Process method for preparing static ring used for ship tail shaft sealing and lubricating

A process method and stern shaft technology are applied in the field of preparing static rings for sealing and lubricating the stern shaft of ships, which can solve the problems of easy deformation, poor heat resistance, unsuitable for use in large ships, etc., and achieve excellent lubrication and wear resistance and mechanical properties. , good mechanical properties and lubricating properties, the effect of large-scale stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

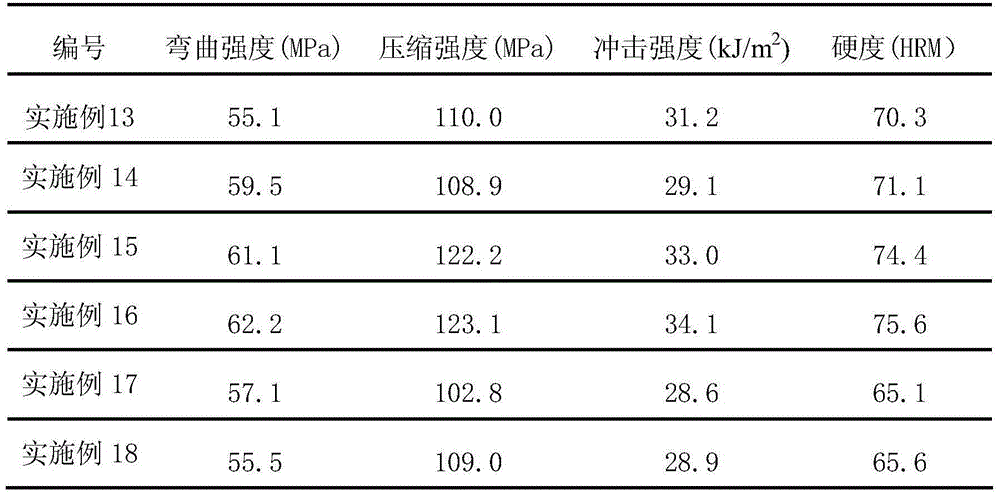

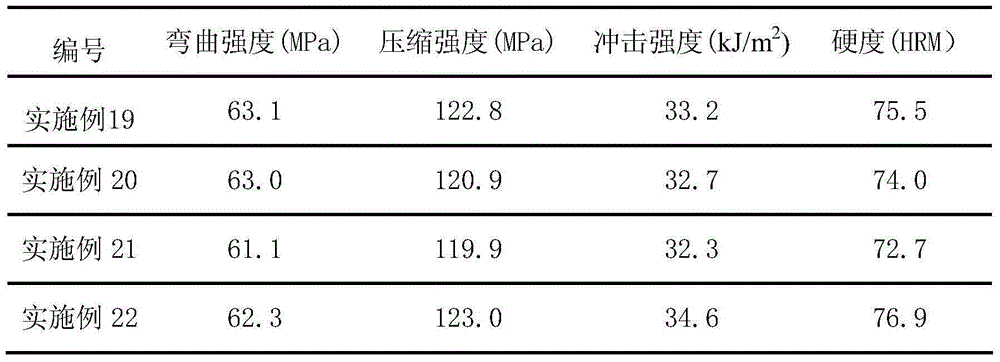

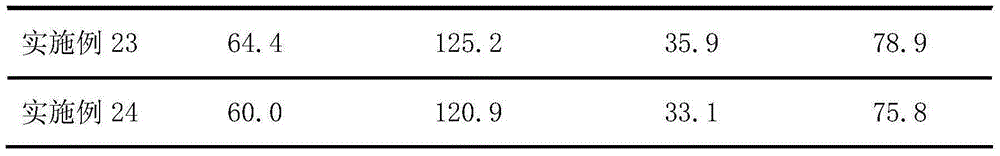

Examples

Embodiment 1

[0056] Dissolve 200g of phenolic resin PF6290A in 1L ethanol solvent, add silane coupling agent 3-aminopropyltriethylsilane KH-550 according to 0.5% of the weight of phenolic resin, mix well to obtain a mixed solution, soak continuous long fibers (600d) After soaking in the mixed solution, take it out, place it in an oven and dry it at 60°C to obtain reinforced long fibers impregnated with glue.

[0057] Configure the titanate coupling agent LD-144 into an ethanol solution with a solid content of 1%, and spray the titanate coupling agent ethanol solution while stirring the inorganic filler talc powder and dolomite powder at high speed in a high-speed disperser, per kilogram Spray 20mL of the inorganic filler, dry it in an oven at 90°C, and redisperse it with a high-speed disperser to obtain the activated inorganic filler.

[0058] Put the staple aramid fibers (5mm) in the mixer to loosen them, then spray the silane coupling agent KH-550 in ethanol solution with a solid content...

Embodiment 2

[0063] Dissolve 250g of phenolic resin PF6290A in 1L ethanol solvent, add silane coupling agent 3-aminopropyltriethylsilane KH-550 according to 1% of the weight of phenolic resin, mix well to obtain a mixed solution, soak continuous long fibers (400d) After soaking in the mixed solution, take it out, place it in an oven and dry it at 70°C to obtain reinforced long fibers impregnated with glue.

[0064] Configure the titanate coupling agent LD-144 into an ethanol solution with a solid content of 5%, and spray the titanate coupling agent ethanol solution while stirring the inorganic filler talc powder at a high speed in a high-speed disperser. 30mL, dried in an oven at 80°C, and re-dispersed with a high-speed disperser to obtain activated inorganic fillers.

[0065] The short fiber jute fiber (3mm) is placed in the mixer to open, and then in the still, spray silane coupling agent KH-550 solid content and be the ethanol solution of 0.8%, every kilogram of short fiber sprays 40mL,...

Embodiment 3

[0070] Dissolve 350g of phenolic resin PF6290A in 1L ethanol solvent, add silane coupling agent 3-aminopropyltriethylsilane KH-550 according to 1.5% of the weight of phenolic resin, mix well to obtain a mixed solution, soak continuous long fibers (800d) After soaking in the mixed solution, take it out, place it in an oven and dry it at 70°C to obtain reinforced long fibers impregnated with glue.

[0071] Configure the titanate coupling agent LD-144 into an ethanol solution with a solid content of 10%, and spray the titanate coupling agent ethanol solution while stirring the inorganic filler dolomite powder at a high speed in a high-speed disperser. 50mL, dried in an oven at 70°C, and re-dispersed with a high-speed disperser to obtain activated inorganic fillers.

[0072] Put short-fiber aramid fiber (1mm) in the mixer to loosen, then spray silane coupling agent KH-550 ethanol solution with a solid content of 1.5% into the kettle, spray 30mL per kilogram of short fiber, and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com