Patents

Literature

41results about How to "Realize dynamic sealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sealing device and bearing box system

PendingCN110081177AImprove reliabilityGuaranteed service lifeEngine sealsBearing unit rigid supportHuman healthMagnetic line

The invention provides a sealing device and a bearing box system. The device is installed in a bearing cavity which is provided with a shaft, a bearing and a shaft sleeve, wherein the bearing and theshaft sleeve are arranged outside the shaft in a sleeving mode, the shaft sleeve abuts against the end surface of the bearing, and the shaft sleeve is made of a magnetic material; the sealing device comprises a first magnetic conductor, a permanent magnet and a second magnetic conductor; the first magnetic conductor, the permanent magnet and the second magnetic conductor are arranged outside the shaft sleeve in a sleeving mode, the first magnetic conductor abuts against the end surface, the permanent magnet is clamped between the first magnetic conductor and the second magnetic conductor, andthe permanent magnet, the first magnetic conductor, the shaft sleeve and the second magnetic conductor are matched to form a closed magnetic line; and gaps are formed between the outer wall of the shaft sleeve and the inner wall of the first magnetic conductor and between the outer wall of the shaft sleeve and the inner wall of the second magnetic conductor, and pole teeth are arranged on the inner wall of the first magnetic conductor and the inner wall of the second magnetic conductor, and the gaps and the pole teeth are all filled with magnetic fluid. The embodiment of the sealing device caneffectively ensure the sealing effect on the bearing cavity, thereby avoiding environmental pollution and harm to human health.

Owner:BEIJING UNIV OF CHEM TECH

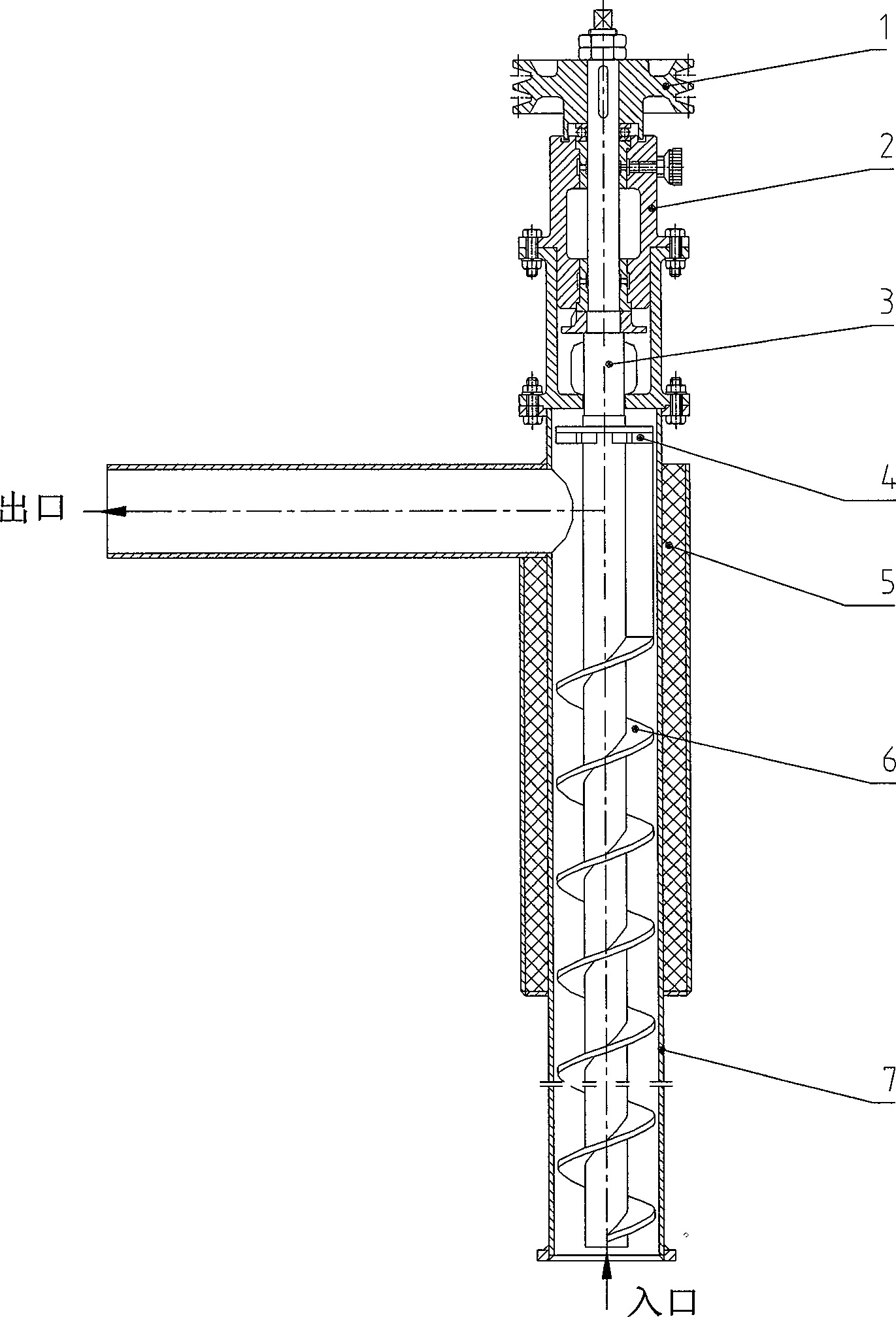

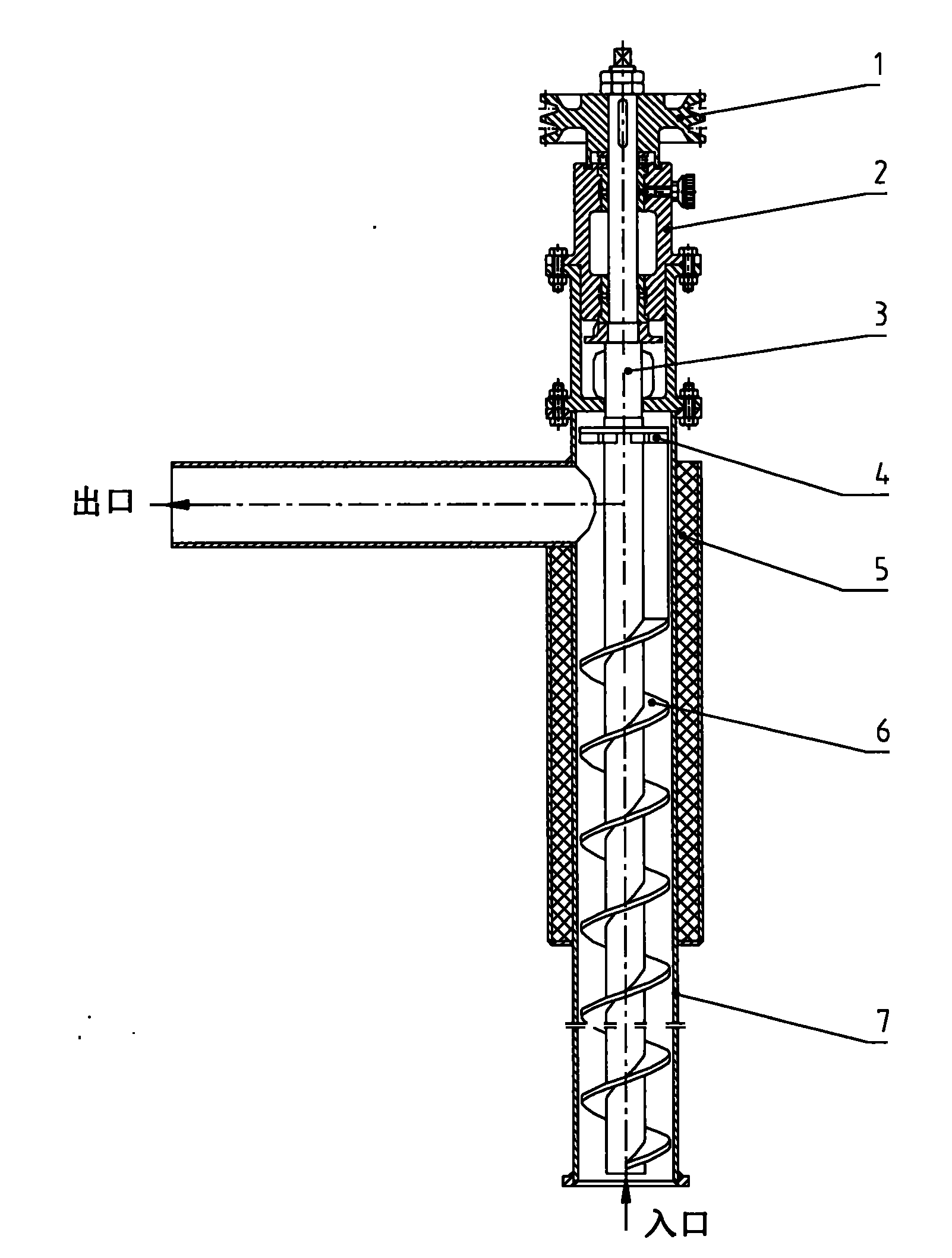

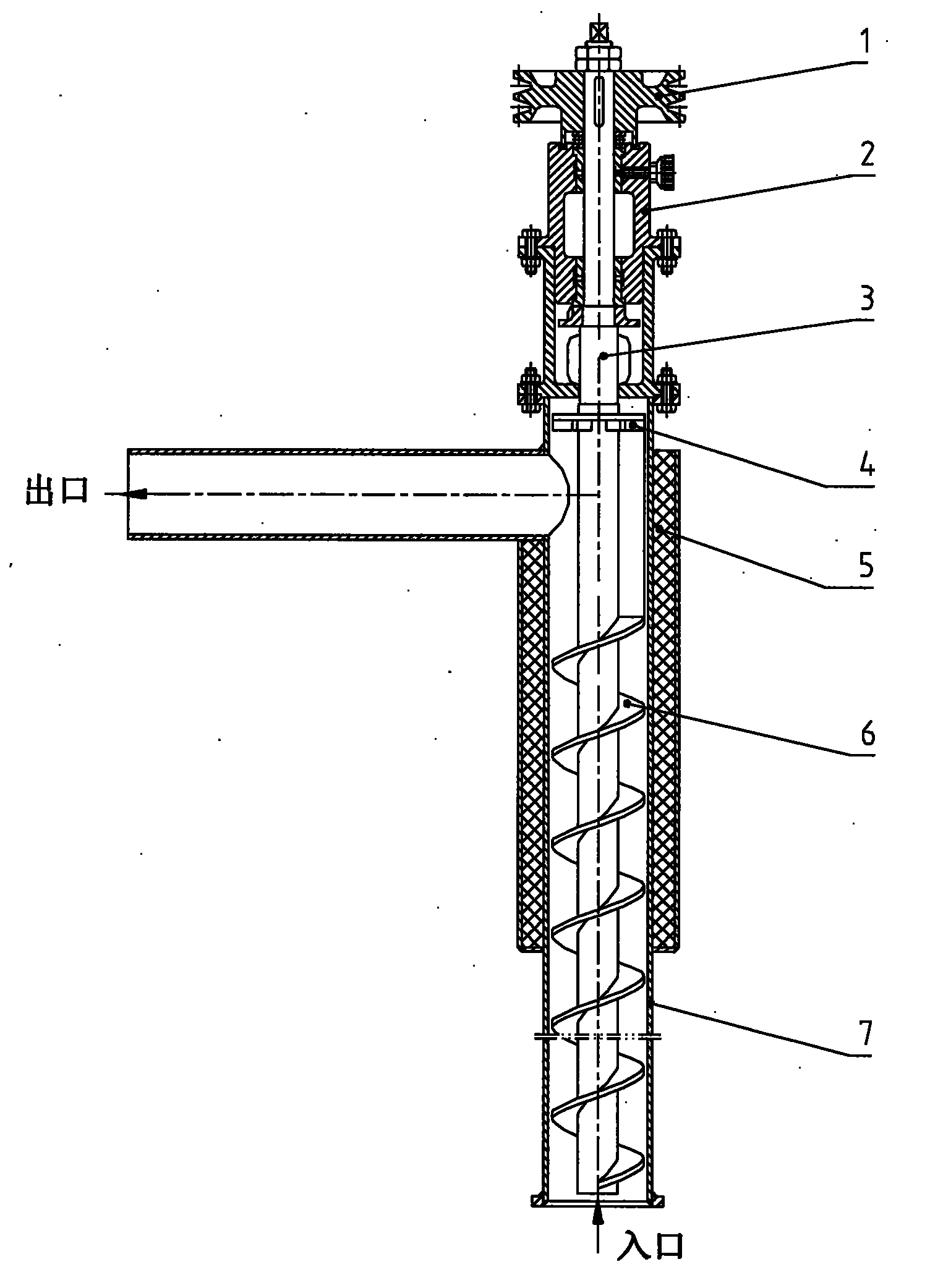

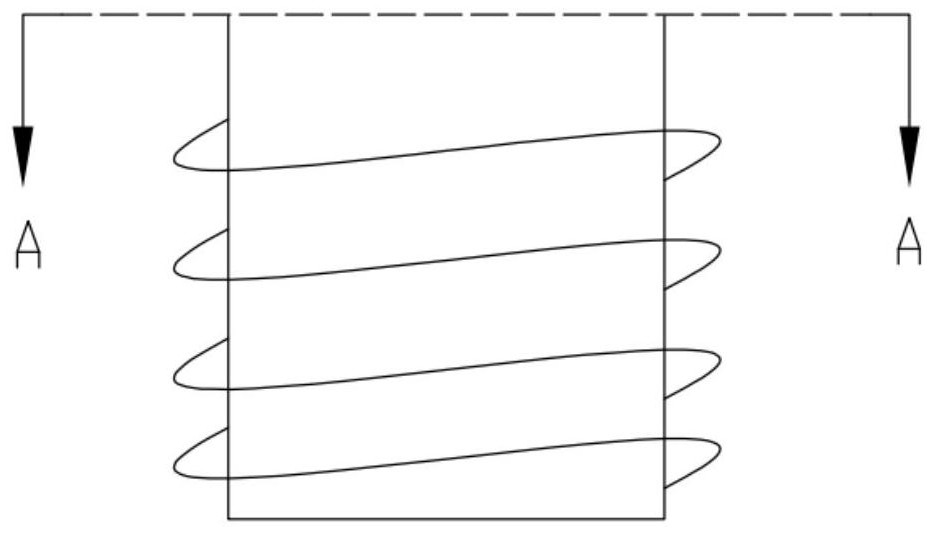

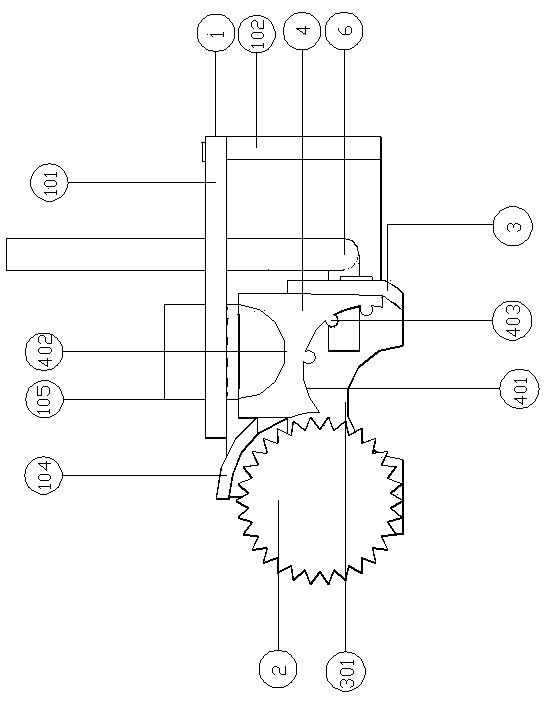

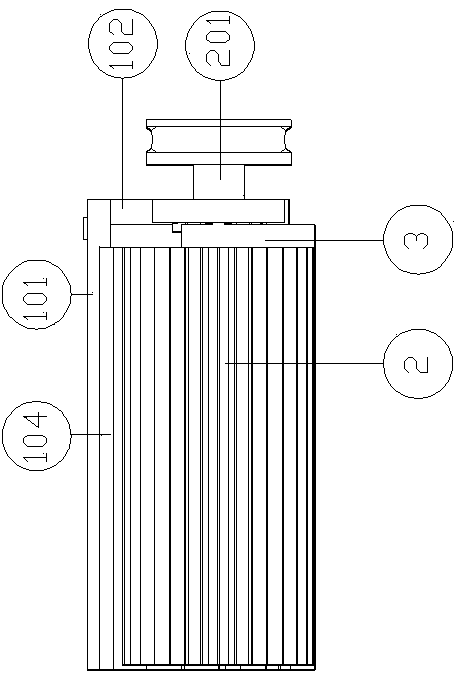

Novel liquid metal transfer pump

ActiveCN101451532AExtended service lifeMake sure it's intactSpecific fluid pumpsPump componentsImpellerEngineering

The present invention related to a fluent metal delivery pump which includes a pump case, a drive capstan and blade, characterized in that the pump case is a upright cylinder; the drive capstan is a screw axis mounted inside the cylinder; and the blade is helical blade surrounding the screw axis; the screw axis is supported by a gear bearing that fixed above the cylinder; and a drive capstan is supported by the gear bearing seat that coaxially connected with the cylinder. sealing blade wheel is provided in the invention which can rotate when driven by the drive capstan and generate centrifugal pull to form some certain negative-pressure inside the pump case, realize dynamic sealing of the pump, prevent cadmium liquor from overbrimming from the gear bearing seat. A structure that utilizing part above the liquid level of the cylinder clad the insulating course is adopted in the invention, so that cadmium liquor remained inside the pump will not cooled quickly after pump stopped which can prevent the remained cadmium liquor from quick crystallization and make mechanical damage to each components, and can prolong service life of the pump.

Owner:ZHUZHOU SMELTER GRP

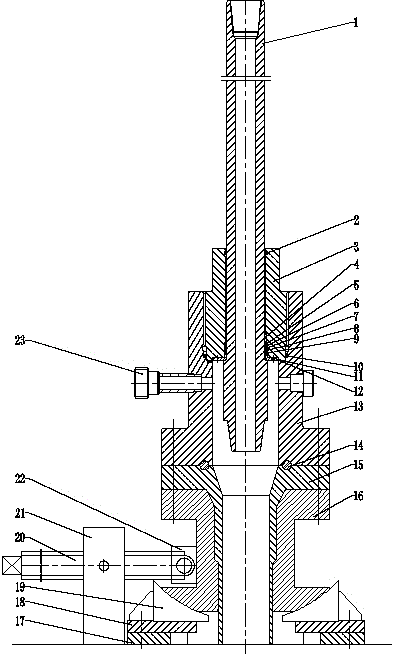

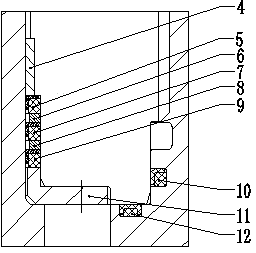

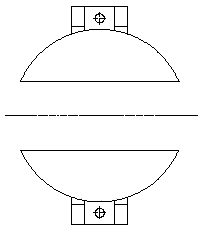

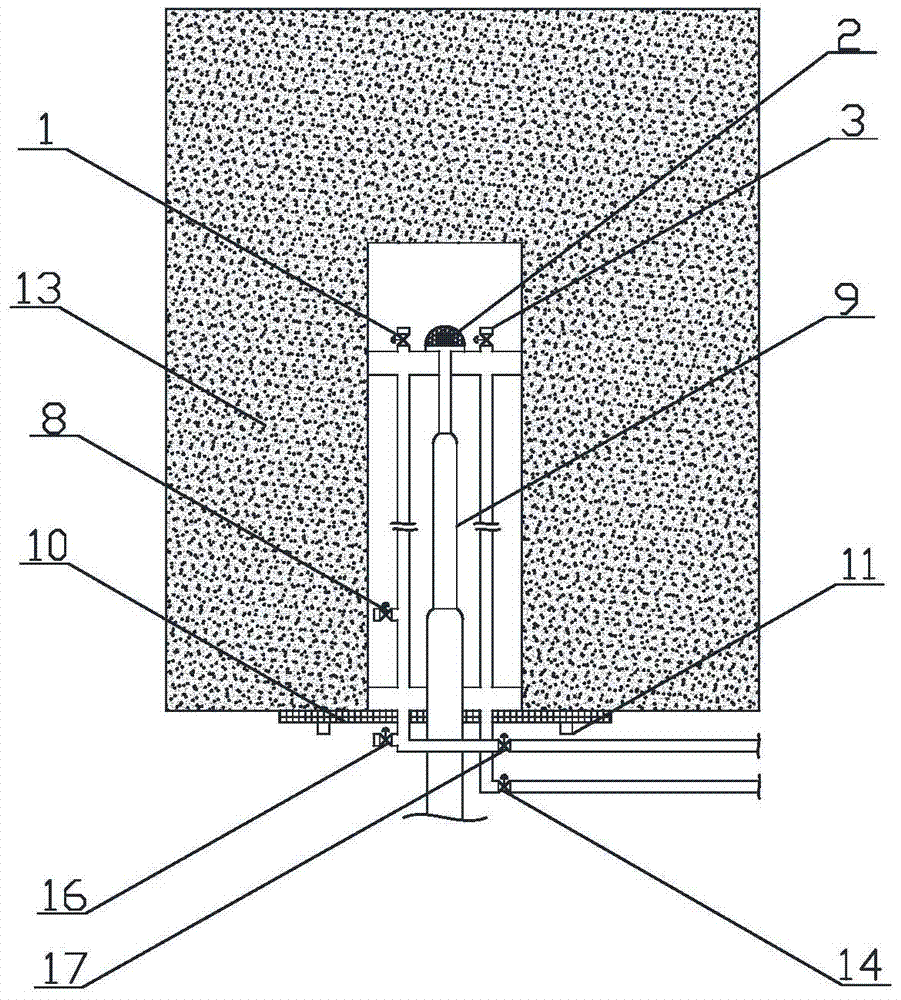

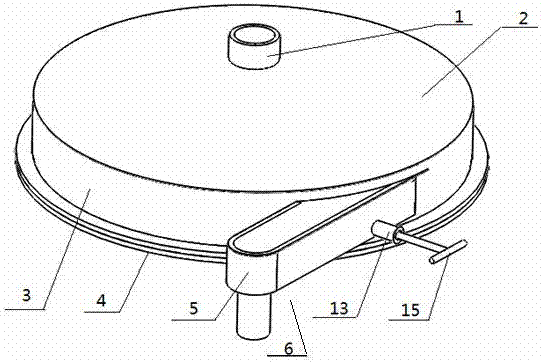

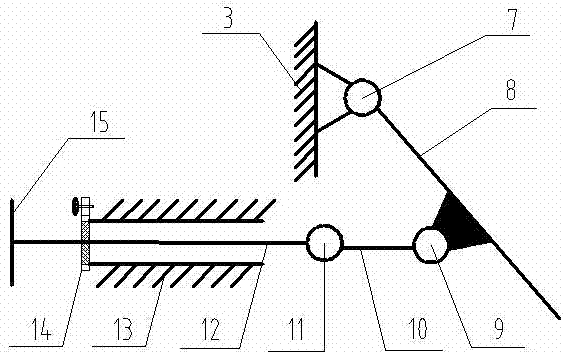

Inclinable experiment well-mouth sealing device

InactiveCN103982155AMeet the needs of the cycleExtended service lifeFlushingSealing/packingWell drillingEngineering

The invention relates to an inclinable experiment well-mouth sealing device for a drilling experiment platform. The technical scheme is as follows: a sealing bush is in threaded connection with a flange, and the flange is provided with a ledge capable of meeting the axial location of the sealing bush; a press ring is fixed at the lower end of the sealing bush by a screw, a movable sealing ring group is fixed between a polished drill rod and the sealing bush by the press ring, a support ring and the ledge of the sealing bush, and the movable sealing ring group is in a compacted state to realize lower movable sealing between the polished drill rod and the sealing bush; the lower end of the flange is fixed together with a well shaft and an arc-shaped base by screws; the arc-shaped base is arranged on an arc-shaped support seat; a through hole in a side lug on the arc-shaped base is fixed together with a through hole in a guide rail by a screw, and the guide rail is fixed together with a guide rail connection support seat by a connection screw. The inclinable experiment well-mouth sealing device disclosed by the invention can be used for experiment well drilling at different angles, and plays the roles of well-mouth blowout prevention and well-mouth sealing.

Owner:SOUTHWEST PETROLEUM UNIV

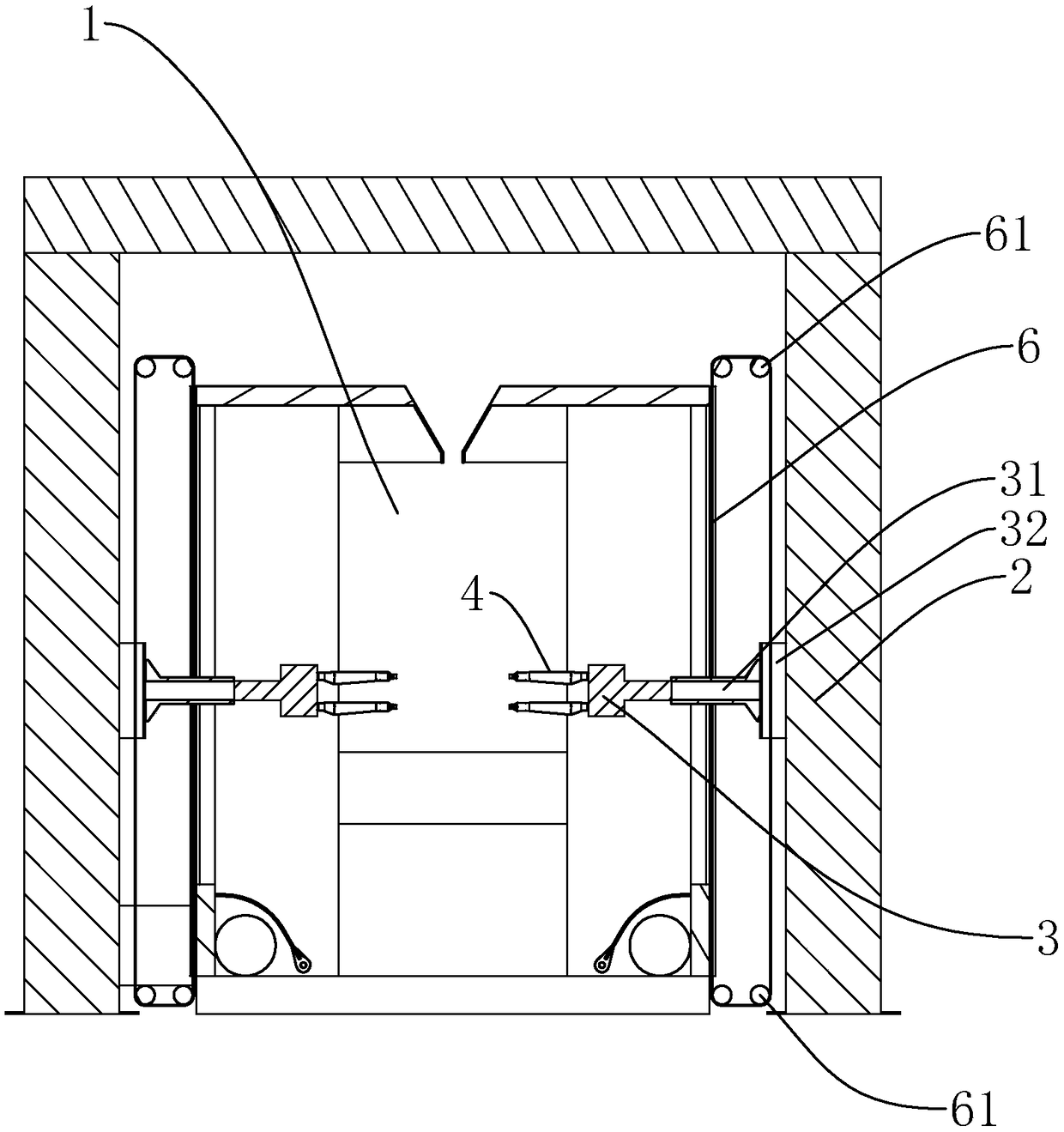

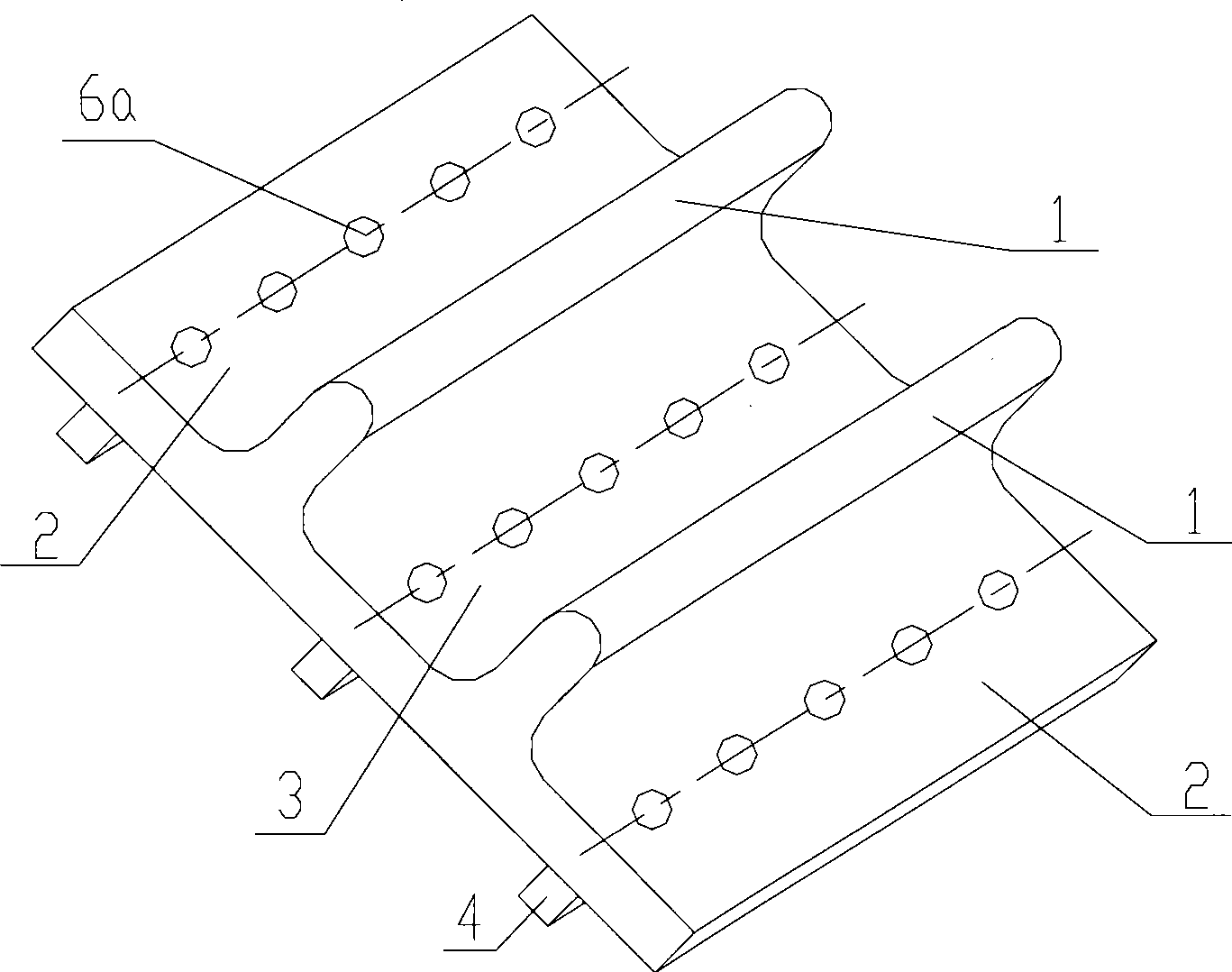

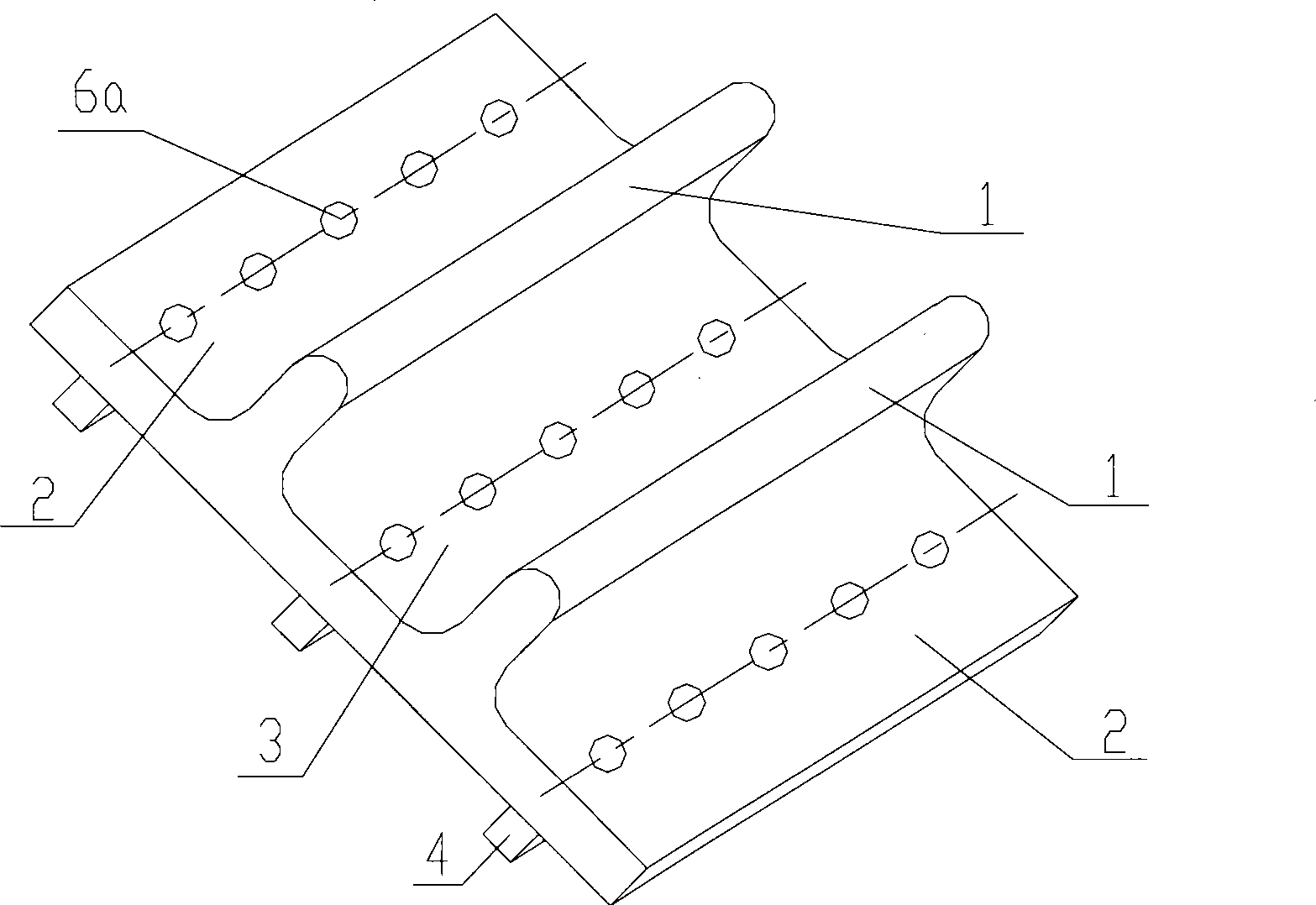

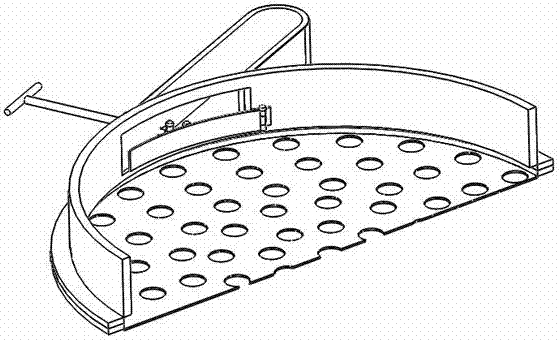

Powder spraying chamber with automatic gun collection beam inlet-outlet groove openings using dynamic sealing structures

PendingCN109365201ARealize dynamic sealingLess likely to leakSpray boothsReciprocating motionPowder Spray

The invention discloses a powder spraying chamber with automatic gun collection beam inlet-outlet groove openings using dynamic sealing structures. The powder spraying chamber comprises a spraying chamber main body and a powder spraying system, wherein the powder spraying system comprises lifting machines, automatic gun collection beams and spraying guns; the automatic gun collection beams are connected with the lifting machines through connection rods; inlet-outlet groove openings are formed in the side wall of the spraying chamber main body and are used for providing space needed for up-and-down reciprocating motion of the connection rods; inlet-outlet groove opening sealing devices are arranged on the inlet-outlet groove openings; the inlet-outlet groove opening sealing devices are flexible sealing tapes using dynamic sealing structure manners; through holes for penetration of the connection rods are formed in the flexible sealing tapes; the flexible sealing tapes are used for sealing the inlet-outlet groove openings in the side wall of the spraying chamber main body and an air flowing path outside the spraying chamber main body; the flexible sealing tapes are capable of movingalong the automatic gun collection beams and achieving dynamic sealing. The powder spraying chamber is excellent in sealing effect, low in possibility of powder leakage and relatively convenient to clean.

Owner:YU TUNG ZHONGSHAN ENG

Sealing part

ActiveCN101392832ARealize dynamic sealingGuaranteed tightnessEngine sealsEngineeringMechanical engineering

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

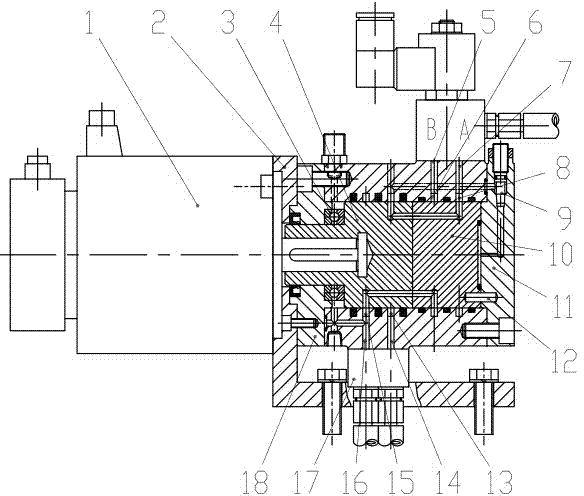

Electro-hydraulic type high-frequency fatigue testing machine and design method thereof

ActiveCN104849158AMeet the precision requirementsEasy to processMaterial strength using repeated/pulsating forcesElectric machineElectro hydraulic

The invention discloses a fatigue testing machine and a design method thereof. An electro-hydraulic type high-frequency fatigue testing machine comprises a movable disk and a static disk which are in contact with each other from the end surfaces, wherein shells are arranged outside the movable disk and the static disk for sealing the movable disk and the static disk; the contact end surface of the movable disk is hinged to a plurality of circular movable disk pressure oil holes and movable disk oil return holes; static disk pressure oil holes and static disk oil return holes are formed in the static disk end surface in contact with the movable disk; the oil holes in the static disk correspond to the oil holes in the movable disk; when the movable disk rotates, the movable disk pressure oil holes and the movable disk oil return holes can be respectively communicated with the static disk pressure oil holes and the static disk oil return holes; a channel for pumping pressure oil into the end face and a device for controlling the pressure oil amount of the channel are arranged on the end part, which is far away from the movable disk, of the static disk. The high-frequency generator of the testing machine is reasonable in structural design and favorable for processing and high-frequency demand implementation; furthermore, the sealing pressure on the movable disk and the static disk in the high-frequency generator can be adjusted, so that the driving power of a servo motor and the energy loss can be reduced.

Owner:SICHUAN DEXIANG KECHUANG INSTR

Large-diameter sealing element

InactiveCN108105381ARealize dynamic sealingGuaranteed tightnessEngine sealsEngineeringMechanical engineering

The invention relates to a large-diameter sealing element, which comprises two or more than two bulges. The other side, opposite to each bulge, of the sealing element is in a rectangular shape; the length of each bulge is the length of each rectangular shape and is equal to the length to be sealed of a plane or the length to be sealed of an arc surface; a connecting part with a first preset widthis arranged between each two adjacent bulges; a groove is formed in a lower part corresponding to each bulge of the sealing element; or the sealing element is provided with a cushion block under eachconnecting part; and the sealing piece and the cushion blocks as well as one or two sealed planes or arc surfaces or curve surfaces are fixedly installed through a mechanical installation way. The invention provides the sealing element used for ensuring a sealing effect between the planes or the arc surfaces of two parts requiring to be sealed.

Owner:新昌县双彩乡捷丰五金厂

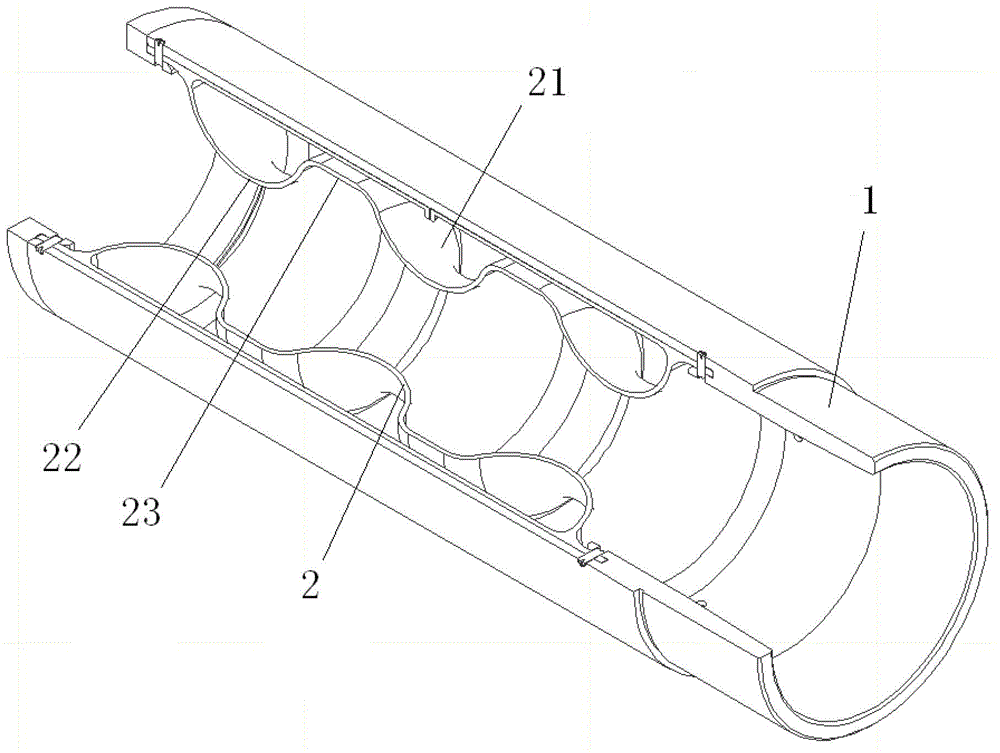

Motive seal device for expansion pipe

ActiveCN103410468ARealize dynamic sealingKeep the annulus cleanSealing/packingArchitectural engineeringBuilding construction

The invention discloses a motive seal device for an expansion pipe. The motive seal device for the expansion pipe comprises a cylindrical connection outer sleeve (1), wherein a cylindrical sealing rubber core (2) is fixedly connected in the connection outer sleeve (1), the outer side wall of the sealing rubber core (2) is in sealed connection with the inner side wall of the connection outer sleeve (1), and a cavity (21) for inflating is formed in the sealing rubber core (2). The motive seal device for the expansion pipe can prevent foreign materials inside a well from entering an expansion construction tool, the expansion pipe and a suppressing oil pipe are annularly kept clean in the construction process, and therefore smooth proceeding of the expansion construction is ensured.

Owner:PETROCHINA CO LTD

Novel liquid metal transfer pump

ActiveCN101451532BSolve delivery problemsAvoid enteringSpecific fluid pumpsPump componentsImpellerDrive shaft

The present invention related to a fluent metal delivery pump which includes a pump case, a drive capstan and blade, characterized in that the pump case is a upright cylinder; the drive capstan is a screw axis mounted inside the cylinder; and the blade is helical blade surrounding the screw axis; the screw axis is supported by a gear bearing that fixed above the cylinder; and a drive capstan is supported by the gear bearing seat that coaxially connected with the cylinder. sealing blade wheel is provided in the invention which can rotate when driven by the drive capstan and generate centrifugal pull to form some certain negative-pressure inside the pump case, realize dynamic sealing of the pump, prevent cadmium liquor from overbrimming from the gear bearing seat. A structure that utilizingpart above the liquid level of the cylinder clad the insulating course is adopted in the invention, so that cadmium liquor remained inside the pump will not cooled quickly after pump stopped which can prevent the remained cadmium liquor from quick crystallization and make mechanical damage to each components, and can prolong service life of the pump.

Owner:ZHUZHOU SMELTER GRP

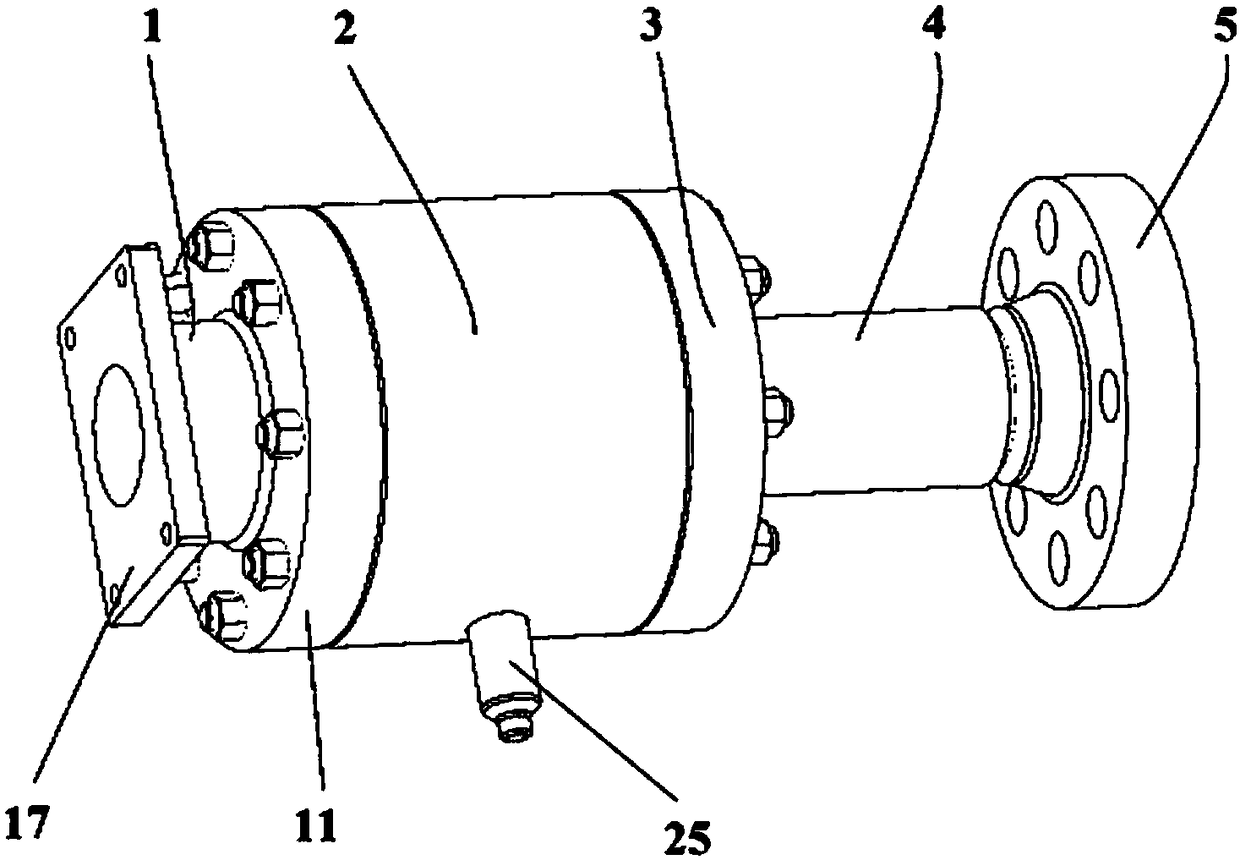

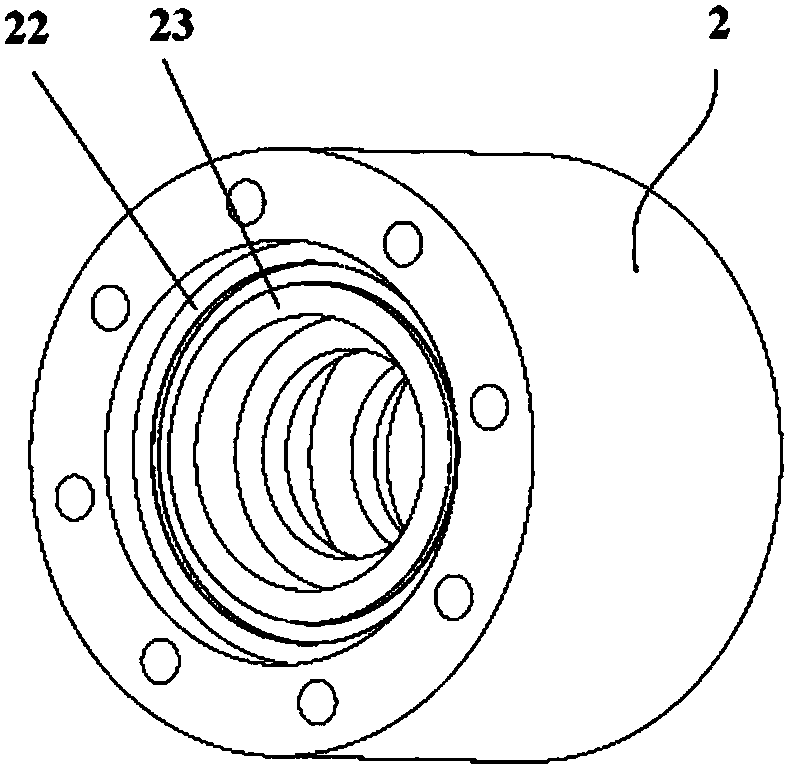

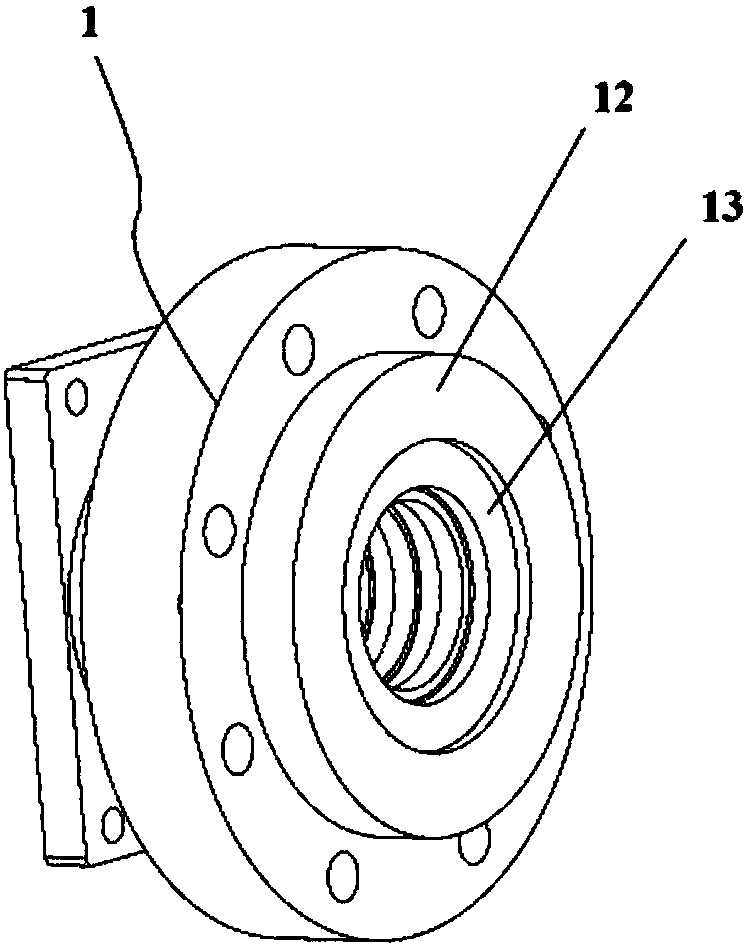

Dynamic sealing device of high-pressure system

The invention discloses a dynamic sealing device of a high-pressure system. The device comprises a first end cover flange, a second end cover flange, a cavity flange, a second end cover flange, a connecting piece and a butt joint flange are sequentially installed in the same axial direction; a mounting cavity sealed and communicated is formed in the axial direction in the center of the first end cover flange, the cavity flange, the second end cover flange, the connecting piece and the butt joint flange; the inner diameters of the first end cover flange and the second end cover flange are the same, and Y-shaped sealing rings are installed on the inner walls of the first end cover flange and the second end cover flange; the inner diameter of the cavity flange is larger than the inner diameter of the first end cover flange, and a channel is formed in the side wall of the cavity flange. A high-pressure nitrogen barrier is formed between the high-pressure medium in the high-pressure industrial system and the atmosphere, and the reliability of dynamic sealing is improved; and high-temperature and high-pressure medium in an industrial device cannot leak into the atmosphere, so that a certain function part of the industrial device can be plugged and pulled under a high-pressure working condition, and an operation is carried out under a high-pressure operation working condition.

Owner:XIAN AEROSPACE SOURCE POWER ENG CO LTD

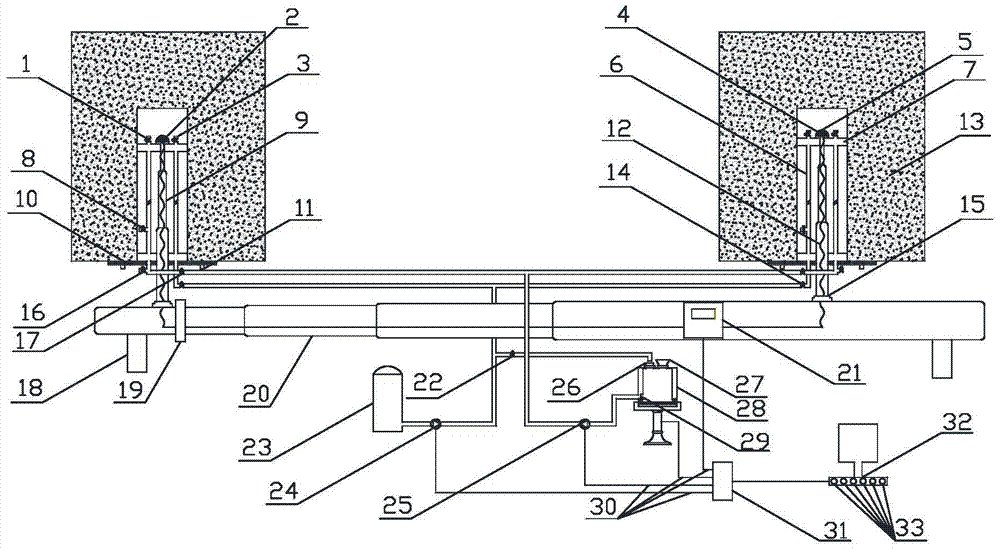

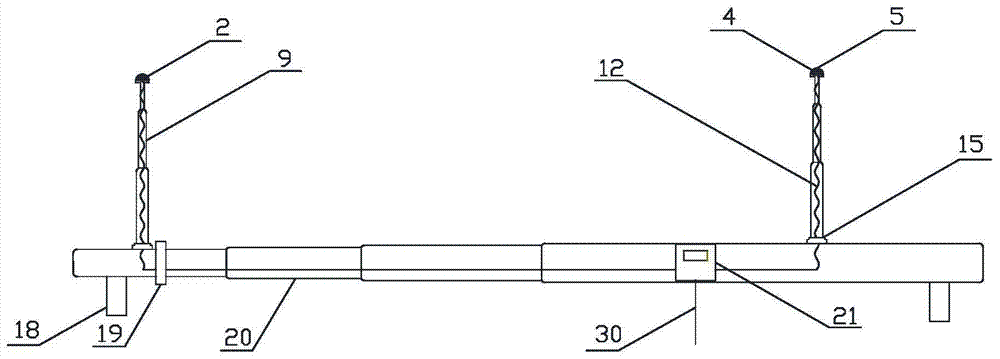

Loosing circle testing system and method based on coupling effect of rock water in drill holes of soft rock

ActiveCN105467010AImprove seal qualityAvoid mixed flowAnalysing solids using sonic/ultrasonic/infrasonic wavesDisplay deviceSlurry

The invention discloses a loosing circle testing system and method based on a coupling effect of rock water in drill holes of soft rock. The loosing circle testing system comprises a hole sealing device, a grouting device, a water injection device, a testing device and a control device. The testing device comprises a telescopic rod body, a displayer, ultrasonic transmitters, ultrasonic receivers and a stand column used for supporting the telescopic rod body. The ultrasonic transmitters and the ultrasonic receivers are connected to the input end of the displayer through lines and connected to the control device through the output end of the displayer. Detecting rods are connected to the two ends of the telescopic rod body respectively. The heights of the two detecting rods are the same, and the two detecting rods are kept parallel. Each detecting rod is formed by sleeving a plurality of pipe bodies together. One ultrasonic transmitter and one ultrasonic receiver are installed on the head of each detecting rod respectively. The dynamic hole sealing device achieves synchronization of plugging cracks in the holes through grout and coupling of the rock water, and the problem that when top plate surrounding rock is tested, a large amount of water in the drill holes is lost in the testing process, and can not be supplemented in time is solved.

Owner:SHANDONG UNIV OF SCI & TECH

Dynamic sealing device for expansion pipe

ActiveCN103410468BRealize dynamic sealingKeep the annulus cleanSealing/packingBuilding constructionCivil engineering

The invention discloses a motive seal device for an expansion pipe. The motive seal device for the expansion pipe comprises a cylindrical connection outer sleeve (1), wherein a cylindrical sealing rubber core (2) is fixedly connected in the connection outer sleeve (1), the outer side wall of the sealing rubber core (2) is in sealed connection with the inner side wall of the connection outer sleeve (1), and a cavity (21) for inflating is formed in the sealing rubber core (2). The motive seal device for the expansion pipe can prevent foreign materials inside a well from entering an expansion construction tool, the expansion pipe and a suppressing oil pipe are annularly kept clean in the construction process, and therefore smooth proceeding of the expansion construction is ensured.

Owner:PETROCHINA CO LTD

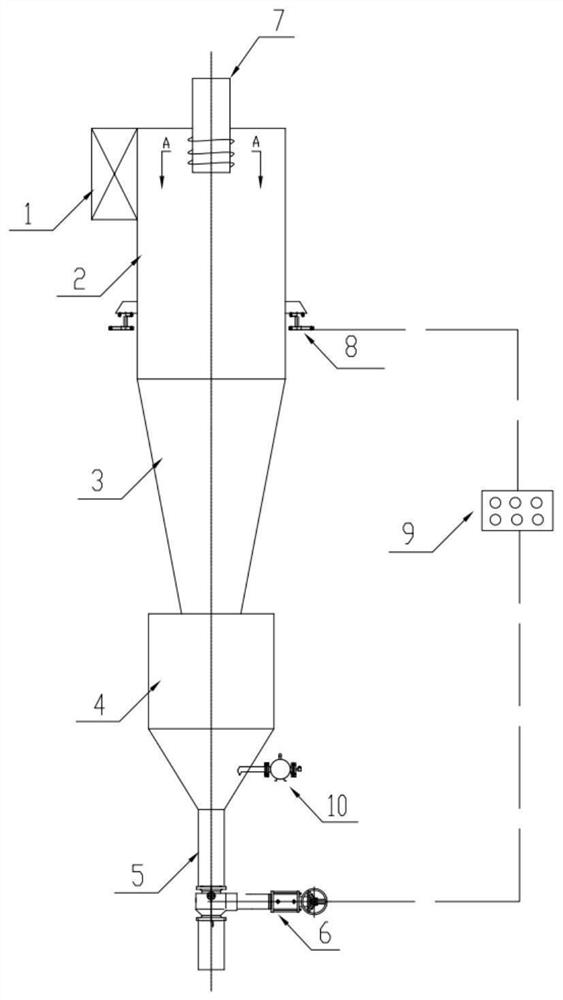

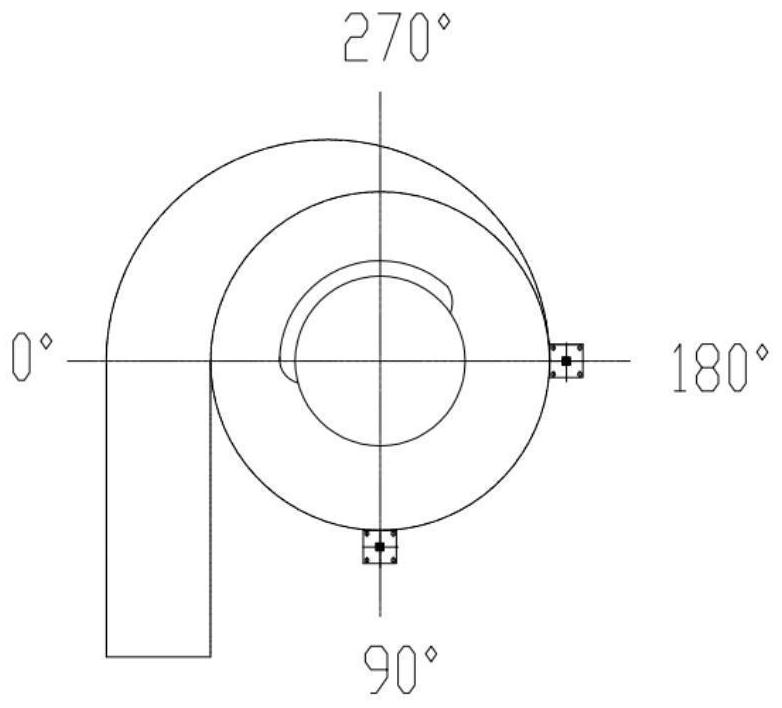

Anti-coking cyclone separator capable of achieving dynamical material seal

PendingCN113134428AGuaranteed separation efficiencyRealize dynamic sealingReversed direction vortexThermodynamicsControl signal

The invention belongs to the technical field of gas-solid separation of high-temperature pyrolysis gas, and particularly relates to an anti-coking cyclone separator capable of achieving dynamical material seal. The anti-coking cyclone separator comprises a feeding port, a barrel, a cone, a storage bin, a dipleg, a discharging controller, a central pipe, a weighing sensor, an electric control system and an arch breaking and flow aiding unblocking device, wherein the feeding port is tangentially connected with the barrel; the central pipe is arranged at the top of the barrel; the cone is connected with the barrel; the storage bin is welded to the cone; the dipleg is welded to the storage bin; the weighing sensor is placed under a lifting lug on the outer wall of the barrel and sends a weight signal to the electric control system. the electric control system sends a control signal to a discharging controller; the discharging controller has different opening degrees to control the falling speed of materials; and the arch breaking and flow aiding unblocking device is arranged on the outer wall of the storage bin. The requirement for an anaerobic or anoxic state is met through the material seal of the separator, meanwhile coking on the outer wall of the central pipe of the separator can be reduced, and the separator can operate efficiently, safely and stably for a long period under severe working conditions such as high temperature, high corrosion and strong abrasion.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

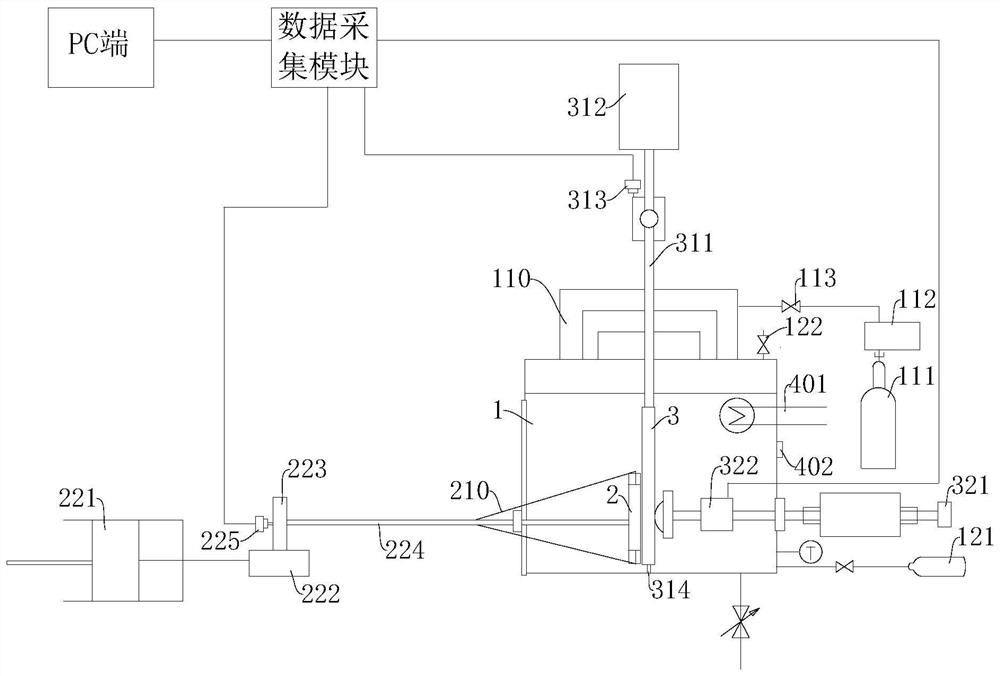

Abrasion system and method for simulating various motions of metal in lead-bismuth alloy environment

ActiveCN113533111AAffects abrasive propertiesRealize dynamic sealingNuclear energy generationInvestigating abrasion/wear resistanceLead bismuthReciprocating motion

The invention provides an abrasion system for simulating various motions of metal in a lead-bismuth alloy environment, and relates to the technical field of material surface motion abrasion testing. The system comprises a lead bismuth alloy environment simulation cavity, the lead bismuth alloy environment simulation cavity is provided with a first metal body and a second metal body which abut against each other, the first metal body is fixed through a clamping device, the clamping device is connected with a horizontal circumferential reciprocating motion mechanism, and the second metal body is connected with an axial reciprocating motion mechanism; the system can simulate the interaction of temperature, load and motion of a first metal body and a second metal body in a lead-bismuth environment, and research the rule of the influence of the interaction on the abradability of the first metal body and the second metal body. In addition, the invention further provides a method for simulating various motions of metal in the lead-bismuth alloy environment, the system is included, and the same beneficial effects can be achieved.

Owner:HARBIN INST OF TECH

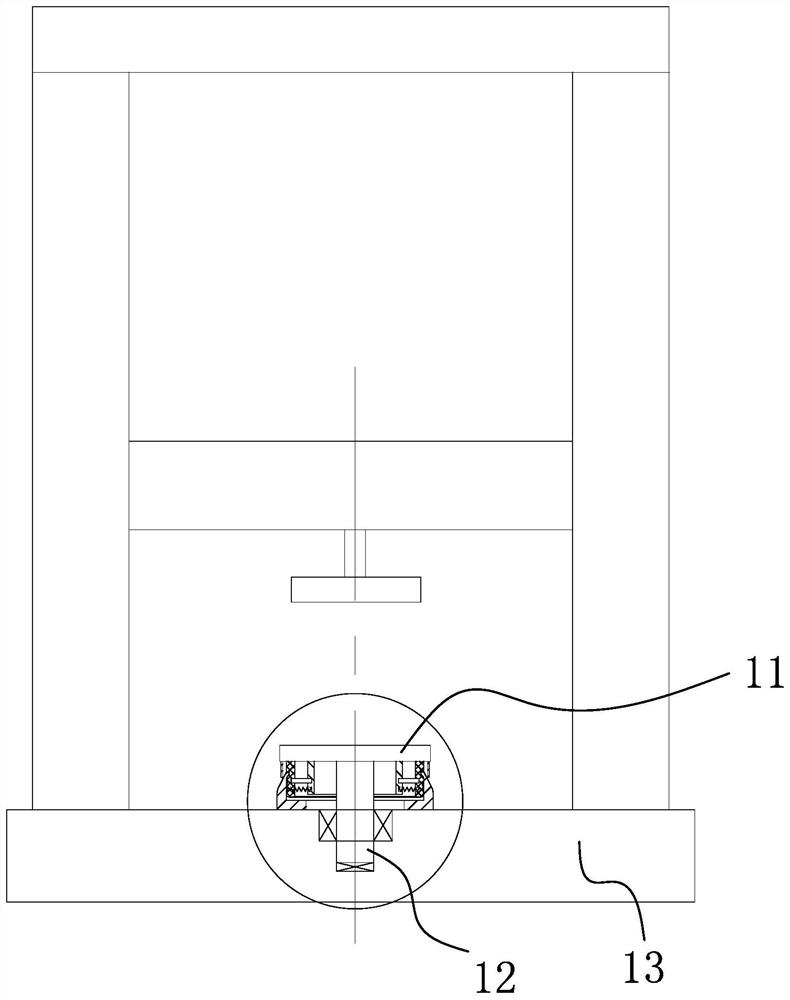

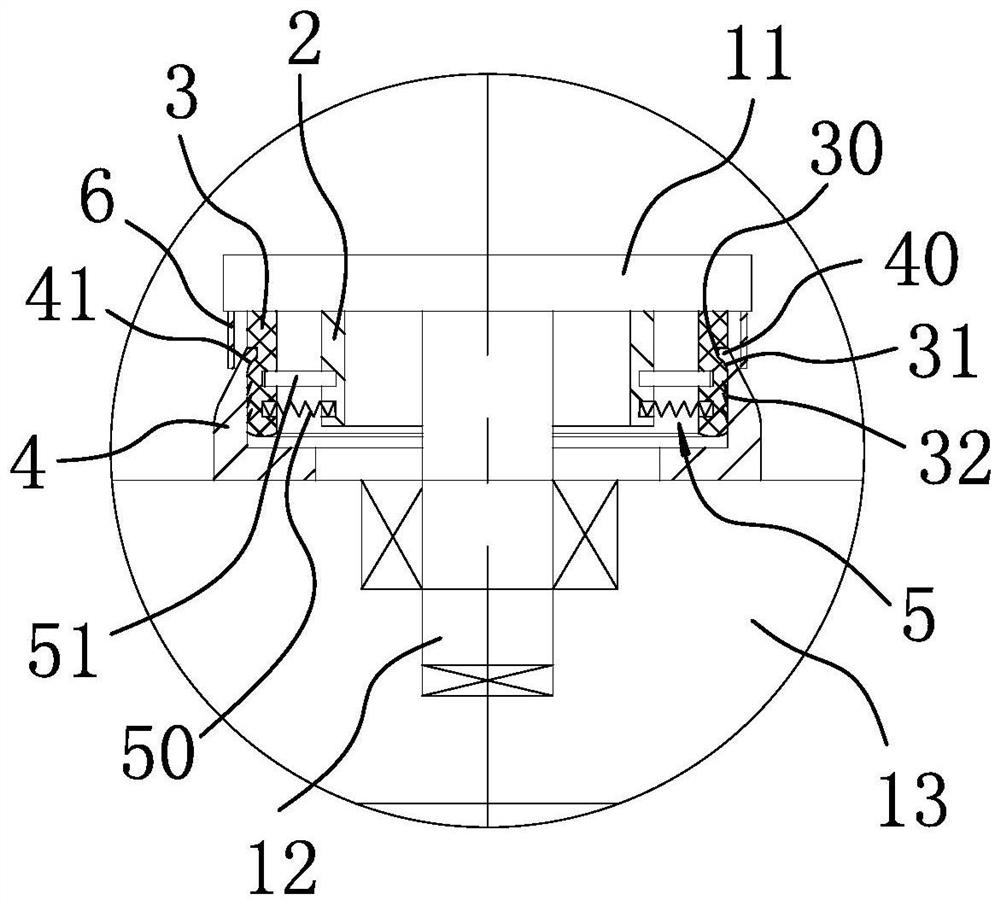

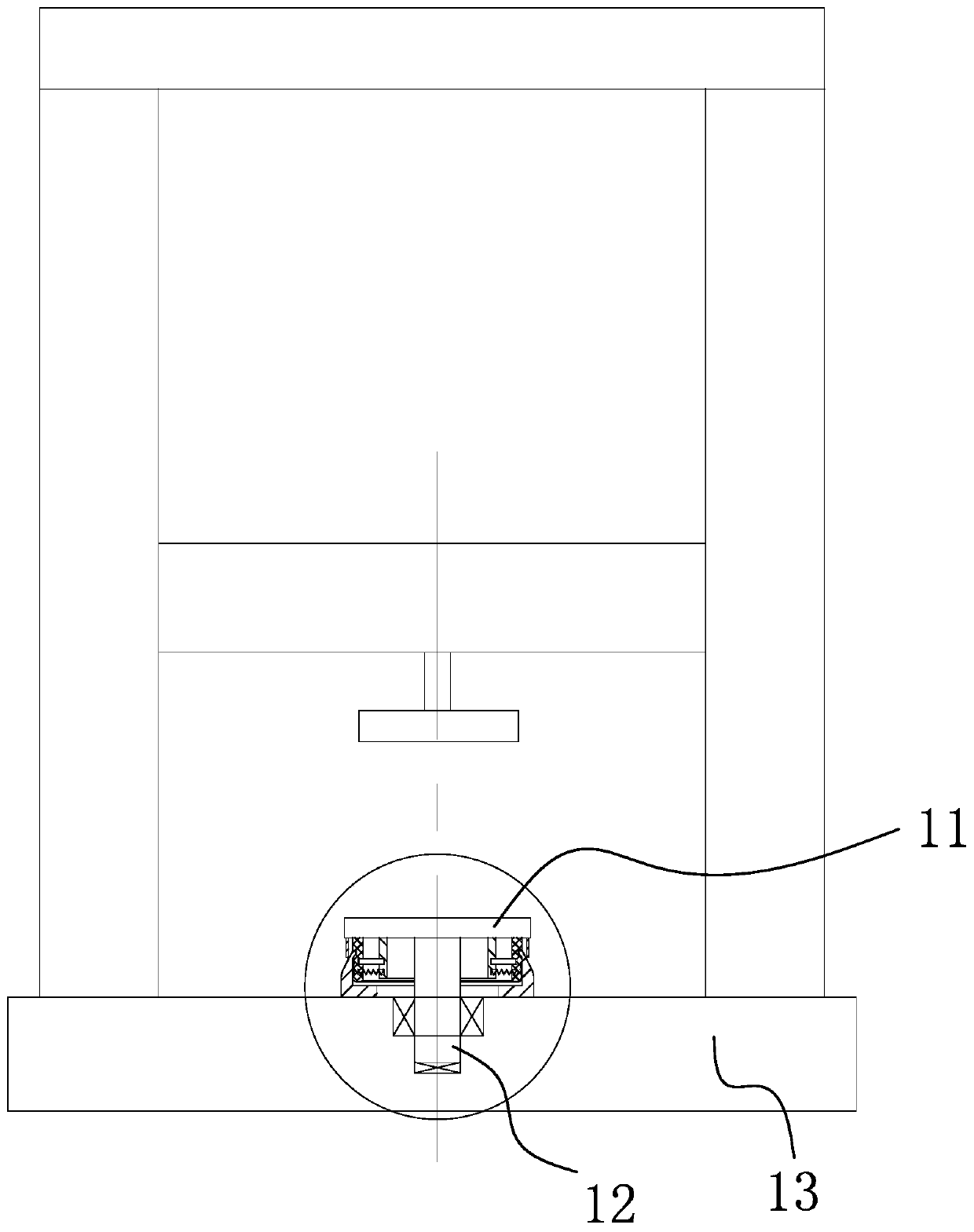

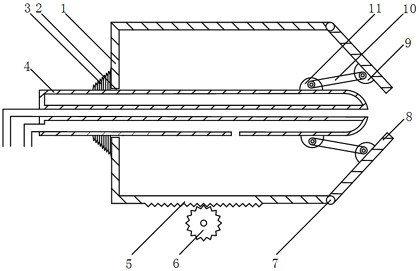

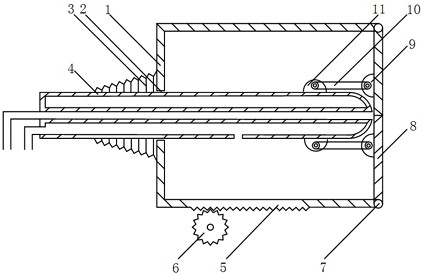

Circumferential sealing mechanism of lower platen of universal testing machine

ActiveCN111366453BRealize dynamic sealingPrevent frequent cleaningStrength propertiesEngineeringMechanical engineering

The circumferential sealing mechanism of the lower pressure plate of the universal testing machine includes a metal inner cylinder whose upper end is fixed on the lower surface of the lower pressure plate, and the metal inner cylinder is sleeved on the outside of the rotating shaft. There is a distance between the lower end of the metal inner cylinder and the upper surface of the testing machine platform. The rubber cylinder fixed on the lower surface of the lower platen and the rubber cylinder is sleeved on the outside of the metal inner cylinder, an annular space is formed between the metal inner cylinder and the rubber cylinder, and a distance 2 is left between the lower end of the rubber cylinder and the upper surface of the testing machine platform, on the testing machine platform A metal sealing cylinder is fixed on the surface, the upper end of the metal sealing cylinder is sleeved on the rubber cylinder, and the inner wall of the metal sealing cylinder and the outer wall of the rubber cylinder are gap-fitted. Between the lower outer wall of the metal inner cylinder and the lower inner wall of the rubber cylinder, an elastic mechanism capable of forcing the lower end of the rubber cylinder to expand radially outwards is provided to the inclined sealing protrusion in the annular sealing groove.

Owner:嘉善县科正建设工程检测有限公司

Electrolytic tank used for post-treatment of copper foil

InactiveCN101634045BRealize dynamic sealingAdjustable distanceElectrolysis componentsElectrolysisCopper foil

Owner:XIAN AEROSPACEMOTOR MACHINE FACTORY

Sealing part

ActiveCN101392832BRealize dynamic sealingGuaranteed tightnessEngine sealsEngineeringMechanical engineering

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Circumferential sealing mechanism for lower pressing plate of universal testing machine

ActiveCN111366453AAvoid frequent cleaningImprove installation efficiencyStrength propertiesEngineeringUniversal testing machine

The invention discloses a circumferential sealing mechanism for a lower pressing plate of a universal testing machine, which comprises a metal inner cylinder, wherein the upper end of the metal innercylinder is fixed on the lower surface of the lower pressing plate, and a spacing I is reserved between the lower end of the metal inner cylinder and the upper surface of a testing machine platform. The circumferential sealing mechanism further comprises a rubber cylinder, wherein the upper end of the rubber cylinder is fixed on the lower surface of the lower pressing plate, the rubber cylinder sleeves the outer side of the metal inner cylinder, an annular space is formed between the metal inner cylinder and the rubber cylinder, a spacing II is reserved between the lower end of the rubber cylinder and the upper surface of the testing machine platform, a metal sealing cylinder is fixed on the upper surface of the testing machine platform, the upper end of the metal sealing cylinder sleevesthe rubber cylinder, and the inner wall of the metal sealing cylinder is in clearance fit with the outer wall of the rubber cylinder, an annular sealing groove is formed in the outer wall of the middle of the rubber cylinder, the upper end of the metal sealing cylinder is provided with an inclined sealing protruding part clamped into the annular sealing groove, and an elastic mechanism capable offorcing the lower end of the rubber cylinder to have the trend of expanding outwards in the radial direction is arranged between the outer wall of the lower end of the metal inner cylinder and the inner wall of the lower end of the rubber cylinder.

Owner:嘉善县科正建设工程检测有限公司

Loose circle test system and method based on rock-water coupling in soft rock drilling

ActiveCN105467010BImprove seal qualityAvoid mixed flowAnalysing solids using sonic/ultrasonic/infrasonic wavesDisplay deviceSlurry

Owner:SHANDONG UNIV OF SCI & TECH

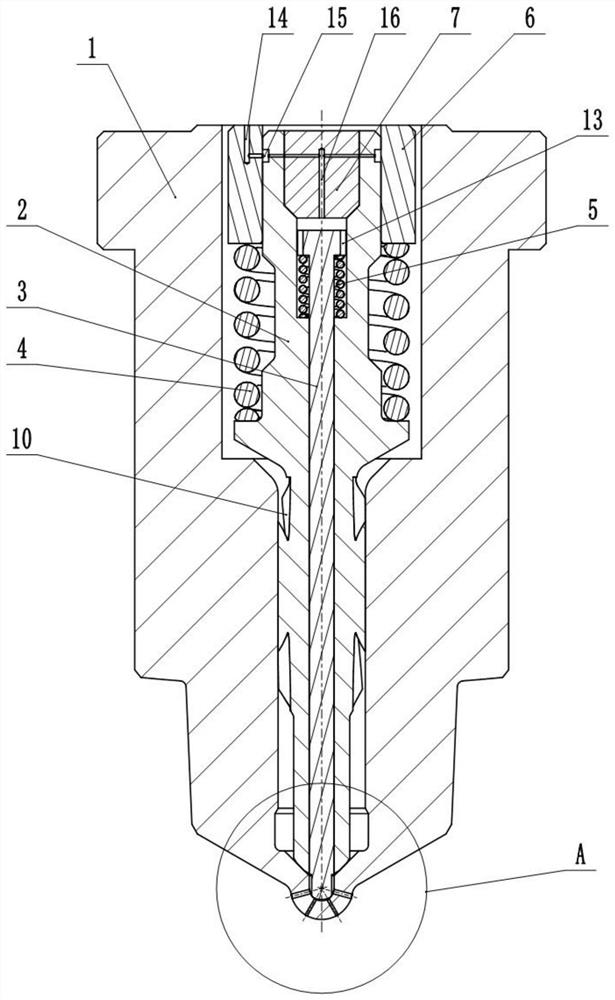

Novel needle valve matching part

ActiveCN114810443AFlexible controlReduce oilFuel injection apparatusMachines/enginesEngineeringInternal combustion engine

The invention relates to the technical field of needle valve matching parts of internal combustion engines, in particular to a novel needle valve matching part which comprises a needle valve body, a first-stage valve element, a second-stage valve element, a pressure adjusting spring, a reset spring, a control sleeve and a plug, the needle valve body is of a hollow structure, the first-stage valve element is installed in the needle valve body, the second-stage valve element is installed in the first-stage valve element, and a pressure storage cavity is formed in the bottom of the needle valve body. A plurality of first-layer spraying holes and a plurality of second-layer spraying holes are formed in the outer side of the pressure storage cavity, the first-level valve element can seal the pressure storage cavity, the bottom of the second-level valve element can stretch into the pressure storage cavity to seal the second-layer spraying holes, and the first-level valve element and the second-level valve element are adopted to independently control the two layers of spraying holes. The second-level valve element can be closed, only the first-level valve element is opened, and therefore only the first-layer spraying holes are opened, and the oil amount is reduced; when high oil quantity is needed, the two-stage valve element can be opened, so that the two layers of spray holes are opened, and the circulation sectional area is increased by increasing the number of the spray holes.

Owner:CHONGQING HONGJIANG MACHINERY

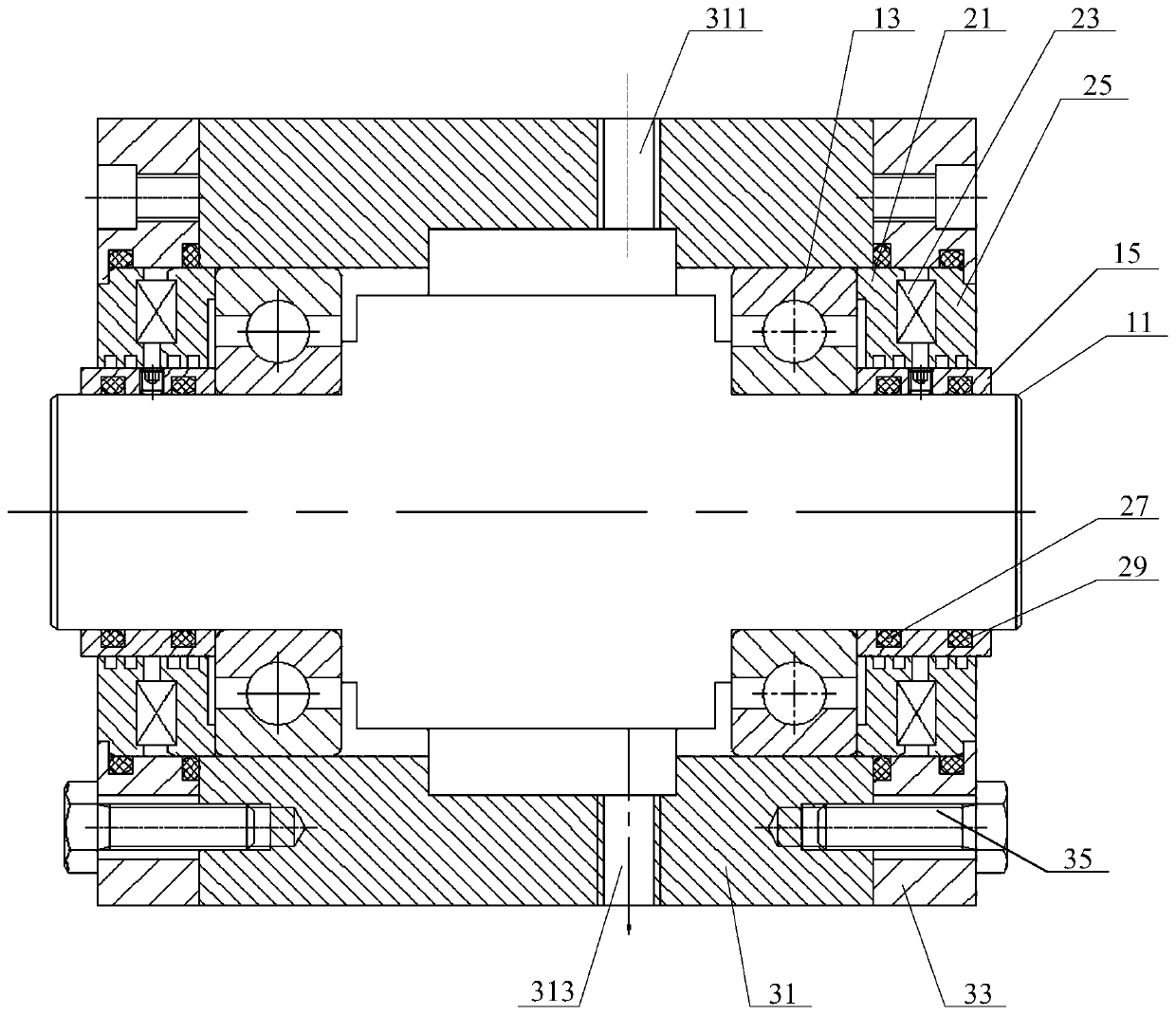

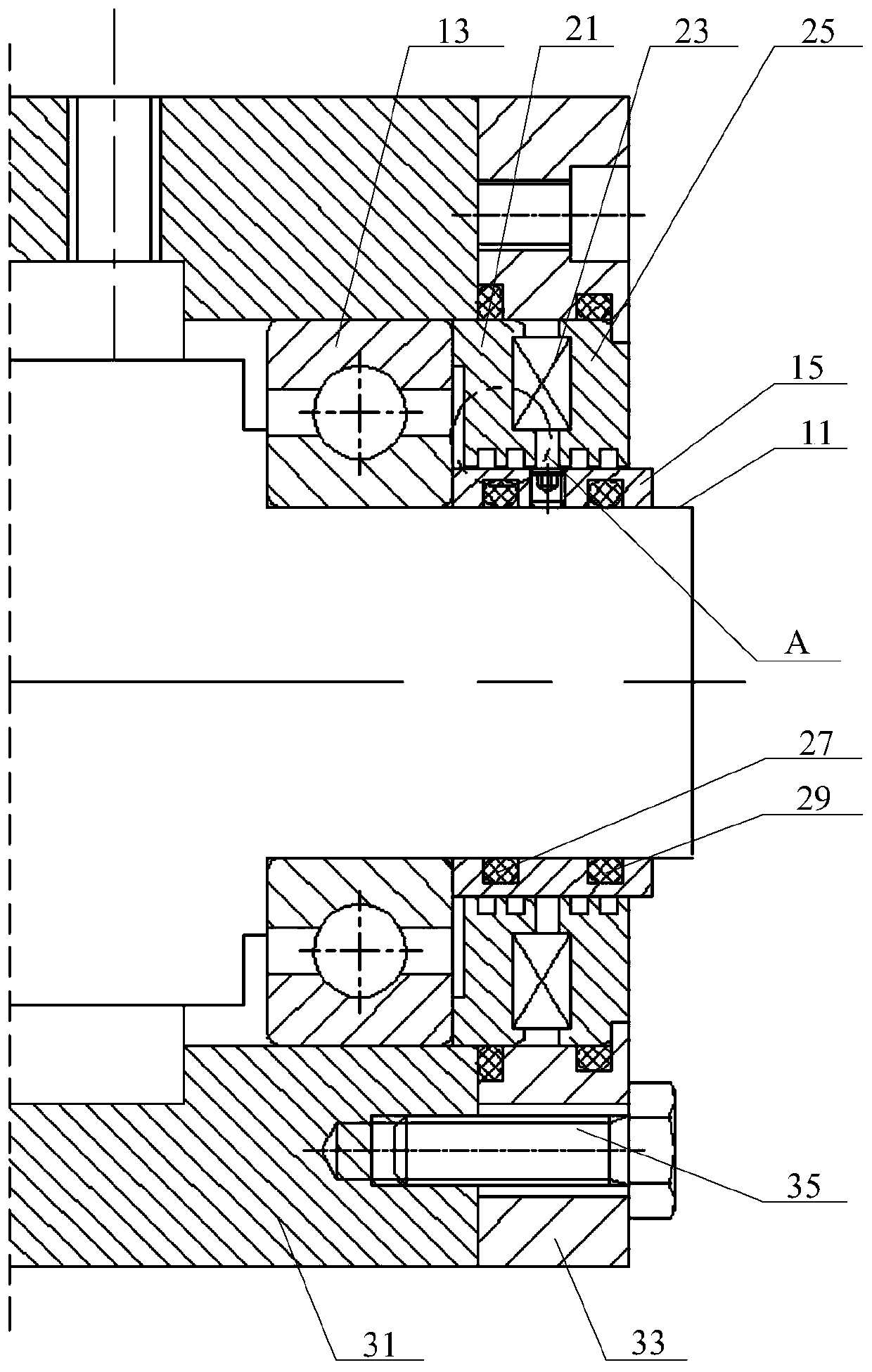

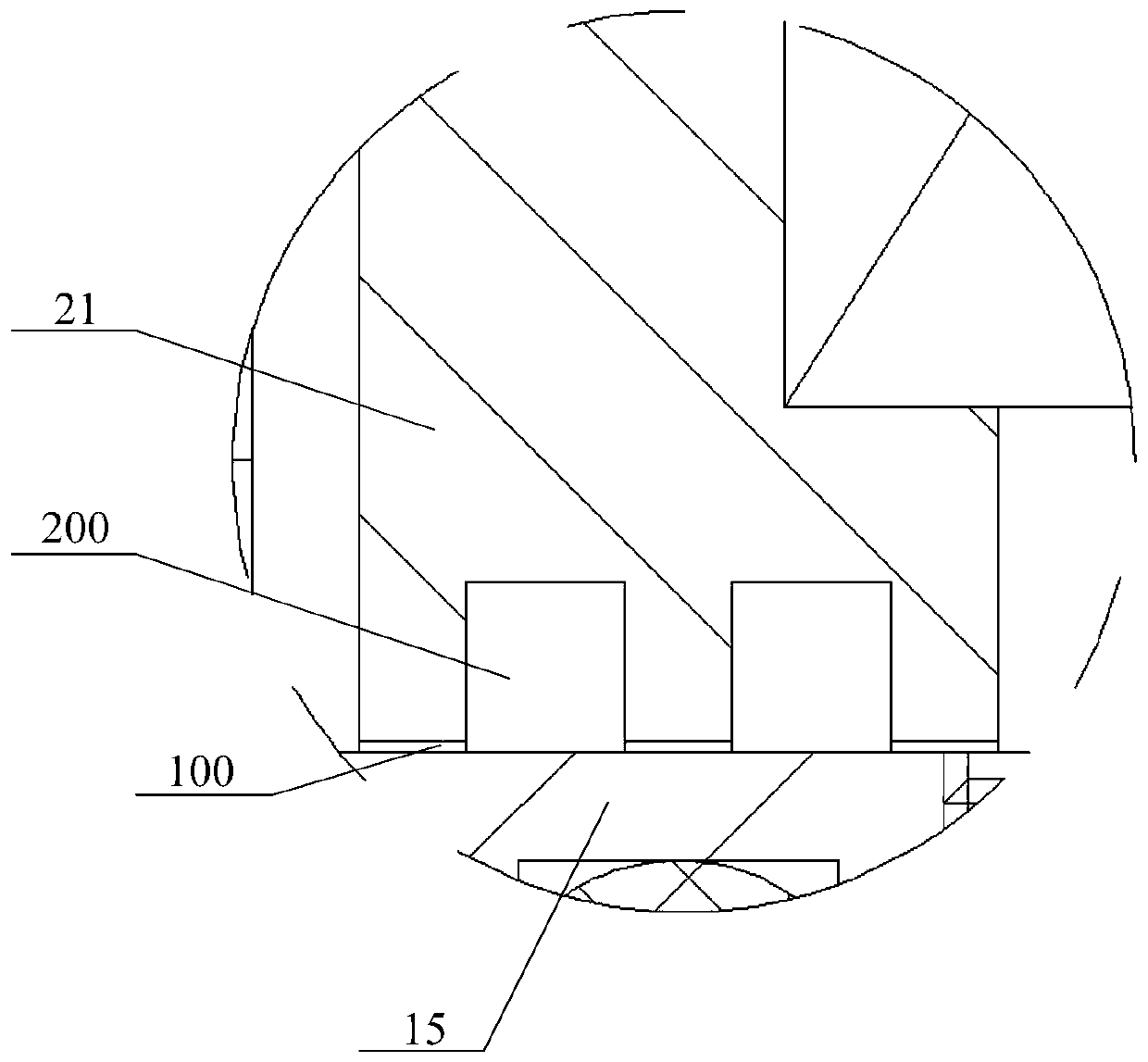

A balance force-measuring device for the test of transverse jet flow effect with high-pressure seal

ActiveCN112051026BSolve the problem of high pressure rotary sealRealize dynamic sealingAerodynamic testingFlight vehicleDynamic balance

The invention discloses a balance force-measuring device used for a high-pressure sealed transverse jet flow effect test. The force-measuring device of the balance adopts a rod-type balance. The central axis of the rod-type balance is provided with a mandrel. The central axis of the mandrel is provided with an airflow channel. The front end of the airflow channel is connected to high-pressure air, and the rear end of the airflow channel is connected to the rear model The horizontal jet nozzle; the mandrel is set with the front balance, the supporting beam and the rear balance in sequence from the front to the back; two diagonal contact bearings are installed between the front balance, the rear balance and the mandrel; the front balance and the rear balance are five-component measurement The force balance measures the normal force, pitching moment, lateral force, yaw moment and rolling moment of the front model and the rear model respectively. The force-measuring balance can ensure the accurate measurement of the aerodynamic characteristics of the aircraft in the state of jet flow effect under the premise of good dynamic sealing performance, which further improves the refined development level of the aircraft.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

Screening assembly with blocking mechanism

The invention discloses a screening assembly with a blocking mechanism. A screen basket cover is arranged at the top of a screen basket, and a feeding opening is formed in the screen basket cover. Thescreen basket cover and the screen basket are tightly connected. A screen cloth is arranged on the lower portion of the screen basket, and the screen cloth and a material basket are tightly connectedthrough a hoop. A discharging opening is formed in one side of the screen basket, and an arc baffle is arranged at the inner end of the discharging opening. One end of the arc baffle is connected with a first fixing hinge column on the inner wall of the screen basket in a hinged mode, and the other end of the arc baffle is hinged to a connecting rod. The connecting rod is connected with one end of a guiding rod through a movable hinge device, and the other end of the guiding rod penetrates through a sleeve to be connected with a handle. When the contacting time of materials and the screen cloth is prolonged, the handle is pulled back, and under the effect of the guiding rod, the movable hinge device, the connecting rod and a second fixing hinge column, the discharging opening is closed bythe arc baffle around a first fixing hinge; and when the effect that the materials penetrate through the screen cloth is good, the handle is pushed forwards, and under the effect of the guiding rod,the movable hinge device, the connecting rod and the second fixing hinge column, the discharging opening is opened by the arc baffle around the first fixing hinge. The screening assembly has the characteristics that the structure is simple, and the screening precision is high.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

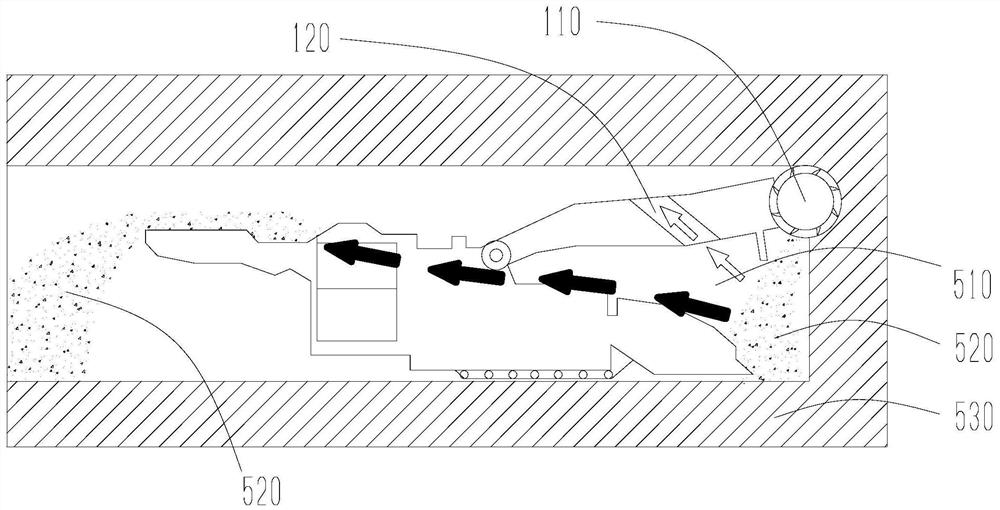

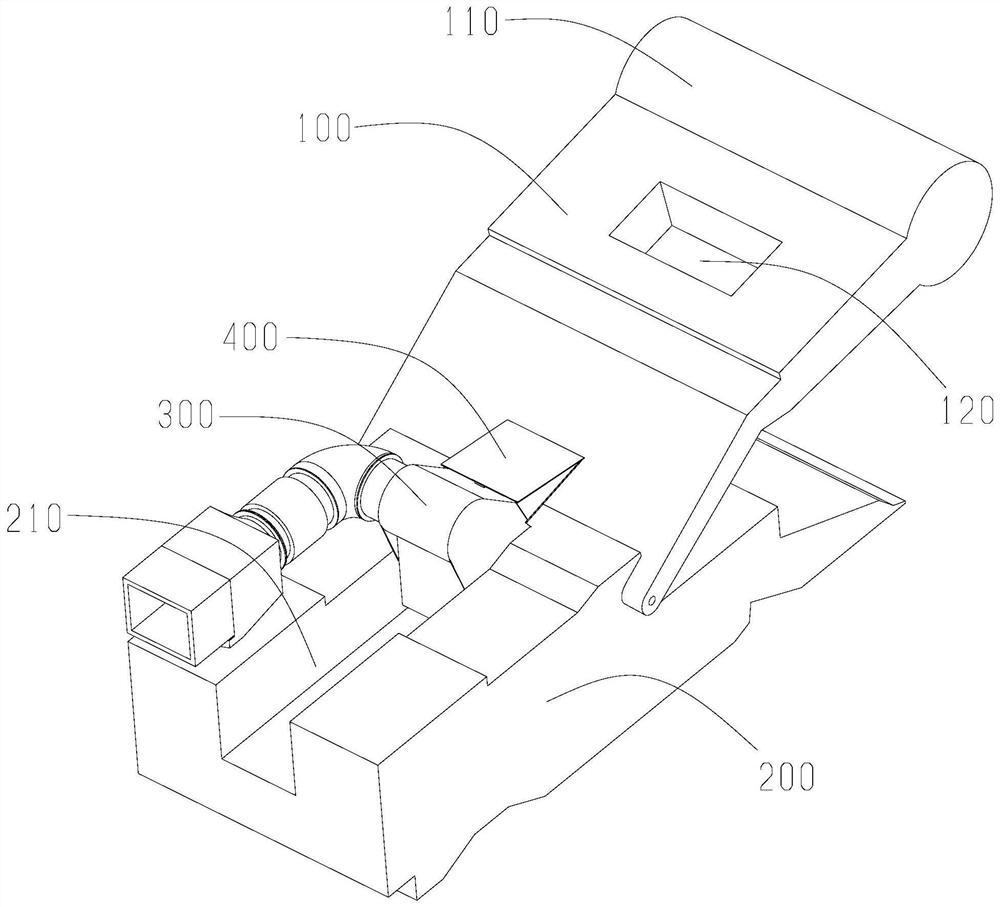

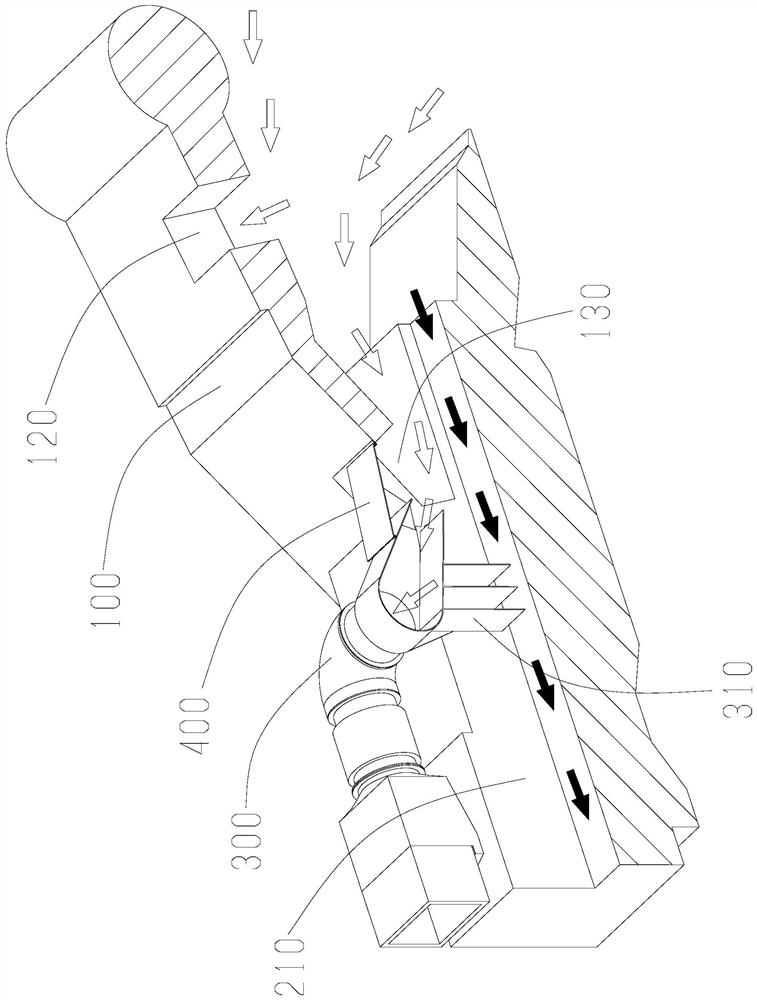

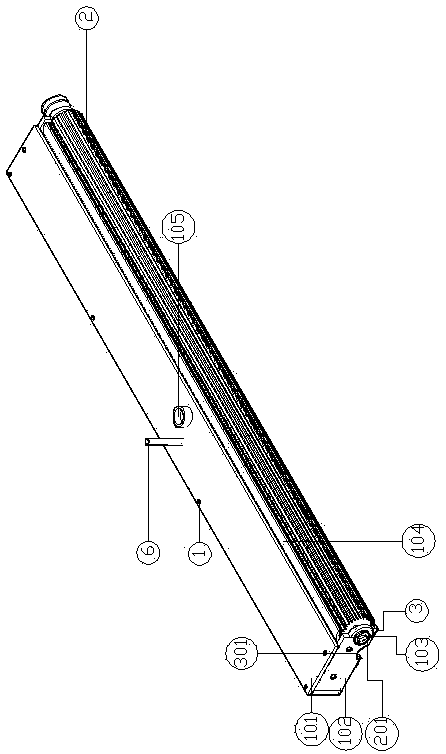

A high-efficiency dust extraction device suitable for low-level dust sources of continuous miners

ActiveCN111075446BRealize dynamic sealingAvoid enteringSlitting machinesCutting machinesMining engineeringCoal mining

The invention relates to the technical field of coal mining machinery, in particular to a high-efficiency dust extraction device suitable for low-level dust sources of continuous miners, comprising a dust extraction port and a cover, and the dust extraction port is arranged on a cutting arm near a pivot shaft The upper edge of the dust extraction port is pivotally provided with a cover. The cover includes a plate body and shields arranged on both sides of the plate body. Dust outlet, the upper surface of the end of the dust extraction pipe close to the dust extraction port is an inclined plane, the plate body is lapped on the inclined surface, and the shield covers the opening between the dust extraction port and the dust extraction pipe, so that the dust extraction pipe and the exhaust pipe A movable seal is formed between the dust ports. The structure of this application is a purely mechanical seal. Compared with parts such as bellows, it has better durability, more reliability, longer life and is not easy to be damaged.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

A hood-sealed waterproof pitot tube

ActiveCN114113672BResume normal useMeet structural requirementsAircraft componentsSpeed/acceleration/shock instrument detailsUncrewed vehicleEngineering

The invention discloses a hood-sealed waterproof pitot tube, which comprises a sealed cabin, the two ends of the sealed cabin are respectively provided with a first opening and a second opening, and a pitot tube is arranged in the sealed cabin, and the pitot tube is connected from the first One opening end is inserted into the airtight cabin, and a sealing mechanism is provided between the first opening and the pitot tube; a hatch door that can be opened and closed is provided on the second opening, and the first opening is flexibly connected with the pitot tube; The cabin is provided with a drive mechanism that drives the airtight cabin to slide on the pitot tube, and a linkage mechanism that drives the door to open and close when the airtight cabin slides on the pitot tube is provided between the hatch door and the pitot tube. This solution is aimed at the use of water-air dual-purpose drones. When the drone enters the water, it relies on the airtight cabin to close the pitot tube. When it leaves the water, the airtight cabin can be opened to restore the pitot tube. The invention adopts the sealing rubber sleeve, which can realize dynamic sealing and achieve waterproof effect.

Owner:中国空气动力研究与发展中心空天技术研究所

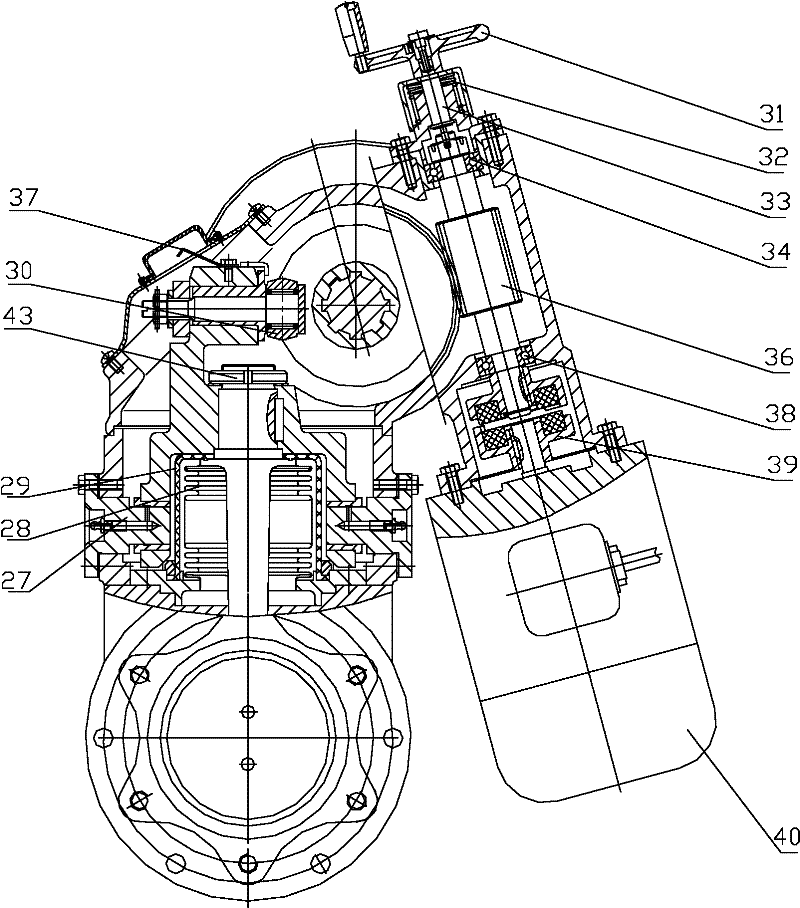

Nuclear electric torpedo vacuum valve

ActiveCN102022555BLax closeReduce impactOperating means/releasing devices for valvesLift valveEngineeringTurbine

The invention provides a nuclear electric torpedo vacuum valve, comprising a valve body, a torpedo-shaped valve core arranged in the valve body, a lever assembly for connecting the valve core, a fork assembly for driving the lever assembly to move, and a drive device for driving the fork assembly to actuate. The valve core consists of an arc-shaped enclosed disc and an arc-shaped tail cone connected with the enclosed disc; a corrugated pipe is arranged on a lever, a protective cover is covered outside the corrugated pipe; a fork can rotate around a support shaft; a roller is fixed on the upper end of the fork; and the drive device comprises a turbine shaft and a turbine for driving the turbine shaft to rotate. A spline on the turbine shaft are connected to a guide rail, a guide slot is arranged on the guide rail, the roller fixed on the upper end of the fork is embedded in the guide slot, a disc spring is sleeved on the turbine shaft, and a disc spring box with a compression disc spring is covered outside the disc spring. The electric torpedo vacuum valve is featured by simple structure, excellent sealing performance, fast responsiveness, and small action impact, meets the requirement on quick shutoff for nuclear safety, and can be operated manually or driven electrically.

Owner:CNNC SEVENTH RES & DESIGN INST CO LTD

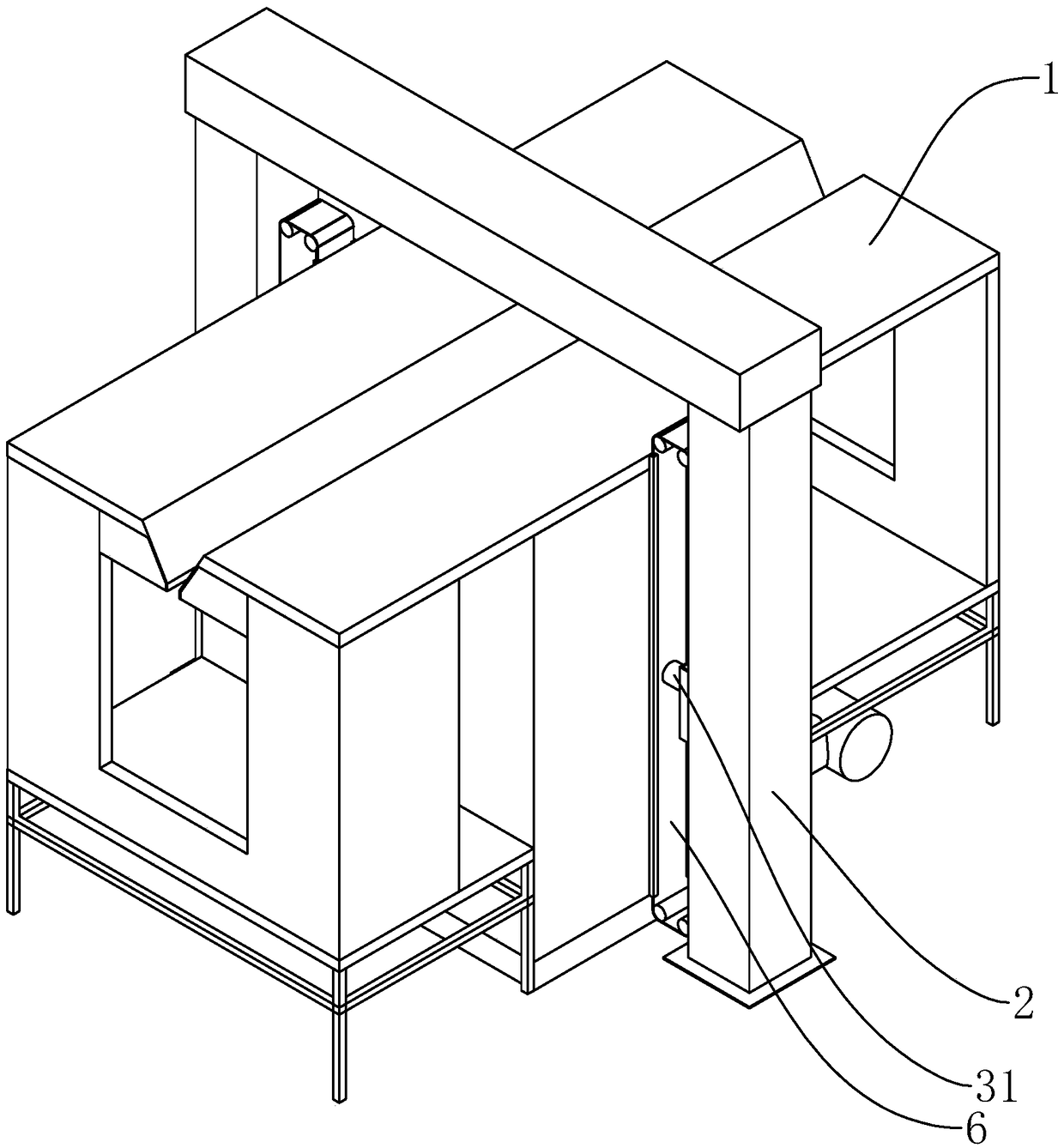

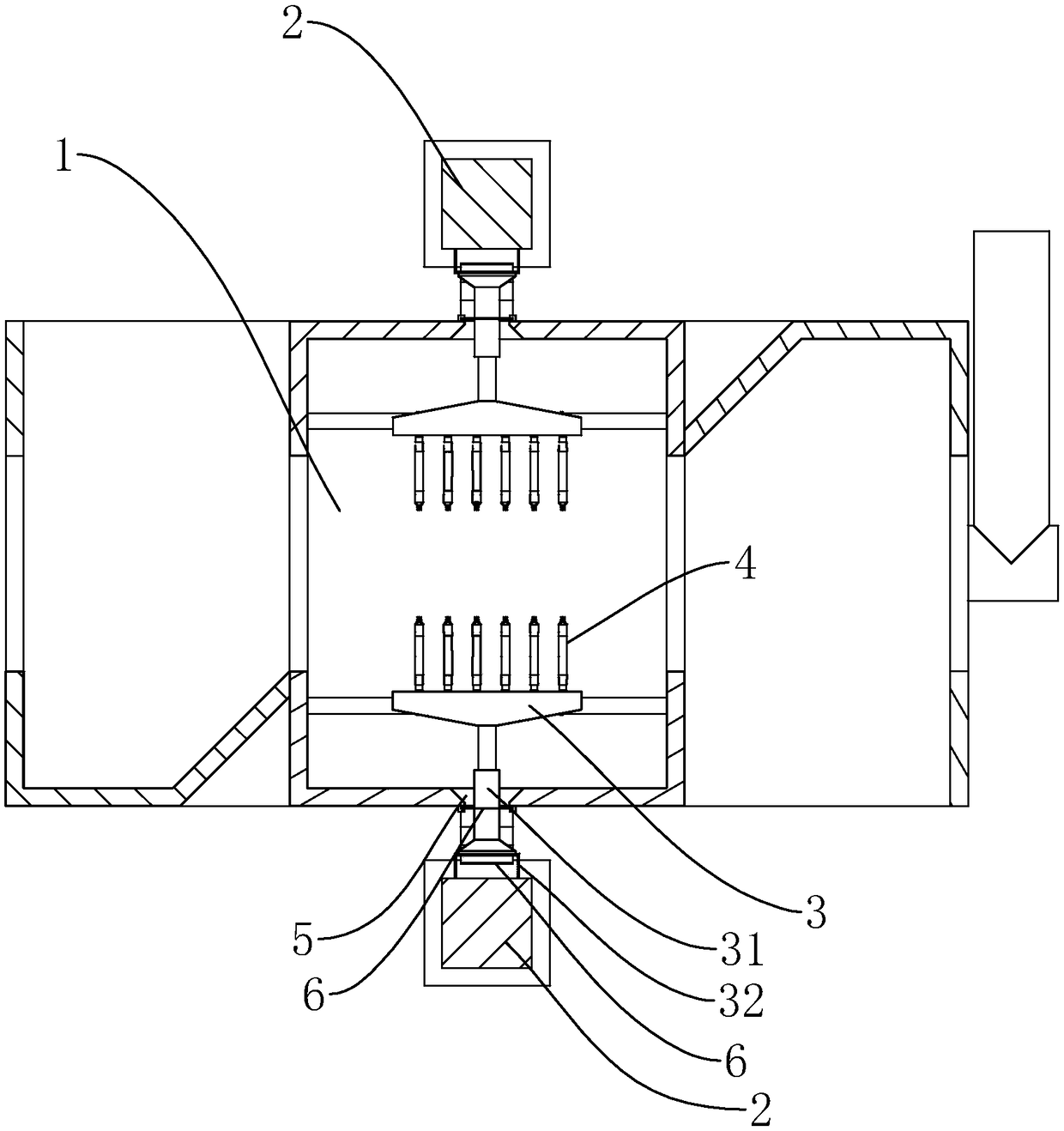

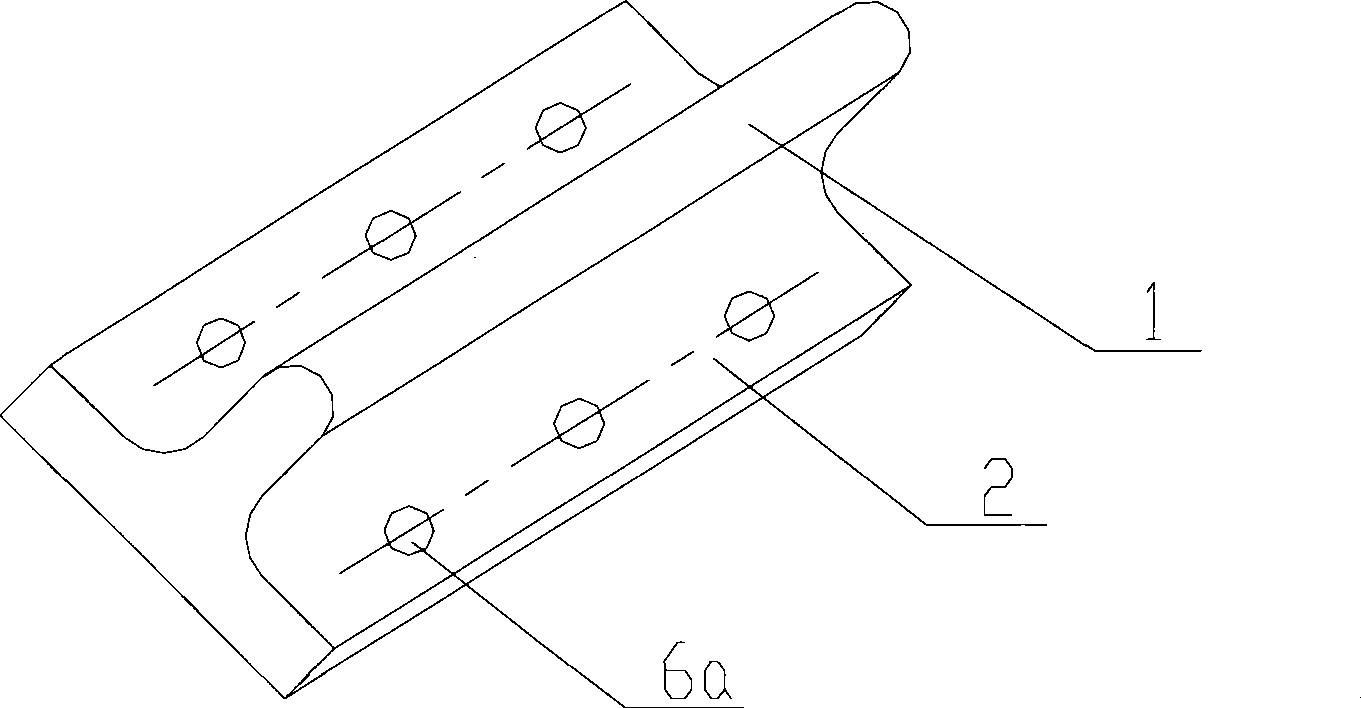

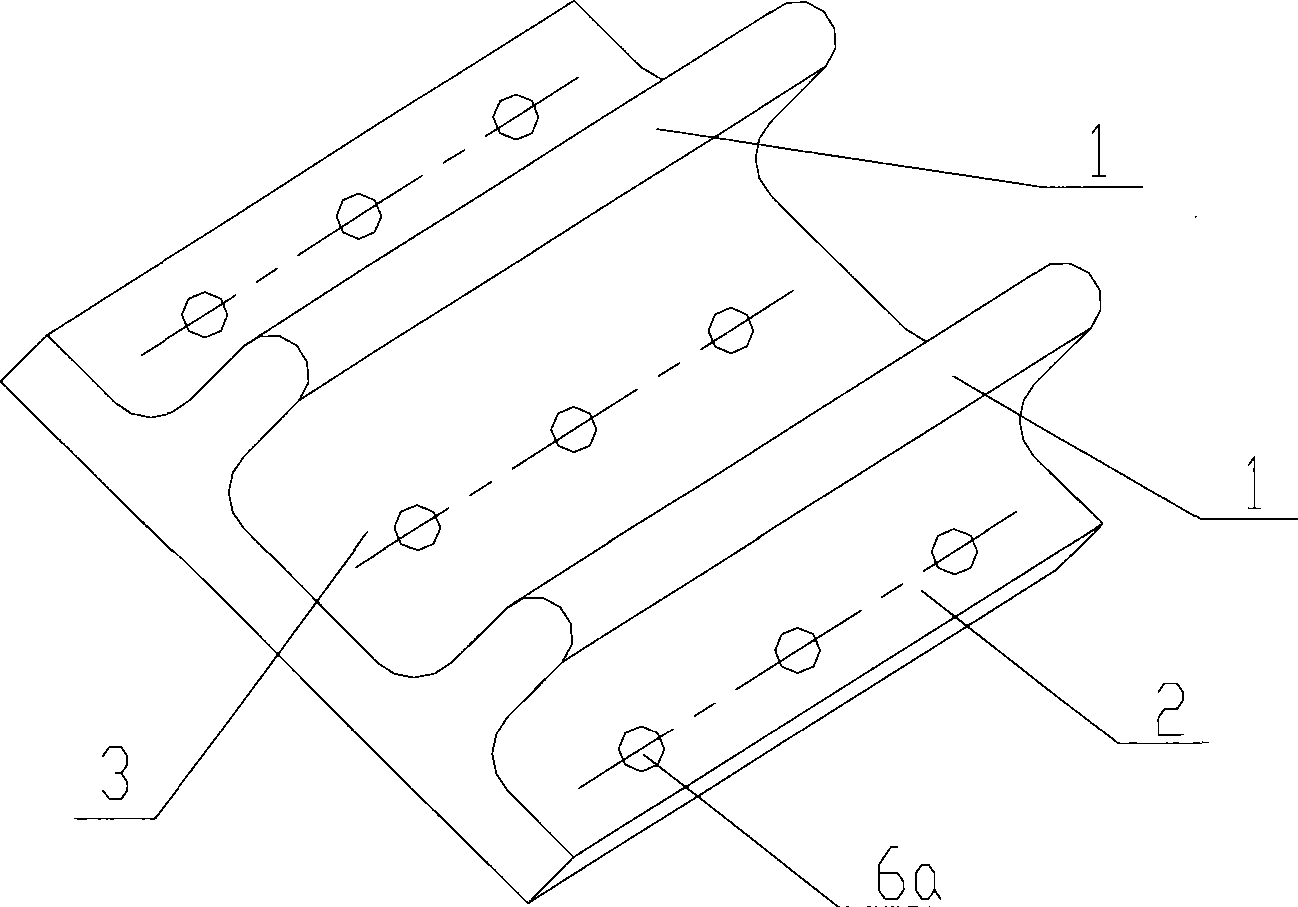

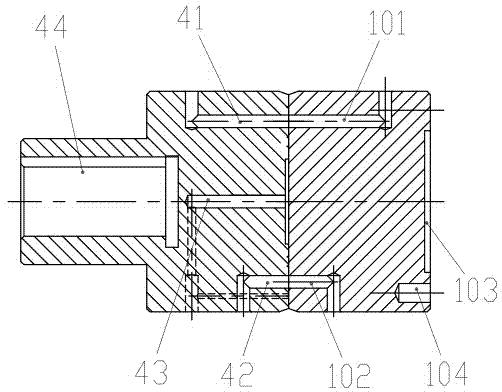

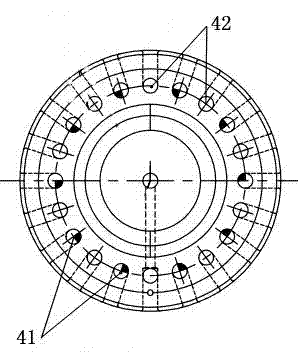

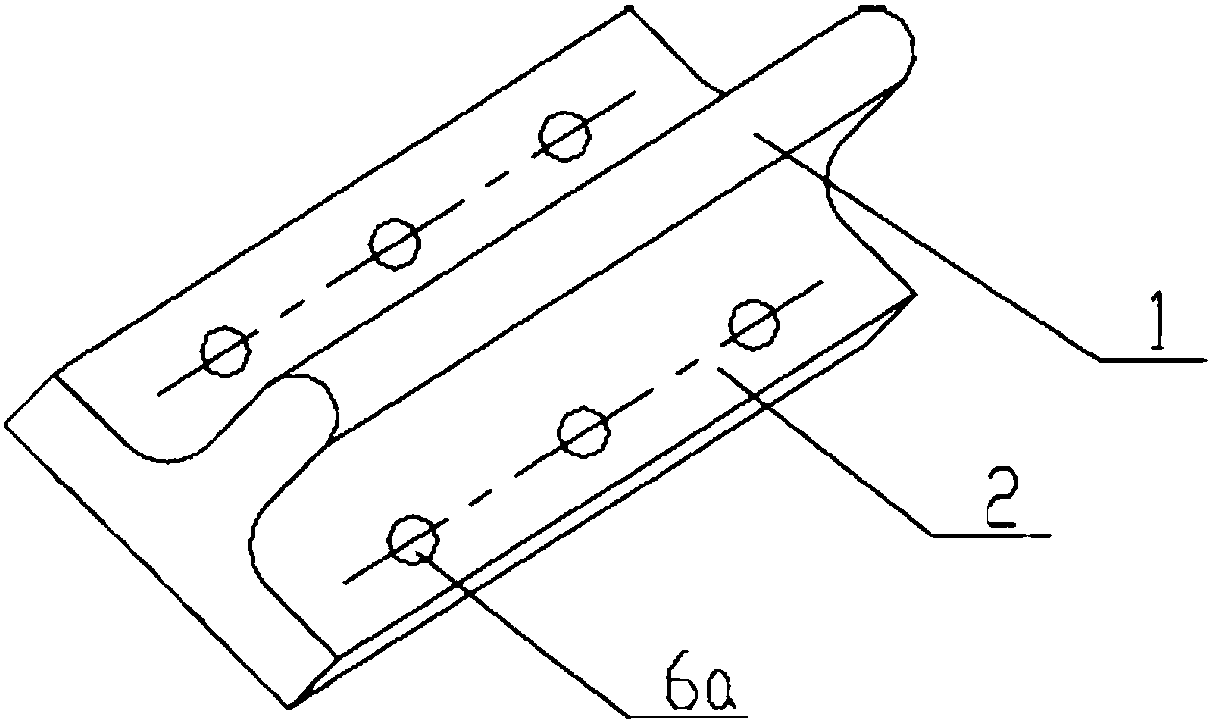

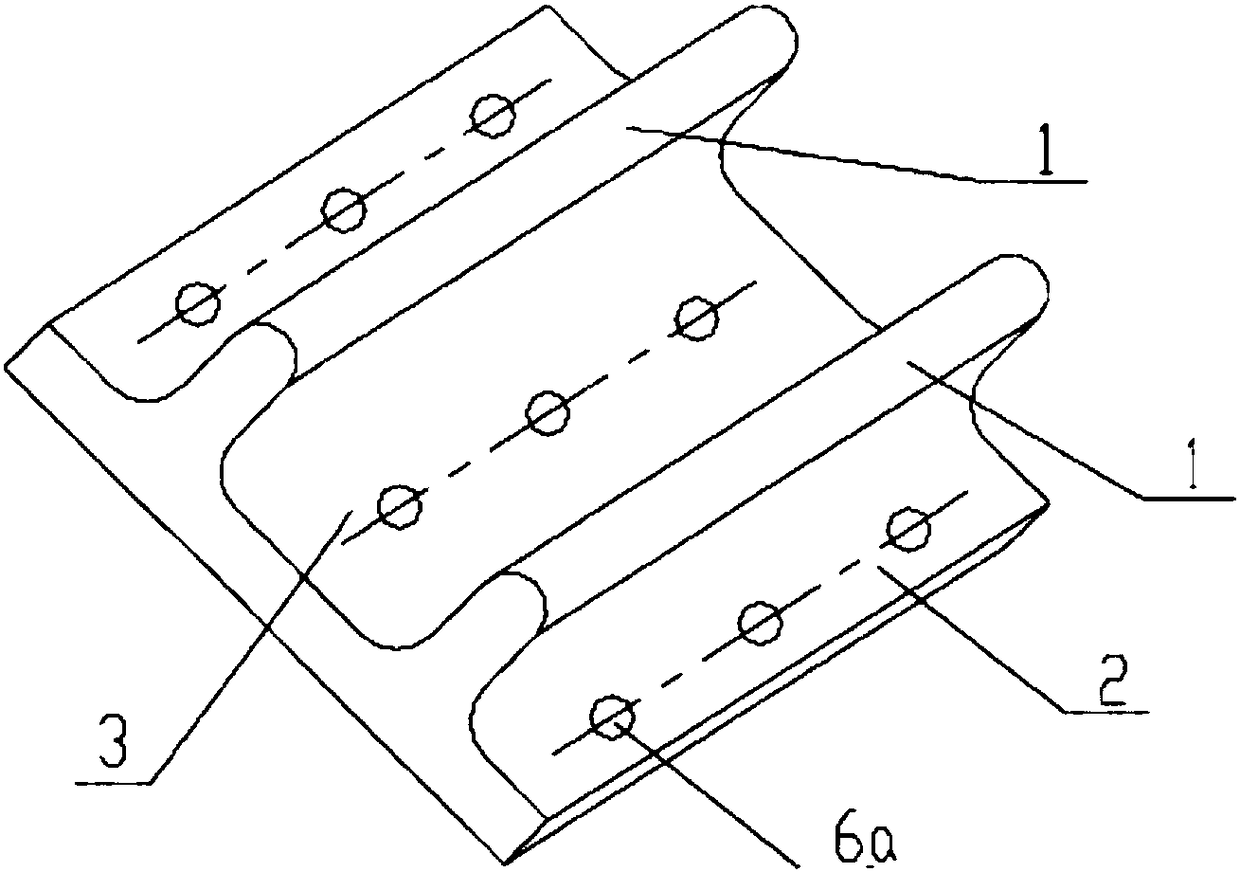

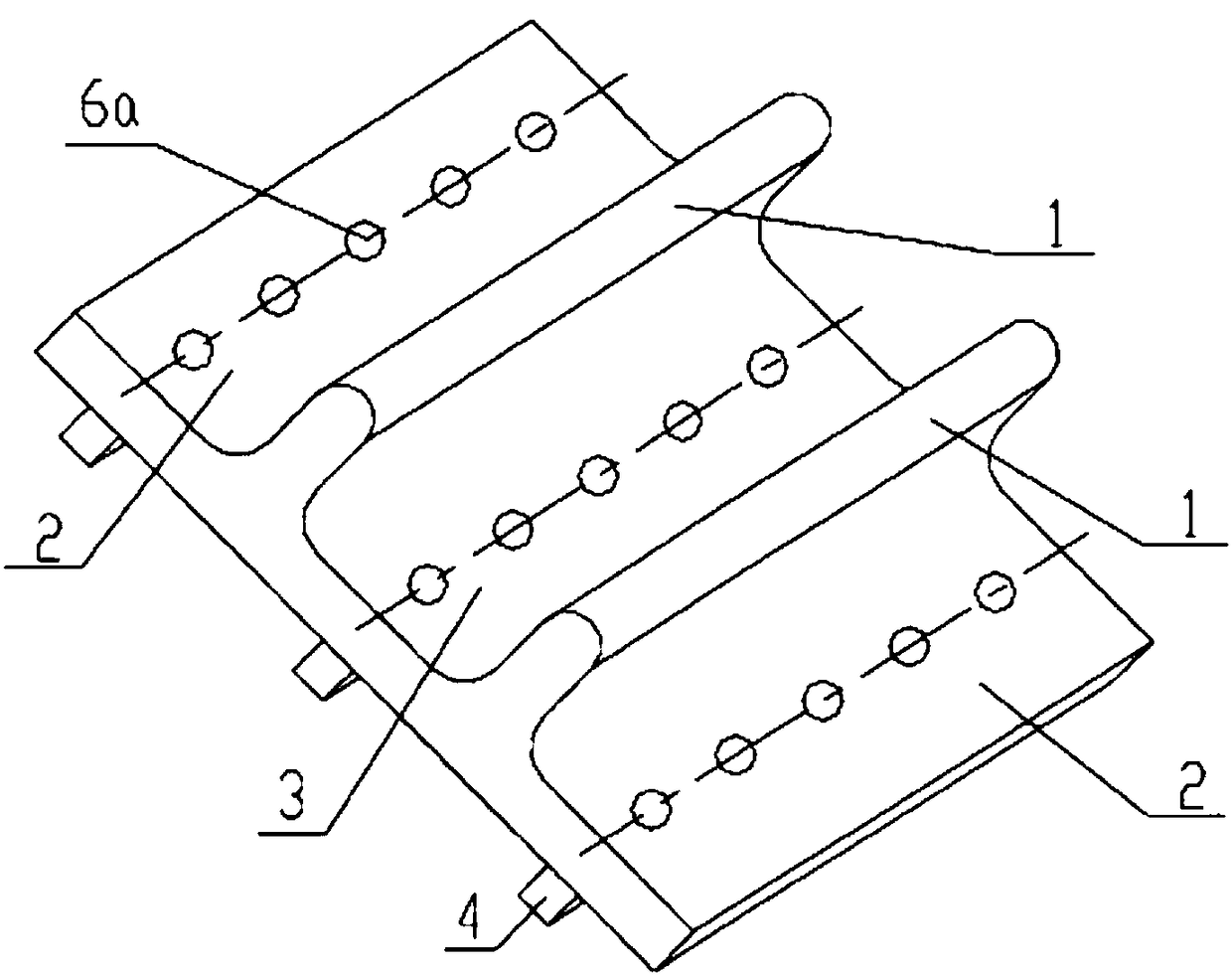

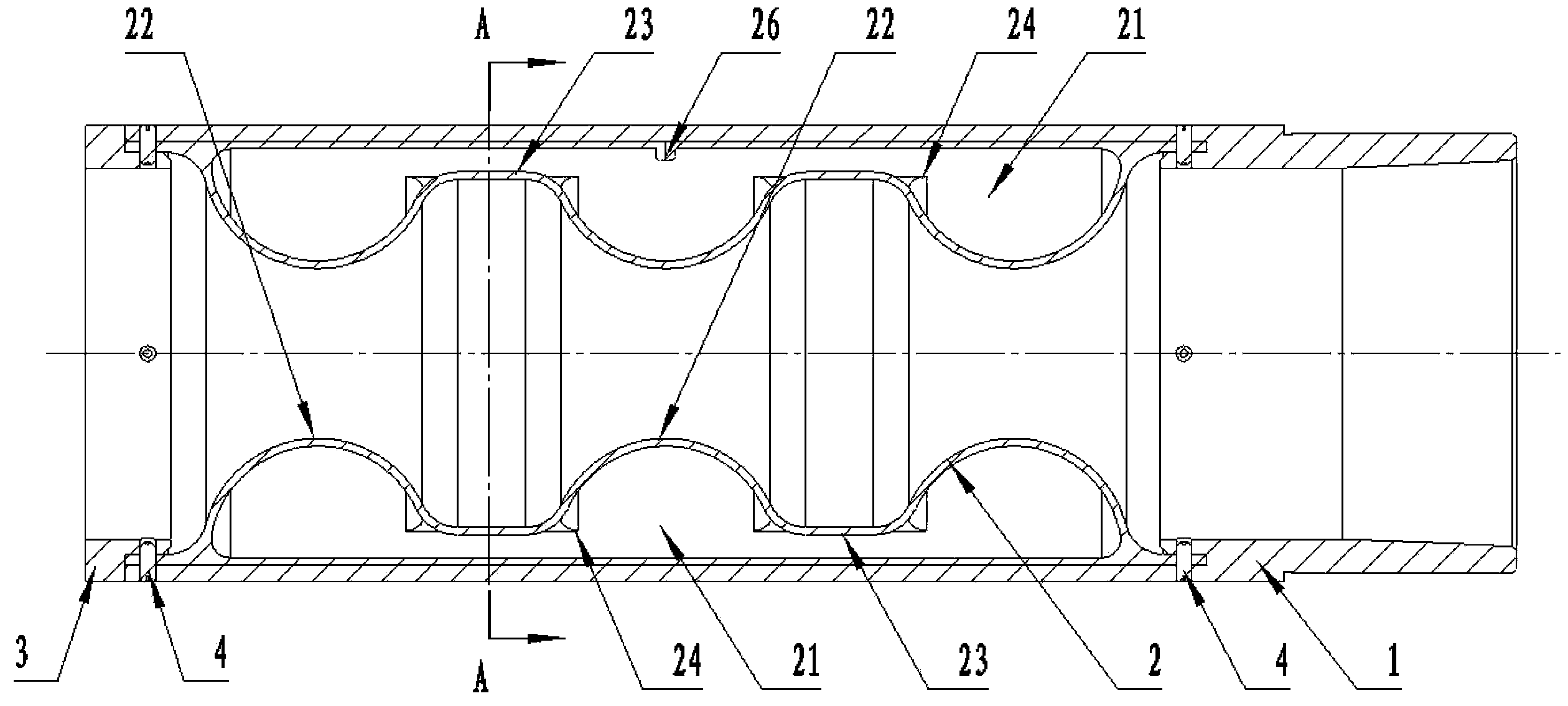

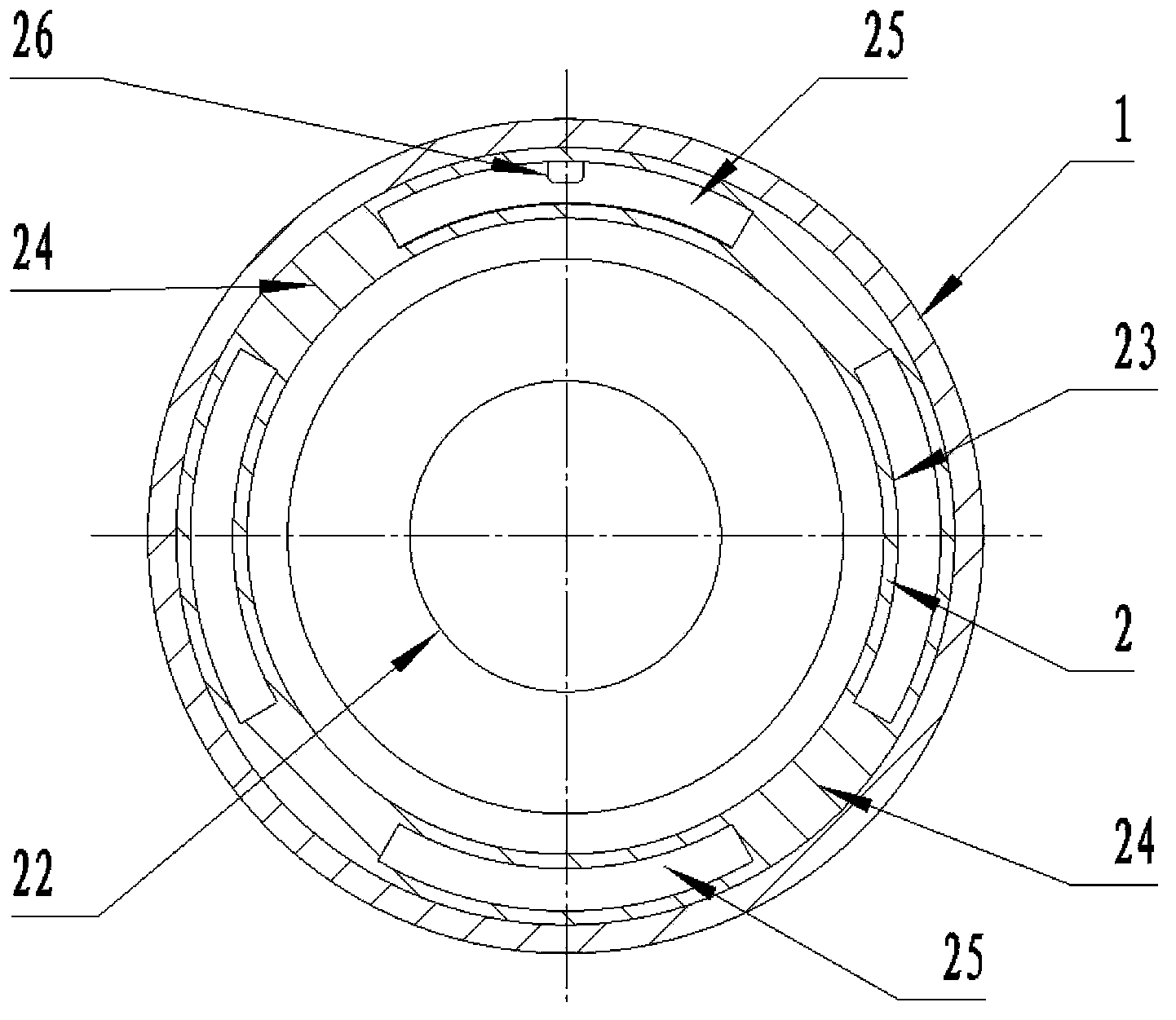

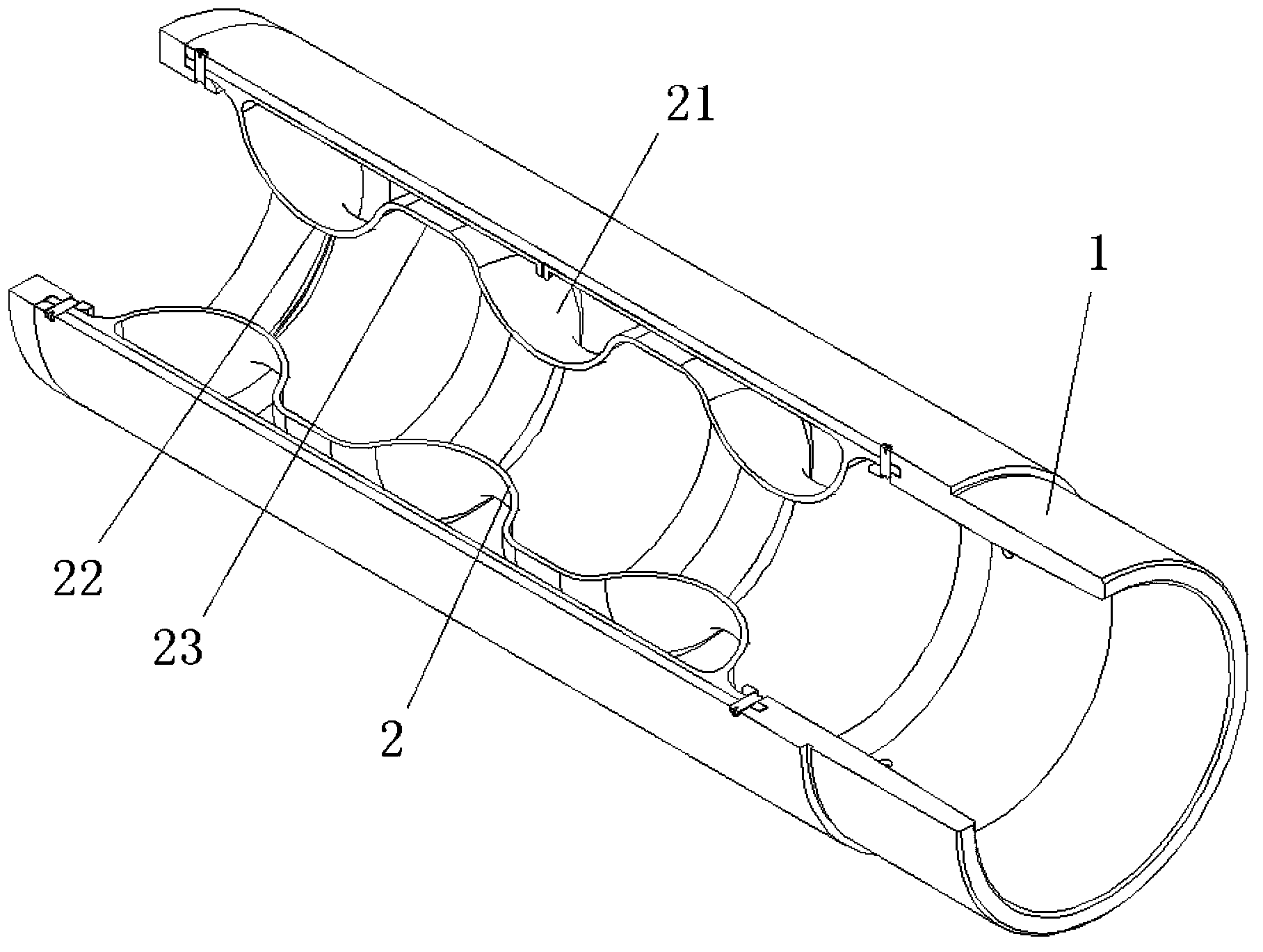

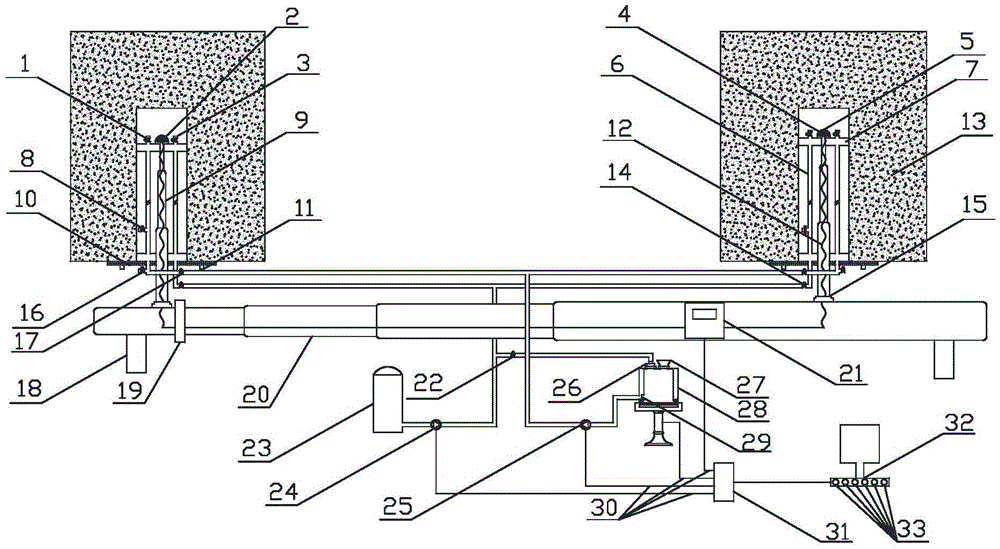

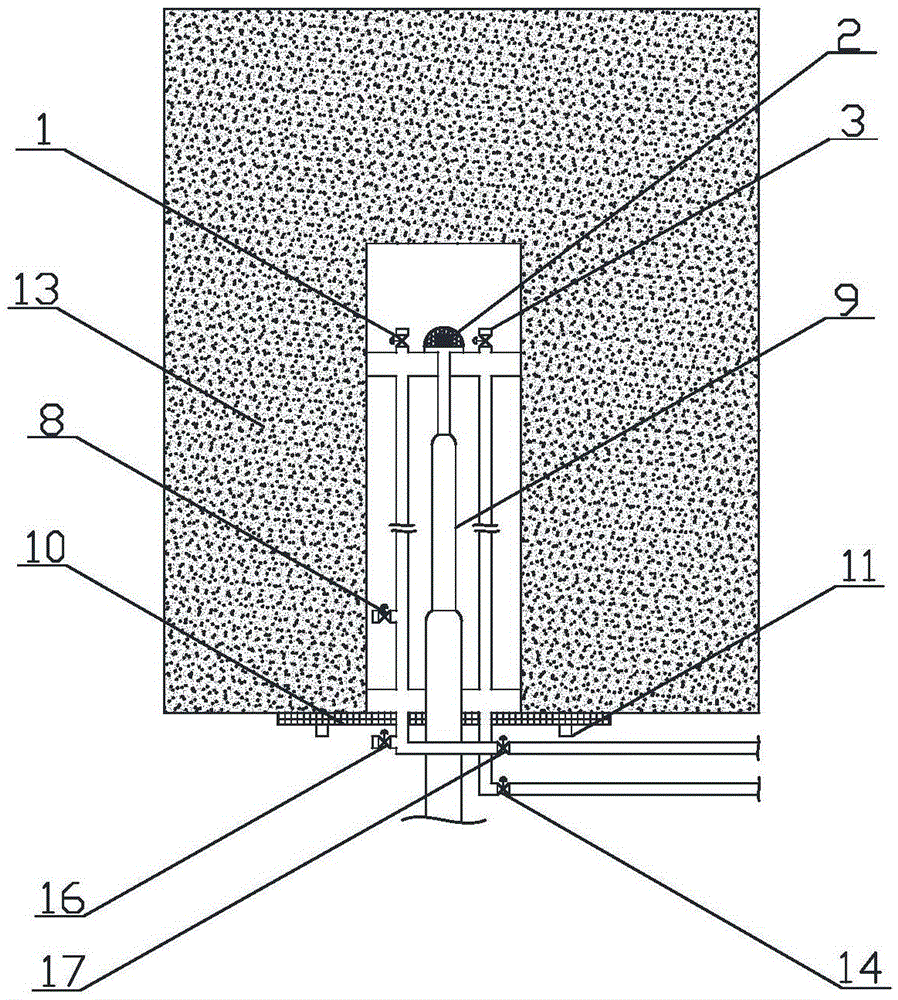

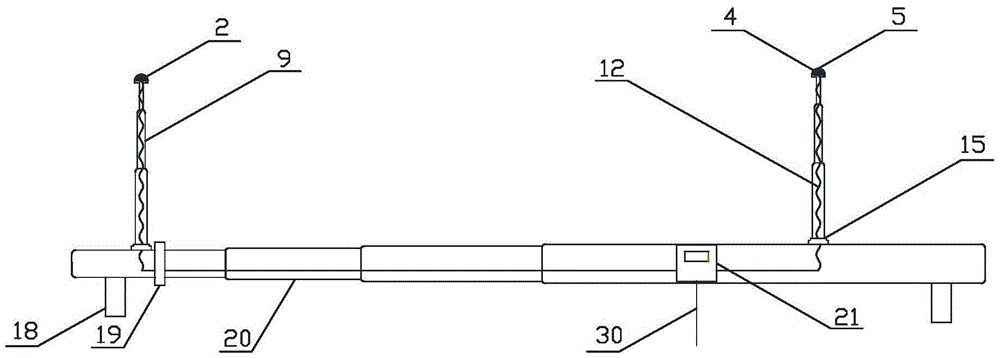

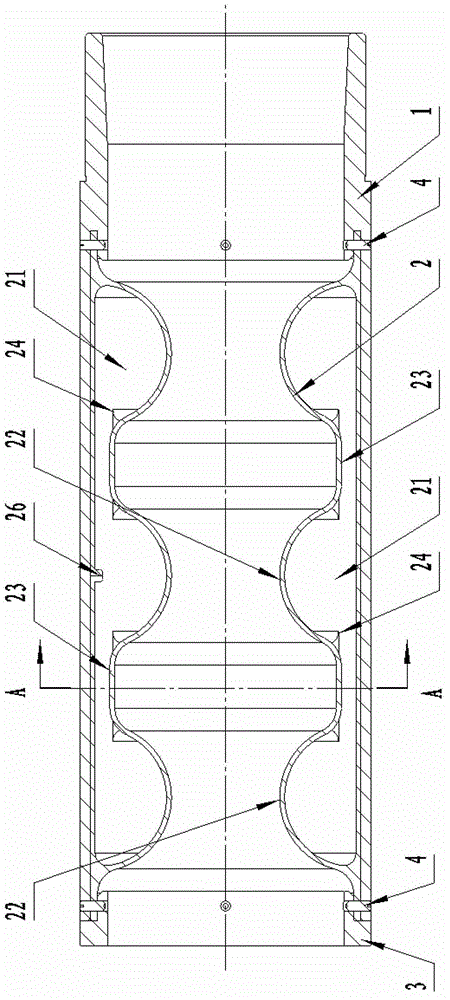

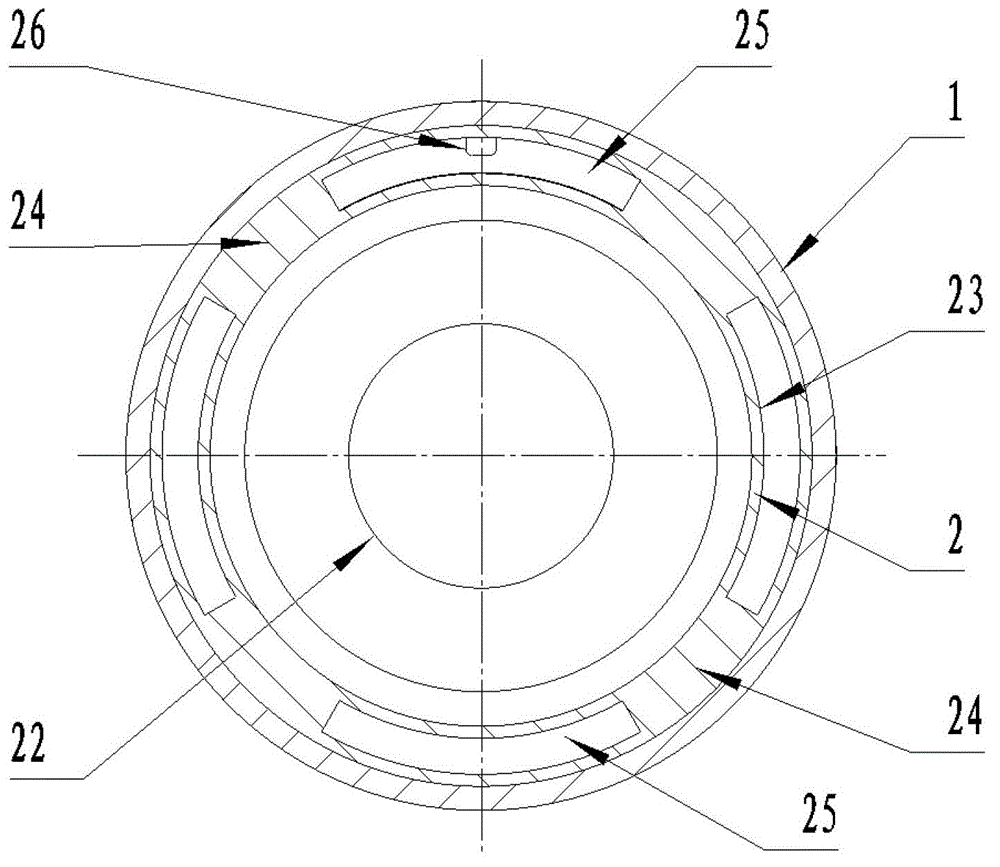

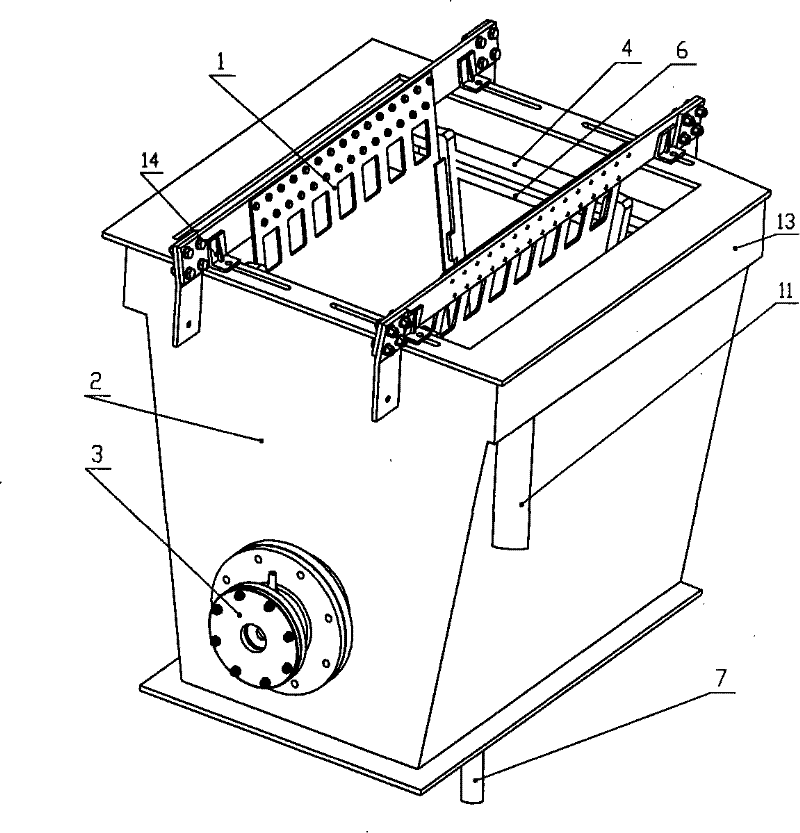

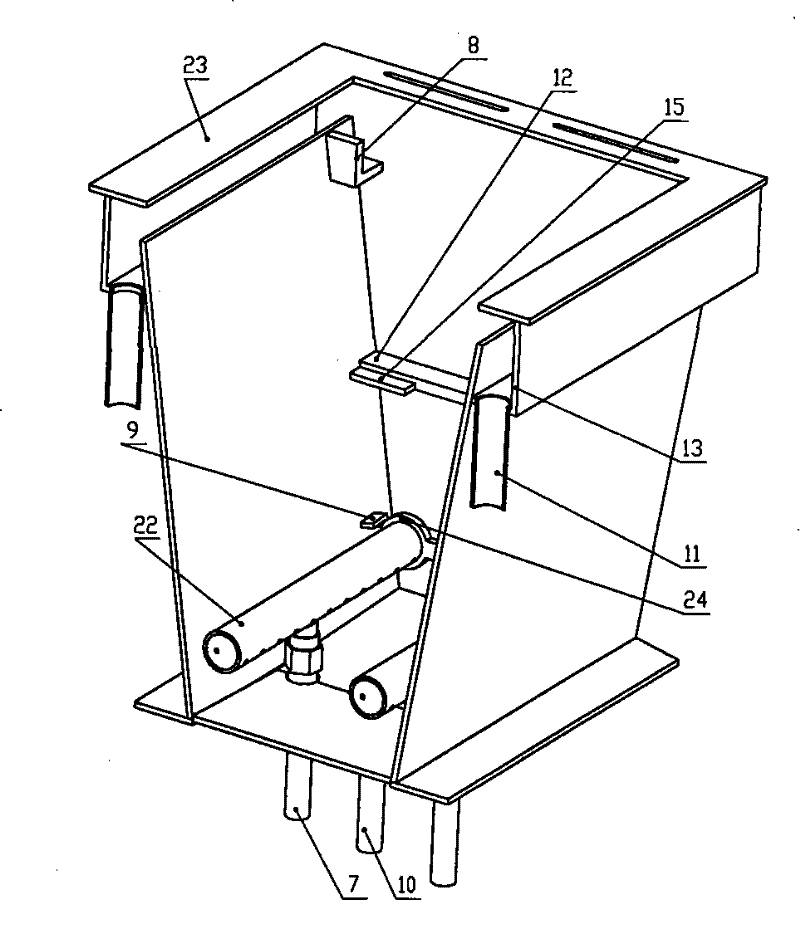

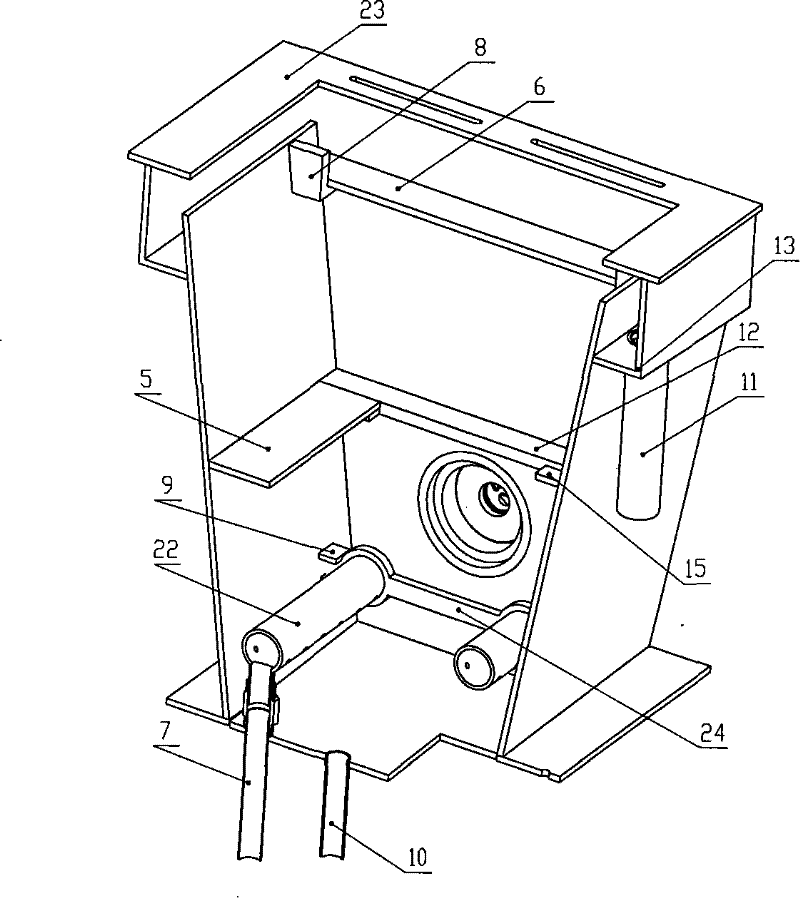

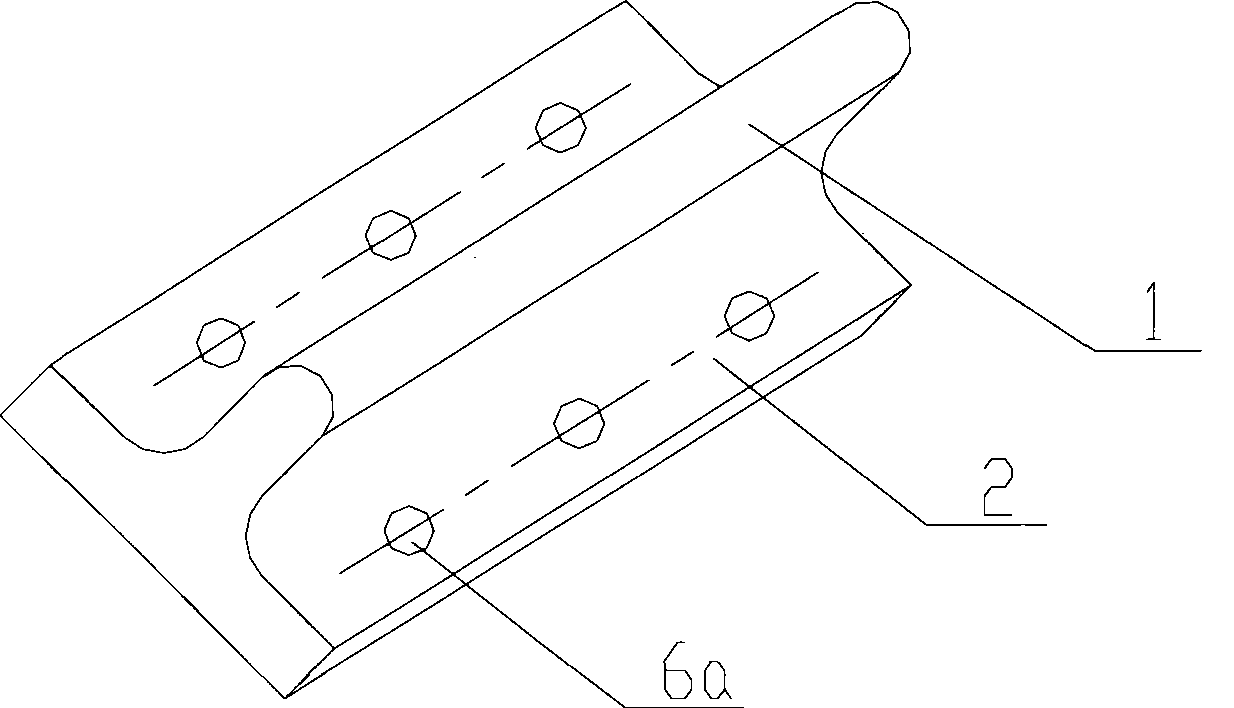

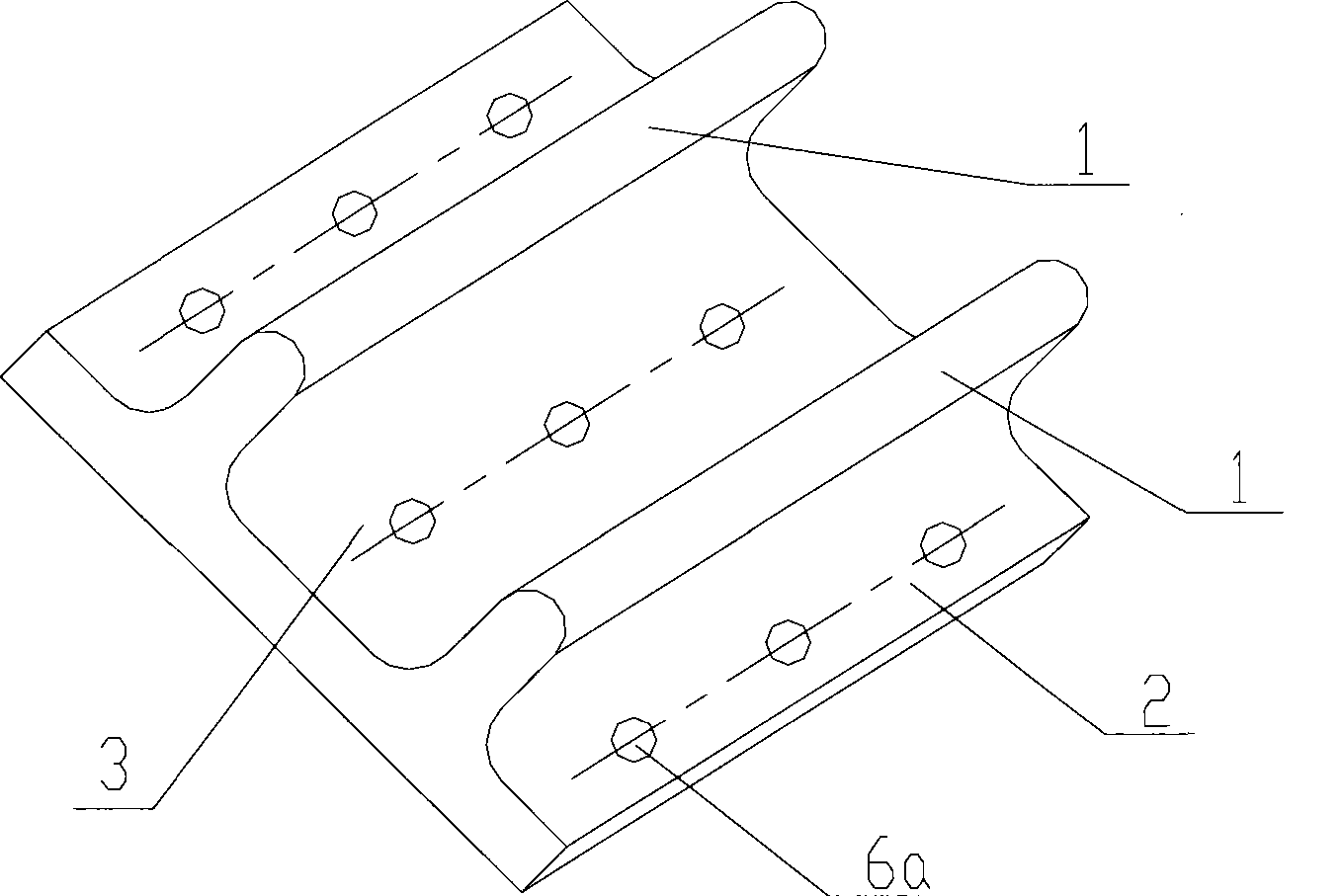

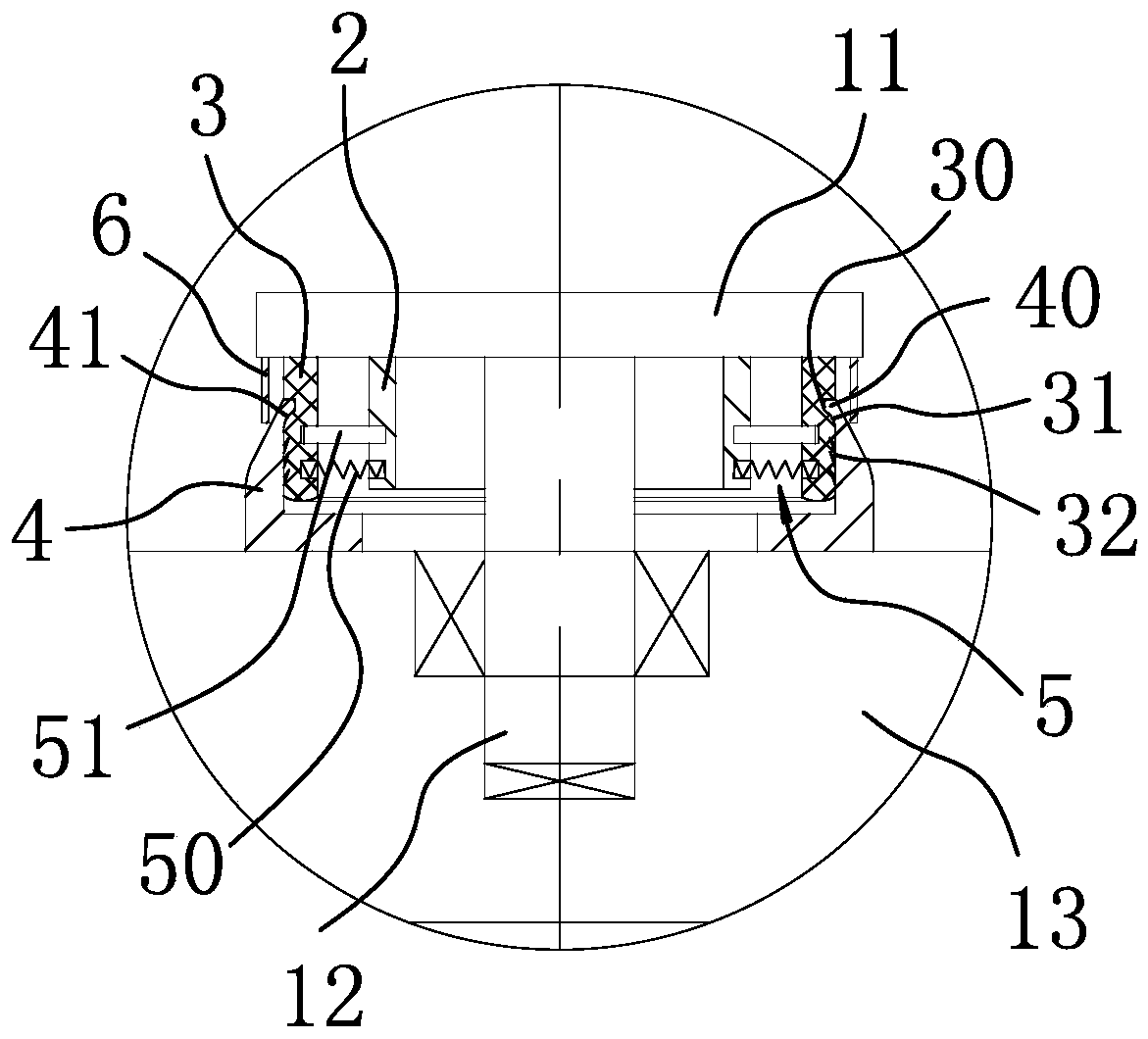

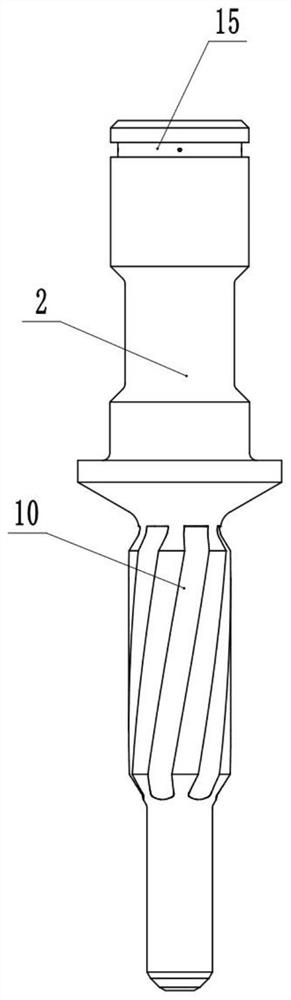

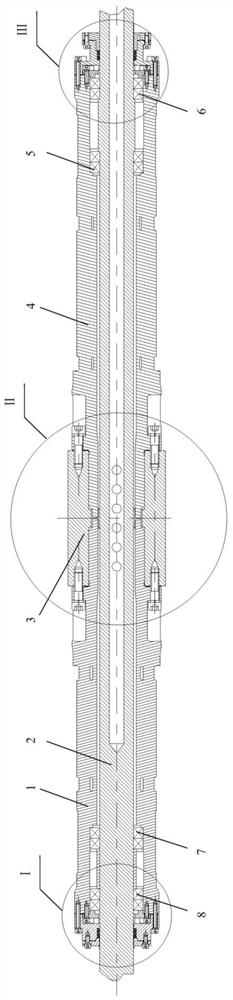

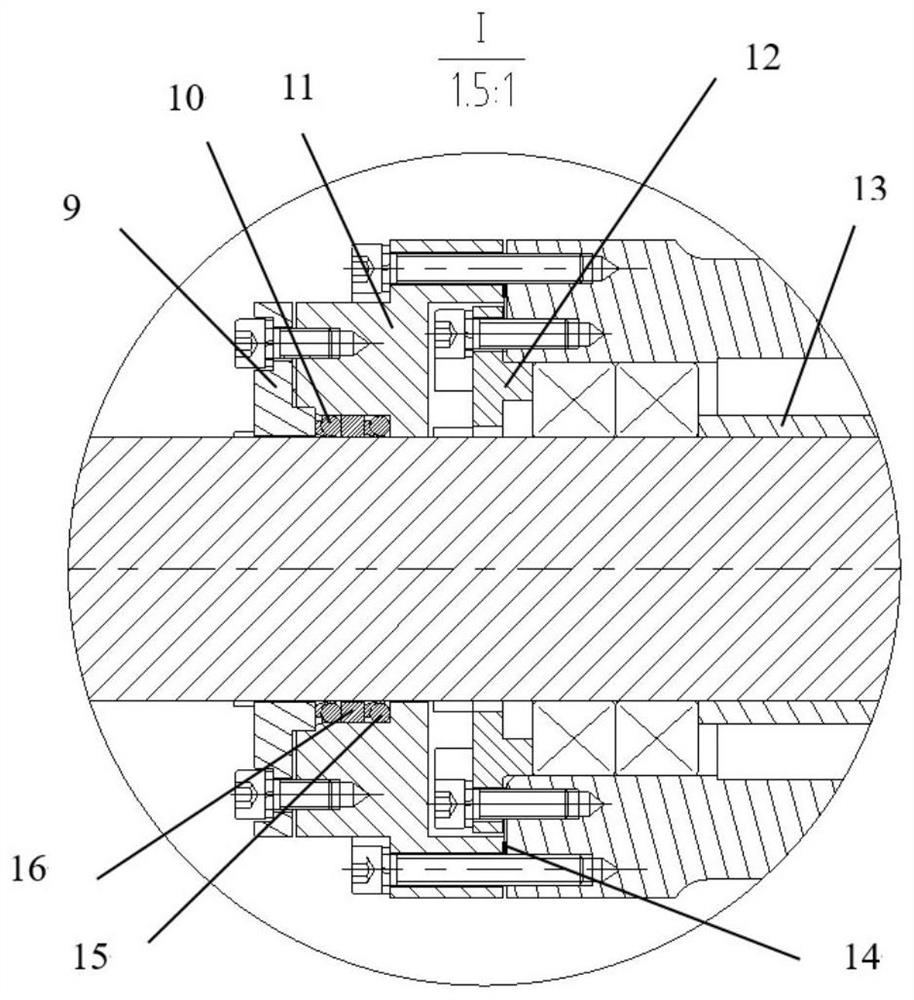

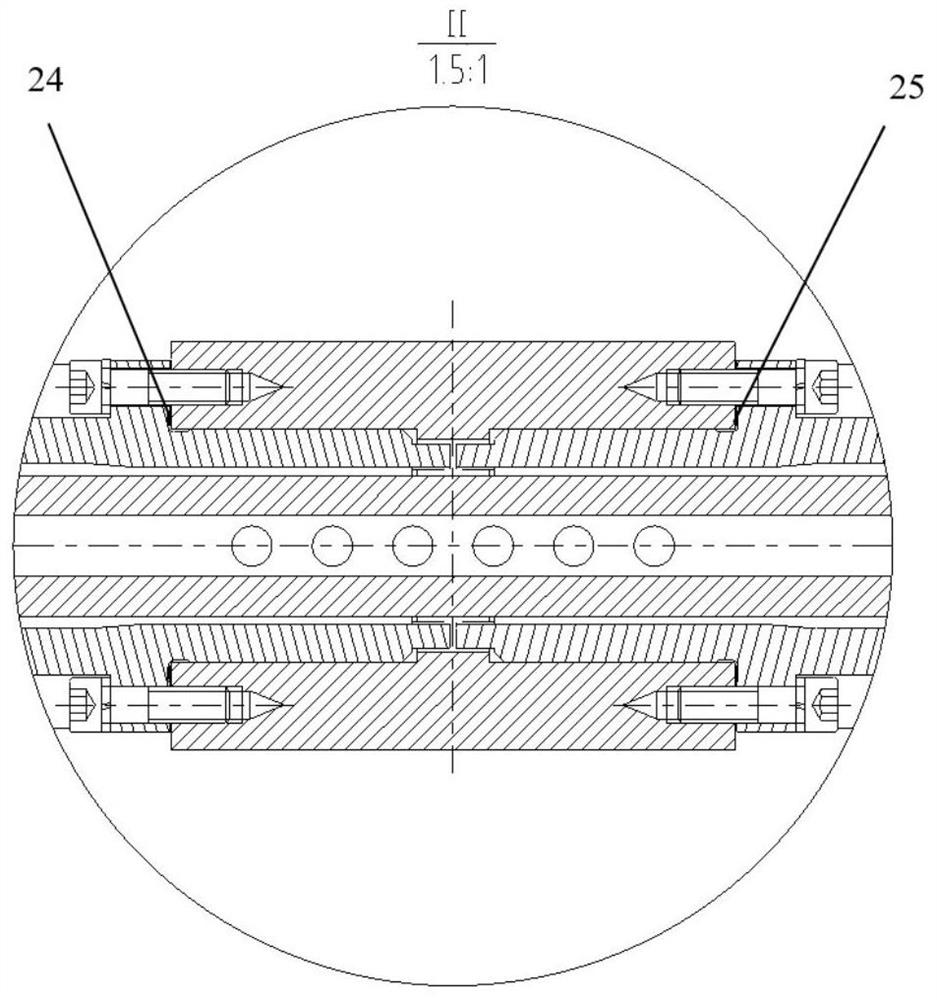

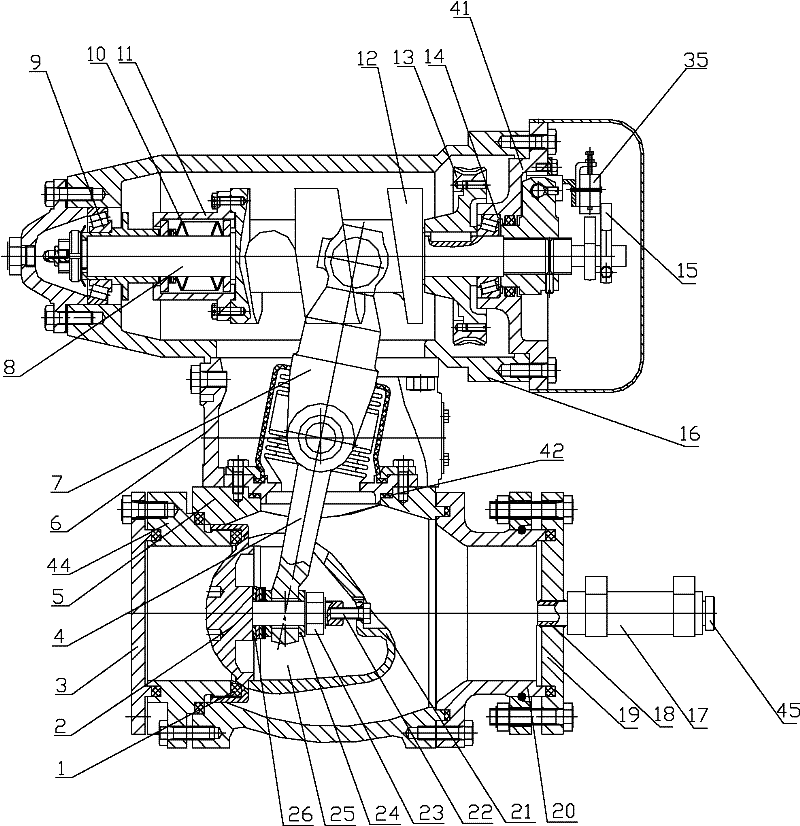

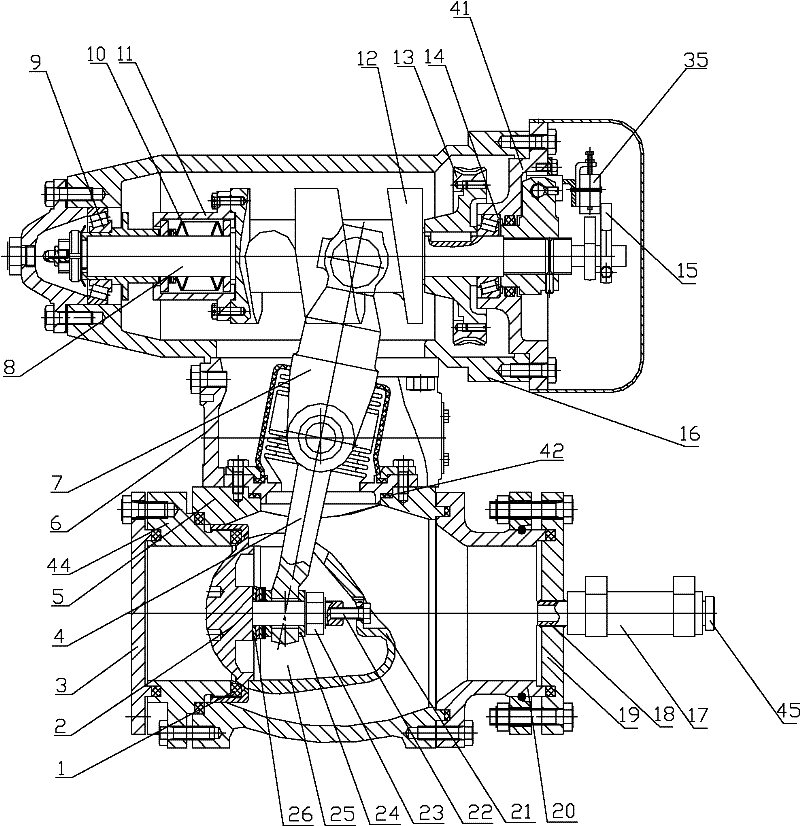

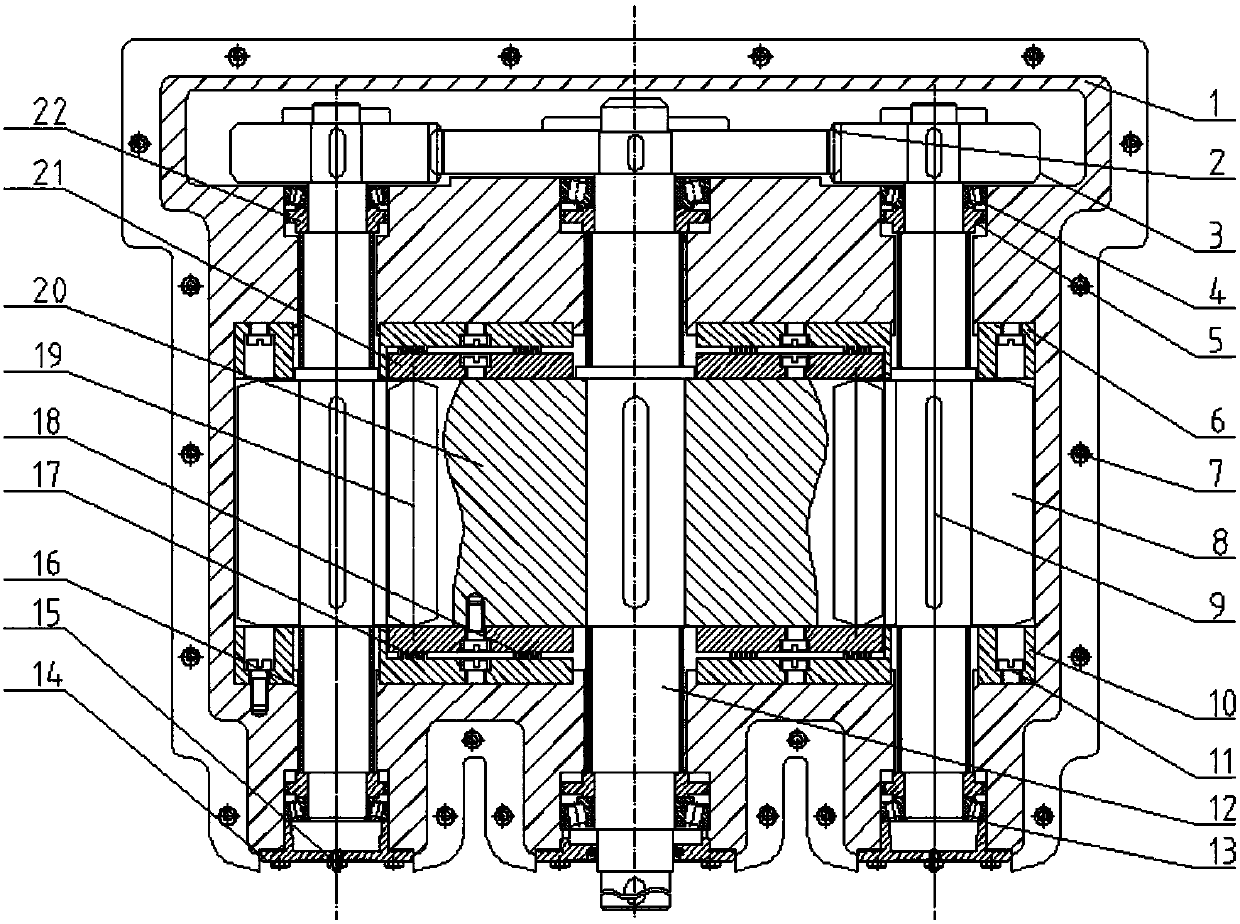

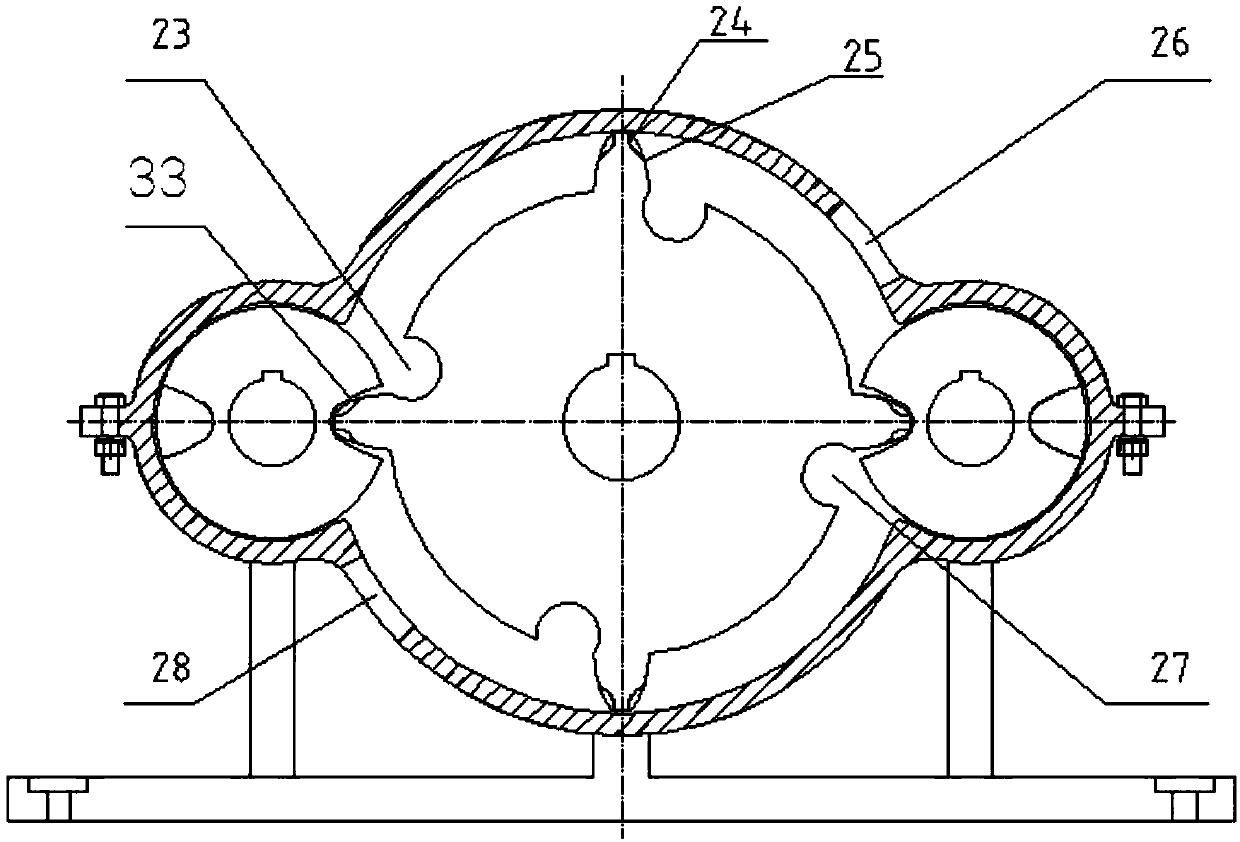

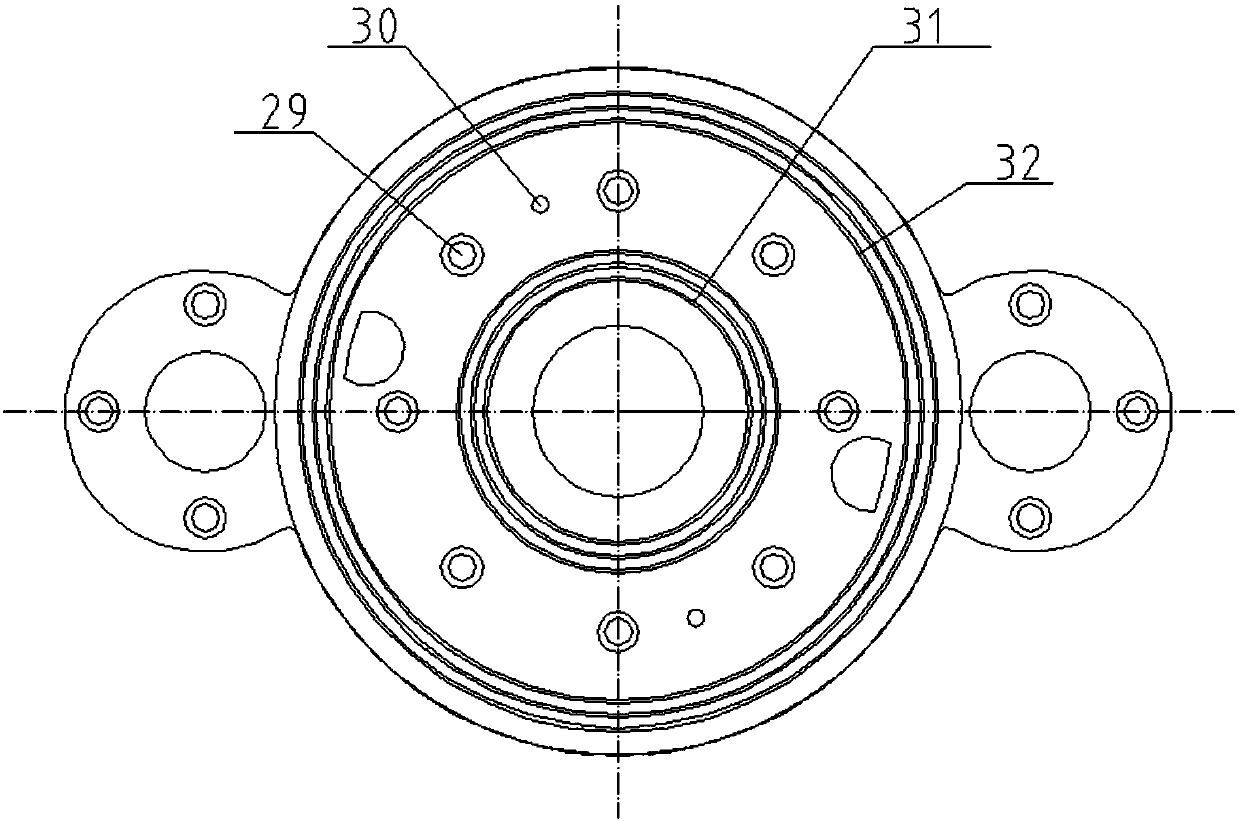

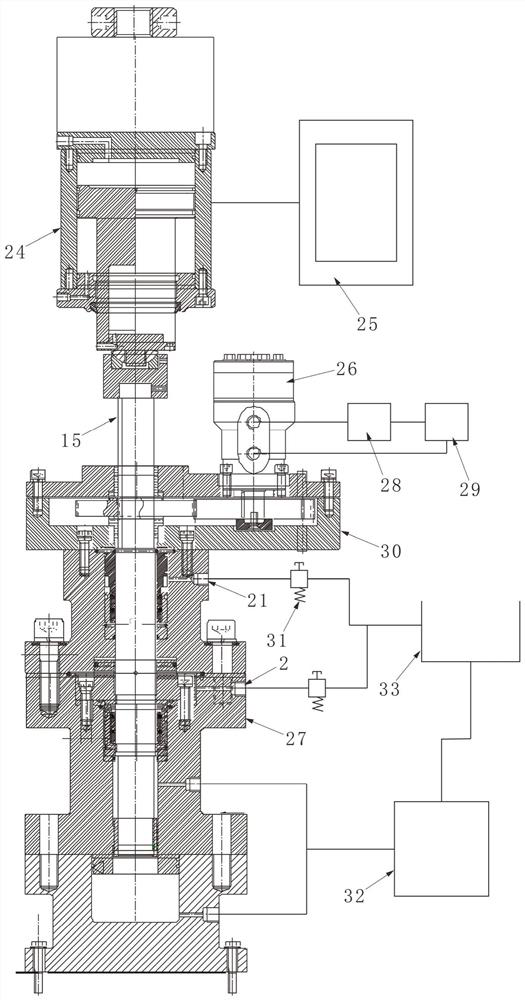

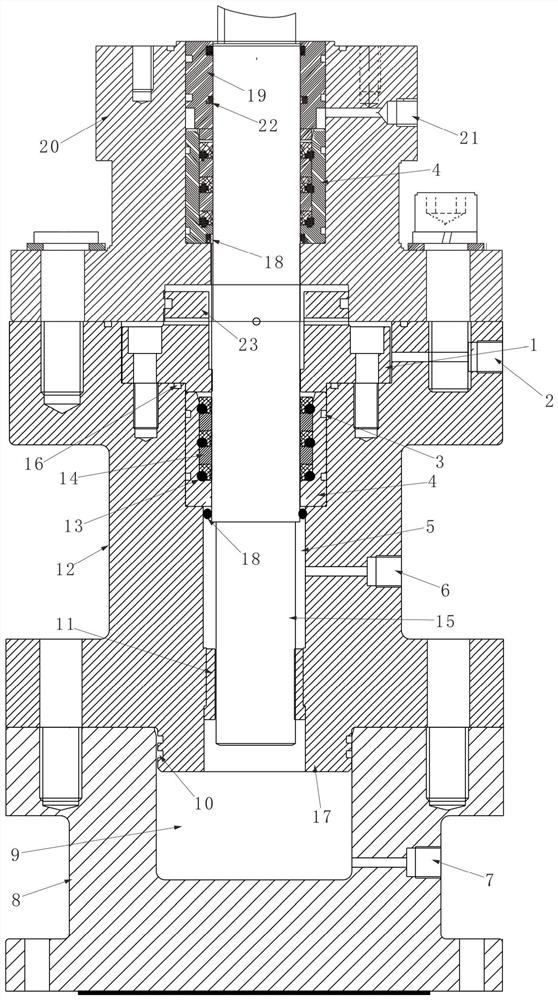

A combined sealing method and device for a continuous low temperature combustion rotary engine

ActiveCN106895151BOvercoming sealing problems during intake, combustion, and expansion processesRealize dynamic sealingEngine sealsSealing arrangements for enginesRotary engineCombined method

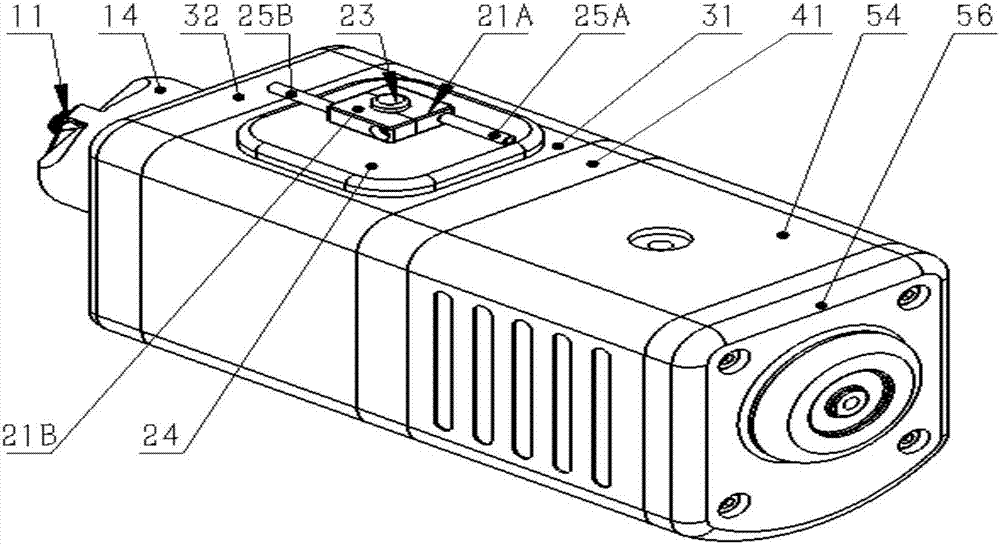

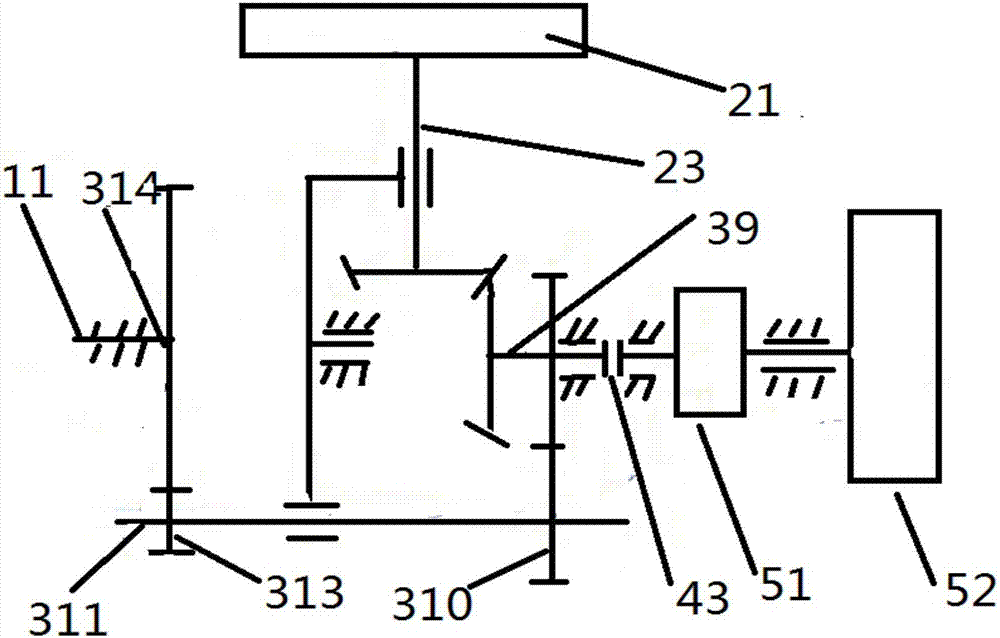

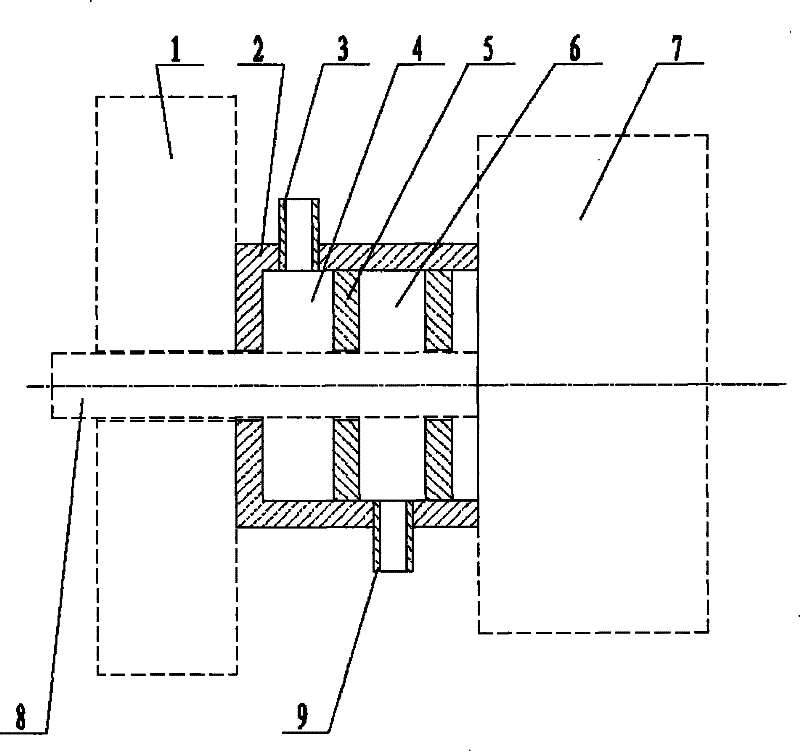

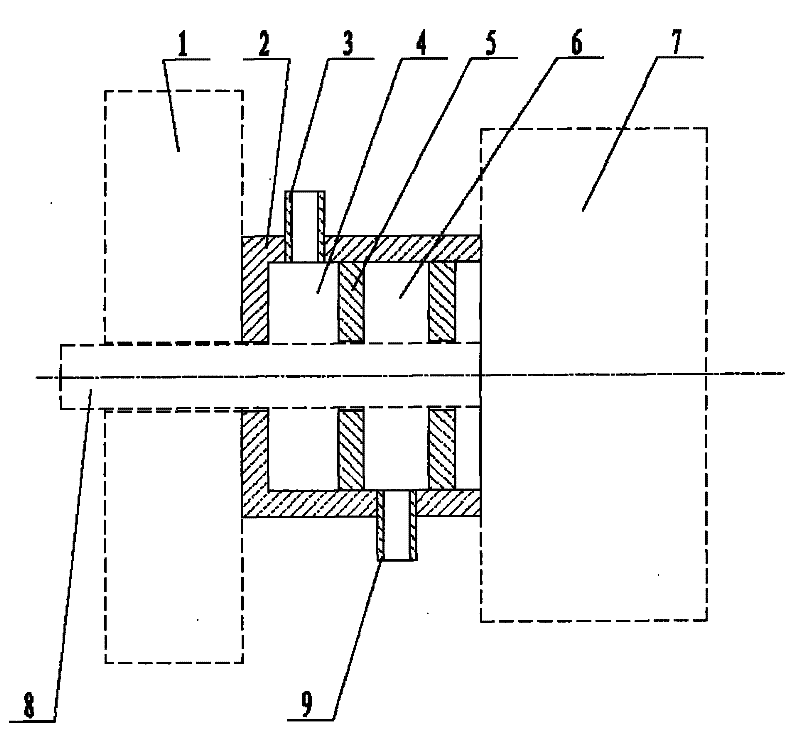

The invention discloses a combined sealing method and device for a continuous low-temperature combustion rotary engine. The combined sealing method and device are characterized in that the device comprises a continuous low-temperature combustion rotary engine shell (1), a main shaft timing gear (2), an auxiliary shaft timing gear (3), a right auxiliary shaft oil seal (5), an end face sealing hex socket (6), an auxiliary wheel (8), an auxiliary shaft (9), an end face seal (10), a main shaft (12), a bearing seal (16), an end face outer leakage sealing ring (17), an end face inner leakage sealing ring (18), a main shaft auxiliary gear matching part (19), a main shaft gear (20), an end face inner seal (21), a left auxiliary shaft oil seal (22), an upper air inlet (23), a main shaft gear protrusion groove (24), a main shaft gear protrusion (25), an upper exhaust port (26), a lower air inlet (27), a lower exhaust port (28), an end face sealing installation hole (29), an end face sealing positioning pin (30), an end face inner leakage sealing groove (31), an end face outer leakage sealing groove (32) and an auxiliary wheel groove (33). By means of the scheme, the sealing problem in the air intake, combustion and expansion processes of the novel continuous combustion low-temperature rotary engine is solved, due to axial sealing and radial sealing and meanwhile by the adoption of a non-contact combined sealing technology, movable sealing of the whole system can be achieved, and the sealing requirement is met.

Owner:HUNAN UNIV

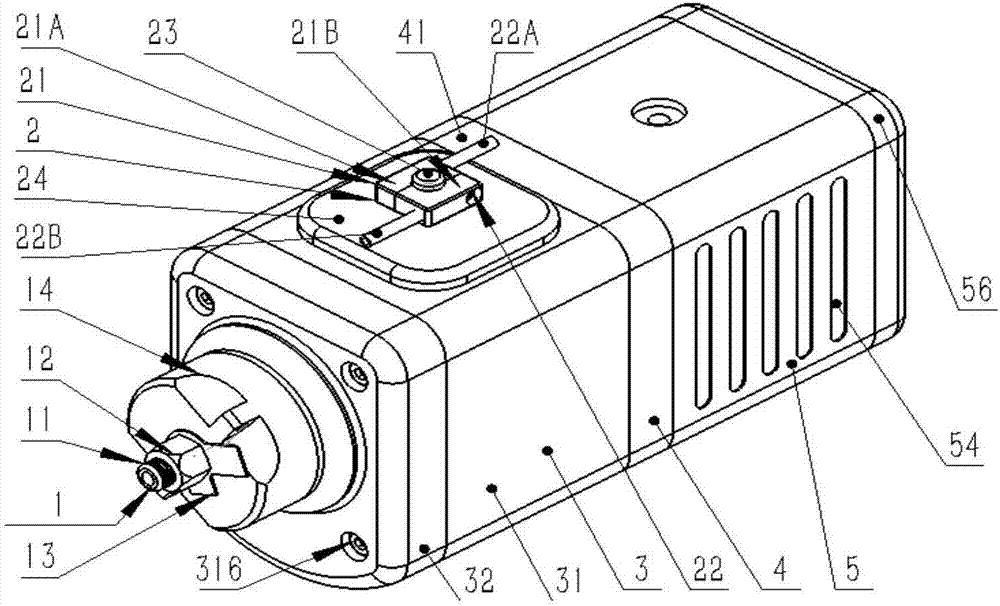

A high temperature and ultra high pressure rotary linear reciprocating dynamic seal test device

ActiveCN113137196BAchieve recyclingRealize dynamic sealingSurveyCore removalHydraulic motorUltra high pressure

The invention discloses a high-temperature, ultra-high-pressure rotary linear reciprocating dynamic sealing test device, which includes a rotary linear motion shaft, which is connected with a hydraulic motor through a gear box to realize the rotary motion of the shaft; the upper end of the rotary linear motion shaft passes through the The gear box is connected with the linear reciprocating motion driving mechanism, and the linear reciprocating motion driving mechanism is connected with the control system to realize the linear reciprocating motion of the shaft; the liquid outlet of the hydraulic motor is connected with the oil cooling system; Both the pressure port and the second decompression port are connected to the cooling pool through the overflow valve, the cooling pool is connected to the temperature rise pressure supply system, and the temperature rise pressure supply system is respectively connected to the first liquid supply port and the second liquid supply port. This solution provides a two-stage decompression dynamic seal (rotary + reciprocating linear) device, which can realize a dynamic seal with a pressure of 140MPa and a temperature of 150°C; at the same time, the device can be used to develop high-temperature and ultra-high-pressure rotary seals with different structures , and verify its sealing ability.

Owner:SICHUAN UNIV

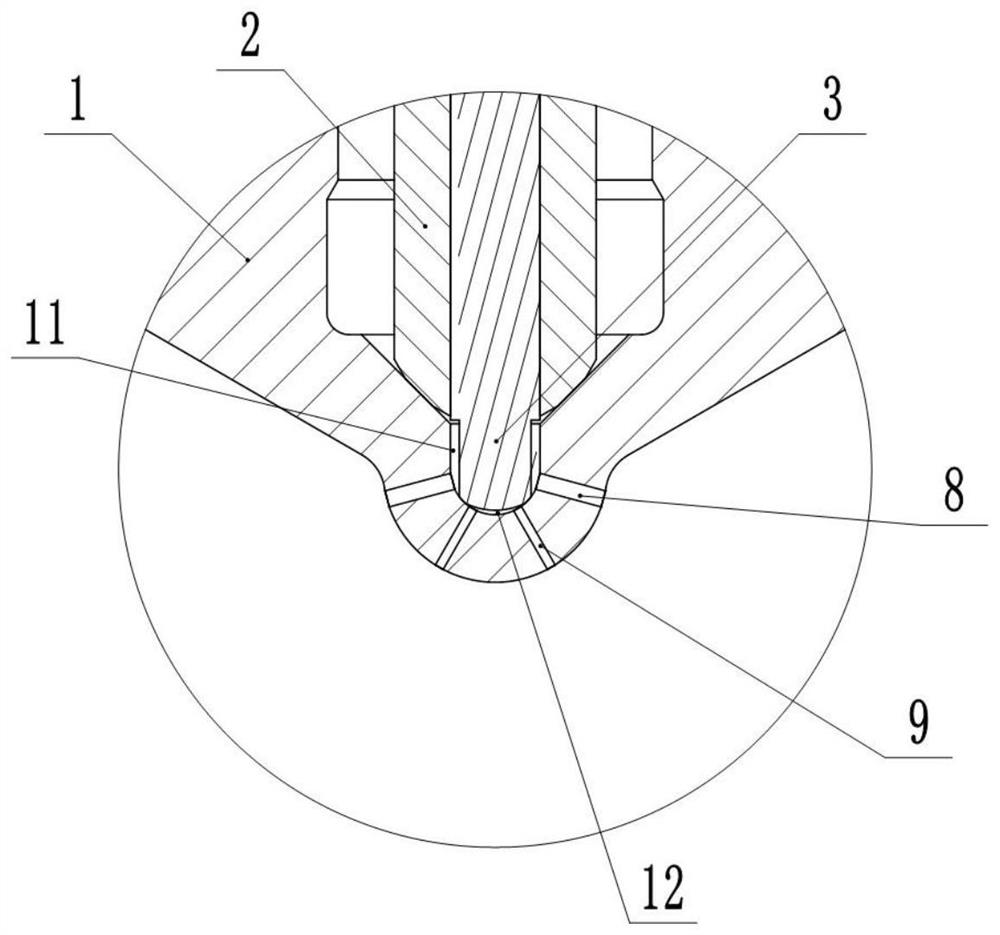

High-pressure water jet flow three-dimensional self-rotation sprayer

ActiveCN107030066AHigh performance workRealize three-dimensional rotation movementClimate change adaptationHollow article cleaningWater flowSpray nozzle

The invention discloses a high-pressure water jet flow three-dimensional self-rotation sprayer. The high-pressure water jet flow three-dimensional self-rotation sprayer comprises a hanging inlet assembly, a nozzle assembly, a cross-shaped shaft core assembly, a connecting device and a braking assembly. An integral mechanical structure of the cross-shaped shaft core assembly is divided into two major parts, each part comprises a planet gear train, and the two gear trains are located at different planes to form a whole space epicyclic gear train. A fixed shaft cylinder gear and a gear shaft serve as a sun gear of the first planet gear train, and a large planet gear and a small planet gear are arranged on the planet gear installing shaft. Similarly, a gear shaft serves as a sun gear of the second planet gear train, a nozzle base serves as a planet gear and is installed on a hollow supporting shaft, and a T-shaped shell serves as a planet carrier. Power is generated through back flushing force and back flushing torque of water flow, on one hand, the nozzle assembly is driven to horizontally rotate, on the other hand, the planet gear train structures are used for driving the whole to rotate around a water inlet hollow shaft, and accordingly three-dimensional rotation movement is achieved. The high-pressure water jet flow three-dimensional self-rotation sprayer is mainly used for cleaning away scars and dirt in inner cavities of a reaction kettle and other large industrial equipment, 360-degree all-direction cleaning of the sprayer is achieved, energy consumption is reduced, and safety and reliability are achieved.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

A sealing device used between motors and structural components

ActiveCN101562365BPrevent leakageRealize dynamic sealingSupports/enclosures/casingsEngineeringHigh pressure chamber

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com