Electro-hydraulic type high-frequency fatigue testing machine and design method thereof

A fatigue testing machine and high-frequency technology, applied in the field of fatigue testing machines, can solve the problems of unfavorable high-frequency generator high-frequency oscillation, difficult groove processing, uncontrollable sealing force, etc. The effect of dynamic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

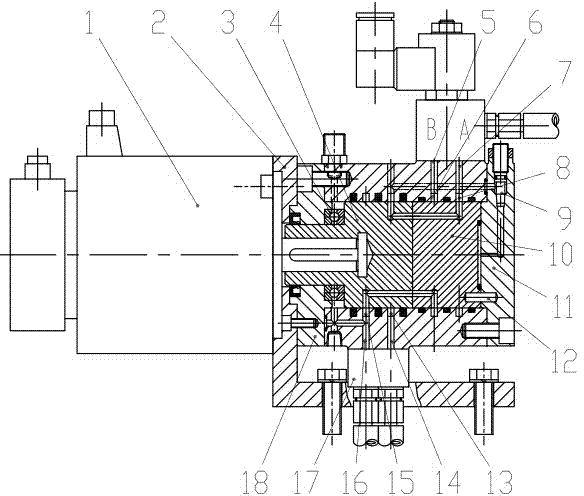

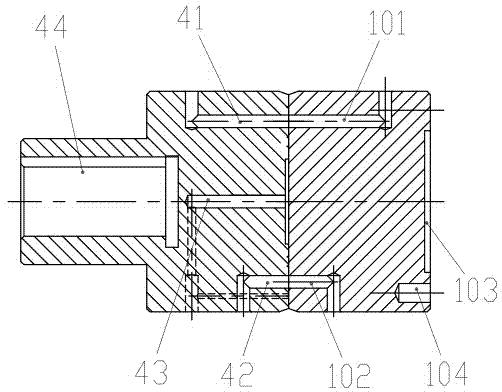

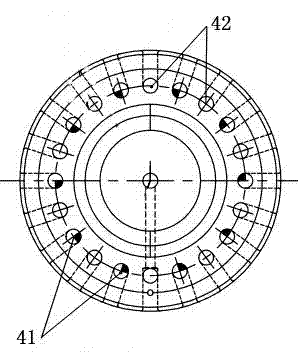

[0045] Such as Figure 1 to Figure 5 As shown, the high-frequency generator structure of the electro-hydraulic high-frequency fatigue testing machine includes a moving plate 4 and a static plate 10 whose end faces are in contact with each other, and a casing is arranged outside the moving plate and the static plate to seal them. A plurality of circular pressure oil holes 42 and oil return holes 41 of the moving disk are drilled and reamed on the contact end surface of the moving disk 4, and a static disk pressure oil hole 101 and a static Disk oil return hole 102, the static disk pressure oil hole 101 is arranged correspondingly to the moving disk pressure oil hole 42, and the static disk oil return hole 102 is arranged correspondingly to the moving disk oil return hole 41, so that when the moving disk 4 rotates, the moving disk The disk pressure oil hole 42 and the moving disk oil return hole 41 can communicate with the static disk pressure oil hole 101 and the static disk oi...

Embodiment 2

[0089] In this embodiment, the number of pressure oil holes and oil return holes on the end face of the moving disk is set to 5, then the static disk corresponding to the moving disk is provided with 5 pressure oil holes and 5 oil return holes, and the pressure oil The holes and oil return holes are evenly spaced on the same circular line of the end face, the number of oil holes on the end face of the moving disc is 10, and the number of oil holes on the end face of the static disc is also 10. Other settings are the same as those in Embodiment 1. In this embodiment, each rotation of the moving plate can generate 10 oscillations, which is beneficial to reduce the speed of the drive motor compared with the prior art where only 2 oscillations per rotation , and at the same time meet the requirements of the limit speed of the bearing, which is more conducive to improving the high-frequency frequency of the fatigue testing machine.

[0090] All features disclosed in this specificat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com