Nuclear electric torpedo vacuum valve

A nuclear electric and vacuum valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of high product rejection rate, high manufacturing difficulty and high manufacturing cost, and achieve the advantages of reducing vibration, small resistance and realizing sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

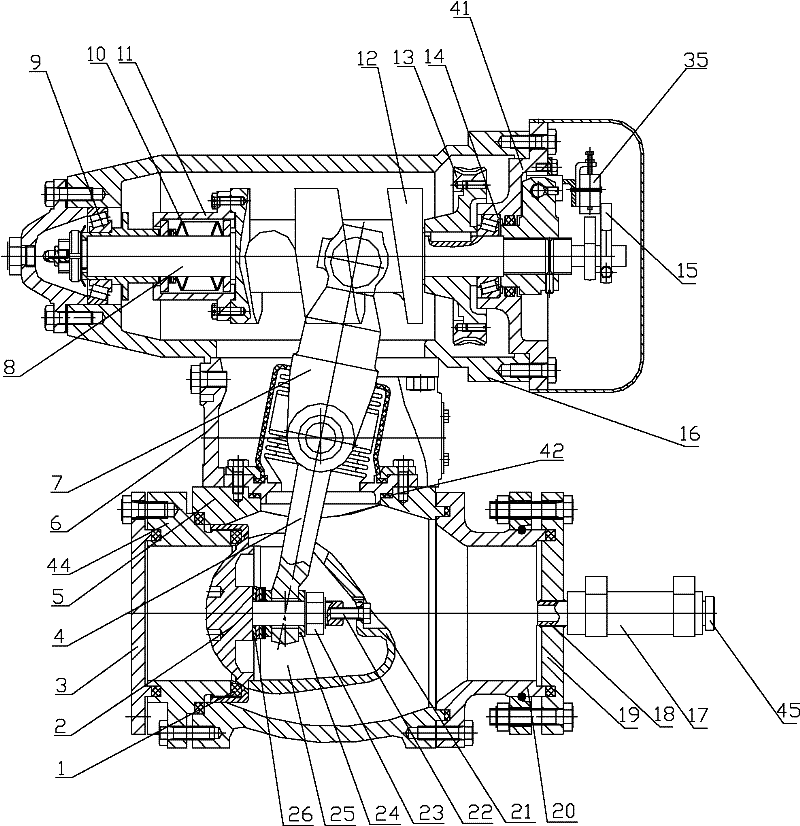

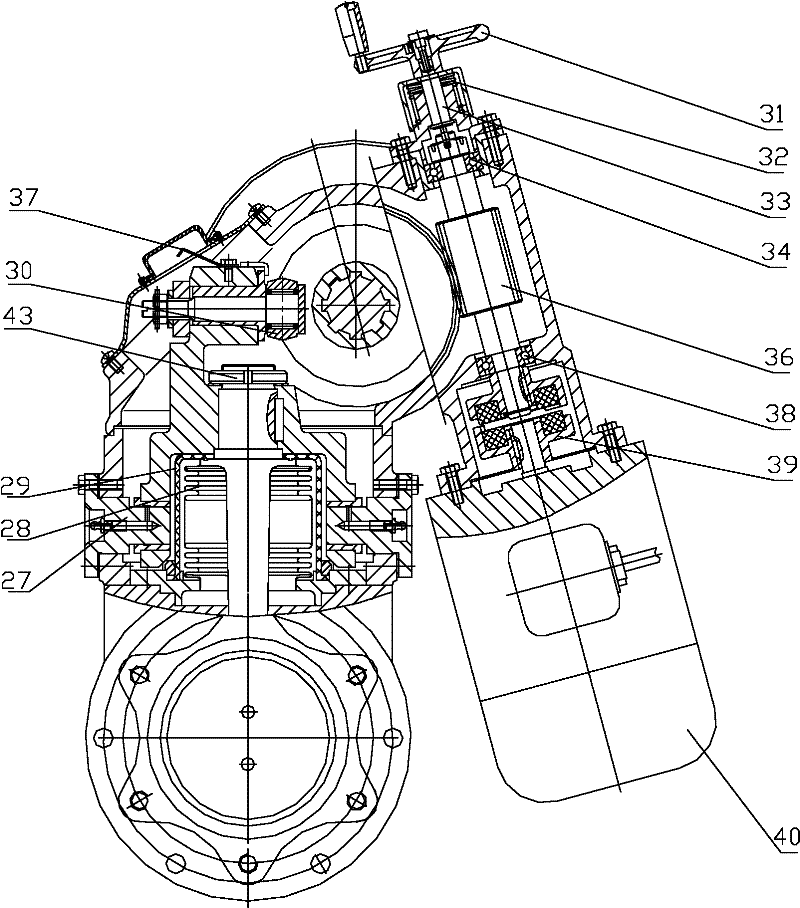

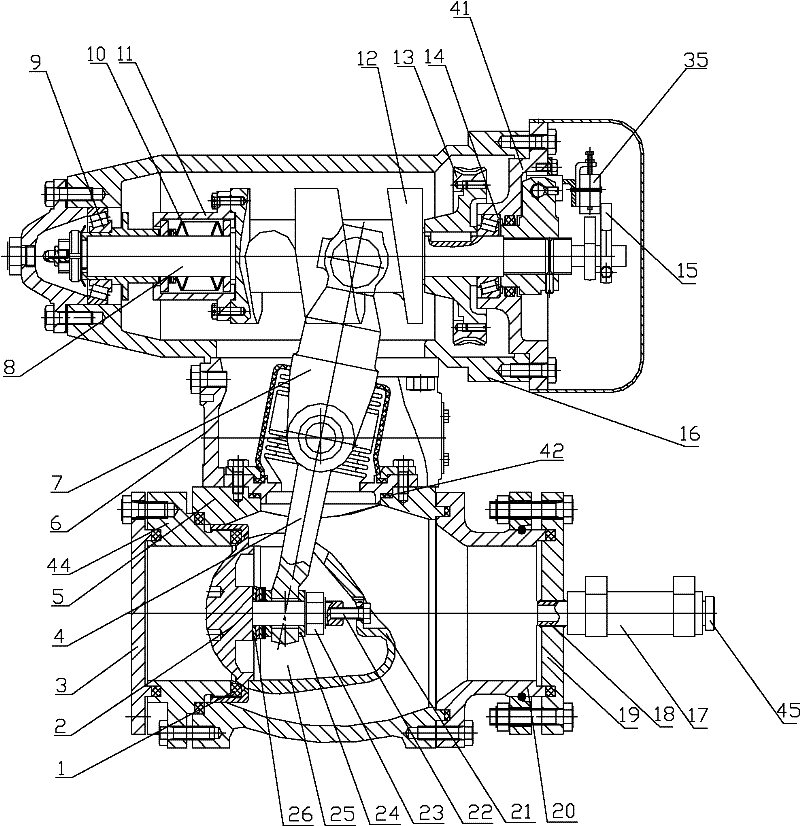

[0020] The nuclear electric torpedo vacuum valve of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] Such as Figure 1 to Figure 2 As shown, a nuclear electric torpedo vacuum valve according to the present invention comprises a valve body 5, a torpedo-shaped valve core 25 arranged in the valve body 5, and a lever assembly connected to the torpedo-shaped valve core 25 to drive the lever assembly A moving fork assembly and a driving device for driving the fork assembly to move. The driving device includes two sets of electric and manual driving devices, and the manual driving device is used as a backup for the electric device.

[0022] The upper end of the valve body 5 is fixed with a middle box body 6 by screws, and the upper end of the middle box body 6 is fixed with a driving mechanism box body 16 by screws. The rear end of the drive mechanism box body 16 is fixedly connected to the flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com