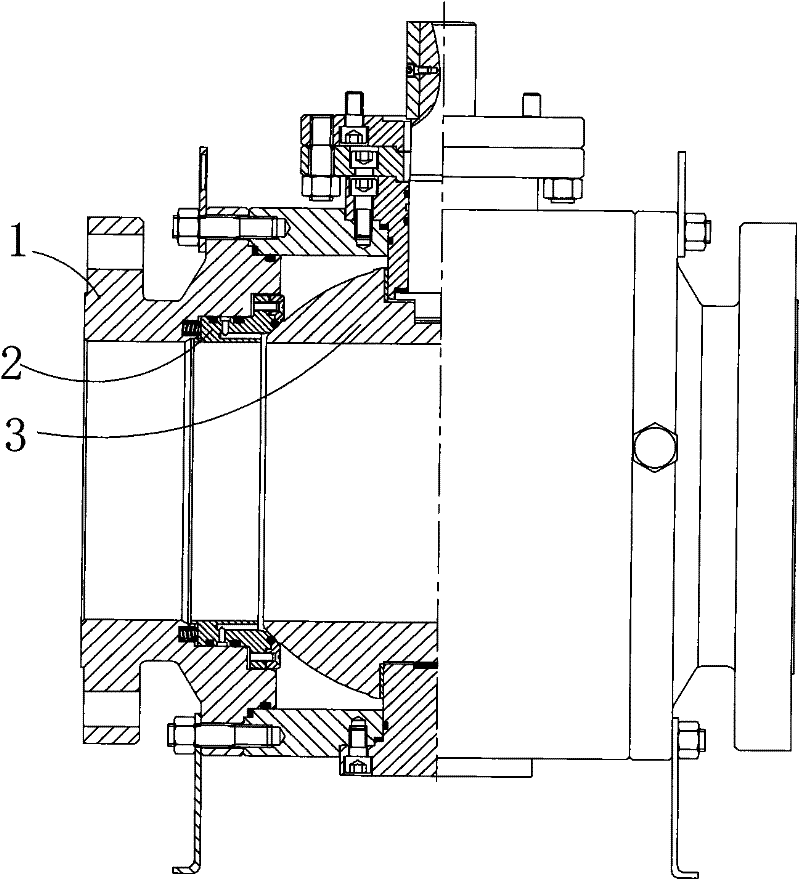

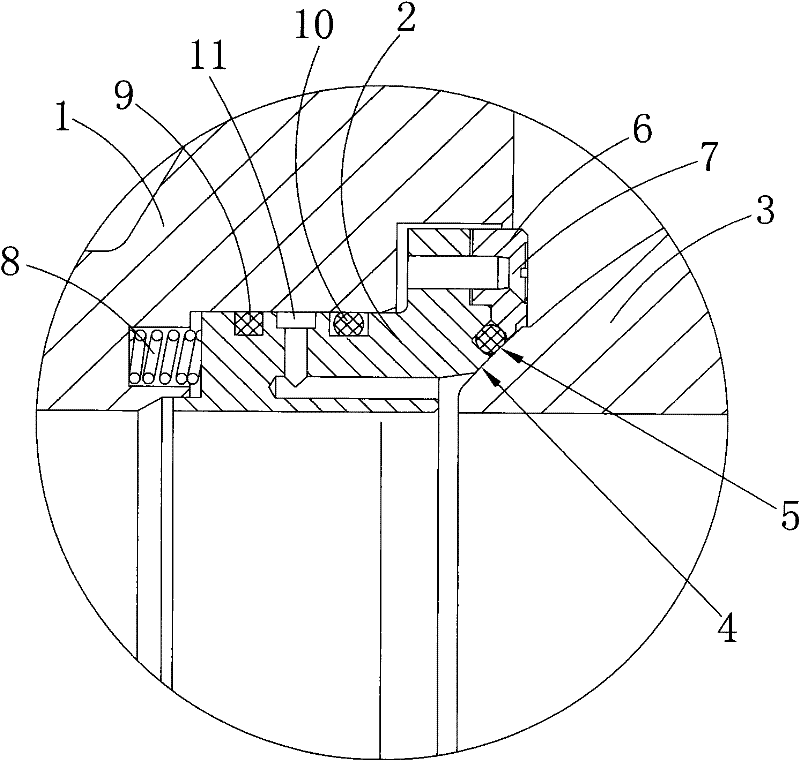

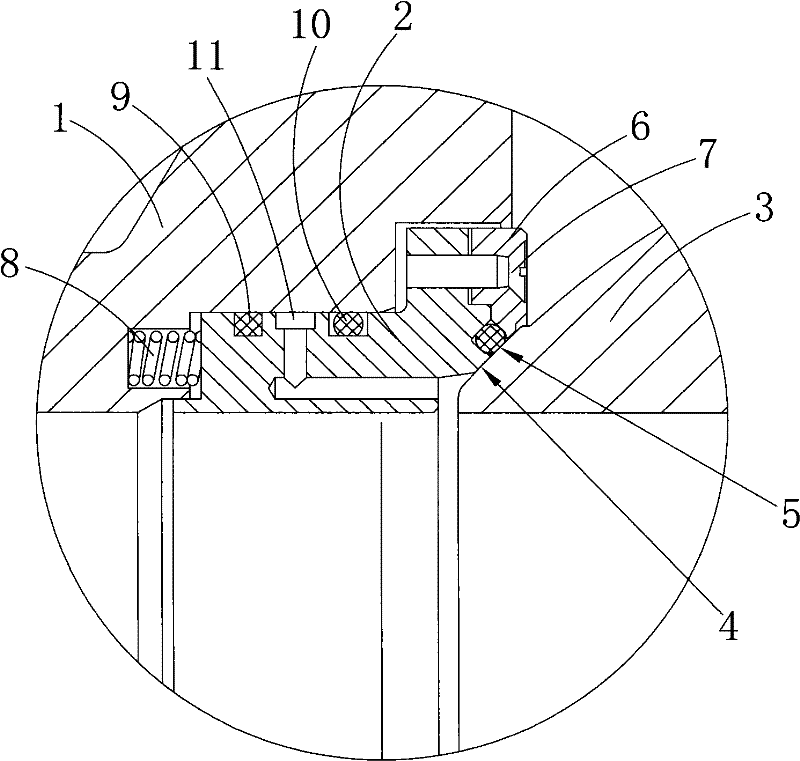

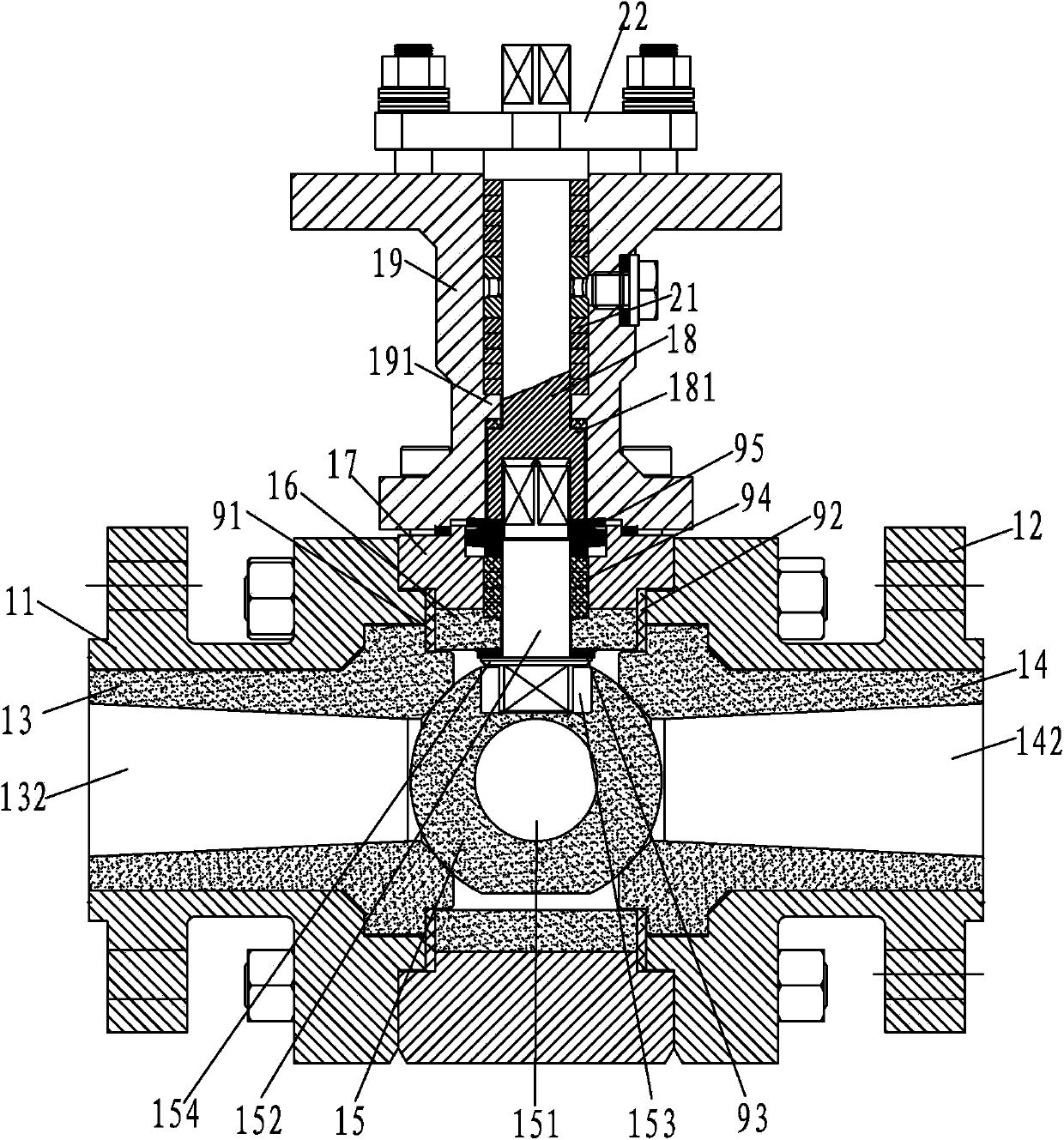

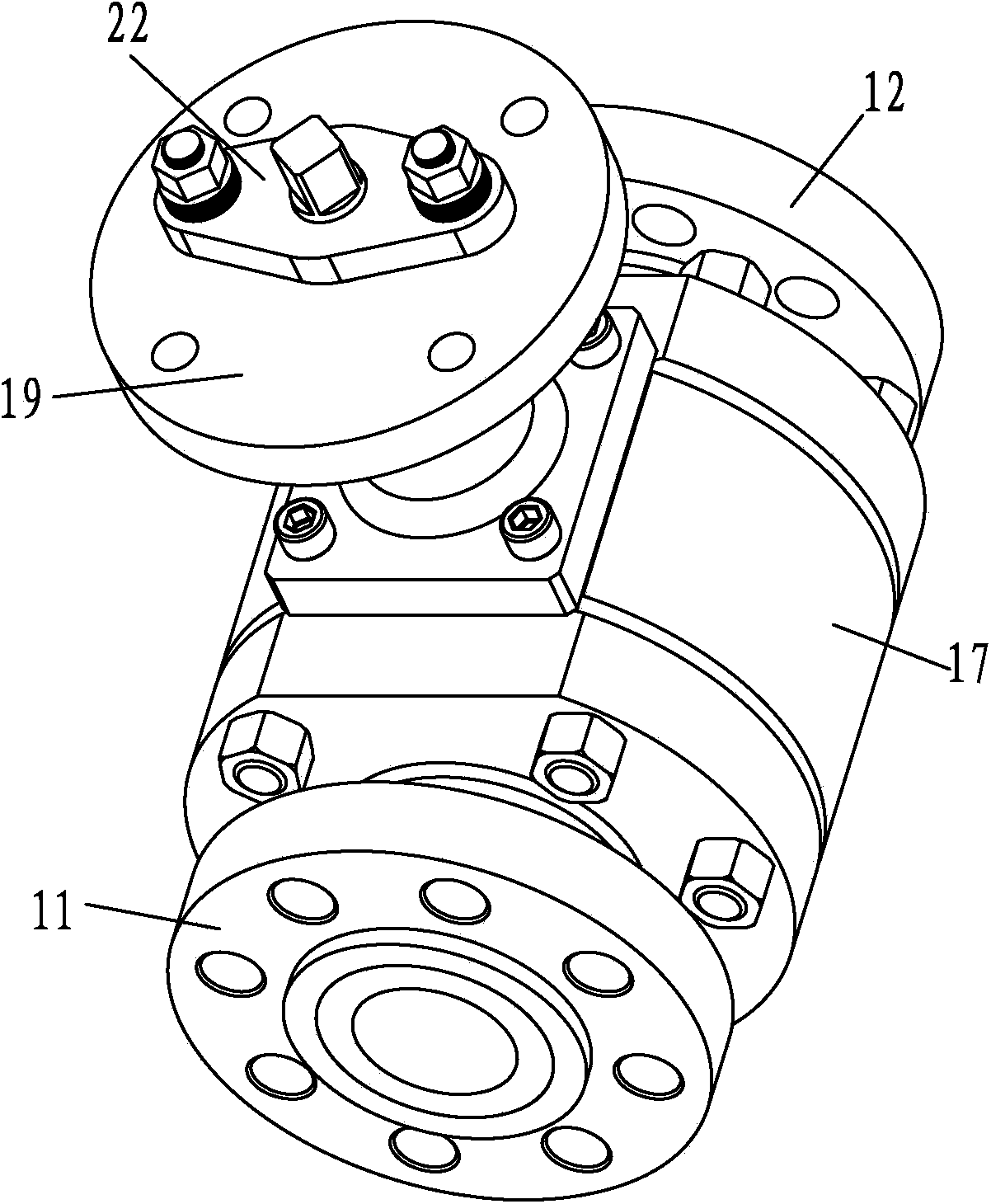

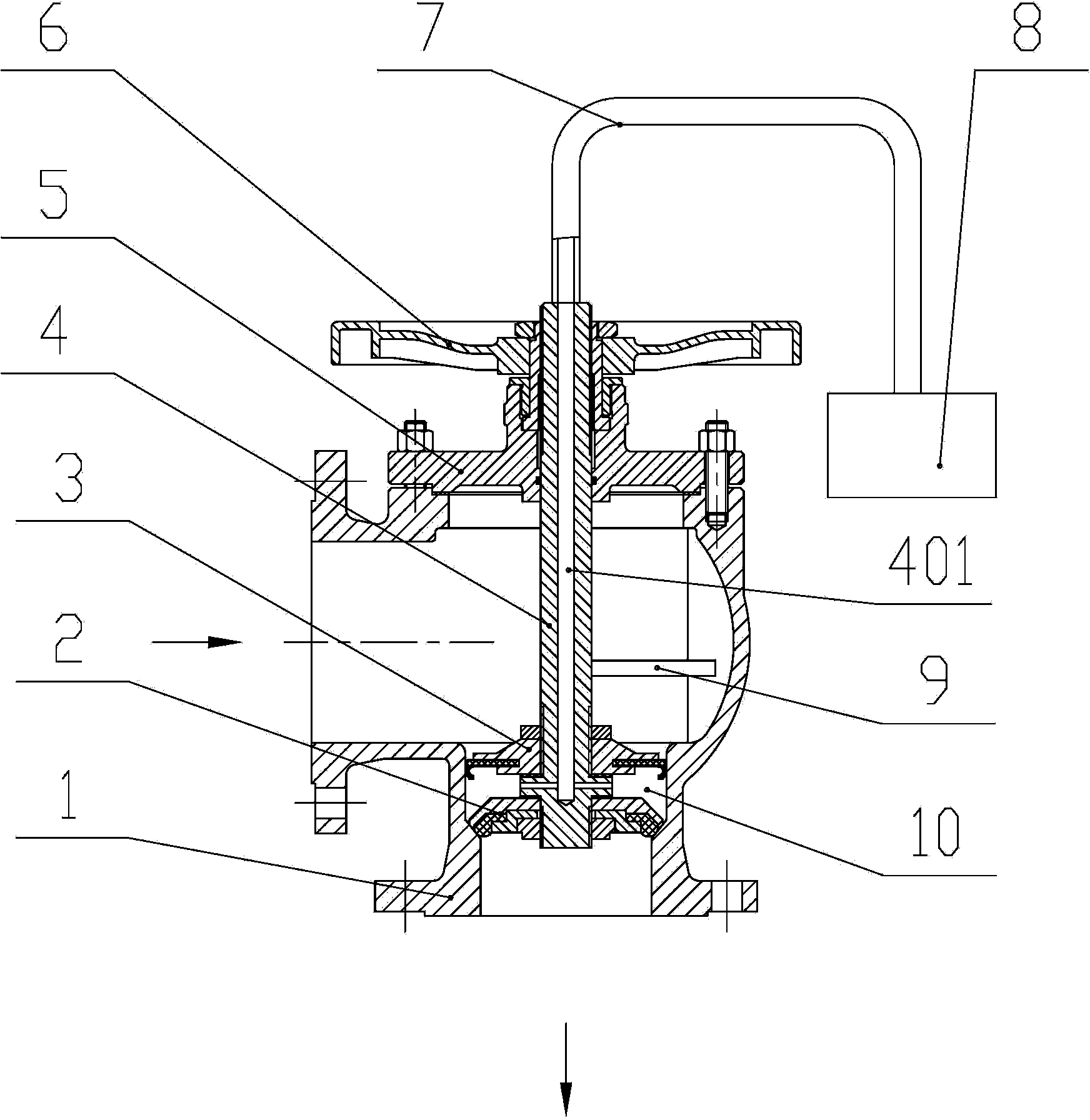

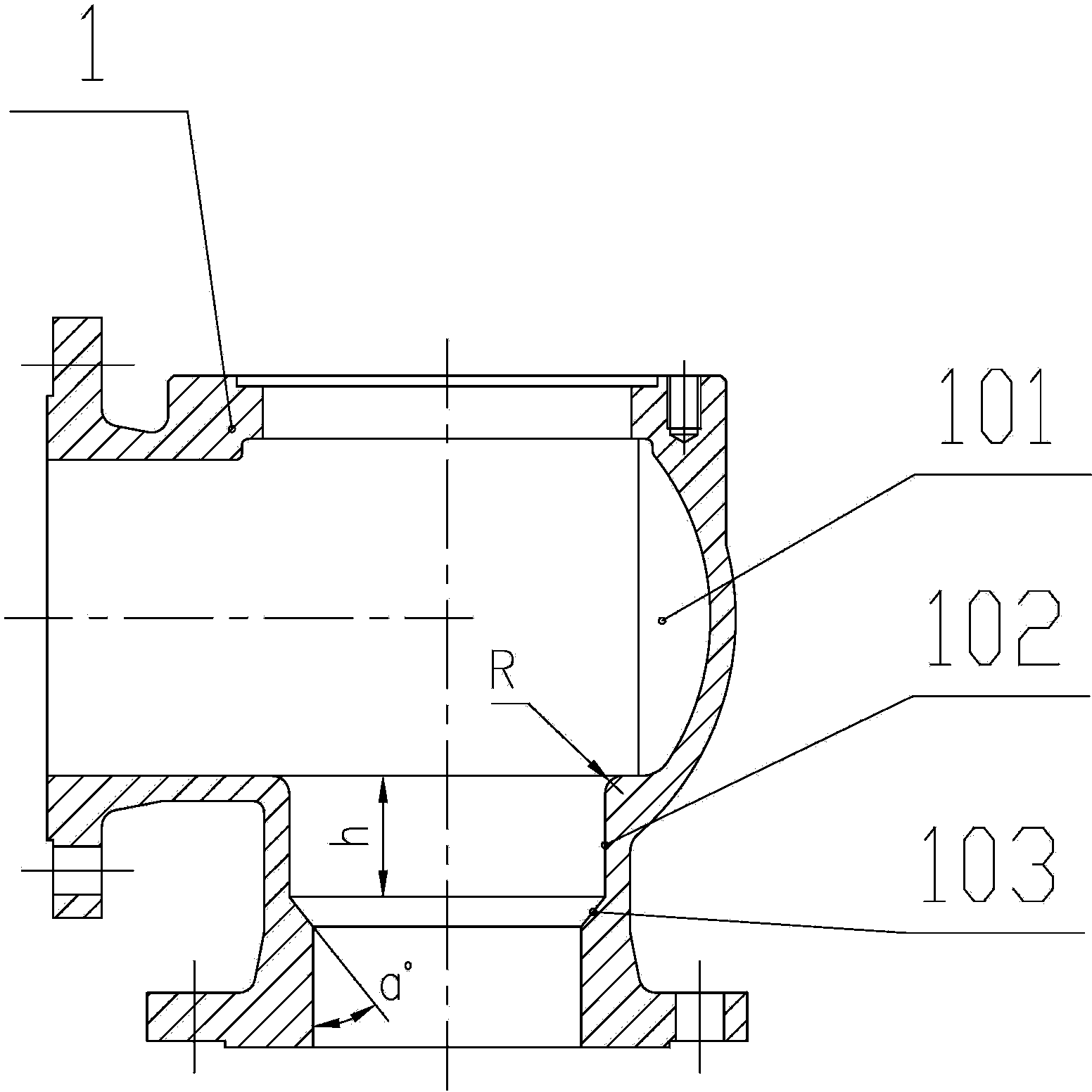

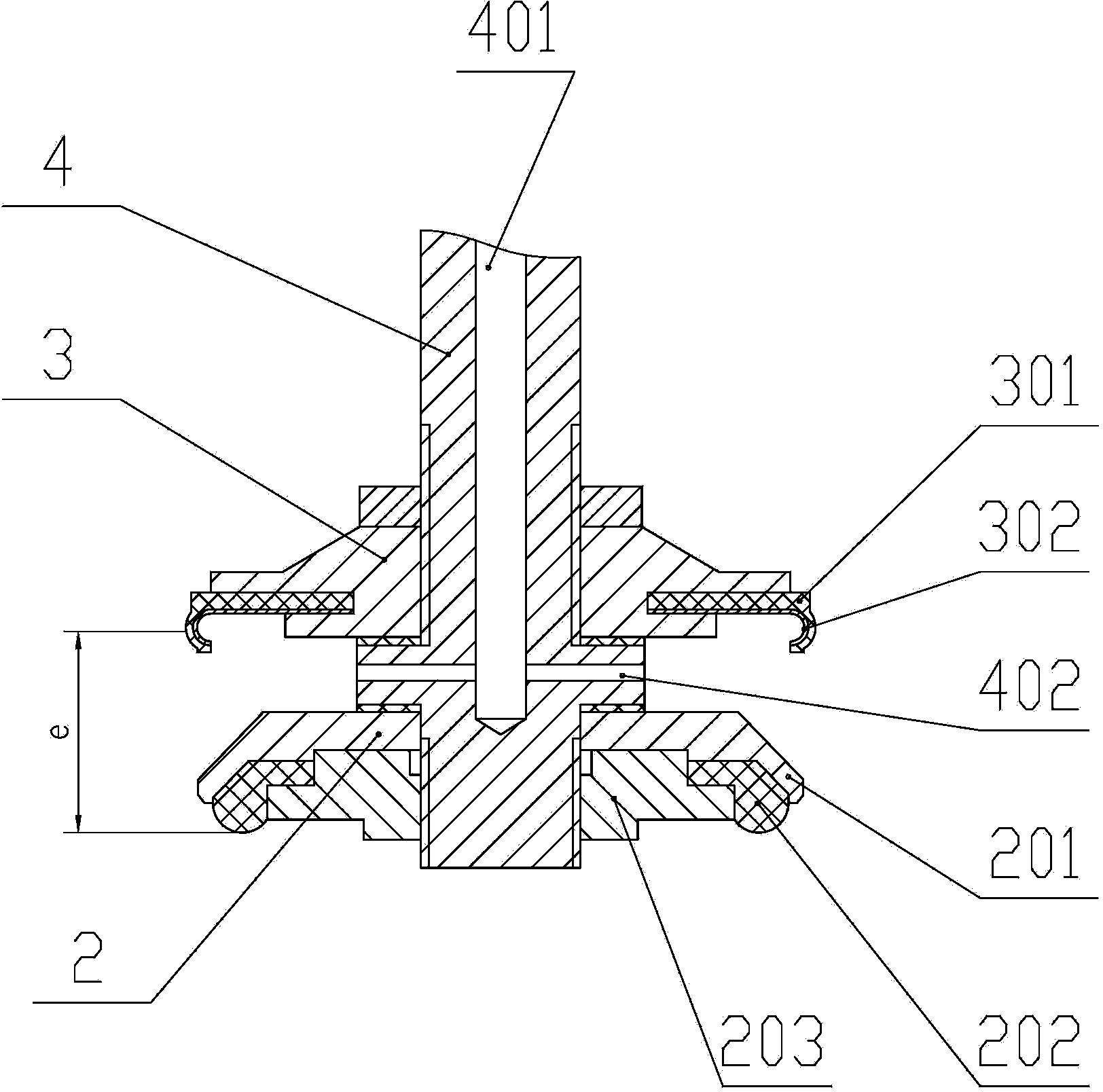

Soft and hard double seal fixed ball valve

InactiveCN102278491AAvoid damageMeet the sealing requirements of "zero leakage"Plug valvesRubber materialEngineering

The invention discloses a soft and hard double-seal fixed ball valve, which comprises a valve body, a valve seat and a spherical valve core. It is made of metal, and the valve seat has a hard sealing surface. The hard sealing surface is the surface of the valve seat in contact with the spherical valve core. The shape of the hard sealing surface is consistent with the arc surface of the corresponding spherical valve core. The hard sealing surface is the same as the spherical valve core. The contact of the core constitutes the primary hard seal, and the first O-ring of rubber material is fixed on the valve seat, and the contact between the first O-ring and the spherical valve core forms the secondary soft seal. The hard double seal combination sealing structure makes the sealing performance of the ball valve more reliable and basically meets the "zero leakage" sealing requirement. The outer surface of the first O-ring made of rubber has a polytetrafluoroethylene layer, which not only ensures the elasticity and toughness of the sealing surface, It also reduces friction, improves wear resistance, and increases the opening and closing times of the ball valve to more than ten times.

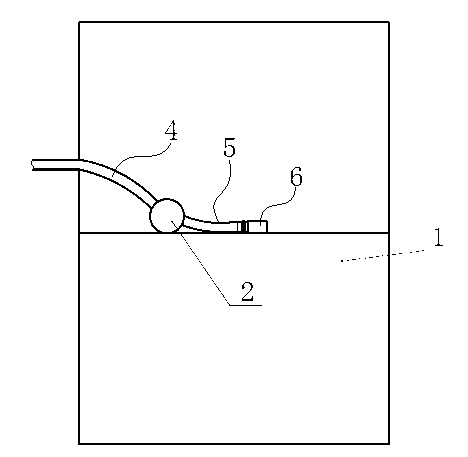

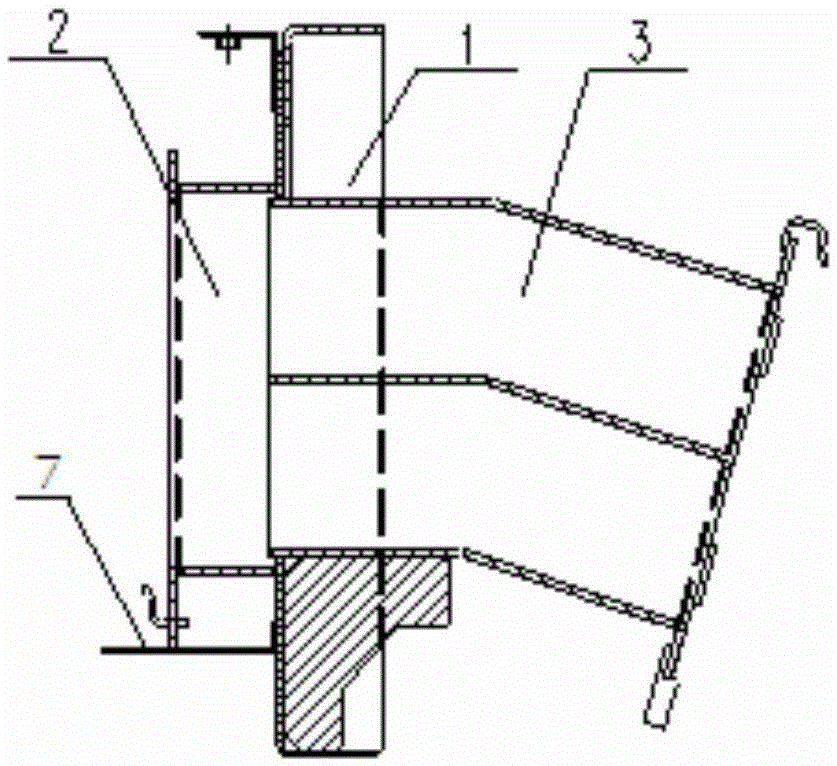

Flexible plastic quick grouting hole sealing device and method

ActiveCN106401522ARaise the initial pressureFlexibleDrilling rodsWell/borehole valve arrangementsSlurryMechanical engineering

The invention discloses a flexible plastic quick grouting hole sealing device and method. The device is mainly composed of an umbrella buckle type plugging device, a slotting flexible plastic grouting pipeline and a double-cone pipe connector device. The initial grout pressure in pipes is positively stored in a sealed mode through the differential flow of grout fed into and discharged out of the grouting pipes, and the processes of automatic pushing out, spreading and plugging of a convex angle umbrella buckle are completed. A flexible plastic pipe capable of being coiled is adopted to be inserted into a drill hole at a time, and the primary quick hole sealing operation requirement is met. According to the flexible plastic quick grouting hole sealing device and method, the process of traditional hole sealing operation is simplified, operation is convenient and quick, the cost is low, and the device and the method are novel hole sealing device and method which have wide application and popularization value.

Owner:CHINA UNIV OF MINING & TECH

Manufacturing process of metal seated ball valve nickel-based tungsten carbide wear-proof coating

InactiveCN111455306AAvoid crackingImprove compactnessMolten spray coatingSurface cleaningWear resistance

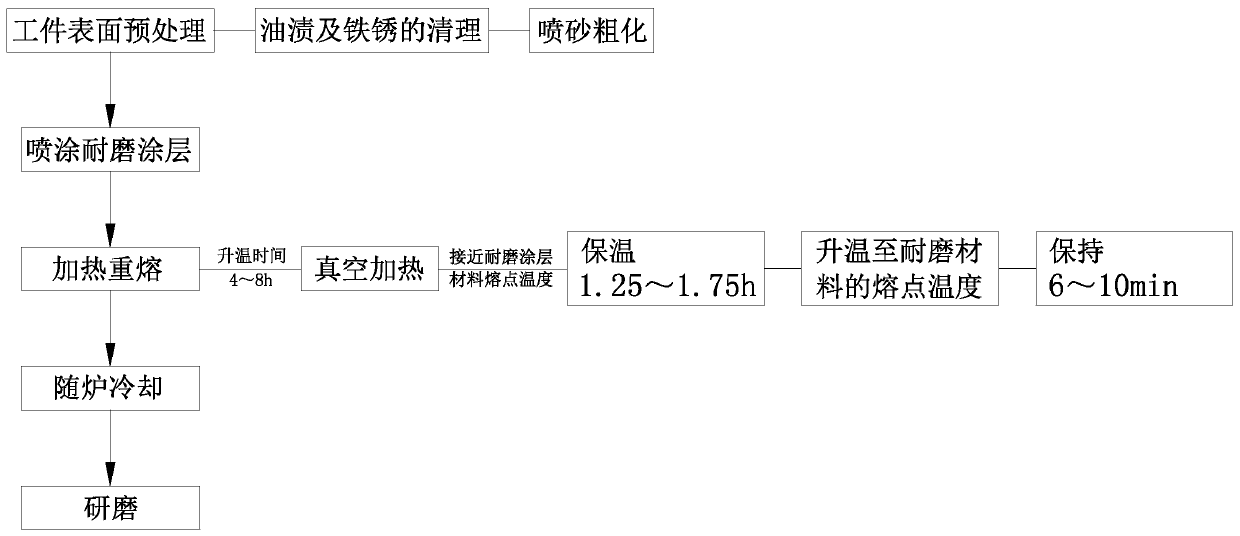

The invention discloses a manufacturing process of a metal seated ball valve nickel-based tungsten carbide wear-proof coating. The manufacturing process includes the following steps that S1, the surfaces of workpieces are pre-treated, wherein a machined ball body and a machined valve seat are subjected to surface cleaning and coarsening; S2, a wear-proof coating is sprayed, wherein a wear-proof coating powder material is evenly sprayed to the surfaces of the ball body and the valve seat through a hypersonic flame spraying process; S3, heating and remelting are carried out, wherein the sprayedball body and the sprayed valve seat are put in a vacuum furnace in batches for heating and remelting, and the ball body and the valve seat are metallurgically bound with the wear-proof material; S4,cooling is carried out, wherein after being remelted, the ball body and the valve seat are slowly cooled along with the vacuum furnace; and S5, grinding is carried out, wherein the cooled ball body and the cooled valve seat are precisely ground in sequence through a grinding device. The strength of the wear-proof coating on the sealing face of a ball valve can be improved, then the wear-proof performance of the sealing face of the ball valve is enhanced, and the service life of the ball valve is prolonged.

Owner:CHAODA VALVE GRP

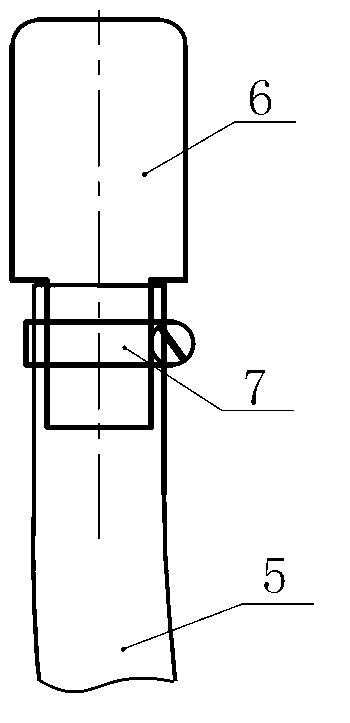

Process method for preparing static ring used for ship tail shaft sealing and lubricating

ActiveCN105150508AImprove mechanical propertiesImprove the lubrication effectCoatingsFiberFlexural strength

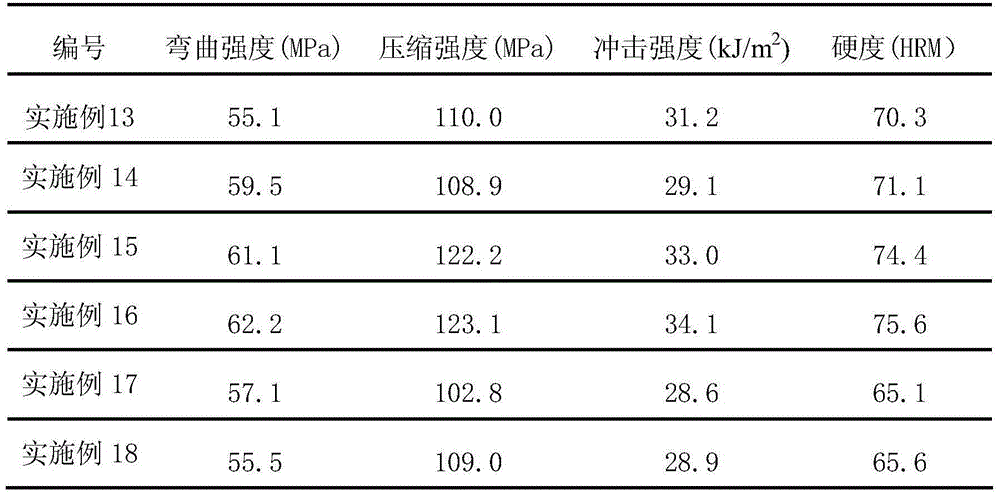

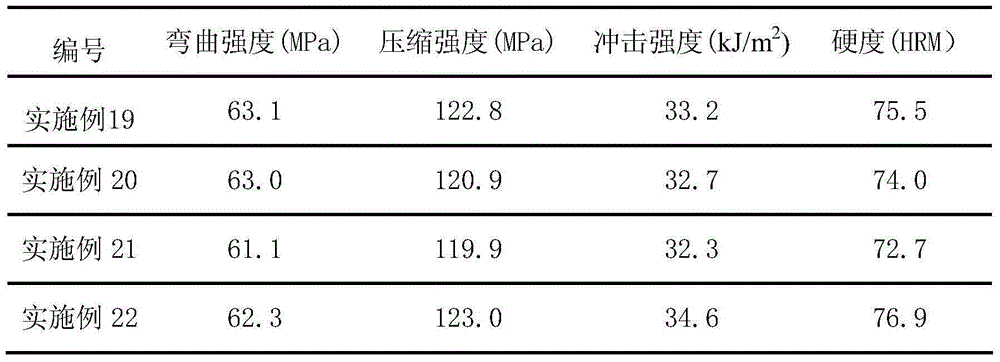

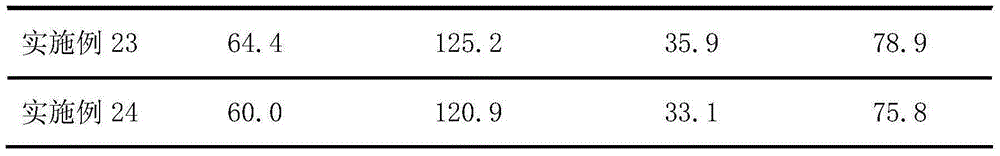

The invention provides a process method for preparing a static ring used for ship tail shaft sealing and lubricating, and belongs to the technical field of sealing materials. The process method includes the steps that continuous long fibers are soaked in glue and then dried; activated short fibers, fillers and the like are evenly mixed and then humidified; the continuous fibers are coated with the mixture to obtain coated fibers; the coated fibers are twisted in a three-ply manner and are infiltrated with a prepared resin glue solution; a mold is filled in a winding and knitting manner; and the mold is buckled after drying is conducted, and hot press molding is conducted. Compared with a traditional static ring, the structure of the obtained static ring has designability and has good a chemical property and a good lubricating property; and experiments prove that the compression strength of the static ring is larger than 120 MPa, the bending strength of the static ring is larger than 60 MPa, the impact strength of the static ring is larger than 32 kJ / m<2>, and the hardness of the static ring is smaller than 75 (Rockwell, RHM).

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

High temperature high pressure ceramic valve

ActiveCN103470800AImprove high temperature resistanceImprove corrosion resistancePlug valvesValve housingsEngineeringHigh pressure

A high temperature high pressure ceramic valve comprises a left flange, a right flange, a left valve seat, a right valve seat, a sphere, a valve body lining and a valve body; the left flange and the right flange are sleeved outside the left valve seat and the right valve seat; centers of the left valve seat and the right valve seat are provided with flow channels; the sphere is arranged between the left valve seat and the right valve seat; a through hole is formed in the center of the sphere; a valve rod is connected to the upper end of the sphere; the valve body is clamped between the left flange and the right flange; the valve body lining is clamped between the left valve seat and the right valve seat; the valve body is sleeved outside the valve body lining; the left flange, the right flange and the valve body are mutually fixed; through holes are formed in the valve body lining and the valve body; the valve rod extends out from the through hole which is formed in the valve body; the left valve seat, the right valve seat, the sphere and the valve body lining are made of ceramic materials. The high temperature high pressure ceramic valve has the advantages of being high temperature resistant and corrosion resistant, enabling the high temperature resistant performance to be greatly improved and enabling the service life under poor working conditions to be prolonged.

Owner:YANTAI KINGWAY SCI & TECH

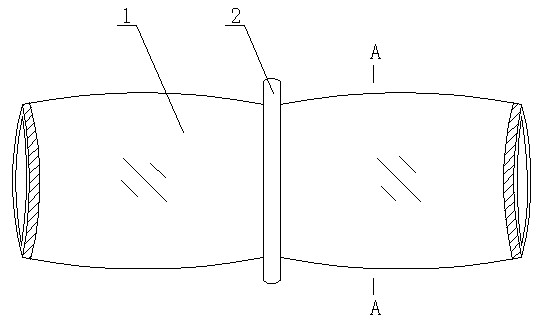

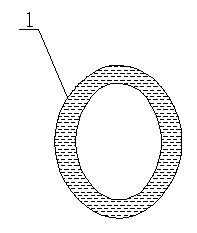

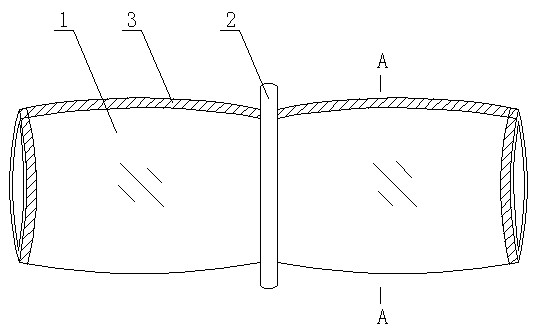

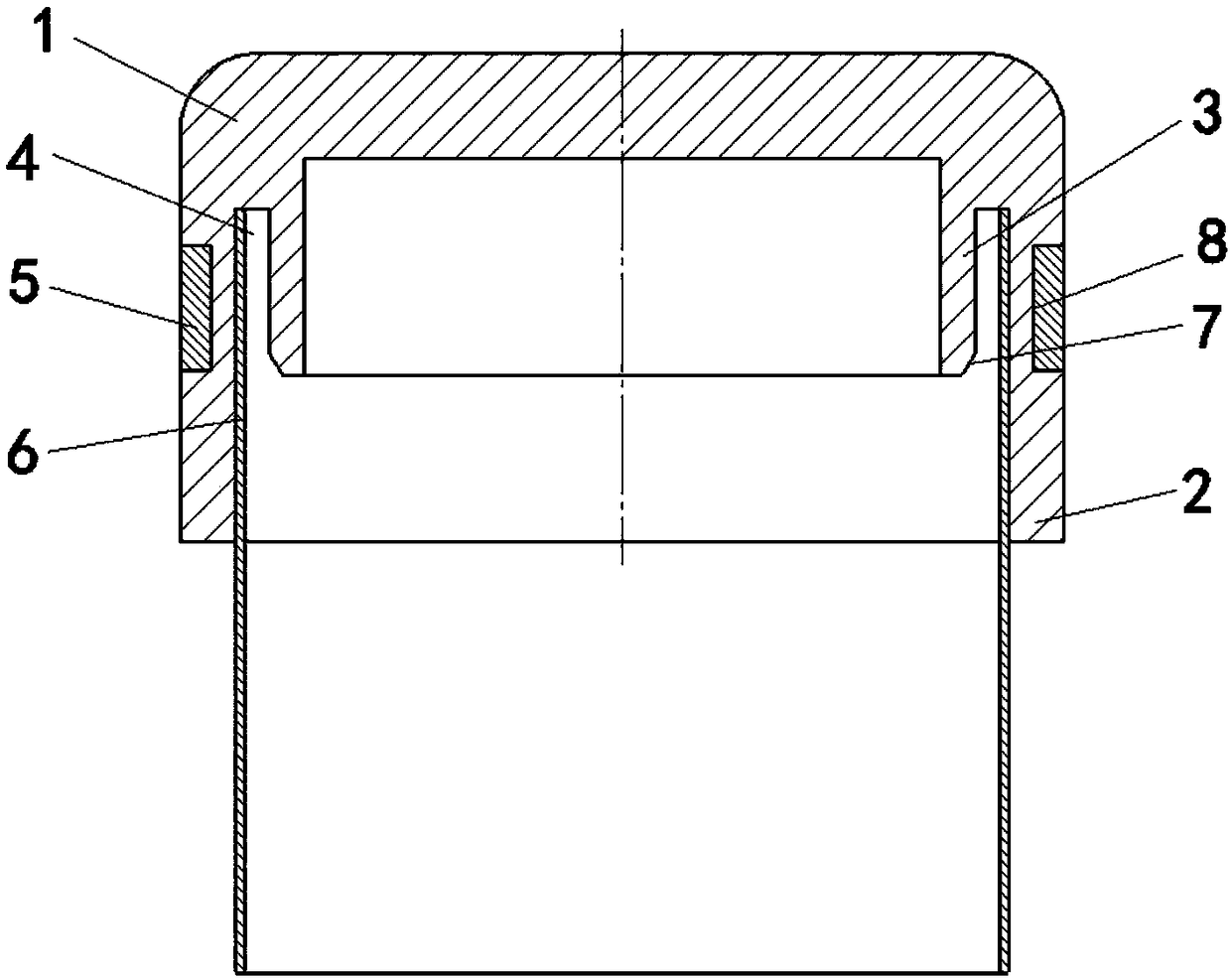

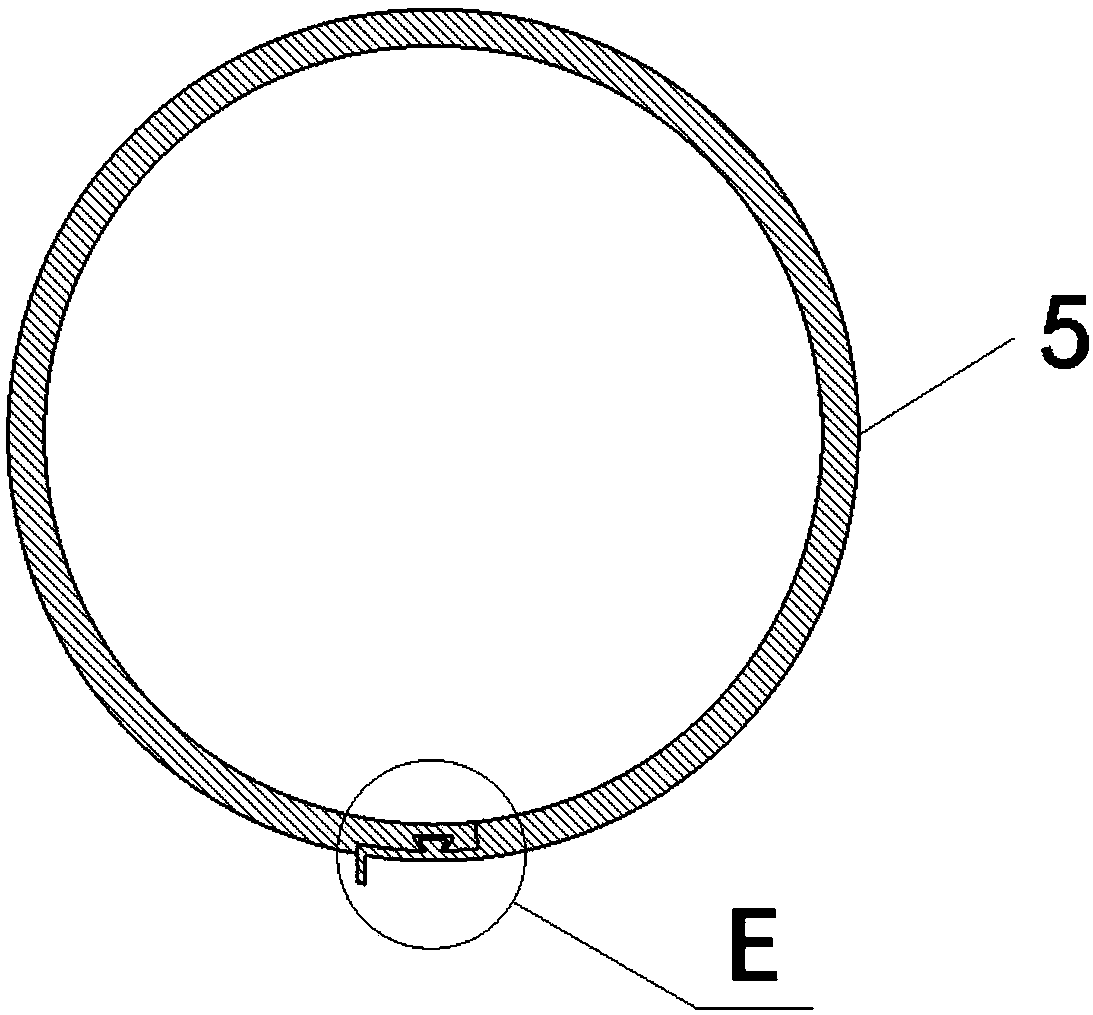

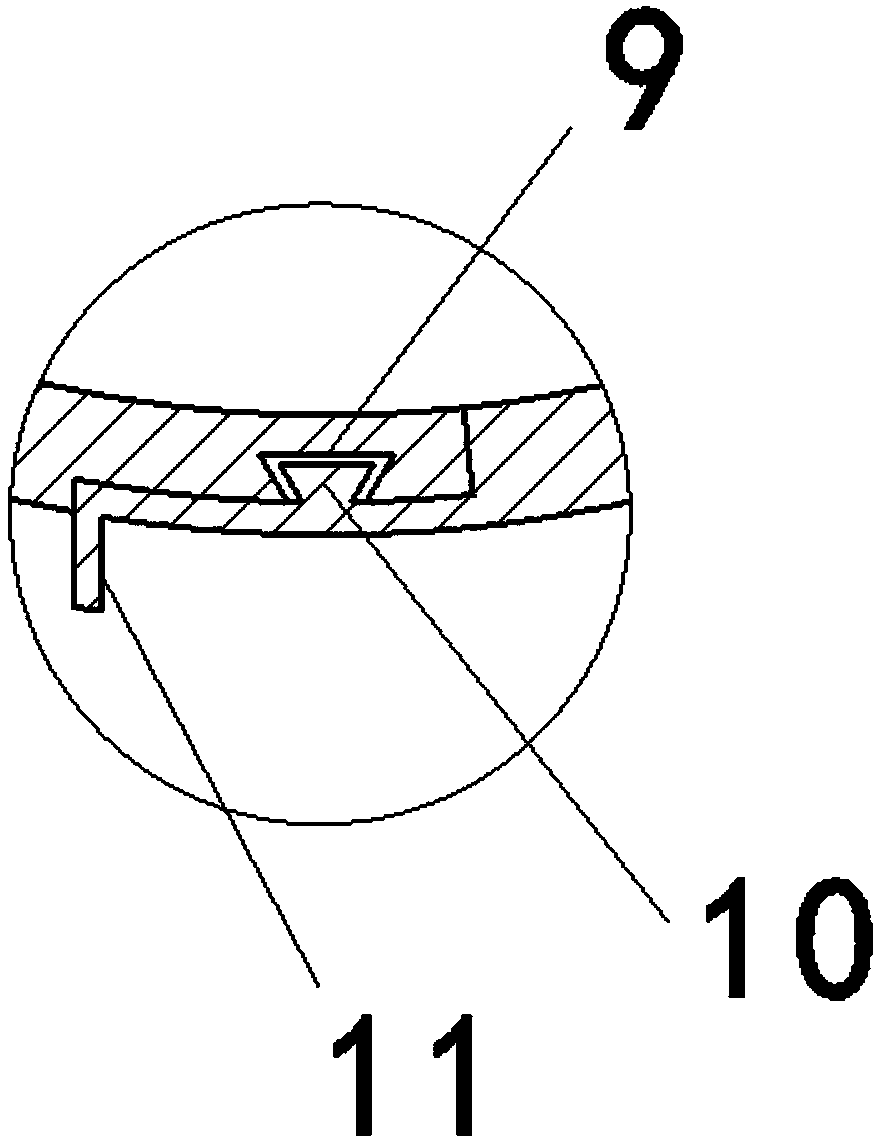

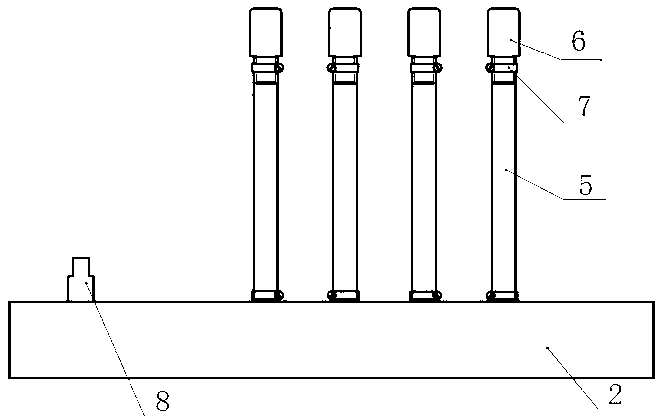

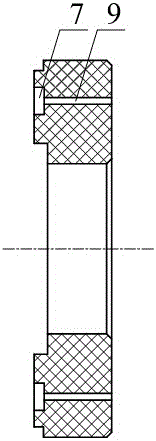

Cylindrical hole sealing bag

InactiveCN102678084AEasy to useMeet the sealing requirementsGas removalSealing/packingDrill holeMechanical engineering

The invention discloses a cylindrical hole sealing bag, which includes a bag body, wherein the bag body is a sandwich bag body formed by an inner layer and an outer layer, and takes the shape of a cylinder; an openable separating device is arranged at the middle part of the bag body and divides the bag body into two mutually-separated parts, and two components of foam materials are filled into the interlayer between the two parts of bag body in a one-to-one correspondence manner; the cylindrical hole sealing bag is not required to be wound and bound for fixation and is very convenient to use, and moreover, the cylindrical bag body fully winds around a drainage pipe so as to meet the hole sealing requirement even when the hole sealing bag has difficulty in splitting; in addition, when the water inflow in a gas drill hole is high, and the hole sealing bag is required to be not split during the whole foaming process, the cylindrical hole seal bag can be used as a hole sealing bag not being split at all and can realize sealing the hole sealing section.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

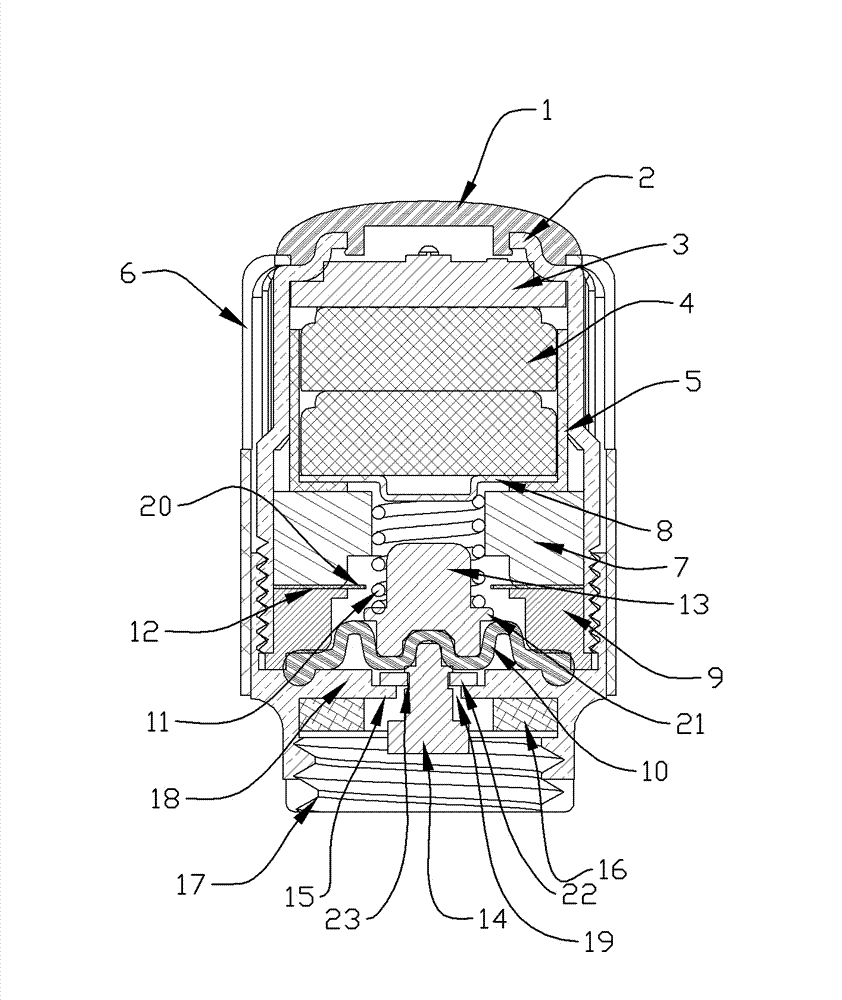

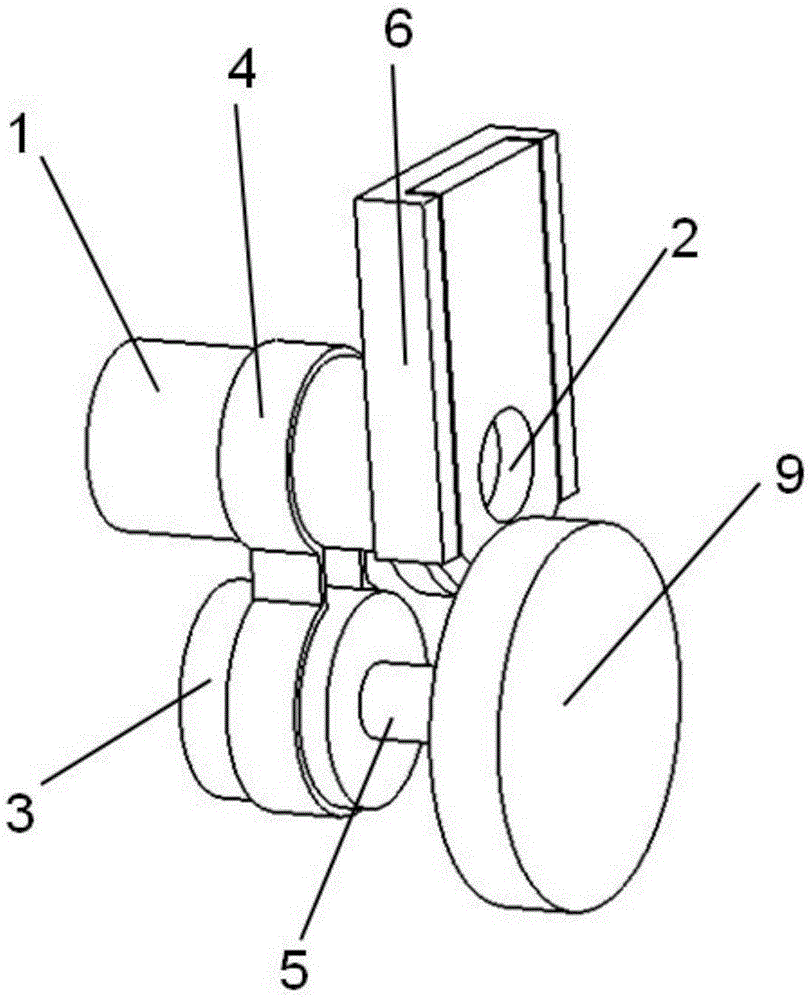

Tire pressure monitoring alarm

The invention discloses a tire pressure monitoring alarm. A bottom nut of the tire pressure monitoring alarm extends inwards to form a valve plate, an elastic diaphragm which is compressed on the valve plate by a contact pressure block is arranged above the valve plate, a spring base is provided with a convex outer edge, and an elastic contact piece extends towards the direction of the spring base. When the tire pressure is normal, the convex outer edge of the spring base is positioned above the elastic contact piece and separated from the elastic contact piece; and when the tire pressure is too low, the convex outer edge of the spring base is just overlapped on the elastic contact piece and conducted with the elastic contact piece to enable the anode of a battery to be ultimately conducted with an anode access point of a flasher circuit board through a battery pad, a spring, the spring base, the elastic contact piece and a shell in sequence, and an alarm circuit board obtains an electric alarm. The alarm is only provided with a cavity communicated with the tire pressure, a reference cavity is replaced by the spring, and the alarm does not have requirements for the sealing performance of the upper part of the elastic diaphragm, and is very easy to satisfy the requirements for the sealing performance in use, and reliable and safe to use.

Owner:DONGGUAN NANNAR ELECTRONICS TECH

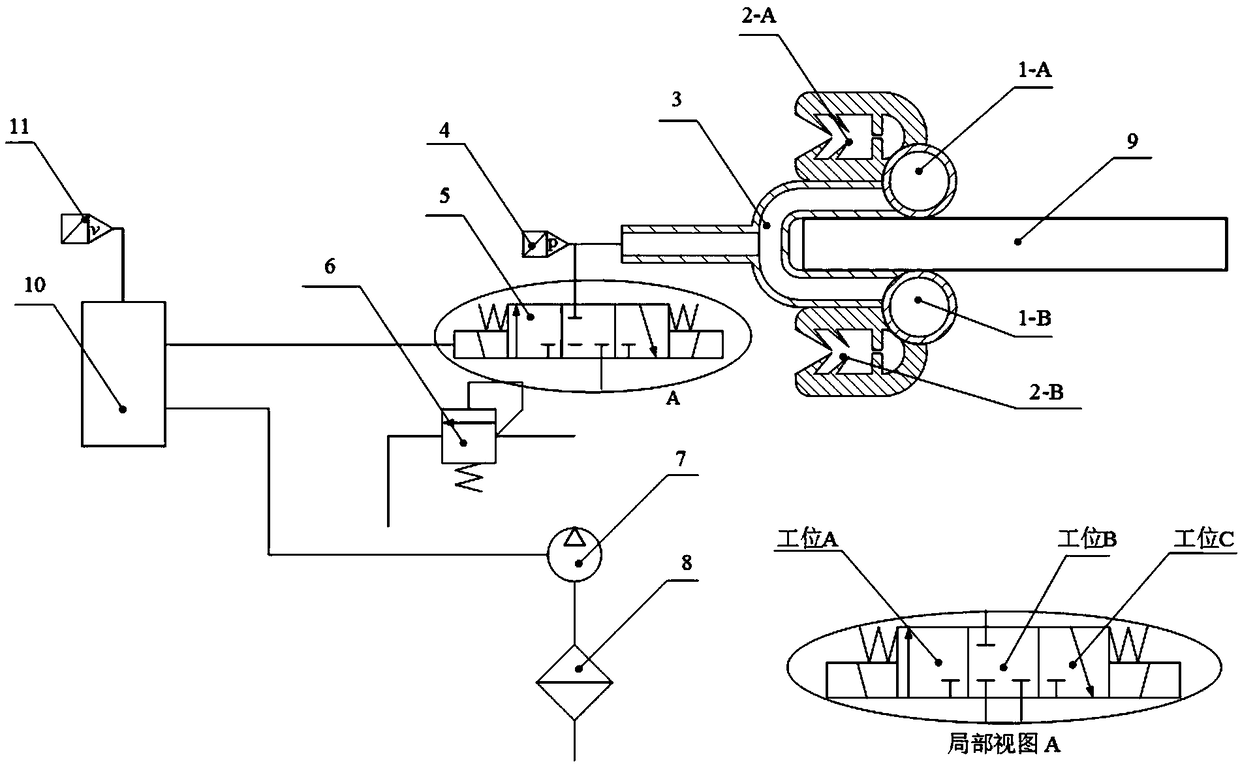

Vehicle window air pressure sealing system

ActiveCN108528181AReduce air pressureAvoid damageEngine sealsVehicle sealing arrangementsInternal pressureAir pump

The invention discloses a vehicle window air pressure sealing system. The system comprises an assembly positioning lip side, air pressure hoses, a loop interface, a three-position three-way solenoid directional valve, a decompression valve, an air pump, a filter, an air pressure sensor, a vehicle speed sensor and a controller. The assembly positioning lip side is fixedly connected with a vehicle body, and the two air pressure hoses are fixed at the inner and outer sides of vehicle window glass; the two air pressure hoses are communicated through the loop interface and form a gas loop with thethree-position three-way solenoid directional valve, the decompression valve, the air pump and the filter; and the air pressure sensor, the vehicle speed sensor, the controller, the three-position three-way solenoid directional valve and the air pump form a control loop. The vehicle window air pressure sealing system has the advantages that signals of the air pressure sensor and vehicle speed sensor serve as input, the controller controls the three-position three-way solenoid directional valve and the air pump to work, and the internal pressure in the air pressure hoses is adjusted to ensure that the vehicle window glass always fits the air pressure hoses to prevent the noise from being transmitted into a vehicle; the elasticity and damping of the air pressure hoses reduce the vibration ofthe vehicle window glass and have the advantages of vibration and noise reduction.

Owner:SHANDONG UNIV OF TECH

Novel test tube sealer

ActiveCN108514903AMeet the sealing requirementsSimple structureLaboratory glasswaresWater bathsEngineering

The invention discloses a novel test tube sealer, which comprises a cover body. An annular crack is formed in the lateral wall of the cover body. The lateral wall of the cover body is divided into anouter wall and an inner wall by the annular crack. A waterproof plastic cover is adhered on the inner side of the outer wall. The external side of the outer wall is provided with an annular groove. Alocking hoop is installed in the annular groove. Compared with wooden plugs and rubber plugs, the provided sealer can well seal a test tube and is capable of preventing the volatilization of reagentsduring the experiment process such as water bath, burning, and the like. When a test tube is used as a container to store substances, the sealer is used to seal the test tube, and the test tube can bestored more conveniently. Furthermore, the sealer has the advantages of simple structure, good sealing performance, and low cost, and is disposable. Thus the tedious and repeated washing of test tubeplugs and the risk that a reagent is polluted are avoided effectively.

Owner:GUIZHOU UNIV

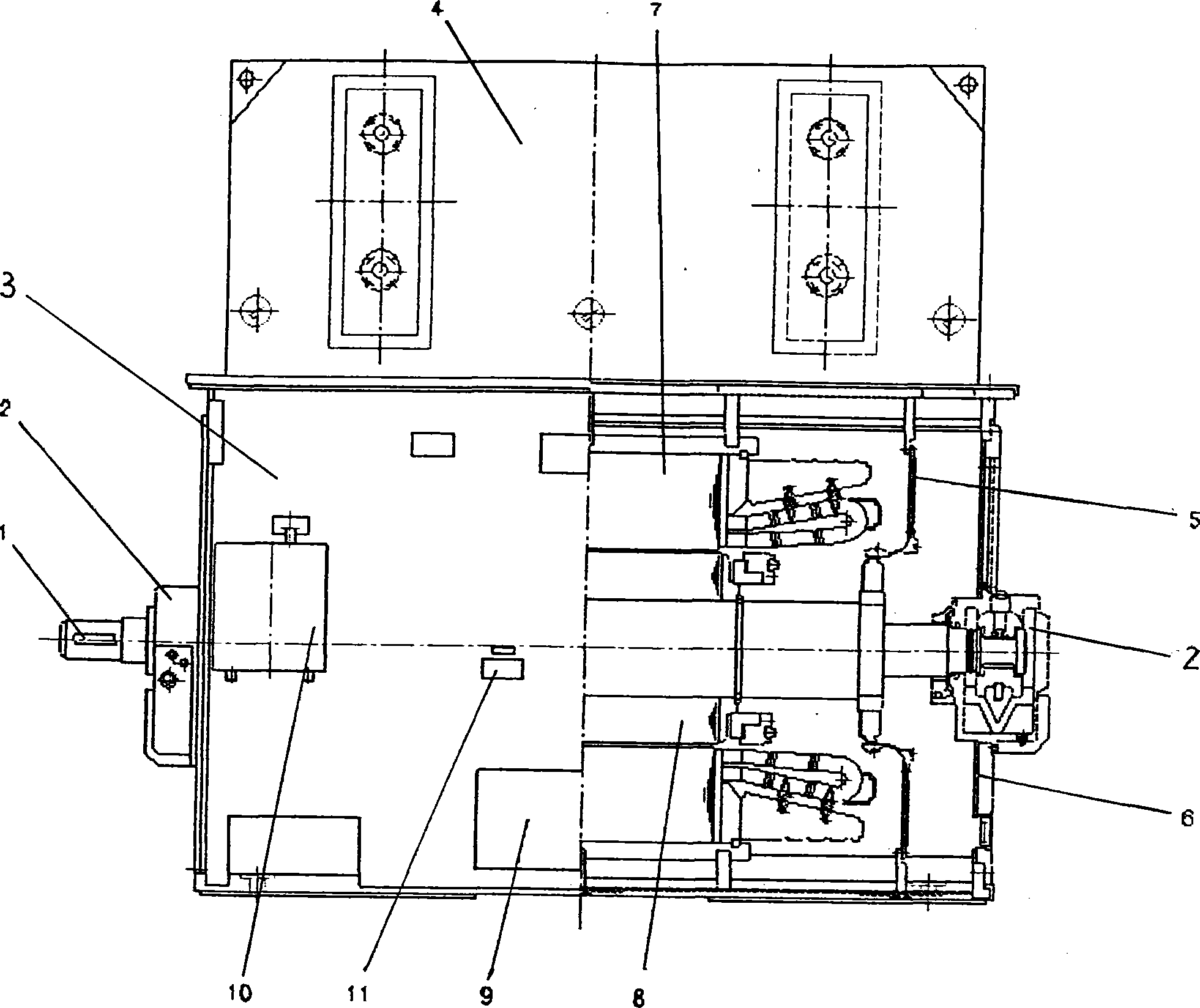

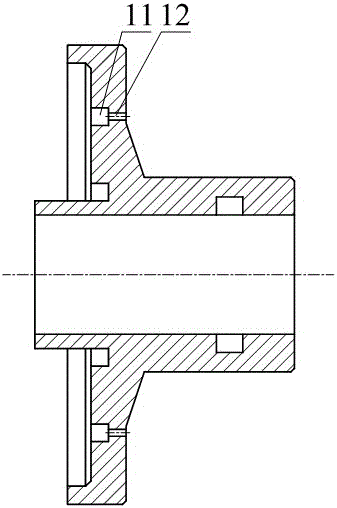

Large high-speed electromotor whole structure

InactiveCN101087081AMeet the design requirementsMeet the use requirementsMagnetic circuit stationary partsManufacturing stator/rotor bodiesResonanceEngineering

A kind of large-scale high-speed machine complete texture, motor includes engine base, end cap, stator, axes, rotor and bearing, thereinto, the engine base is box structure, two dabbers or above are set on upper, lower, lest and right side board, wall of engine base is processed by steel plate whose thickness is 40mm+-3; the end cap is one-shot formed by steel plate whose thickness is 50mm+-3, contact face between end cap and engine base and bearing are smooth, they are sealed with each other; stator, the iron core of the stator fixed with three integral round steel plate whose thickness is 20mm+-3, the iron core of the stator is shaped with built-in craftwork; axes and rotor iron core are processed by thermal process; the bearing is end bracket type bearing, and possesses two floating type seals, outer possesses outer cover. Advantages are: optimization design makes resonance of motor and other electric property fulfill design requirement, and it can fulfill operating requirement of open-air or dust is big, box structure can increase rigidity of engine base, and decrease resonance of motor.

Owner:SHANGHAI LUFA ELECTRIC GRP

Fuel gas generator

PendingCN109798515AImprove stress resistanceGood light transmissionCombustion using gaseous and pulverulent fuelBurnersCombustion chamberOptical measurements

The invention provides a fuel gas generator. The fuel gas generator sequentially comprises an injector assembly, a combustion chamber assembly and a spraying pipe assembly from top to bottom, the injector assembly is arranged on the head part of the fuel gas generator, the spraying pipe assembly is arranged on the tail part of the fuel gas generator, and the combustion chamber assembly is fixed tothe middle by the injector assembly and the spraying pipe assembly through threaded rods; the combustion chamber assembly includes a protective sleeve, an igniter and a transparent combustion chamber, and the protective sleeve is arranged on the periphery of the transparent combustion chamber; and the protective sleeve is arranged in a spliced mode and includes an upper half segment protective sleeve and a lower half segment protective sleeve. The fuel gas generator mainly aims at gas-liquid injection combustion and can carry out optical measurement in many directions and means.

Owner:CENT SOUTH UNIV

Device and method for examining sealing performance of rubber hoses

InactiveCN103234711AMeet the sealing requirementsSolve the sealing problemDetection of fluid at leakage pointWater coolingIndustrial engineering

The invention discloses a device and a method for examining the sealing performance of rubber hoses. The device and the method aim to verify whether the requirement on improvement of the sealing performance of the rubber hoses can be met or not and to master fastening installation and connection conditions of the hose. The device for examining the sealing performance of the rubber hoses comprises an ageing oven and a sealing pipe; the sealing pipe is arranged in the ageing oven; a plurality of hose connecting seats are arranged on the sealing pipe, an air inlet pipe which partially extends out of the ageing oven is arranged on at least one of the various hose connecting seats, the rubber hoses are arranged on the other remaining connecting seats, and outer ends of the various rubber hoses are connected with second quick connectors; the outer end of the air inlet pipe is communicated with an air supply device; and the air inlet pipe is communicated with the sealing pipe and the rubber hoses. The device and the method have the advantages that pressure maintaining and high and low-temperature ageing examinations under severe running environmental conditions of locomotives can be simulated, and the rubber hoses which pass the examinations can assuredly meet reliability requirements of water cooling systems of locomotive products.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

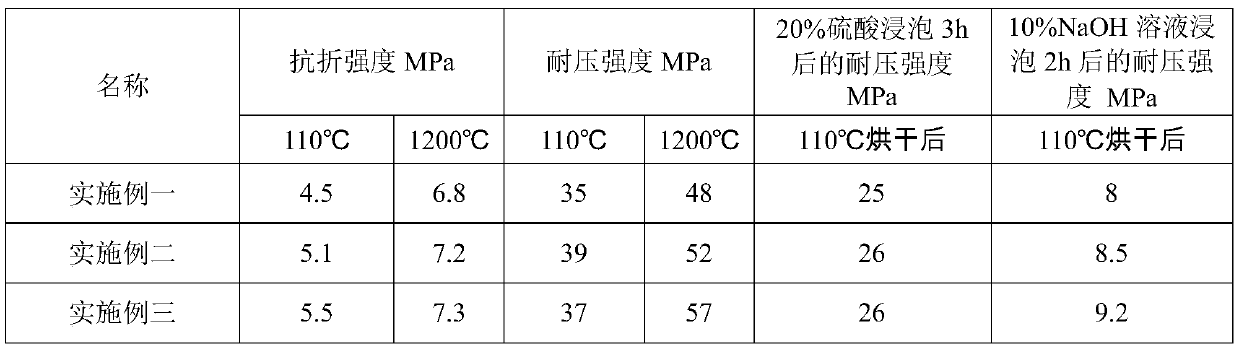

Joint material for SO2 flue joint connection construction and preparation method of joint material

InactiveCN110981515AGuaranteed plasticityGuaranteed acid and alkali corrosion resistanceSODIUM METAPHOSPHATEHigh concentration

The invention discloses a joint material for SO2 flue joint connection construction, which is divided by special-grade high-alumina bauxite, mullite and corundum as basic formulas, and is added with clay, kaolin, superfine powder, lignosulfonate, sodium hexametaphosphate and pulp waste liquid, so that the joint material has favorable workability. Silicon carbide, alpha-aluminum oxide powder, quartz fine powder and other materials are further added into the joint material, acid and alkali erosion and corrosion can be well resisted, and due to the reaction characteristics of kyanite, andalusite,quartz and other components in the joint material at the high temperature, the joint material can well obtain medium-high temperature expansion; the expansion of the joint material at high temperature can block pores in the joint material, thereby ensuring that the joint of flue gas is not easy to erode and corrode by a high-concentration SO2 gas and alkali metals, and achieving the purpose of noleakage of the flue gas.

Owner:江苏润美新材料有限公司

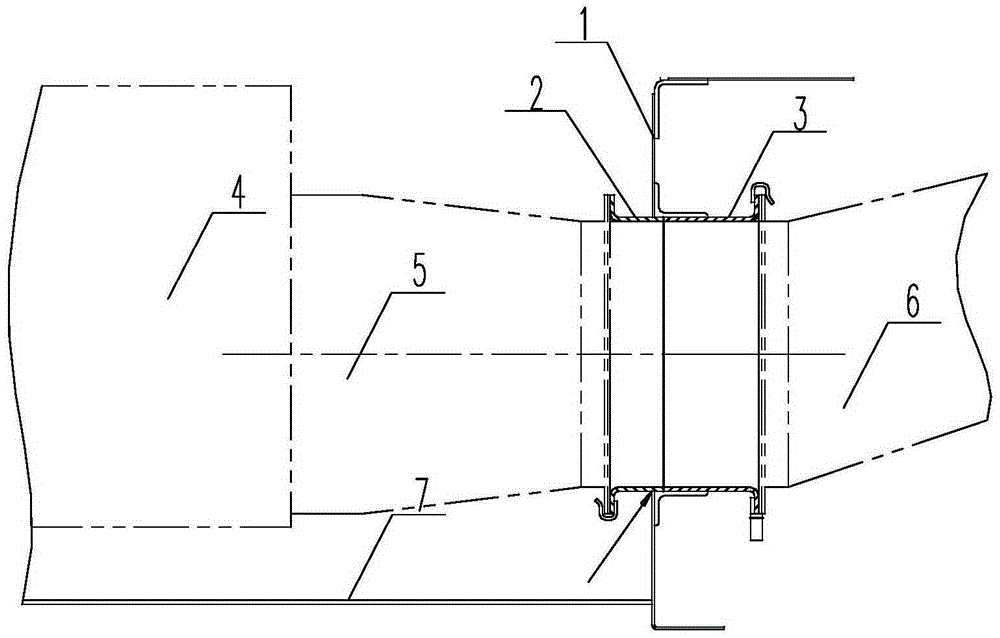

Mounting method for air duct external flange of rail vehicle

InactiveCN105253157AMeet the installation requirementsMeet the sealing requirementsRailway heating/coolingSpot weldingFlange

The invention relates to a mounting method for an air duct external flange of a rail vehicle. The air duct external flange comprises an external flange cylinder and an external flange edge, wherein the external flange cylinder is formed by arranging four wing plates in a surrounding manner; the bottom ends of the left and right wing plates of the external flange cylinder are flush with that of the external flange edge. The mounting method comprises the following steps: putting the pre-welded air duct external flange on the vehicle; moving the air duct external flange to an appointed position to ensure that the left and right wing plates of the external flange cylinder together with the external flange edge fall on a flat top plate of the vehicle while the four wing plates of the external flange cylinder are propped against a middle end top plate of the vehicle; welding the bottom ends of the left and right wing plates of the external flange cylinder and the bottom end of the external flange edge with the flat top plate of the vehicle through spot welding, and welding the four wing plates of the external flange cylinder with the middle end top plate of the vehicle through spot welding, so as to fix the air duct external flange; welding the four wing plates of the external flange cylinder with the middle end top plate of the vehicle through full welding. The air duct external flange mounted according to the mounting method has the advantages that the mounting requirement of an air conditioner external air duct and the sealing requirement of a steel structure of a vehicle body can be met simultaneously; the structure is simple; the technology is easy to realize.

Owner:CRRC NANJING PUZHEN CO LTD

Circular seam welding process

InactiveCN105252123AMeet the thickness requirementMeet the sealing requirementsArc welding apparatusWorkpiece edge portionsRadial planeSeam welding

The invention relates to the welding field and particularly discloses a circular seam welding process. The circular seam welding process is characterized by comprising the steps that, firstly, in the machining stabbing process of the insertion contact part of a sealing cap and a barrel, a circle of slope circular ring plane which forms an angle of 32.5 degrees with a vertical radial plane is arranged on the outer circle of a spigot part of an insertion contact ring plane of the sealing cap and the barrel; a circle of concave ring with the width being 1.5 mm and the depth being 0.5 mm is formed in the root of an axial cylindrical surface explained in detail by the 32.5-degree radial slope ring plane and the axial cylindrical plane; a circle of bottom ring edge with the thickness being 0.3 mm and the width being 0.5 mm is formed at the lowest bottom of the lower edge of the barrel and the inserted sealing cap; and the circle of slope ring plane which forms an angle of 32.5 degrees with the vertical radial plane is arranged in the position, close to the bottom ring edge of the sealing cap, of the bottom ring edge, and then welding is conducted on a trapezoid part. The circular seam welding process has the beneficial effects that transverse parts of the barrel are melted and welded firmly by being welded with the sealing cap; the thickness requirement for the welded parts is met, and the sealing requirement is also met.

Owner:丁春燕

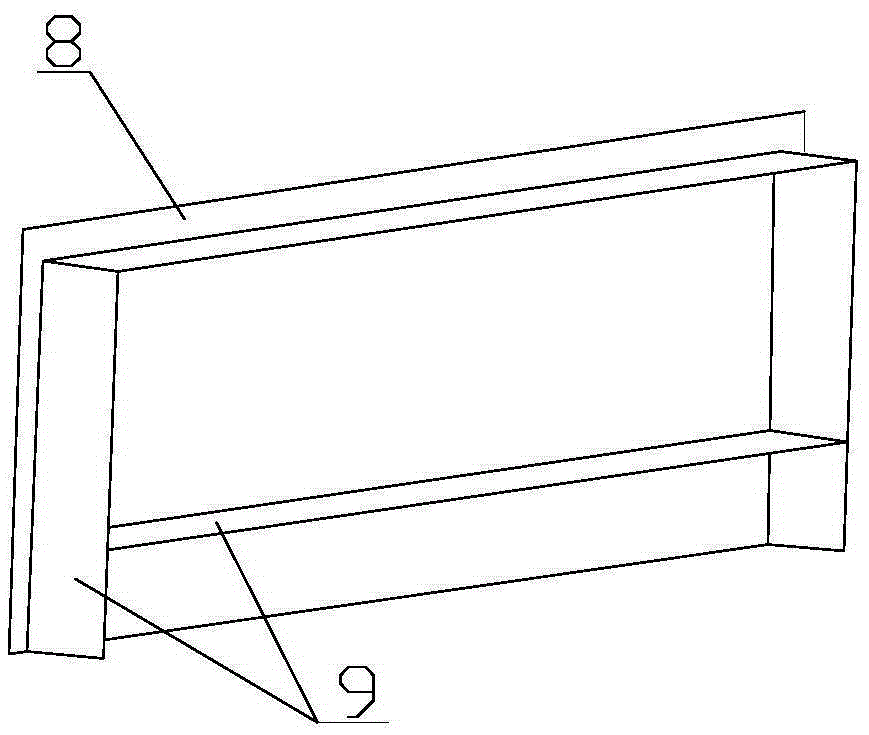

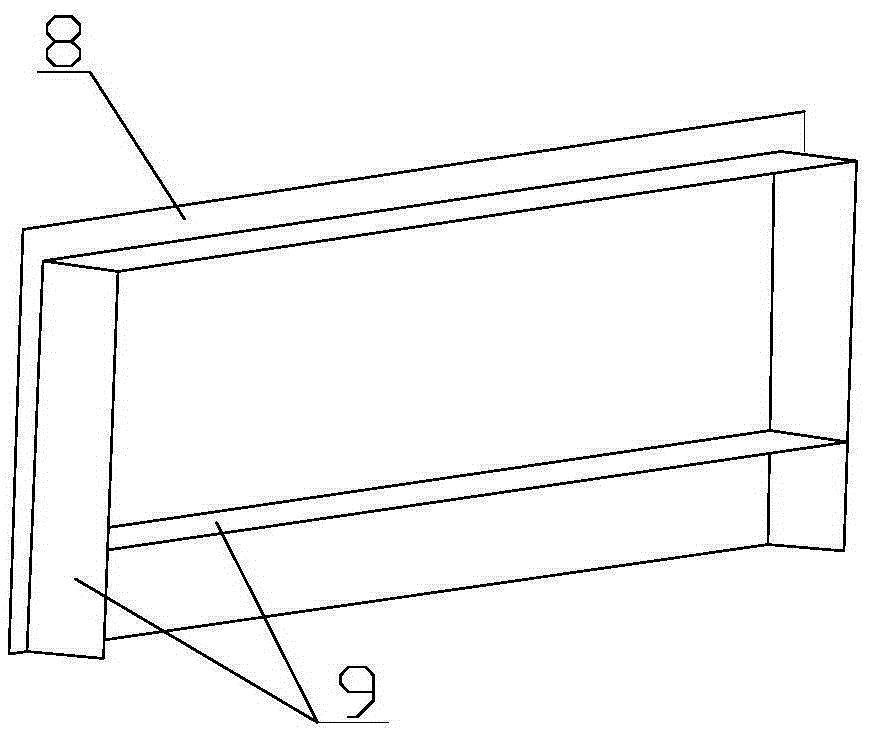

Outer flange structure of air flue of railway vehicle

ActiveCN105235699AMeet the installation requirementsMeet the sealing requirementsFlanged jointsRailway heating/coolingFlueFlange

The invention relates to an outer flange structure of an air flue of a railway vehicle. The outer flange structure comprises an outer flange barrel and an outer flange edge, wherein the outer flange barrel is defined by four wing plates, the bottom ends of the left wing plate and the right wing plate of the outer flange barrel are aligned at the bottom end of the outer flange edge, and the left wing plate and the right wing plate of the outer flange barrel and the outer flange edge are jointly located on a vehicle flat roof plate; and the four wing plates of the outer flange barrel and a top plate of the middle end of the vehicle are fixedly welded. According to the outer flange structure of the air flue of the railway vehicle, innovation is made on the basis of a conventional structure; the brand-new design structure and the brand-new welding process are adopted, the caliber of the outer flange barrel of the air flue is enlarged, and the wing plates on the two sides and the lowermost edge of the outer flange edge extend to the flat roof plate. When a roof is positively installed, an outer flange of the air flue is directly located on the flat roof, the wing plates of the outer flange barrel of the air flue and the lowermost edge of the flange are directly welded to the flat roof plate, the lateral faces of the wing plates of the outer flange of the air flue and the top plate at the middle end are welded, and therefore the outer flange structure of the air flue can meet the installation requirement of an outer air flue of an air-conditioner and the requirement for the sealing performance of a vehicle body steel structure at the same time; and in addition, the structure is simple, and the process is easy to implement.

Owner:CRRC NANJING PUZHEN CO LTD

Novel glue sealing valve

InactiveCN106885001AControl flowControl speedOperating means/releasing devices for valvesSlide valveMotor driveEngineering

A new type of rubber sealing valve, which is composed of a rubber inlet section, a glue outlet hole, a motor, a fixed ring, a rotating shaft, a fixed frame, and a rubber adjusting plate. The fixing frame and the rubber adjusting plate are closely attached. The hole is set at the lower end of the fixed frame, the glue inlet section passes through the fixed ring and communicates with the glue outlet hole on the fixed frame, the glue inlet section is connected with the motor through the fixed ring, the rotating shaft is connected with the motor and the glue disc, the glue disc is close to the fixed The upper position of one end of the frame is provided with a slideway, and the slider is arranged at the lower end of the glue outlet and cooperates with the slideway. The slideway is a cam-shaped annular groove structure. Compared with the prior art, the beneficial effect of the present invention is: Drive the glue adjusting plate to rotate, so that the slider moves up and down in the cam-shaped annular groove of the glue adjusting plate. By adjusting the upper and lower positions of the glue adjusting plate and the glue outlet hole, the flow and speed of glue can be controlled, and The amount of glue and the speed of glue output are more accurate, which can better meet the sealing requirements of glued items.

Owner:天津梓彦科技发展有限公司

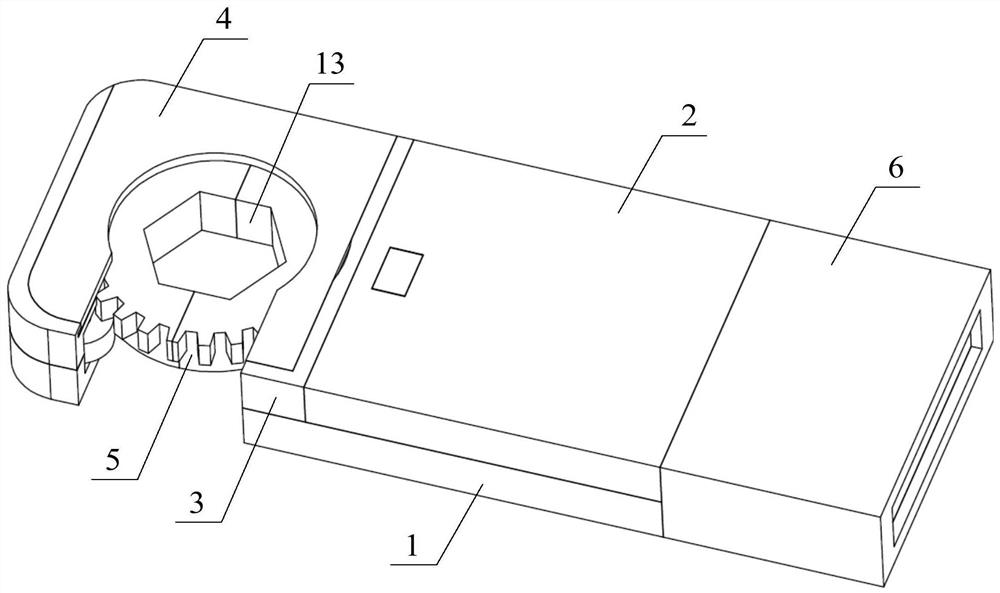

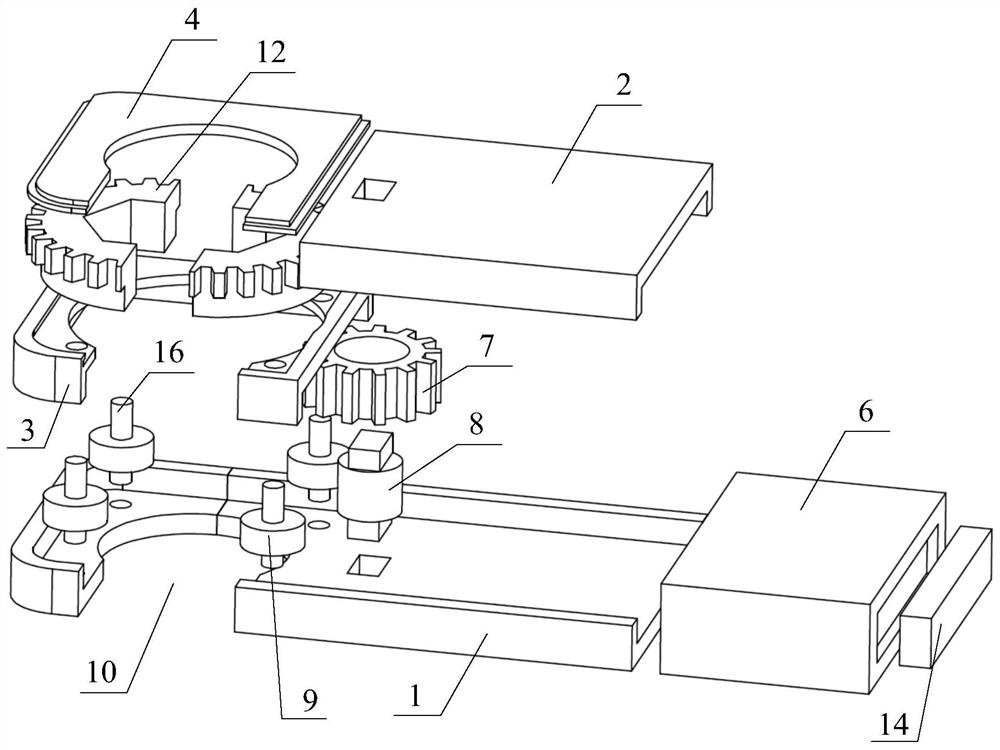

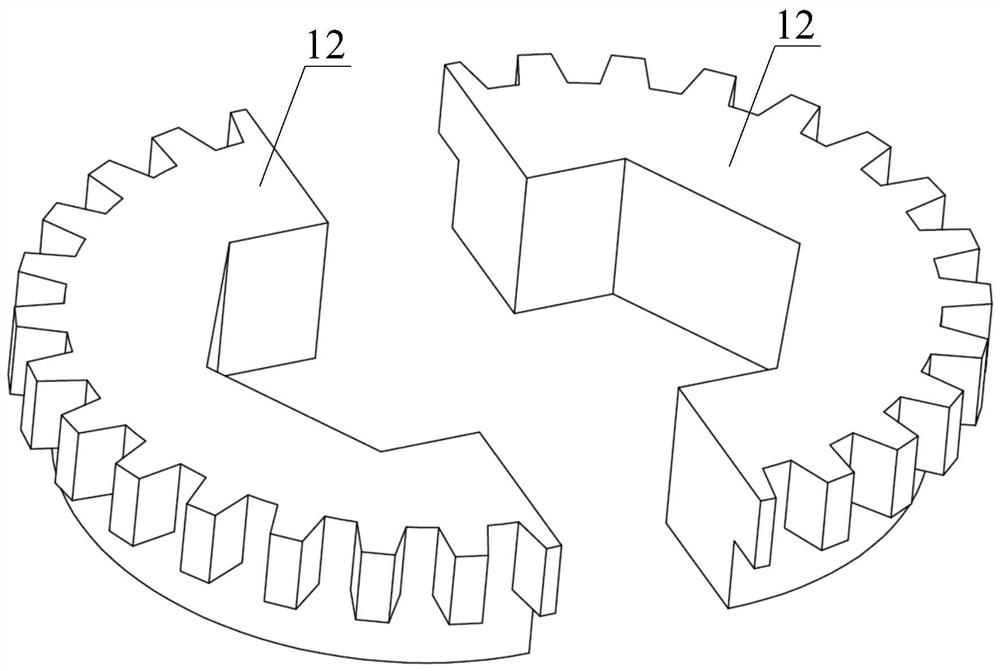

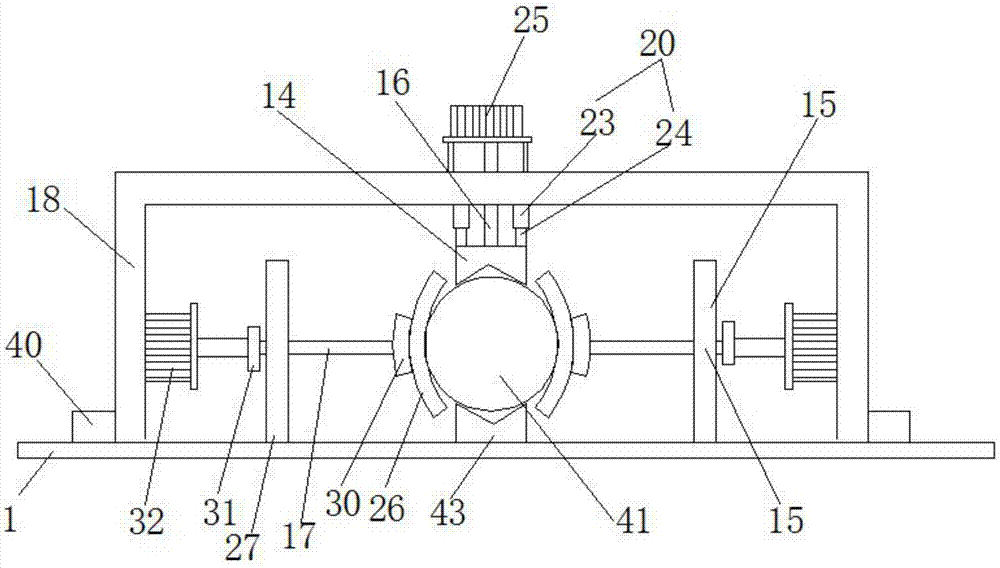

Intelligent special clamping sleeve joint assembling and disassembling tool

PendingCN112454241AMeet stringent installation requirementsMeet the sealing requirementsPortable power-driven toolsPower driven toolsElectric machineGear wheel

The invention discloses an intelligent special clamping sleeve joint assembling and disassembling tool. According to the assembling and disassembling tool, a middle fixing plate is installed at the front end of a lower cover plate; an upper cover plate is installed at the rear end of the lower cover plate; through holes are formed in the lower cover plate, the middle fixing plate and a sliding cover plate; the sliding cover plate is slidably installed on the middle fixing plate; four guide pulleys are arranged between the lower cover plate and the middle fixing plate; a fastening gear comprises two half gears which are oppositely arranged; a clamping space is formed between the two half gears; part of the peripheral surface of each half gear is in rolling fit with the corresponding guide pulley; a motor stator is fixedly installed between the upper cover plate and the lower cover plate; a motor rotor gear sleeves the peripheral side of the motor stator and is engaged with the fasteninggear; and a controller is used for controlling the motor stator and the motor rotor gear to rotate. According to the assembling and disassembling tool, the working efficiency can be improved, the operation threshold is lowered, the strict installation requirement can be easily met, and the clamping sleeve joints with different sizes and different fastening requirements can be fastened.

Owner:BEIJING PERIC HYDROGEN TECH

Fixing clamping bolt device for steelmaking vacuum groove

The invention discloses a fixing clamping bolt device for steelmaking vacuum groove. The device comprises a fixed clamping bolt, a movable cutting sleeve, a spherical washer and a high strength nut. The movable cutting sleeve is sleeved on the fixed clamping bolt; the movable cutting sleeve and the fixed clamping bolt are locked by the high strength nut; the spherical washer is arranged between the high strength nut and the movable cutting sleeve; and the spherical washer and the movable cutting sleeve are in spherical contact. The fixing clamping bolt device of the present invention does not oxidize or deform in high temperature, and is convenient for disassembly and replacement.

Owner:江苏三嘉矿冶设备有限公司

Dynamic seal component of finished cooler

The invention discloses a dynamic seal component of a finished cooler. The dynamic seal component comprises a cover plate, a spring, a corrugated pipe, a spring base, a first corrugated pipe base, a second corrugated pipe base, a seal base and a rotating ring, wherein one end of the spring is propped against the cover plate, and the other end is propped against the spring base; the first corrugated pipe base is arranged on the cover plate; the second corrugated pipe base is arranged on the seal base; one end of the corrugated pipe is connected onto the first corrugated pipe base, and the other end is connected onto the second corrugated pipe base; the spring base is integrally connected with the seal base through a thread; and the seal base is tightly contacted with the rotating ring. The service cycle of the dynamic seal component of the finished cooler can be prolonged, and cost is saved for a user.

Owner:四川锦宇装备有限公司

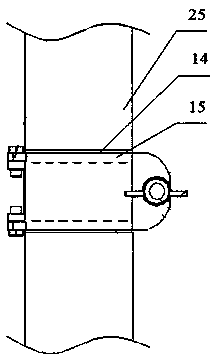

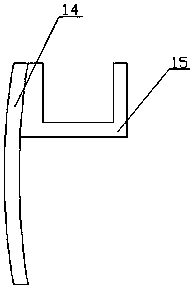

Sealing mechanism for tower tube sleeving type anti-corrosion device

InactiveCN108518313AAvoid enteringAvoid corrosionWind motor supports/mountsMachines/enginesEngineeringTower

The invention relates to a sealing mechanism for a tower tube sleeving type anti-corrosion device. The anti-corrosion device comprises a shell mechanism. The shell mechanism comprises an upper clamp body and a lower clamp body. The upper clamp body and the lower clamp body are arranged oppositely to form a cavity allowing a tower tube to be embedded therein. The sealing mechanism comprises sealingstrips arranged at the two side ends of the upper clamp body and the lower clamp body. The sealing strips comprise sealing portions a arranged on the end faces of the inner sides of the upper clamp body and the lower clamp body and sealing portions b arranged at the ends of the sealing portions a. Each sealing portion a is of an arc structure, and each sealing portion b is of a U-shaped structure. The side edges of the upper clamp body and the lower clamp body are embedded into the sealing portions b. The sealing mechanism has the advantages of being simple in structure, improving sealing performance and prolonging the service life of the tower tube.

Owner:南通汇金科技信息咨询服务有限公司

Large double-channel sealing valve not prone to deformation

The invention relates to the technical field of sealing valves, and discloses a large double-channel sealing valve not prone to deformation. The sealing valve comprises a sealing valve main body; valve body plates are arranged on two sides of one end of the sealing valve main body correspondingly; a rotating shaft part is mounted at one end of each valve body plate; each rotating shaft part is composed of a transmission shaft, a bearing seat, a bearing and a driving force arm; rotating connecting rods are arranged at one ends of the rotating shaft parts; one ends of the side walls of the valve body plates are fixedly connected with sealing parts; channels of the valve body plates are provided with installation grooves; the sealing parts are fixedly installed in the installation grooves; each sealing part is made of a flexible material with a metal protection layer; and a driving component of the large double-channel sealing valve is an electric actuator. According to the large double-channel sealing valve not prone to deformation, it is guaranteed that the sealing performance of the sealing valve is good, internal leakage is not larger than 0.1%, meanwhile, the large double-channel sealing valve has the advantages of being high in structural strength and not prone to deformation, it is guaranteed that ash deposition of the sealing valve does not cause improper opening and closing or jamming, the sealing valve can be manufactured according to the shape of the valve, and the area of a channel opening is guaranteed to the greatest extent.

Owner:YANGZHOU GAOBIAN MACHINE

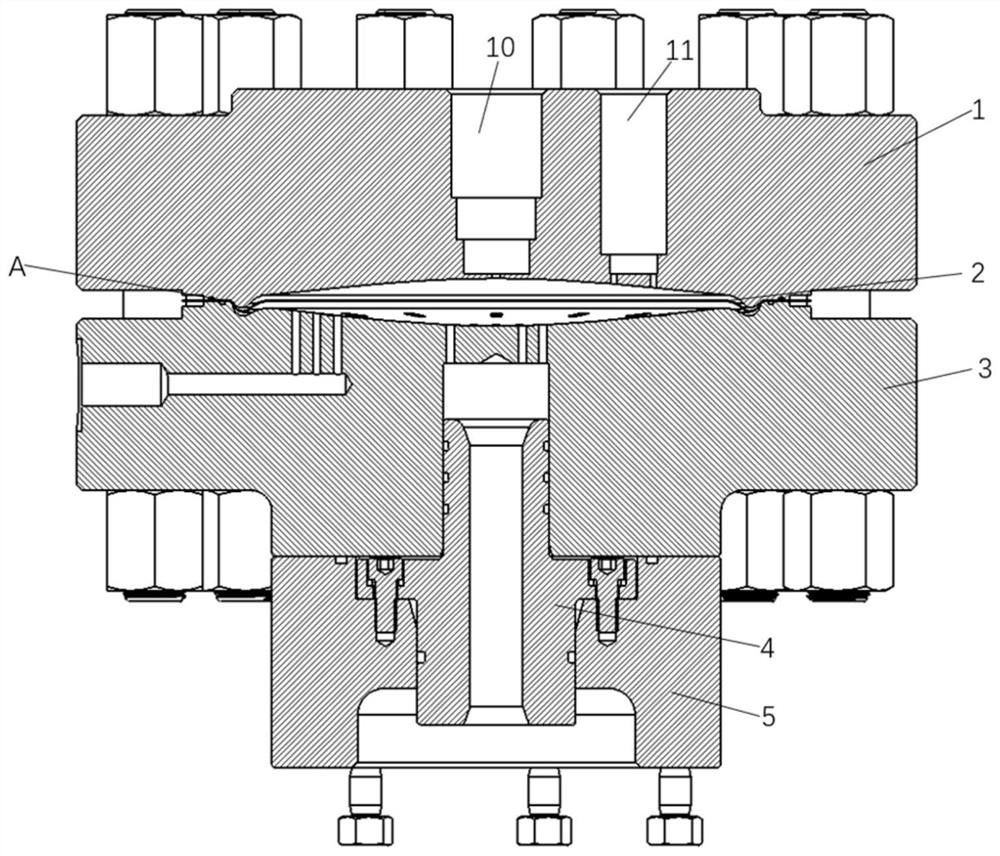

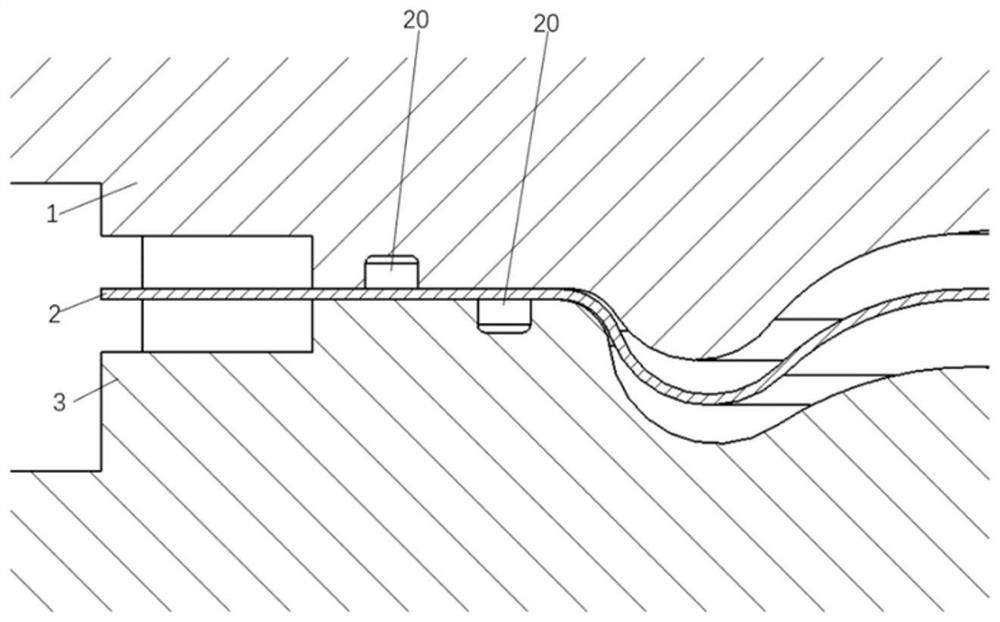

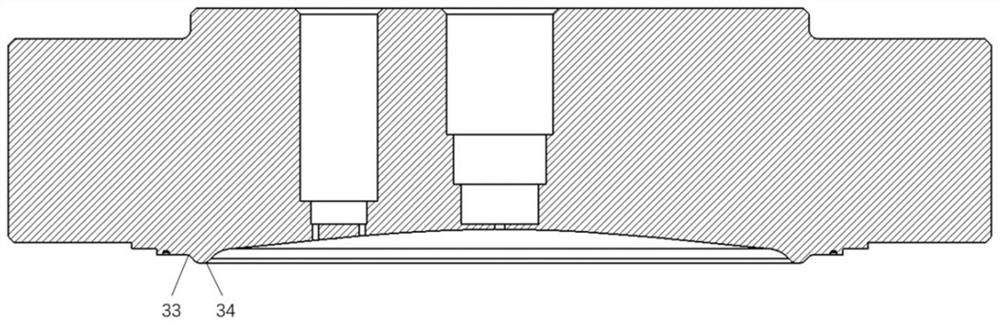

Curved diaphragm for diaphragm compressor

ActiveCN114810559ANo fatigue failureExtend your lifeFlexible member pumpsPositive-displacement liquid enginesCylinder blockMechanical engineering

The invention belongs to the technical field of diaphragm compressor equipment, and particularly relates to a curved diaphragm for a diaphragm compressor, which comprises a cylinder cover, a cylinder body, a cylinder sleeve and a cylinder sleeve support, the cylinder sleeve is connected with the cylinder sleeve support, the cylinder sleeve support is connected with the cylinder body, and the cylinder sleeve is arranged between the cylinder body and the cylinder sleeve support; the curved diaphragm is clamped between the cylinder cover and the cylinder body, an air side is formed between the concave side of the curved diaphragm and the cylinder cover, and an oil side is formed between the convex side of the curved diaphragm and the cylinder body; according to the invention, the punch-formed curved diaphragm is adopted, so that the maximum working stress of the curved diaphragm is kept below the allowable stress, the curved diaphragm does not generate fatigue failure, and the service life of the curved diaphragm is prolonged. The shapes of the curved surfaces of the cylinder body and the cylinder cover diaphragm cavities are in specific curve rotation, a motion space is reserved for the convex side, close to the edge, of the curved diaphragm, the elastic deformation of the curved diaphragm is increased, the volume of the diaphragm cavities is increased, and the displacement of the diaphragm compressor is improved.

Owner:CHINA AGRI UNIV

Test bench for low-pressure sealing test of nuclear power instrument valve

InactiveCN107328527AMeet the sealing requirementsAchieve clamping and fixingDetection of fluid at leakage pointSolenoid valvePinch valve

The invention provides a test bench for low-pressure sealing test of nuclear power instrument valves. The invention adjusts the temperature of the incubator through the heater and liquid nitrogen to meet the requirements of testing the sealing performance of valves at different temperatures. At the same time, the PLC controller is used , temperature sensor, pressure sensor, and solenoid valve to realize the automation of the test process and reduce the workload; through the first fixing piece, the second fixing piece, and the V-shaped block, the clamping and fixing of the valve is realized, and the valve is fixed in the four directions of up, down, left, and right at the same time , using the PLC controller and electric push rod to realize the intelligent operation of the fixed process, saving time and effort.

Owner:JIANGSU XINGHE VALVE

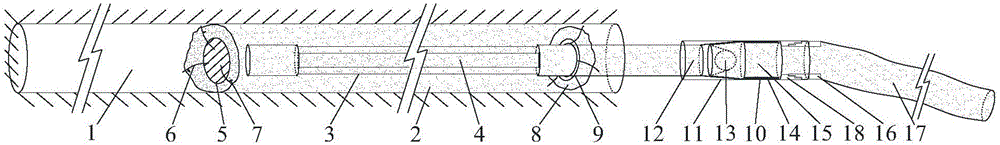

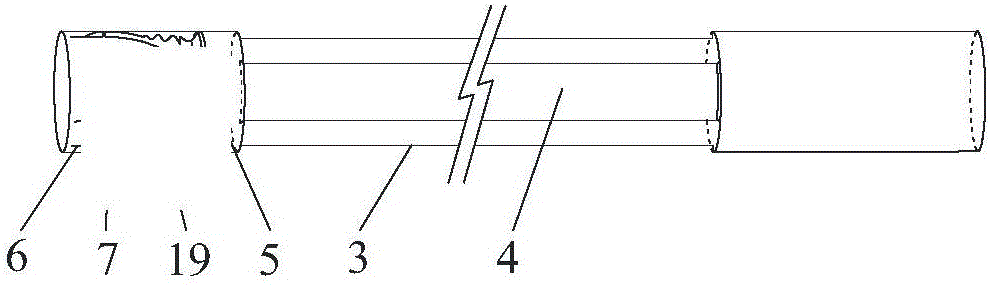

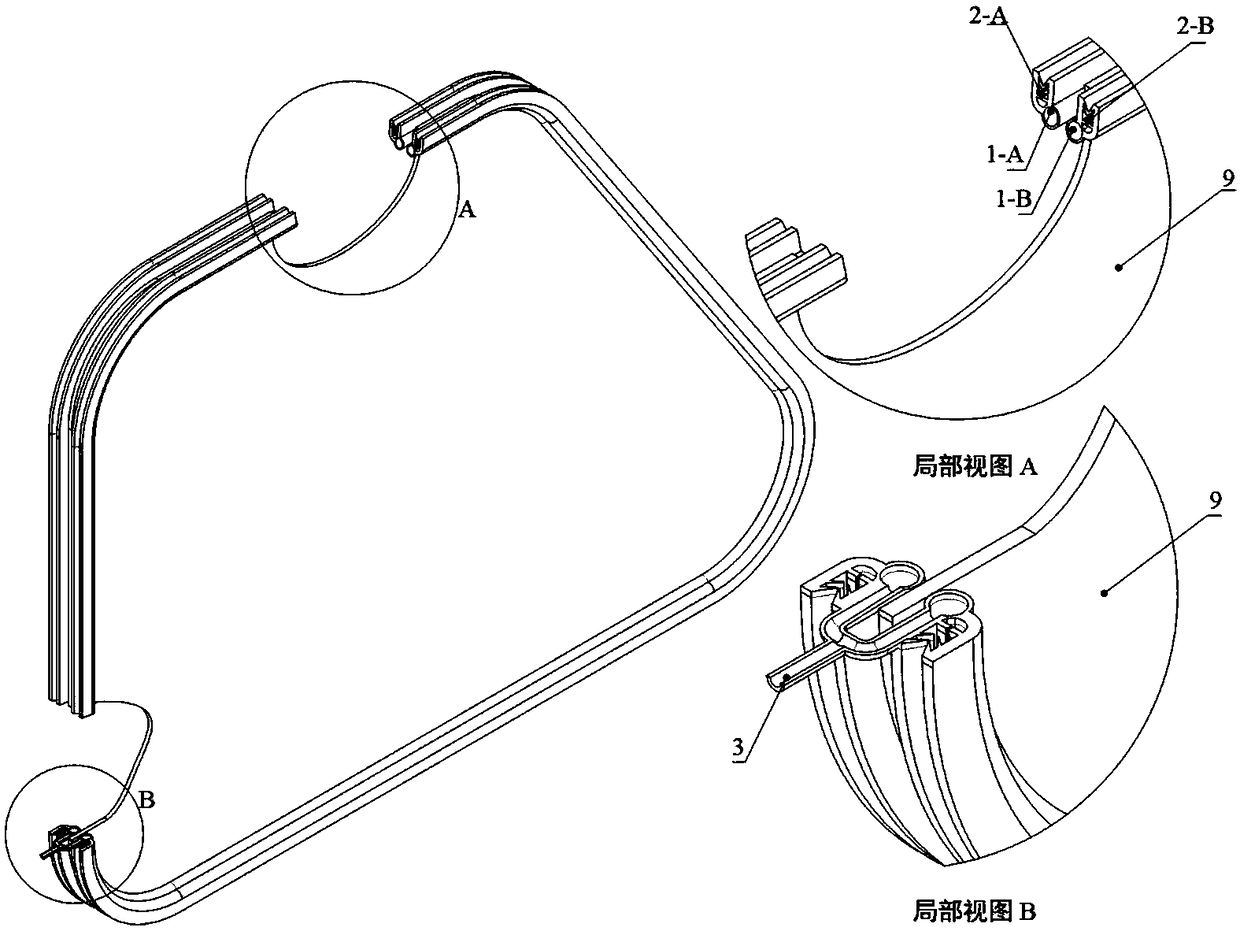

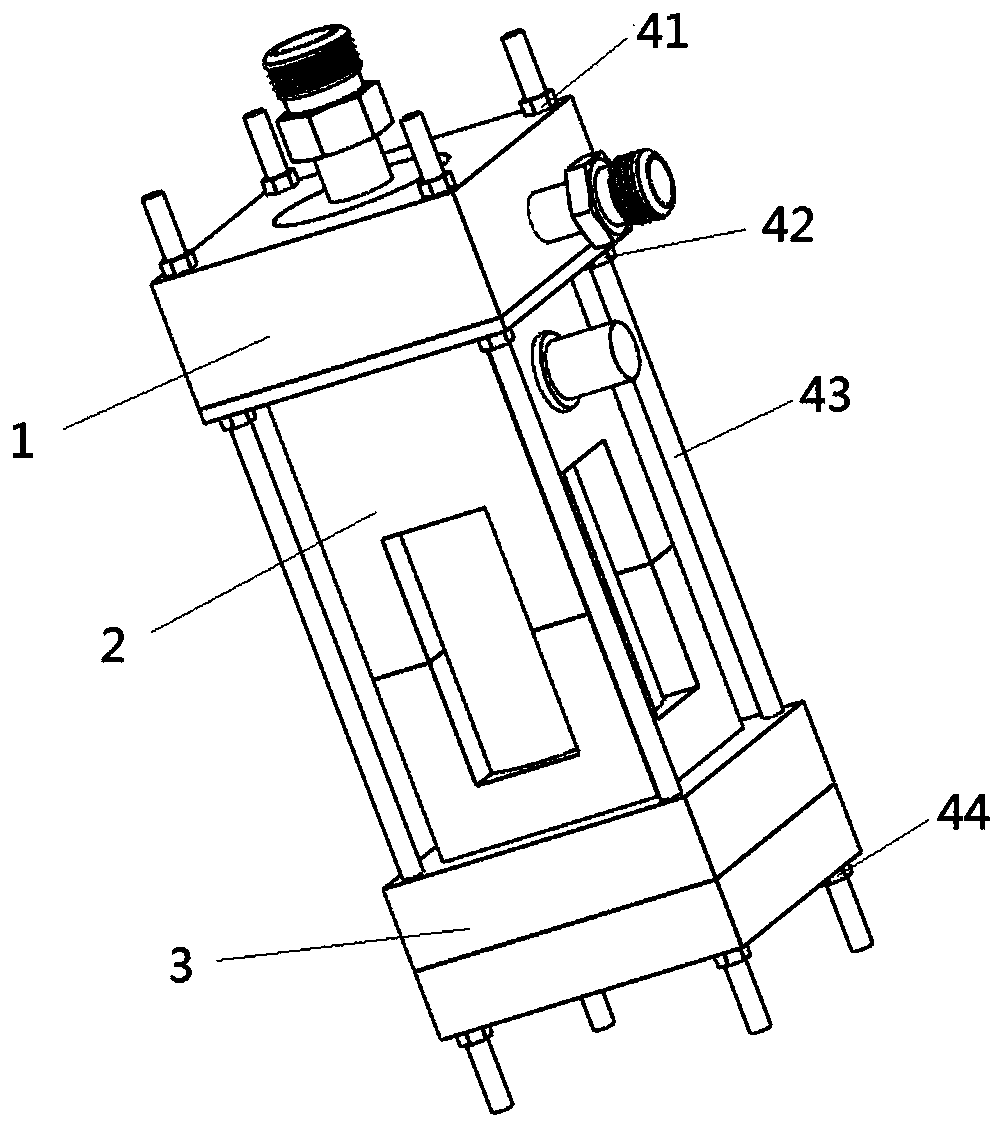

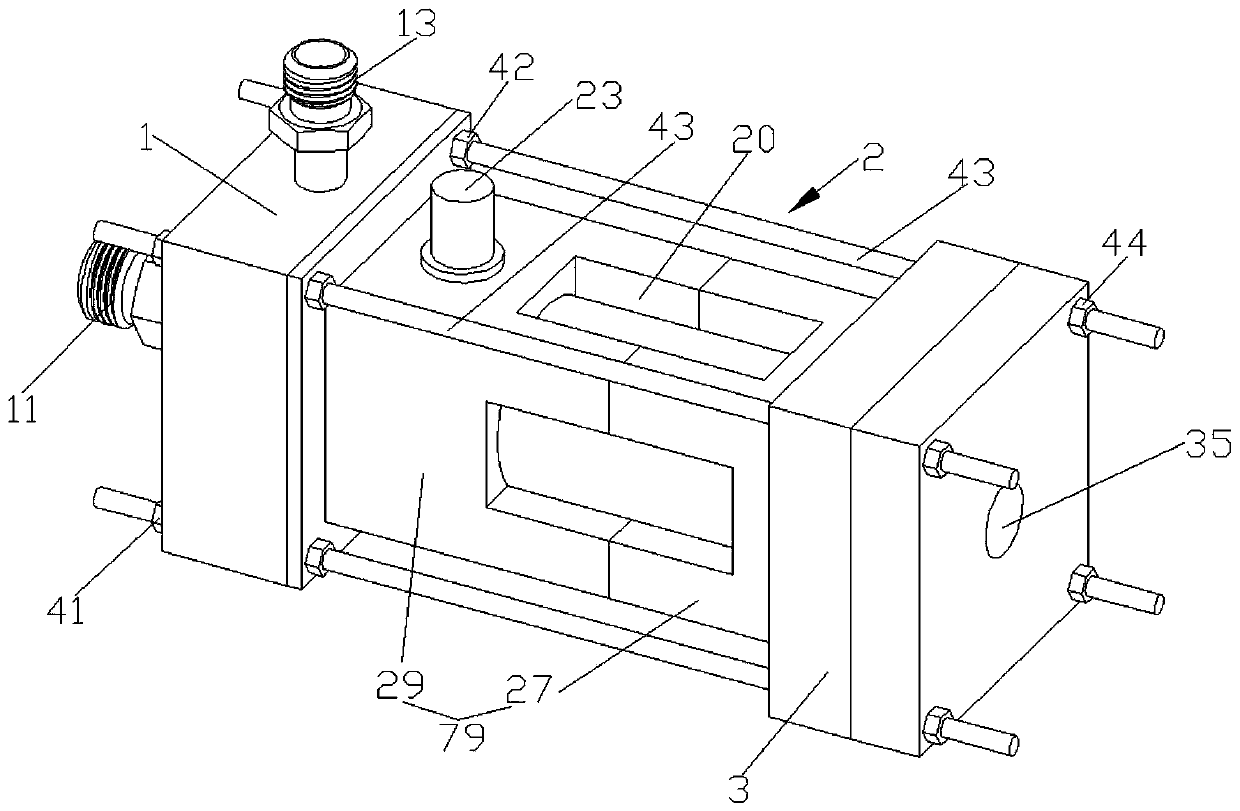

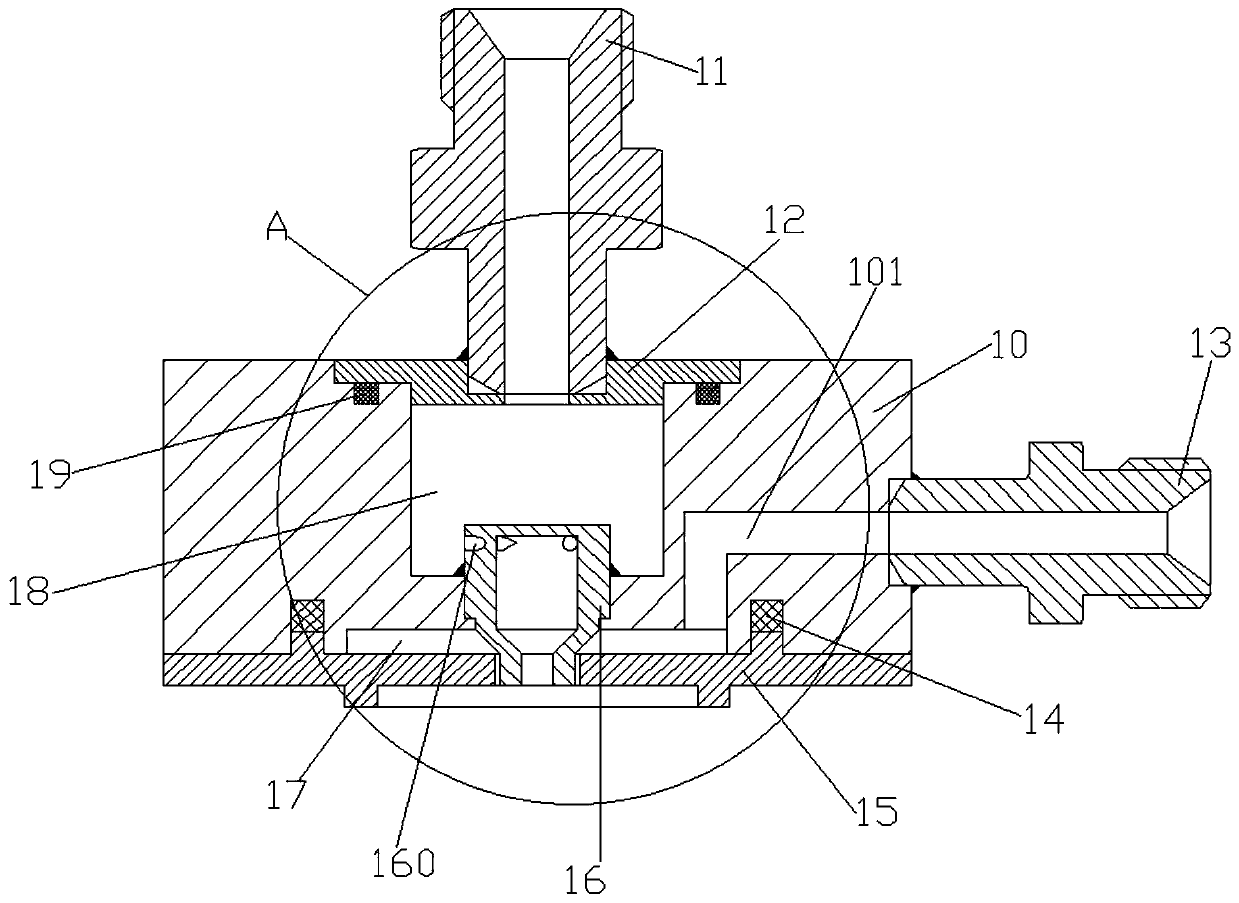

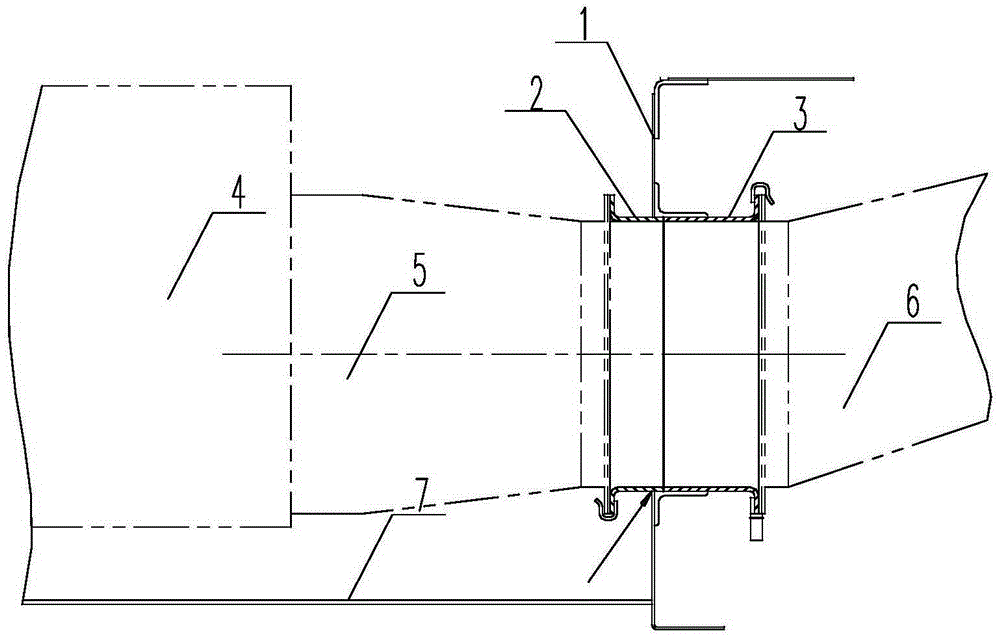

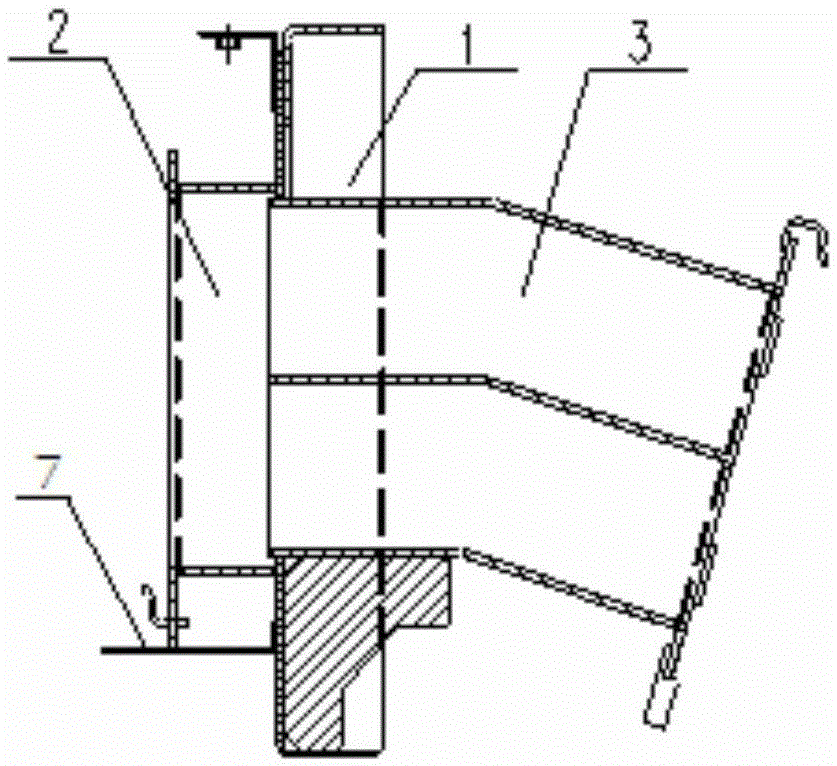

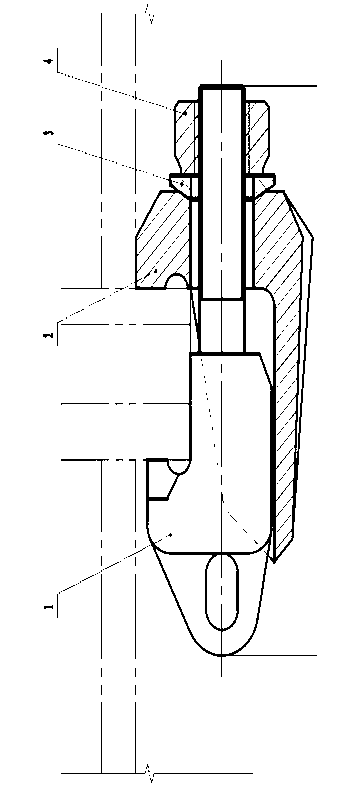

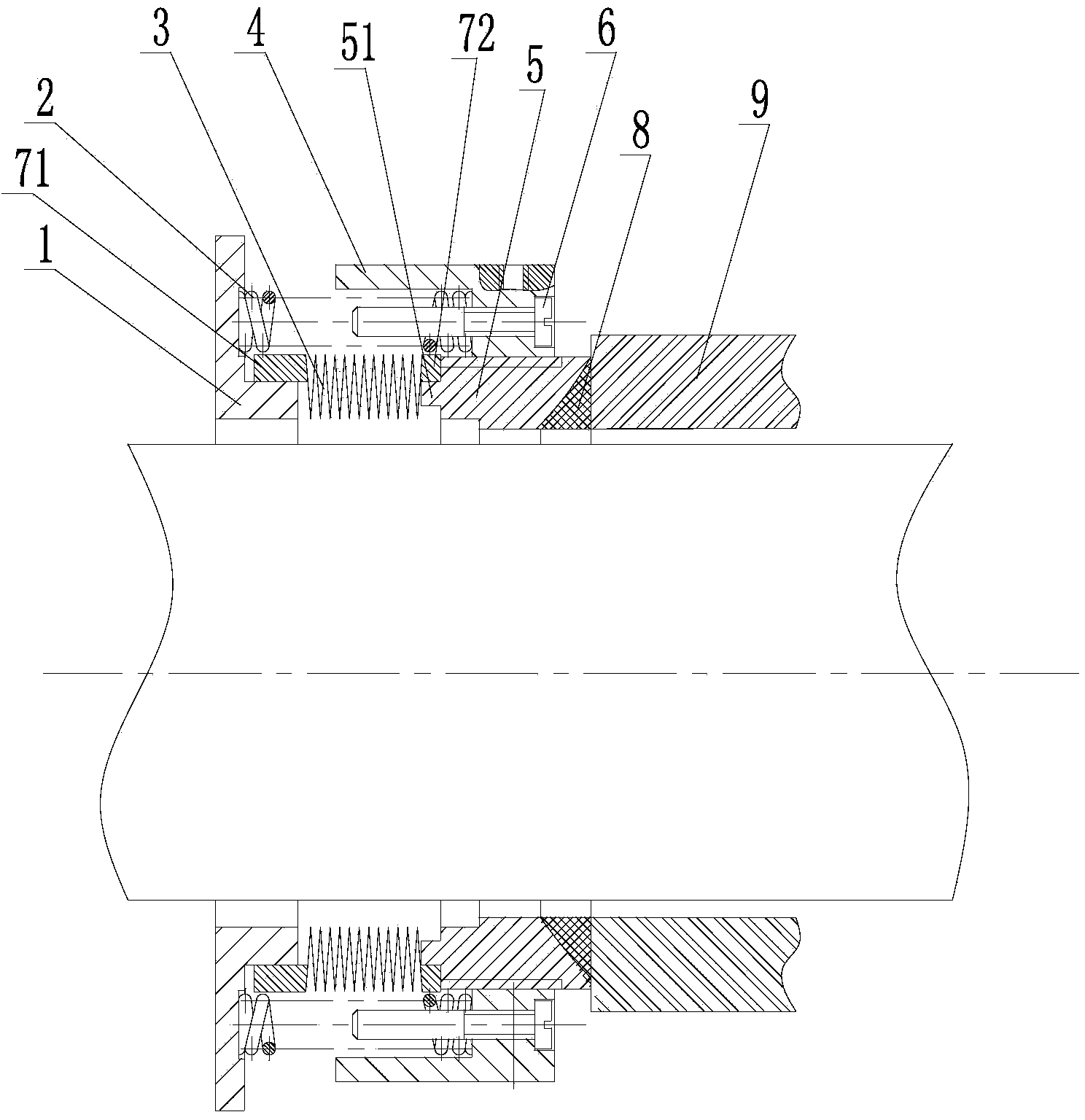

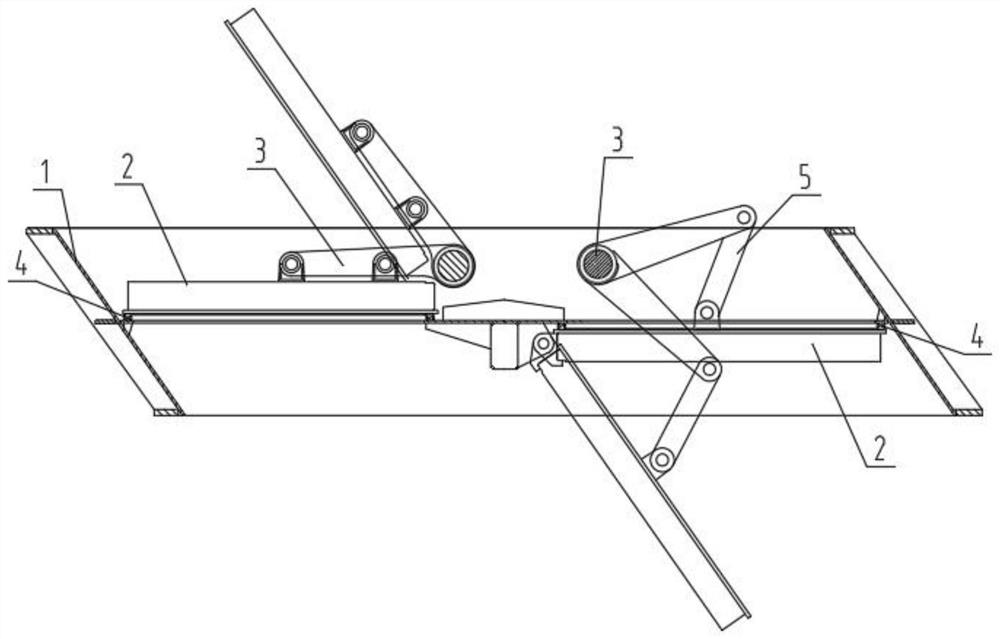

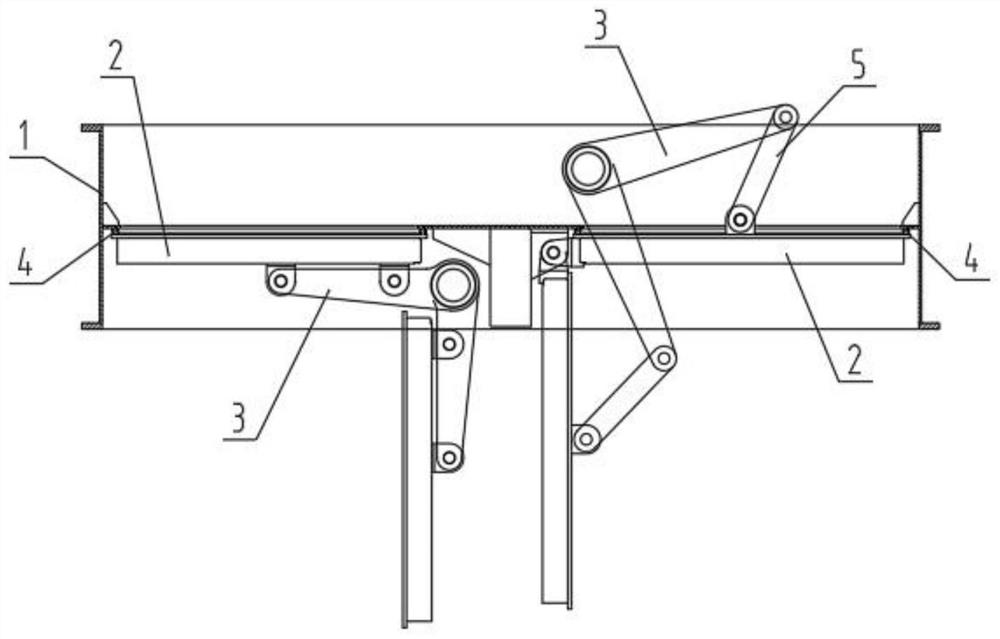

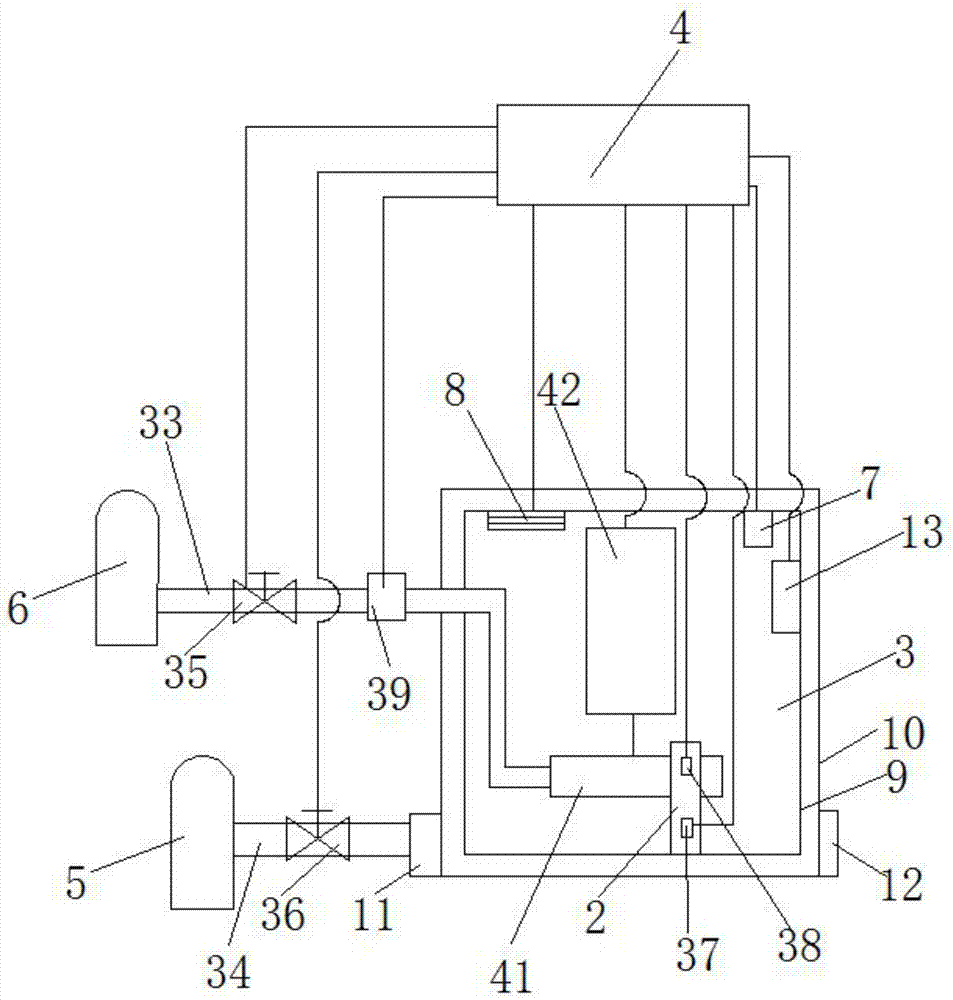

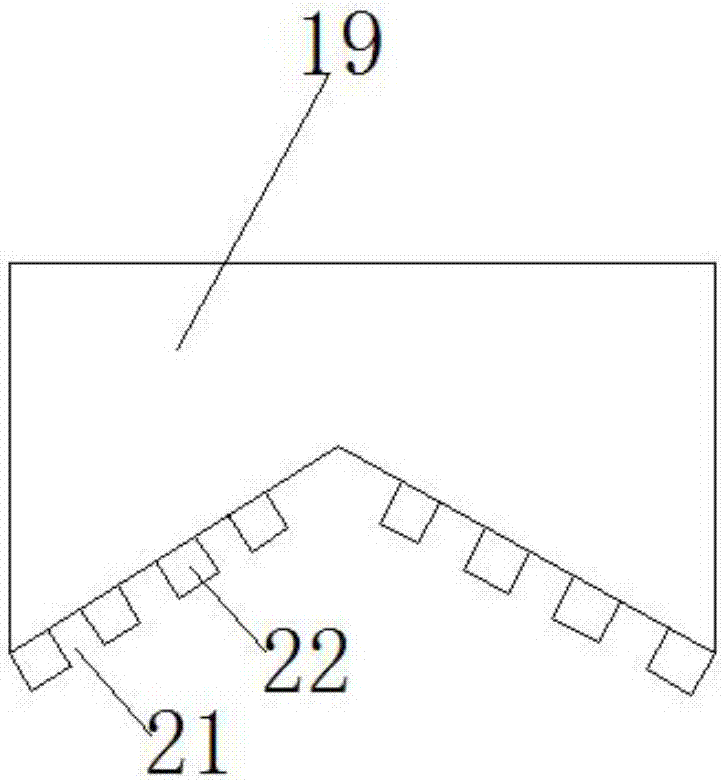

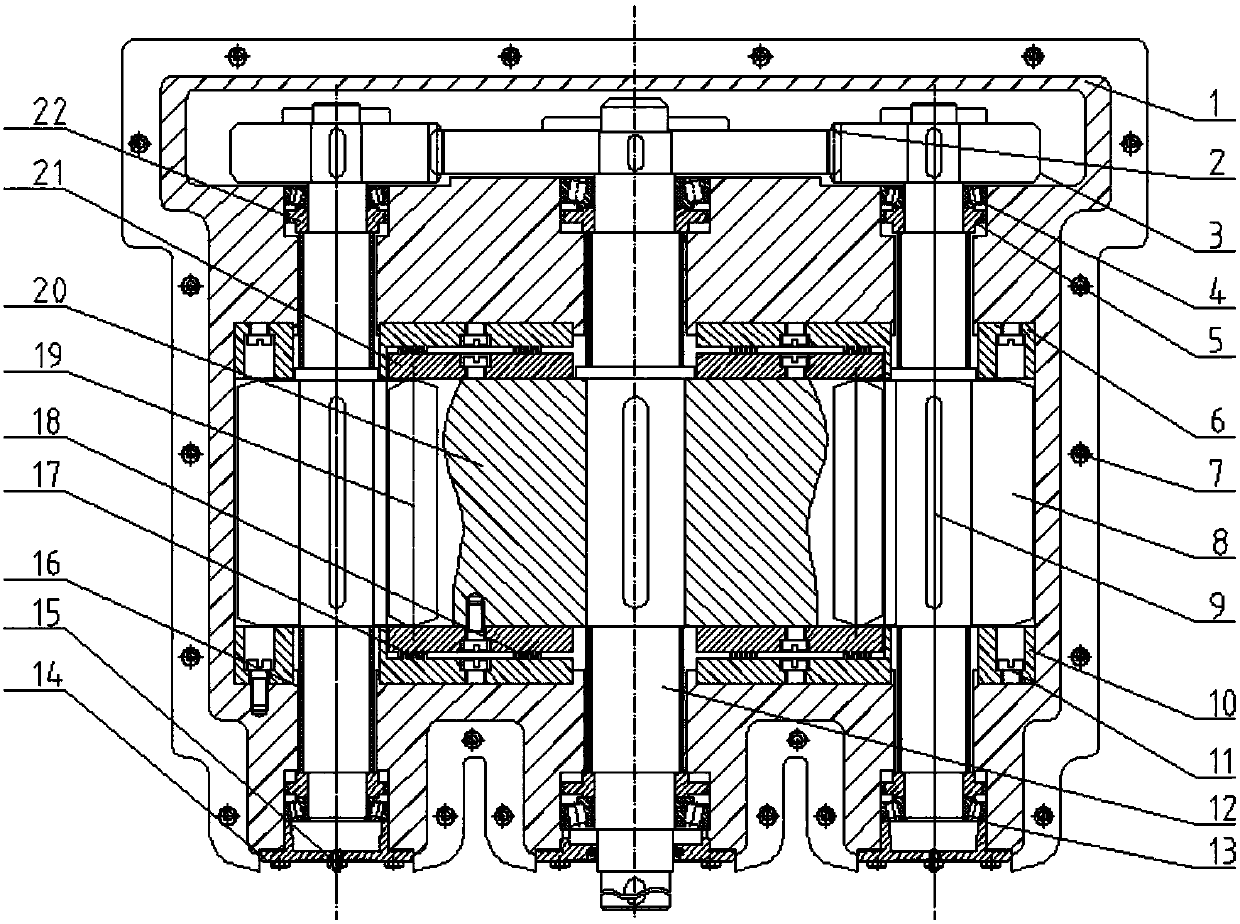

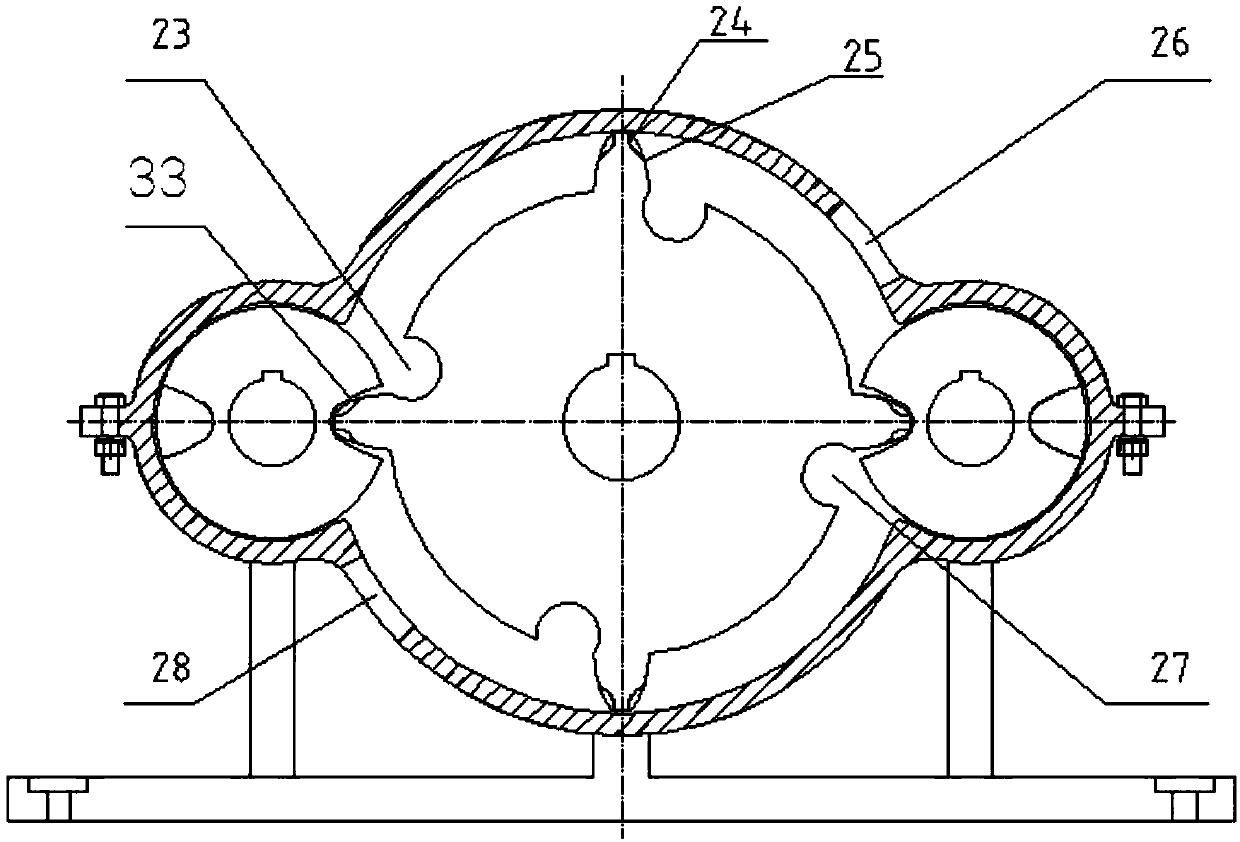

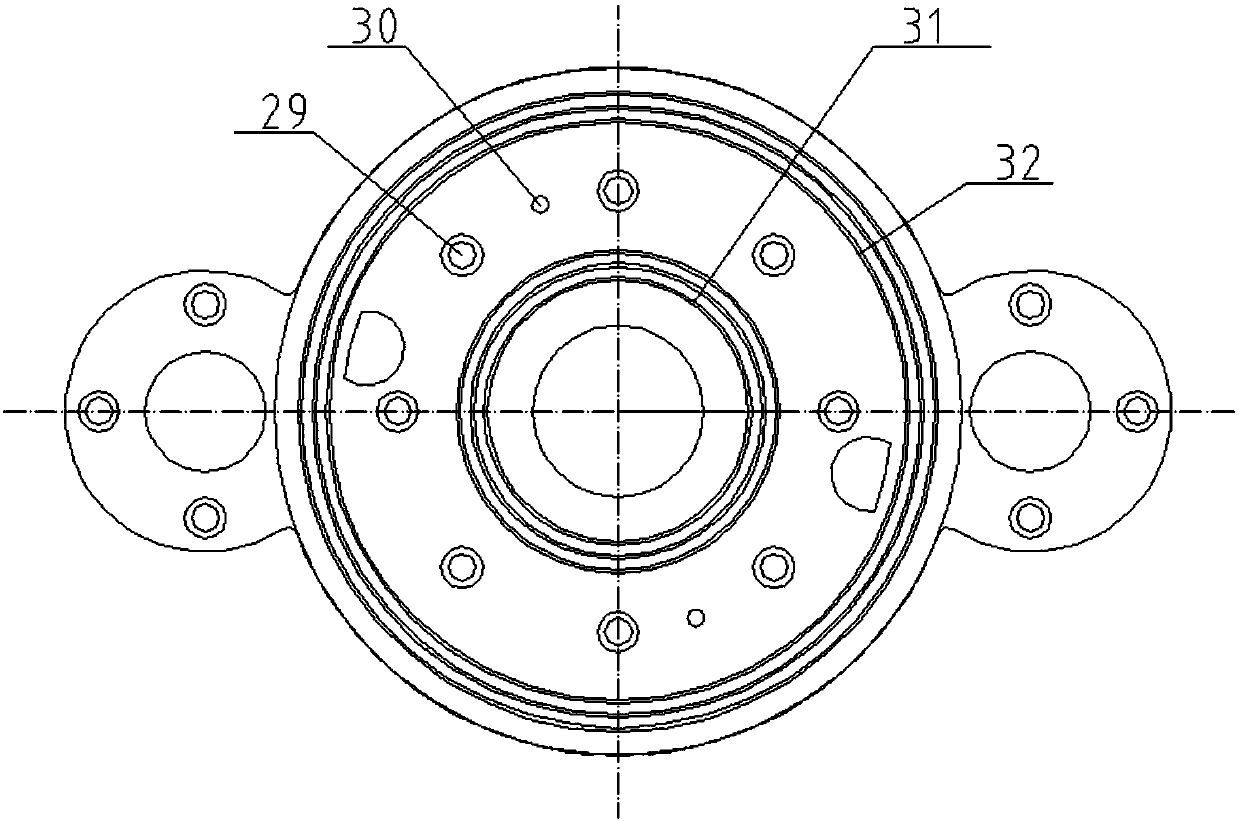

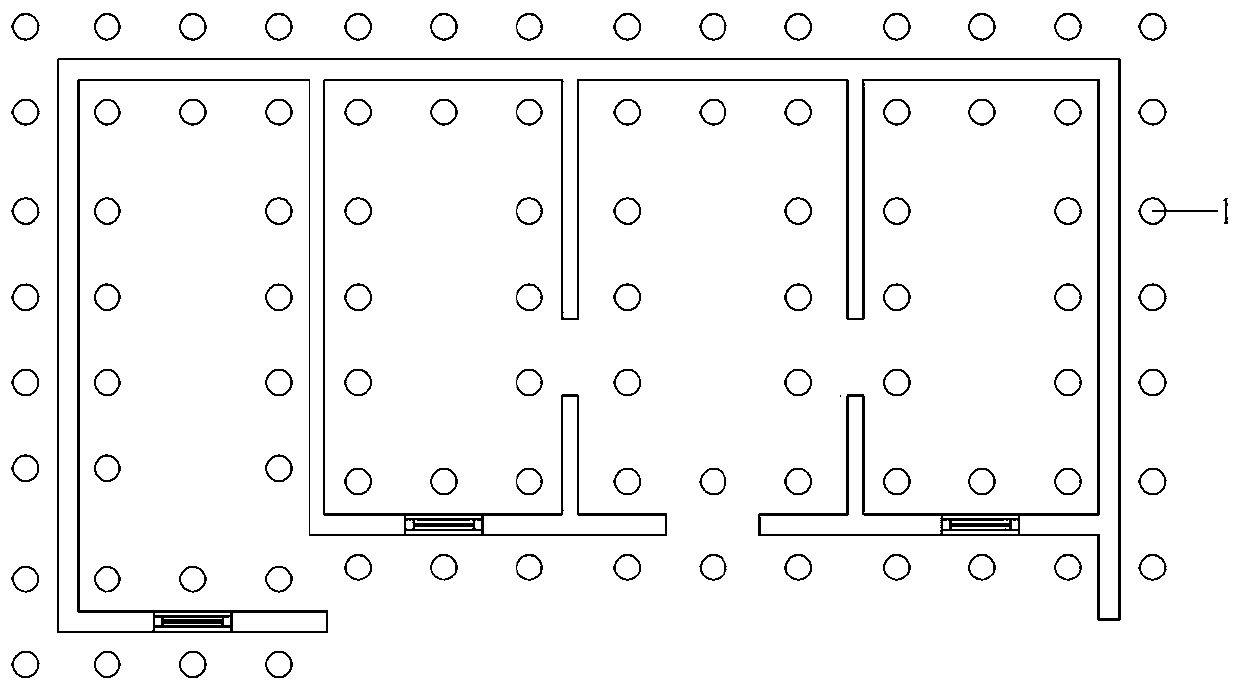

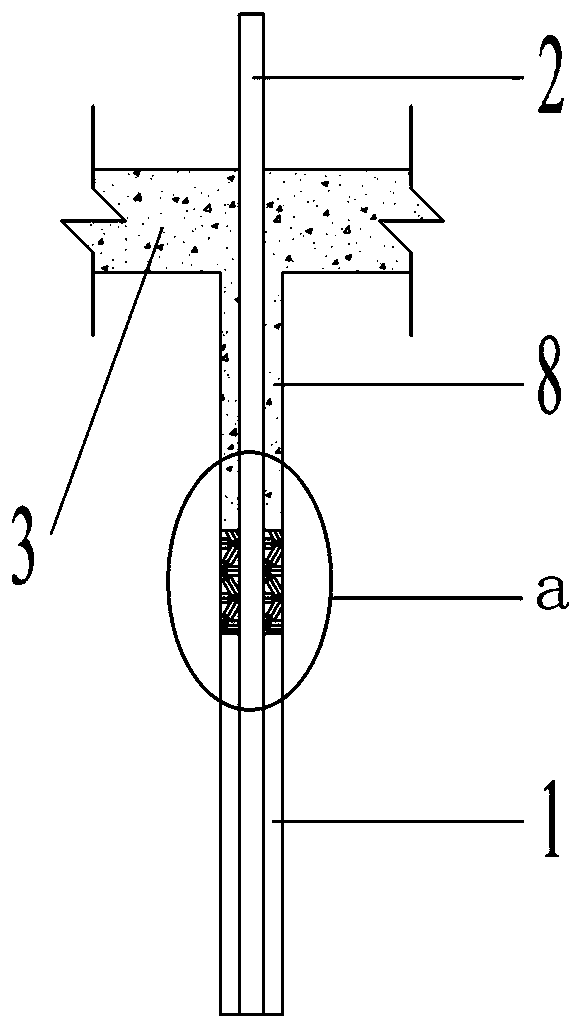

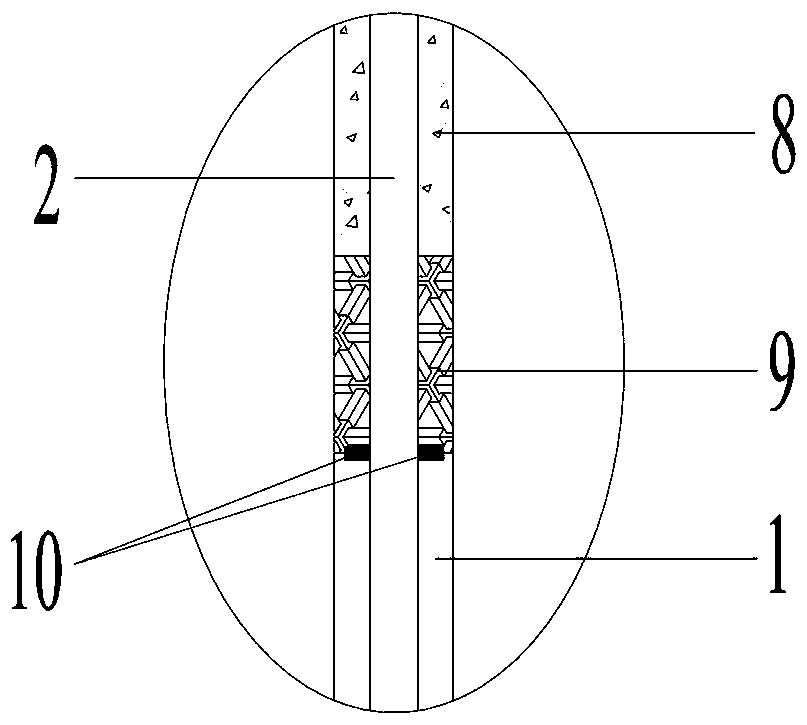

A combined sealing method and device for a continuous low temperature combustion rotary engine

ActiveCN106895151BOvercoming sealing problems during intake, combustion, and expansion processesRealize dynamic sealingEngine sealsSealing arrangements for enginesRotary engineCombined method

The invention discloses a combined sealing method and device for a continuous low-temperature combustion rotary engine. The combined sealing method and device are characterized in that the device comprises a continuous low-temperature combustion rotary engine shell (1), a main shaft timing gear (2), an auxiliary shaft timing gear (3), a right auxiliary shaft oil seal (5), an end face sealing hex socket (6), an auxiliary wheel (8), an auxiliary shaft (9), an end face seal (10), a main shaft (12), a bearing seal (16), an end face outer leakage sealing ring (17), an end face inner leakage sealing ring (18), a main shaft auxiliary gear matching part (19), a main shaft gear (20), an end face inner seal (21), a left auxiliary shaft oil seal (22), an upper air inlet (23), a main shaft gear protrusion groove (24), a main shaft gear protrusion (25), an upper exhaust port (26), a lower air inlet (27), a lower exhaust port (28), an end face sealing installation hole (29), an end face sealing positioning pin (30), an end face inner leakage sealing groove (31), an end face outer leakage sealing groove (32) and an auxiliary wheel groove (33). By means of the scheme, the sealing problem in the air intake, combustion and expansion processes of the novel continuous combustion low-temperature rotary engine is solved, due to axial sealing and radial sealing and meanwhile by the adoption of a non-contact combined sealing technology, movable sealing of the whole system can be achieved, and the sealing requirement is met.

Owner:HUNAN UNIV

Hole sealing structure for reinforcing shallow foundation through grouting method and construction technology thereof

The invention discloses a hole sealing structure for reinforcing a shallow foundation through a grouting method and a construction technology of the hole sealing structure, and belongs to the field ofshallow foundation reinforcing. The problem that sealing of a shallow foundation grouting hole is unreasonable is solved. The hole sealing structure comprises a grouting stop plate, grouting stop ribs, grouting holes, a hole sealing positioning belt and hole sealing concrete, the grouting holes penetrate through the grouting stop plate and an outdoor grouting stop plate to be evenly distributed on the two sides of a foundation wall, a positioning device is fixed to the grouting pipe so as to determine the position of the hole sealing positioning belt, the outdoor grouting stop plate is linearly arranged along the outer wall of the foundation wall, and the grouting stop ribs are embedded into foundation soil along the outdoor grouting stop plate. The construction technology of the hole sealing structure comprises the steps of early-stage preparation, foundation ditch excavation, drilling, grouting pipe installation and hole sealing. The grouting stop effect is good, construction is easy and convenient, shallow foundation bearing capacity and stability are greatly improved, the construction cost is low, and economic benefits are remarkable.

Owner:ZHENGZHOU UNIV

Double seal mud valve with flushing function

ActiveCN104343995AImprove sealingMeet the sealing requirementsOperating means/releasing devices for valvesLift valveWater sourceHigh pressure water

The invention discloses a double seal mud valve with a flushing function. The double seal mud valve is characterized in that an oblique sealing surface is arranged in a flow channel of a valve body, and a cylindrical sealing surface is arranged between the bottom surface of an inner cavity of the valve body and the oblique sealing surface; the lower end of a valve rod is fixedly provided with an upper valve clack and a lower valve clack, and a water injection hole is formed in the center of the valve rod; a plurality of flushing holes are formed in the lower end of the valve rod in the horizontal direction, and the upper end of the water injection hole is communicated with a high-pressure water source; the lower end of the water injection hole is communicated with the flushing holes, and the flushing holes are distributed between the upper valve clack and the lower valve clack; the upper valve clack is of an arc-shaped structure, and the diameter of a biggest part of an excircle of the arc is equal to the diameter of the cylindrical sealing surface in the flow channel; the lower end of the lower valve clack is provided with an arc-shaped sealing surface, and the arc-shaped sealing surface and the oblique sealing surface in the flow channel form a tangent seal; a vertical distance between the biggest part of the excircle of the upper valve clack and the arc-shaped sealing surface at the lower end of the lower valve clack is 0.6 to 0.8 times larger than the height of the cylindrical sealing surface in the flow channel. The double seal mud valve provided by the invention is ingenious in structure; when the valve is closed, multiple seals are realized, the sealing performance is good, and the service life is long.

Owner:深圳市善德环境(集团)有限公司

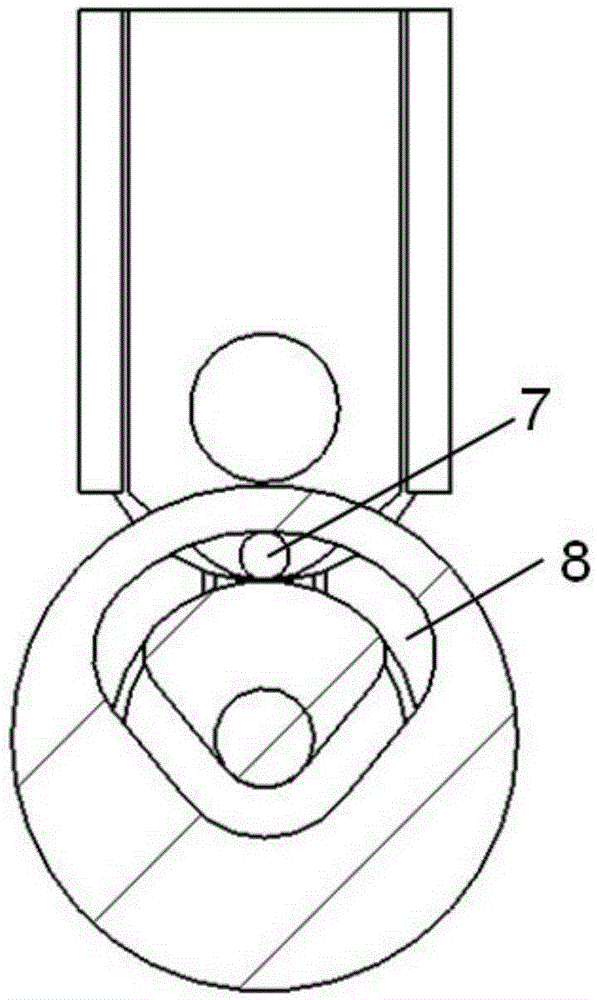

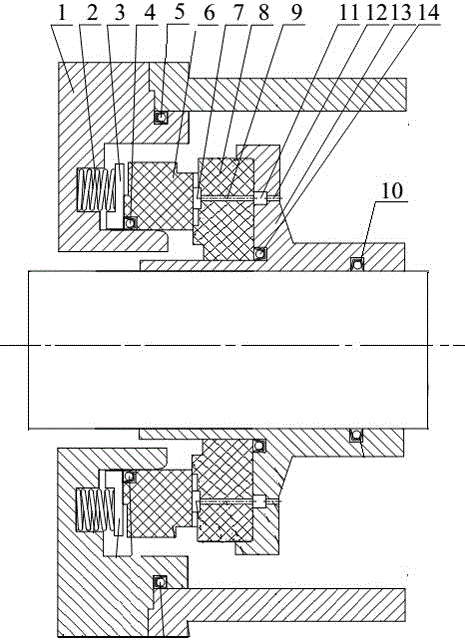

Self-lubricating contact device for low-temperature liquid pump and using method of self-lubricating contact device

InactiveCN106089692ARealize self-drainageReduce frictional heatPositive displacement pump componentsLiquid fuel engine componentsFluid film lubricationEngineering

The invention relates to a self-lubricating contact device for a low-temperature liquid pump and a using method of the self-lubricating contact device. According to the technical scheme adopted by the invention, a pressure cover is connected to a static ring through a pushing plate; the right side of the static ring is in contact fit to a rotary ring; a circular-ring-shaped slot body is formed in the end surface, which is fitted to the static ring, of the rotary ring; a plurality of drainage channels are formed inside the circular-ring-shaped slot body; a sunken high-pressure dynamic pressure slot and a sunken low-pressure dynamic pressure slot are separately formed in the two sides of the circular-ring-shaped slot body; and the circular-ring-shaped slot body communicates with the sunken high-pressure dynamic pressure slot and the sunken low-pressure dynamic pressure slot. The self-lubricating contact device has the beneficial effects that: the drainage channels are rotatably arranged in the rotary ring for directly introducing a sealed medium into the contact end surface in a self-drainage mode; under the fluid static-pressure effect and the guide effect of the circular-ring-shaped slot body, the contact end surface is in a full fluid-film lubrication state, so that friction heat generated by the end surface is greatly reduced; besides, the high-pressure dynamic pressure slot and the low-pressure dynamic pressure slot with V-shaped structures or spiral structures are adopted, no leakage is further ensured, so that stability of a power device is improved.

Owner:魏宇坤

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com