Double seal mud valve with flushing function

A technology of double sealing and mud discharge valve, which is applied in the direction of valve lift, valve details, valve device, etc. It can solve the problems that the valve cannot be sealed and the sealing surface of the valve body cannot be pressed, so as to achieve the effect of good sealing and enhanced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

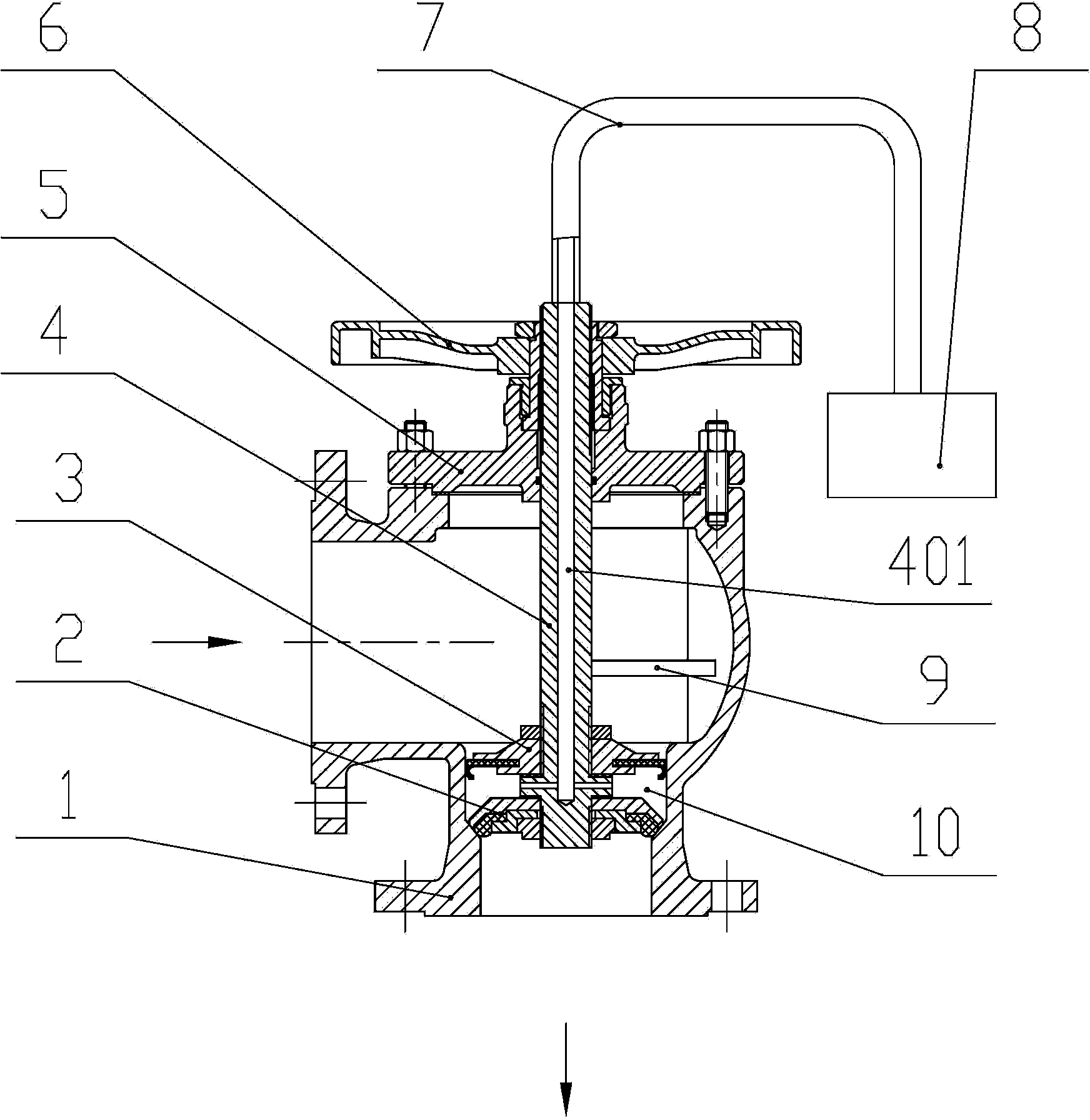

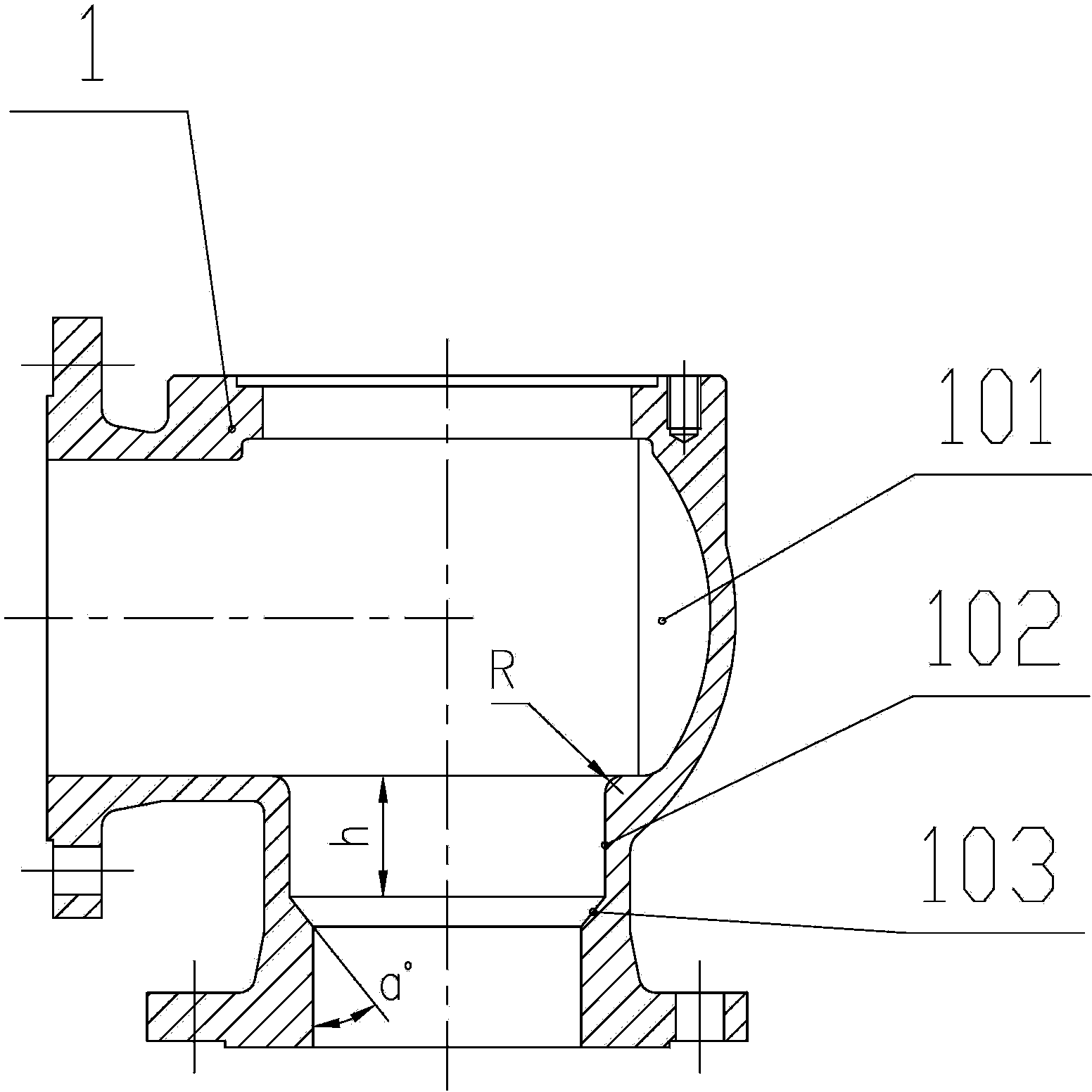

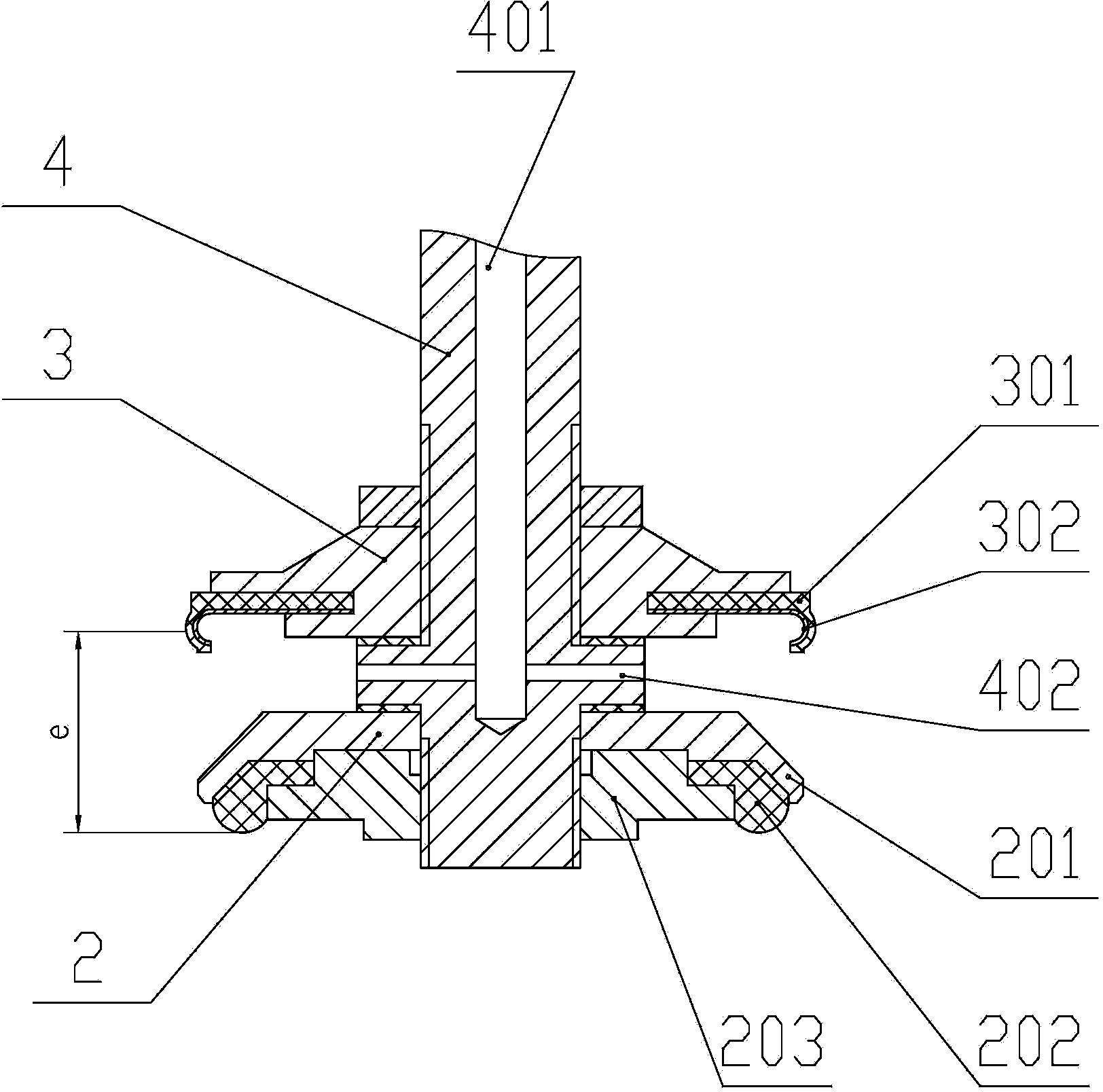

[0015] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. The flushing double-seal mud discharge valve includes a valve body 1, a lower disc 2, an upper disc 3, a valve stem 4 and a valve cover 5. The valve cover 5 is installed on the top of the valve body 1, and the upper part of the valve body 1 is provided with Inner cavity, the lower part of the valve body 1 is provided with a flow channel for medium circulation, and the inner cavity is provided with an anti-rotation groove 101. The valve stem 4 passes through the valve cover 5 and the inner cavity of the valve body 1 and enters the flow channel. The middle part is provided with an anti-rotation pin 9, and the other end of the anti-rotation pin 9 extends into the anti-rotation groove 101 to prevent the rotation of the valve stem 4. An inclined sealing surface 103 is provided in the flow channel of the valve body 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com