Patents

Literature

59results about How to "Avoid frequent cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

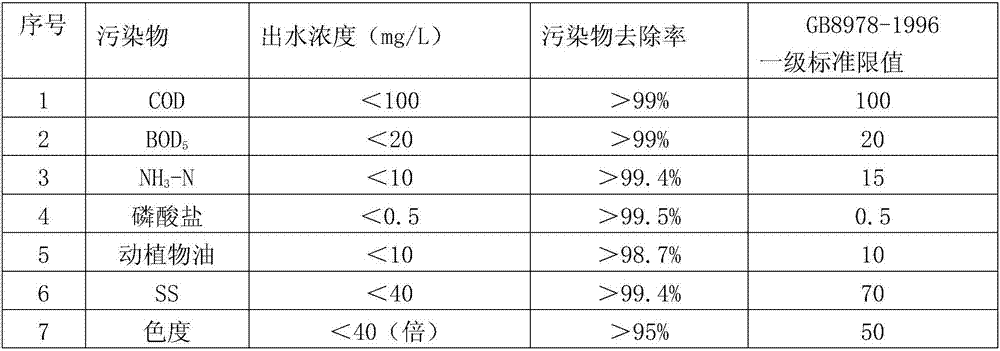

Kitchen garbage slurry anaerobic fermentation wastewater treatment method

InactiveCN106746174AGuaranteed uptimeEfficient removalFatty/oily/floating substances removal devicesWater contaminantsEmission standardWater quality

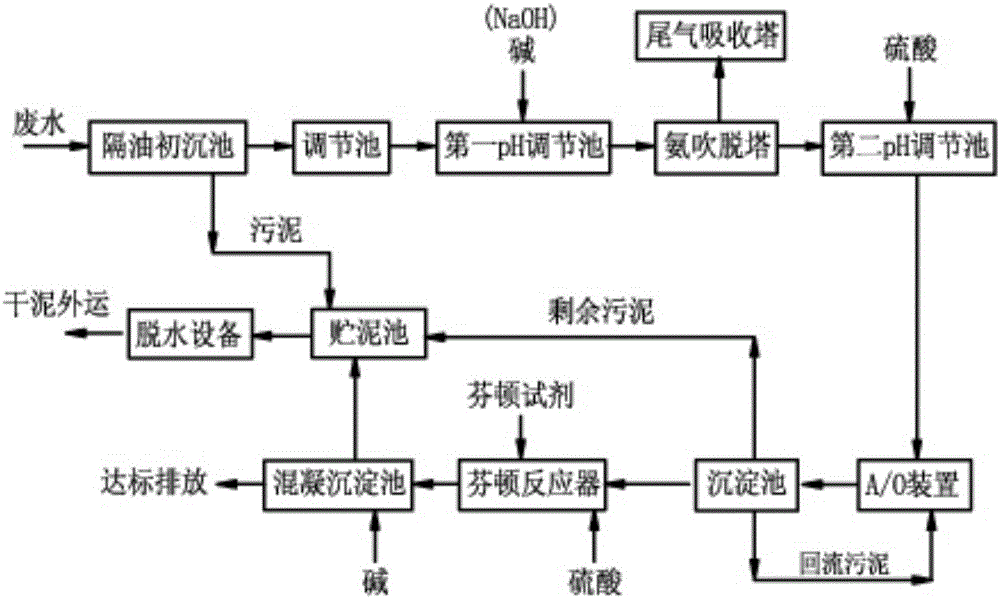

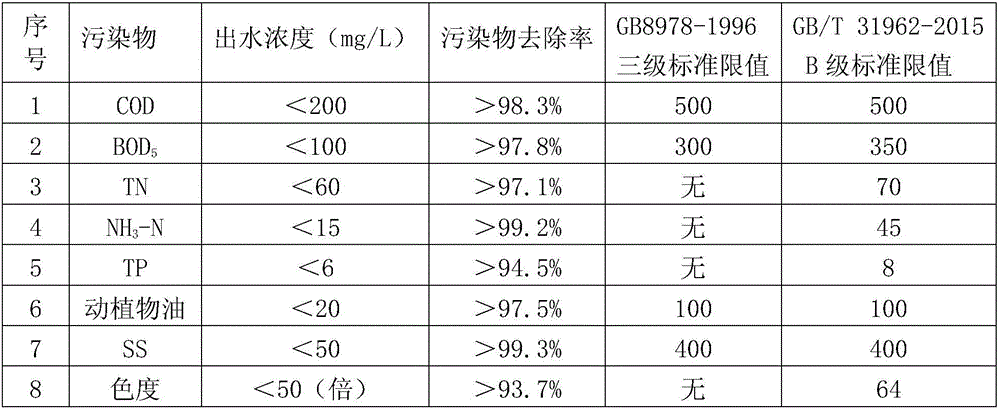

The invention relates to a kitchen garbage slurry anaerobic fermentation wastewater treatment method, in particular to a treatment method for treating wastewater produced in other procedures through wastewater produced after anaerobic fermentation dehydration of kitchen garbage slurry and kitchen garbage. Wastewater is subjected to oil-separation primary precipitation, water amount and water quality adjustment, first pH value adjustment, free ammonia stripping in an ammonia stripping tower, second pH value adjustment, A / O biochemical treatment, precipitation treatment, treatment in a Fenton reactor and treatment in a coagulative precipitation tank, so that pollutants such as COD, BOD5 and SS in the wastewater are removed, TN and TP can be removed effectively, the wastewater chroma can be lowered effectively, the TN and TP removing rates are increased, and pollutants such as COD, BOD5, TN, NH3-N, TP and chroma in the treated wastewater can stably meet the requirements in Integrated Wastewater Discharge Standard (GB8978-1996, grade III standard) and Wastewater Quality Standards for Discharge to Municipal Sewers (GB / T 31962-2015, grade B).

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

Cutting fluid recovering device for machining

InactiveCN107584327AGuaranteed Filtration SpeedAvoid accumulationMaintainance and safety accessoriesGratingEngineering

The invention discloses a cutting fluid recovering device for machining. The cutting fluid recovering device comprises a bracket, wherein a second collecting box, a separating cabin and an absorbing cabin are successively fixed on the bracket; the second collecting box is connected with the bottom of one side of the separating cabin through a guide slot; the middle part on the other side of the separating cabin is connected with the top end of the absorbing cabin through a guide pipe; a filtering box and a third collecting box are successively connected with the bottom of the absorbing cabin through a liquid draining pipe; a filtering plate is fixed on the upper part in the separating cabin; a rotating shaft of a motor extends into the separating cabin and is fixed with a grating plate; anabsorbing column is arranged in the absorbing cabin; a wire is arranged in an interlayer; the bottom of the absorbing cabin is in threaded connection with the top of a first collecting box. Accordingto the invention, the filtering plate, the grating plate, the absorbing column and the filtering box are adopted for treating the cutting fluid in turn, so that the impurities in the cutting fluid can be effectively removed, the device has a self-cleaning function, the recycling efficiency of the cutting fluid is guaranteed and the maintenance frequency is reduced.

Owner:WUXI ZHIGURUITUO TECH SERVICE CO LTD

Zero-discharge treatment process for salt-containing waste water

InactiveCN102557317ADoes not require frequent cleaningAvoid frequent cleaningMultistage water/sewage treatmentOxygenDistributor

The invention provides a zero-discharge treatment process for salt-containing waste water. The process comprises the following steps of: a, performing flash evaporation on salt-containing waste water, exchanging heat with a condensate from a flash tower heater for further heating, entering a degassing tower for removing dissolved oxygen and carbon dioxide, entering a salt solution storage groove for mixing with a circulating salt solution flowing out of the bottom of the flash tower, feeding into a flash tower through a flash tower feed pump, spraying through a salt solution distributor, exchanging heat with steam produced at the bottom of the flash tower, and partially vaporizing; b, recovering heat from a condensate discharged from the flash tower heater through a heat exchanger, returning an extremely small amount of the condensate into a steam ejector for serving as steam saturated water, and feeding the remaining condensate serving as recycled water to a production device for reutilizing; and c, recovering heat from the other part of a concentrated salt solution discharged from the bottom of the flash tower by performing flash evaporation through a flash tank, and feeding the concentrated salt solution into a centrifuge for performing separating treatment or feeding to an evaporation pond for naturally evaporating. According to the zero-discharge treatment process for salt-containing waste water, frequent cleaning of an entire system is avoided; and the process is simple, and has low operating cost.

Owner:WUHAN COMEON ENVIRONMENT ENG

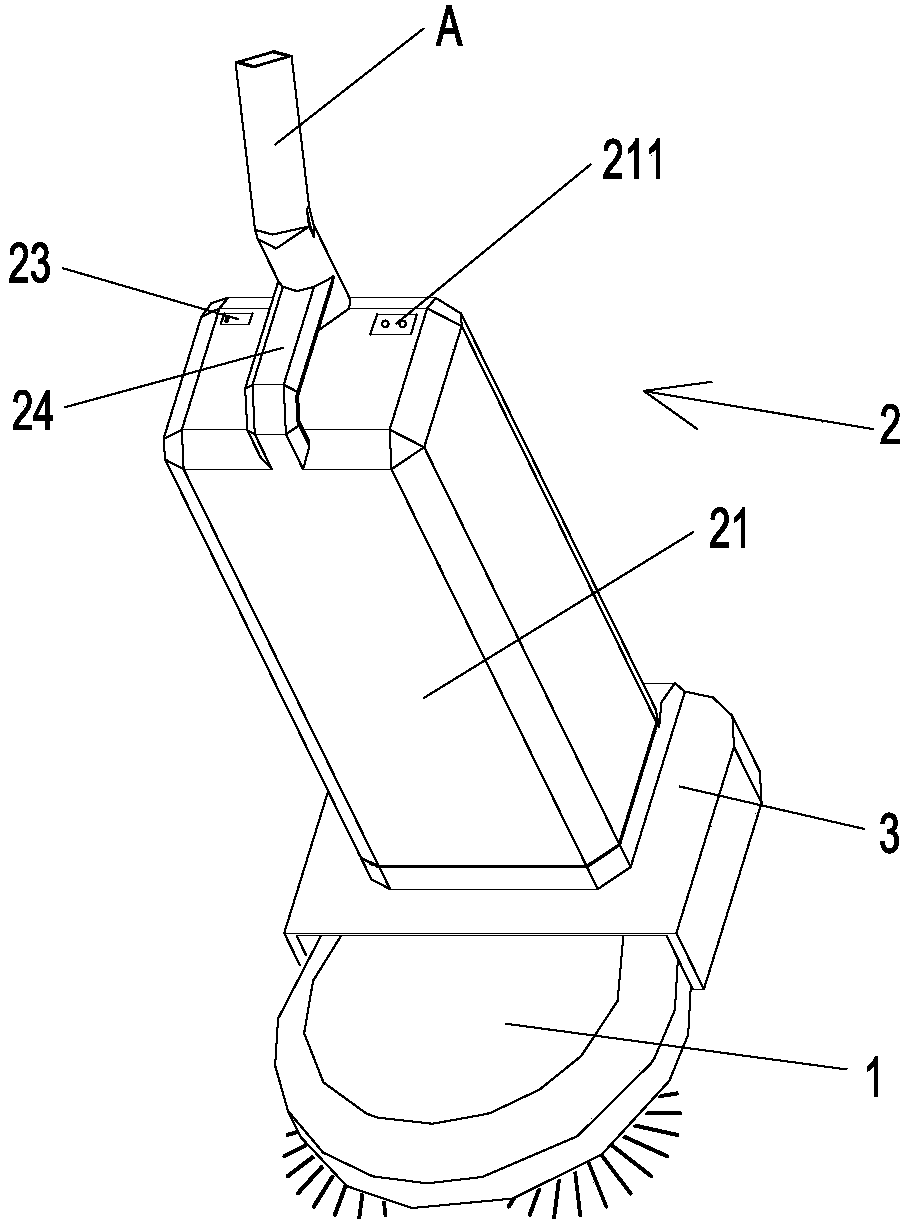

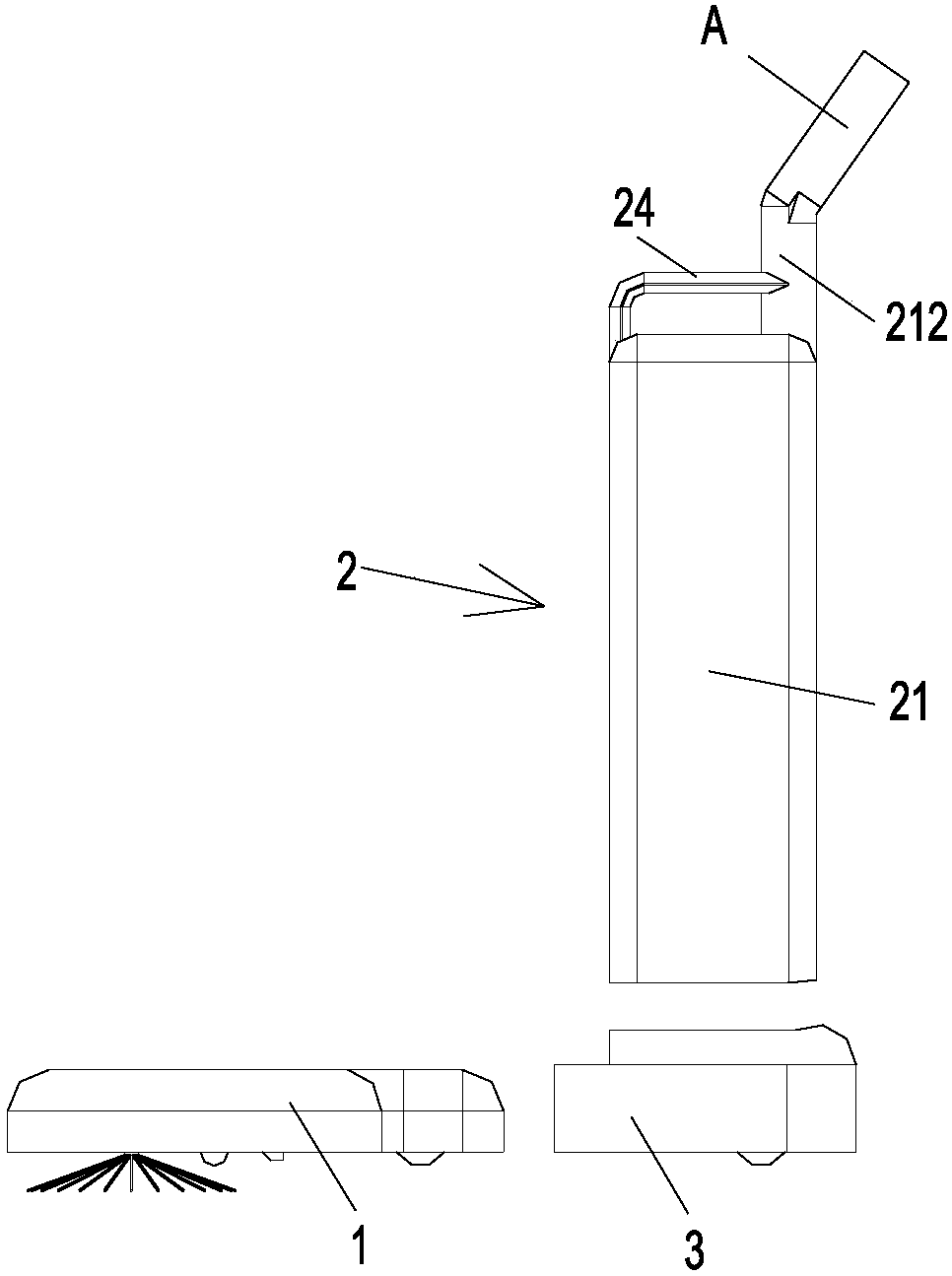

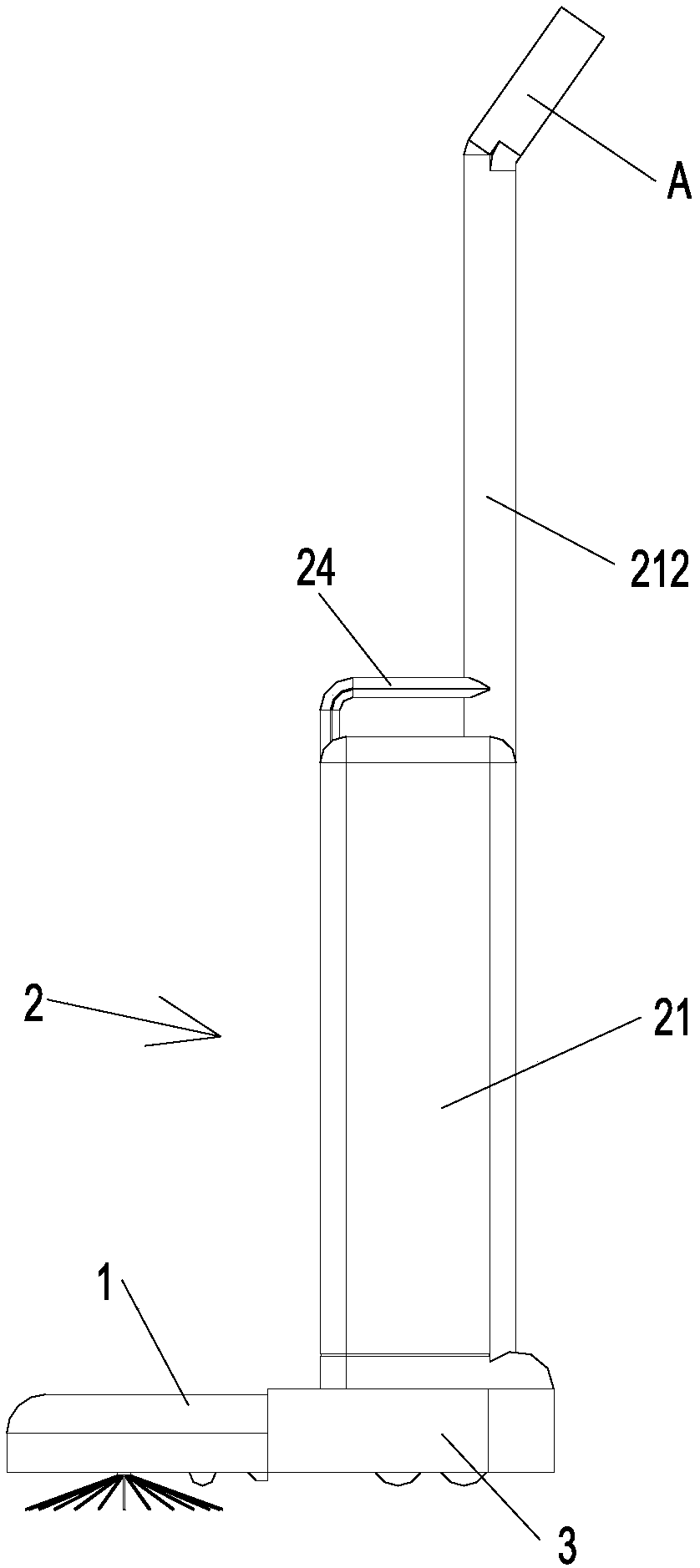

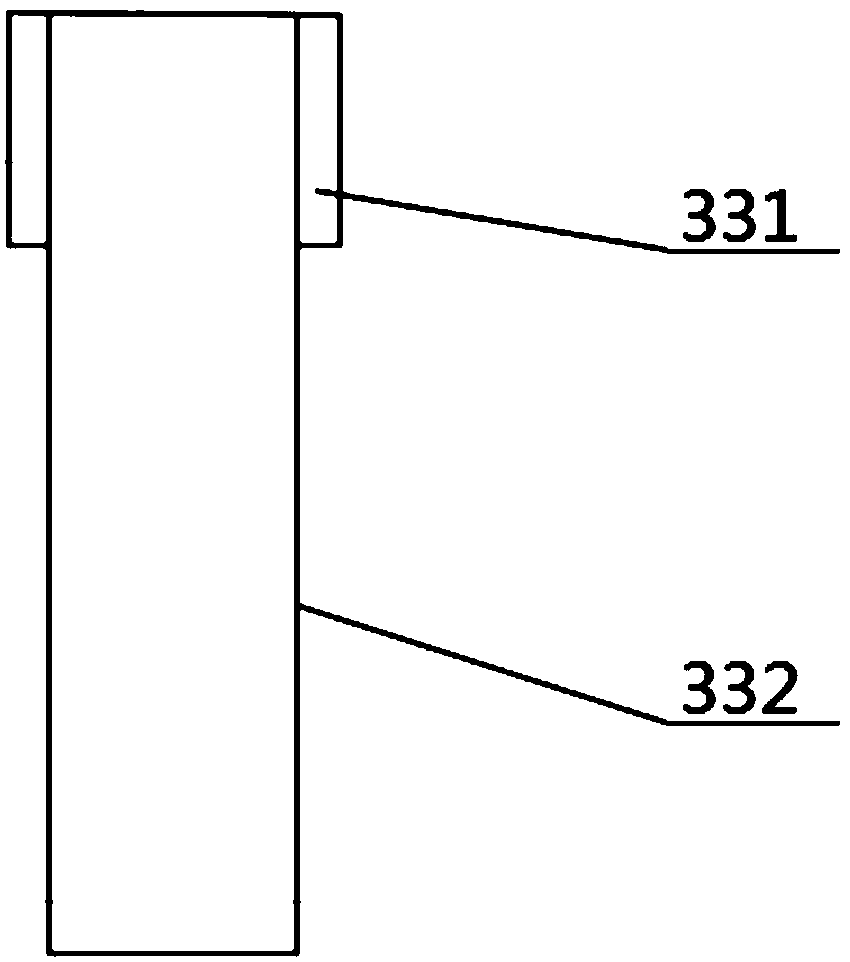

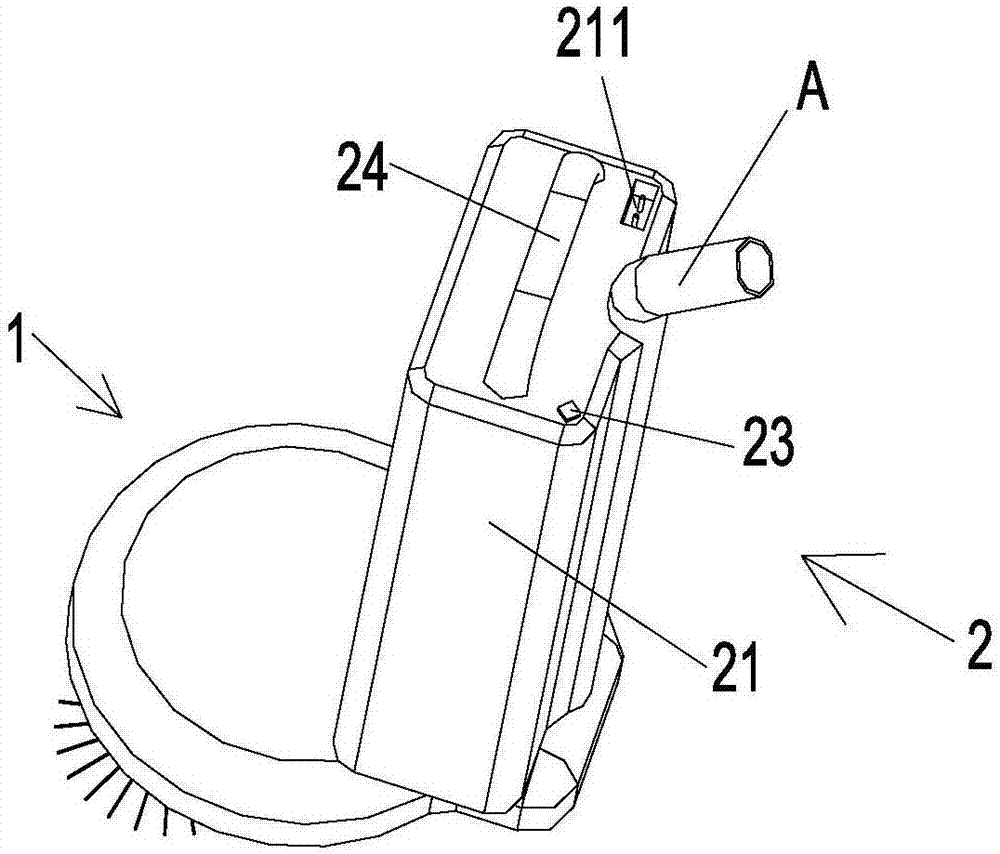

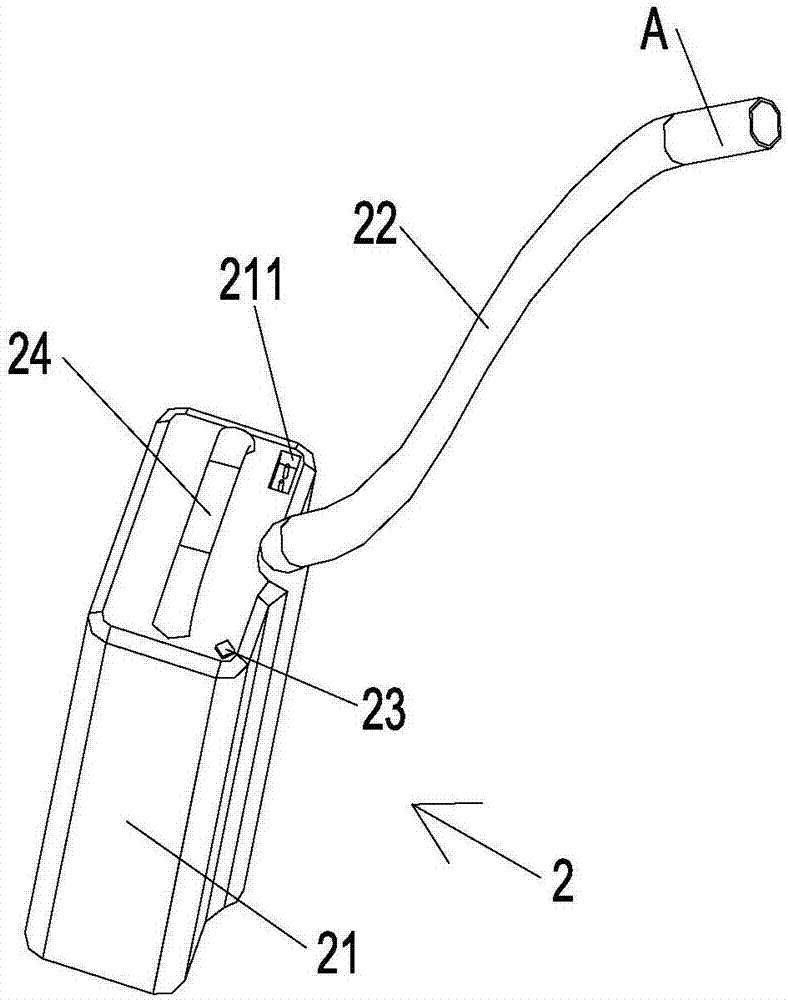

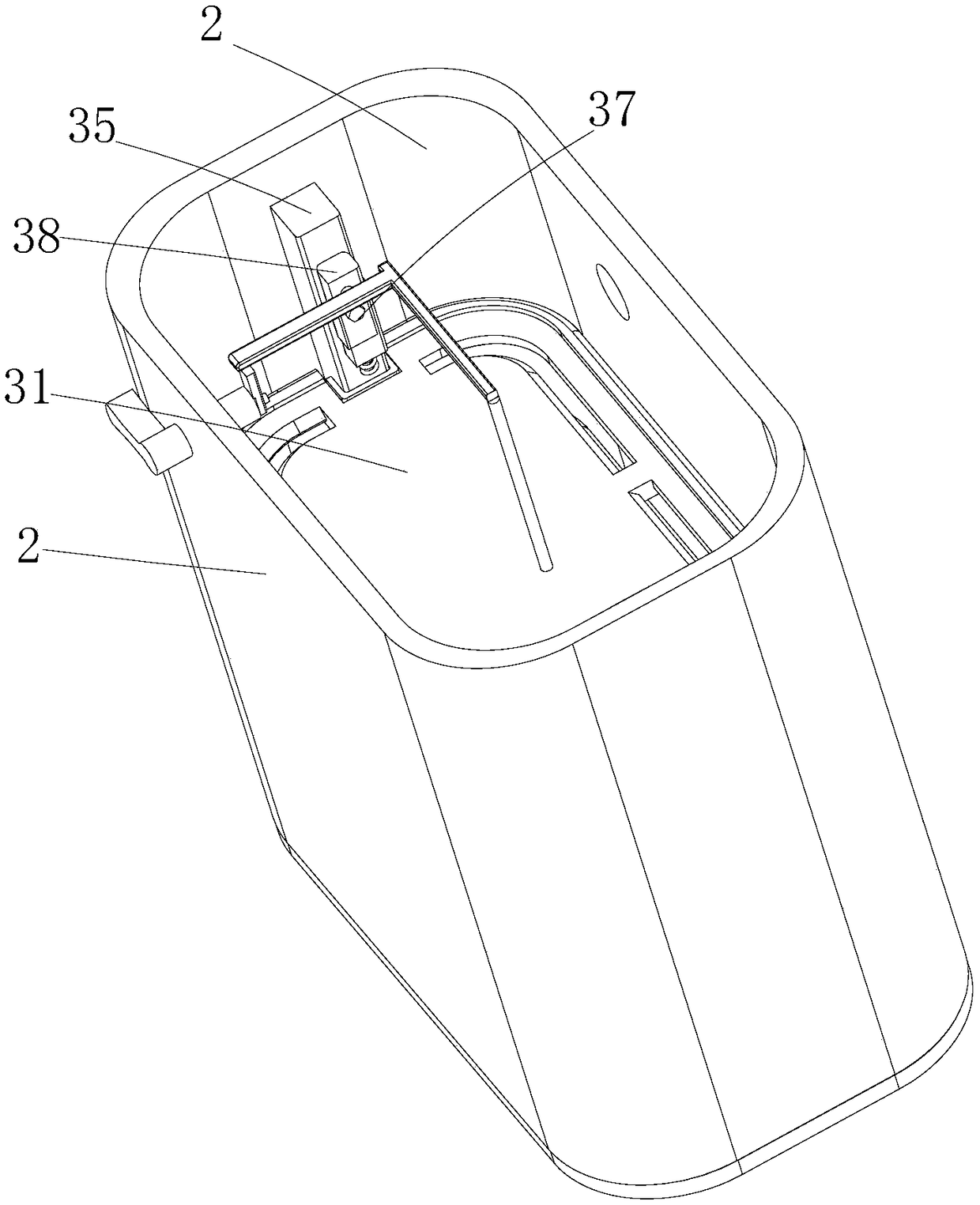

Vertical-type vacuum cleaner

InactiveCN107669213AAvoid frequent cleaningBig spaceCarpet cleanersFloor cleanersEngineeringVacuum cleaner

The invention relates to the field of cleaning electric appliances and discloses a vertical-type vacuum cleaner. The vertical-type vacuum cleaner comprises an intelligent sweeper (1) which is providedwith a dust collection box, a charging base (3) which is used for charging the intelligent sweeper and a vertical-type machine (2) which is provided with a dust cup; the charging base is provided with a channel which makes the dust collection box and the dust cup communicated and a dust recycle switch which controls the state of the channel, the vertical-type machine can be detachably arranged onthe charging base, and under the state that the vertical-type machine is arranged on the charging base, when the intelligent sweeper is arranged on the charging base, the dust recycle switch can be triggered. According to the vertical-type vacuum cleaner, the situation is avoided that the dust collection box of the intelligent sweeper is frequently cleaned, the manual operation time is saved, meanwhile, the vertical-type machine, the charging base and the intelligent sweeper can be combined for use and can also be separated for working, the space of flexible selection by a user according to working requirements is increased, cleaning is complete and time is saved during splitting use, the occupation area is small during assembly storage, and accordingly the user experience is greatly improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES +1

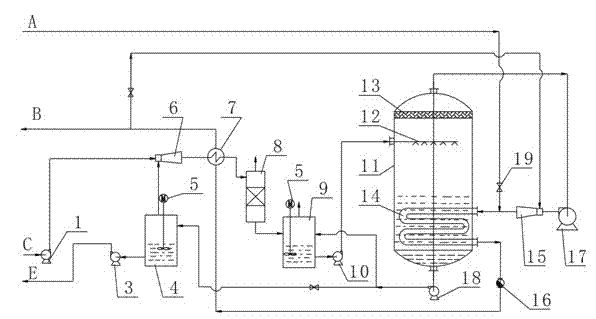

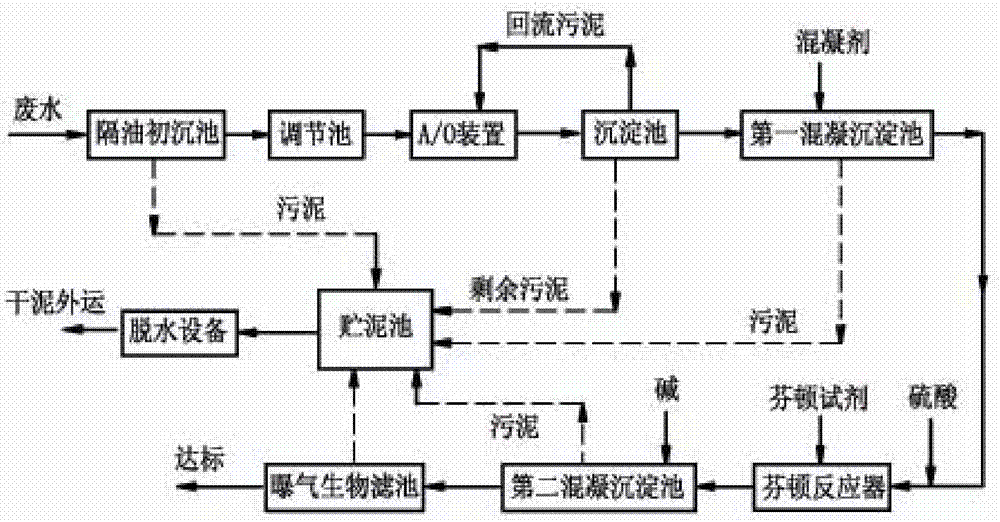

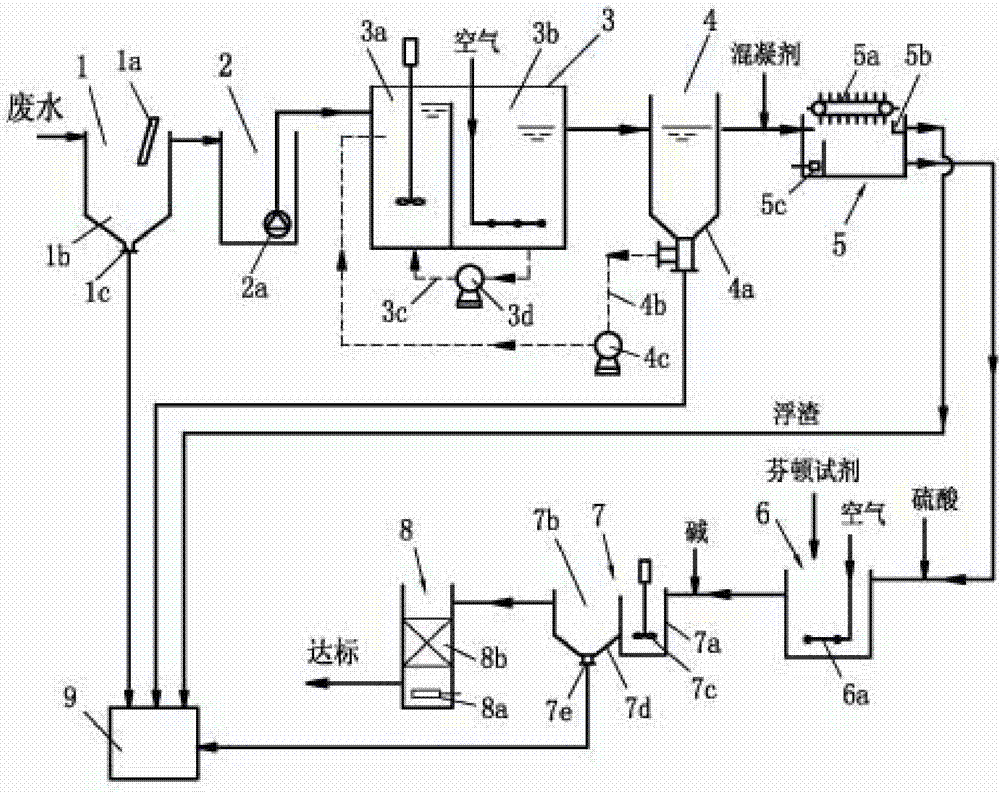

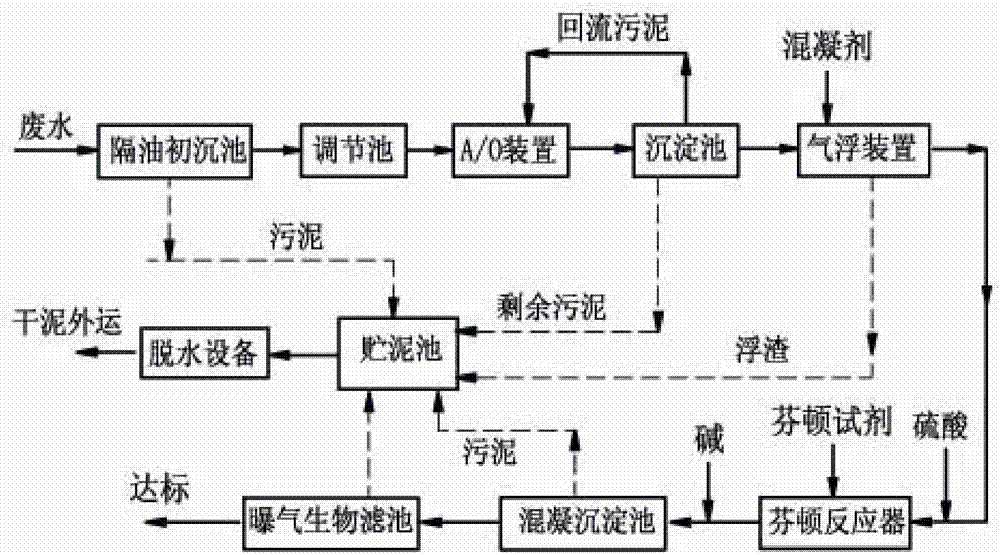

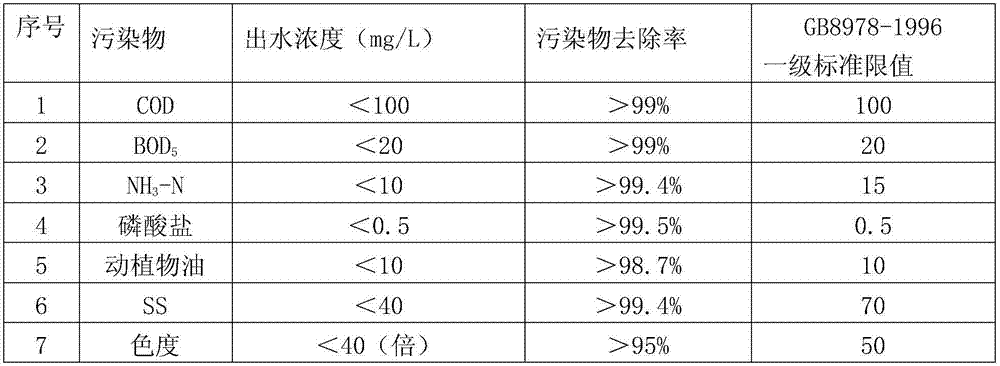

Kitchen waste fermentation wastewater treating method

InactiveCN107352745AAvoid frequent cleaningPrevent sinkingWater treatment parameter controlFatty/oily/floating substances removal devicesOil separationTotal nitrogen

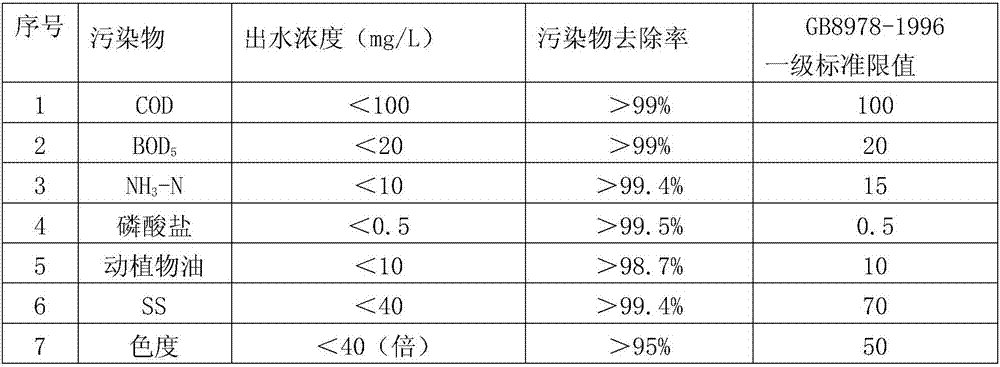

The invention provides a kitchen waste fermentation wastewater treating method which is used for treating wastewater produced from kitchen waste slurry after anaerobic digestion and dewatering and wastewater produced in other procedures of kitchen waste treatment. The wastewater is subjected to oil-separation primary sedimentation, water quantity and water quality regulation, A / O biochemical treatment, sedimentation treatment, treatment in a first coagulative sedimentation tank, treatment in a Fenton reactor, treatment in a second coagulative sedimentation tank and treatment in a biological aerated filter in sequence. With adoption of the method, pollutants such as COD (chemical oxygen demand), BOD5 (biochemical oxygen demand), SS (suspended solids) and the like in the wastewater are removed effectively, TN (total nitrogen) and TP (total phosphorus) can be removed effectively, wastewater chroma can be reduced effectively, TN and TP removal rate is increased, and the pollutants such as COD, BOD5, NH3-N, TP and the like in the treated wastewater as well as the chroma of the treated wastewater can stably meet requirements of level-1 in the integrated wastewater discharge standard (GB8978-1996).

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

Intelligent cleaning system for rear camera of automobile

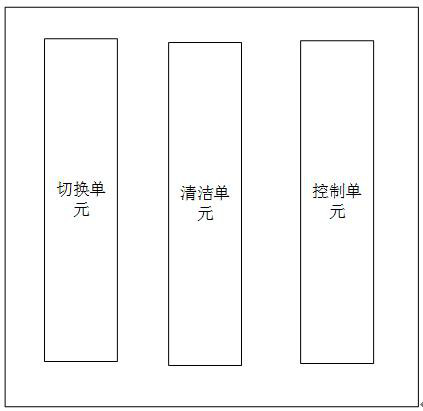

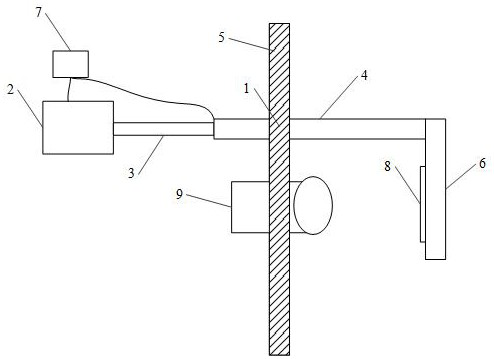

ActiveCN111645637AThe shooting picture is clearClear guaranteeTelevision system detailsImage analysisControl theoryMechanical engineering

The invention discloses an intelligent cleaning system for a rear camera of an automobile, relating to the field of artificial intelligence. According to the system, two automobile rear-mounted cameras are installed, when one rear-mounted camera needs to be cleaned, switching operation is carried out in a short time, automobile rear-mounted cameras meeting use requirement are switched out for use,then the switched automobile rear-mounted camera needing to be cleaned is cleaned, the time for an automobile owner to wait for cleaning of the automobile rear-mounted camera is avoided, cleaning operation cannot occur in a reversing picture, the reversing process cannot be disturbed, and safety is higher.

Owner:绩溪智旭智能化技术开发有限公司

Waste aluminum alloy leftover material dust removal and compression device

InactiveCN112058815ADoes not form dirtImprove cleanlinessDirt cleaningSound producing devicesDust controlMechanical engineering

The invention relates to the field of aluminum alloy recovery devices, in particular to a waste aluminum alloy leftover material dust removal and compression device which comprises a base and two vertical plates and further comprises a controller, an ash removal mechanism and a collection mechanism. The ash removal mechanism is arranged between the two vertical plates slidably, and the ash removalmechanism comprises a cleaning box, an adsorption assembly and two noise reduction assemblies. The collecting mechanism is slidably arranged at the top of the base and comprises a collecting box andan extruding assembly, a sliding plate is slidably arranged at the top of the base, the collecting box is fixedly arranged at the top of the sliding plate, the extruding assembly is arranged at the top of the sliding plate, and the collecting box is connected with the extruding assembly in an inserted mode. The adsorption assembly and the extruding assembly are both electrically connected with thecontroller. According to the waste aluminum alloy leftover material dust removal and compression device, shaken-off impurities can be adsorbed, so that dirt is avoided; and meanwhile, the power consumption of the device is small, so that the treatment cost can be reduced.

Owner:孔姗姗

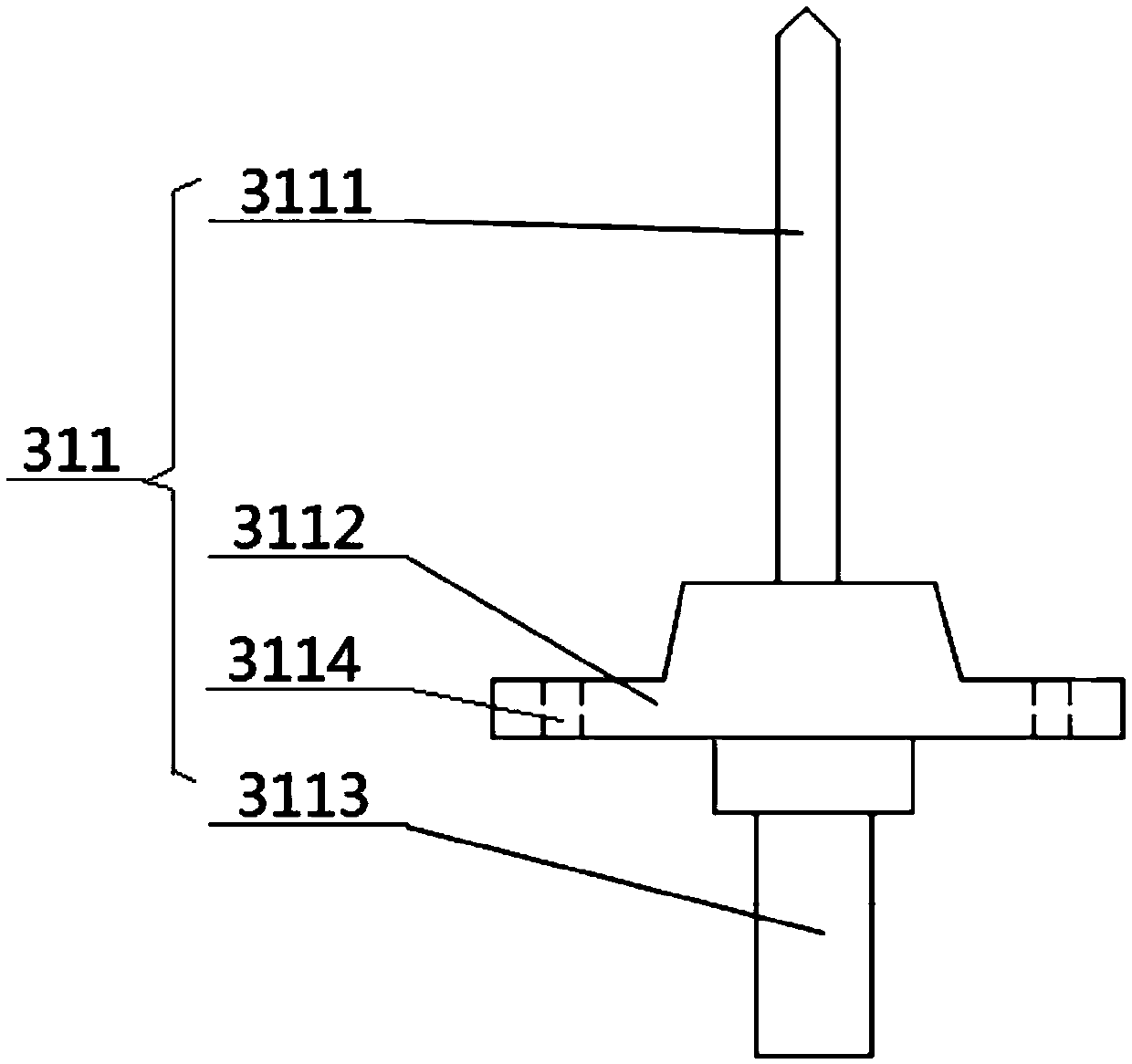

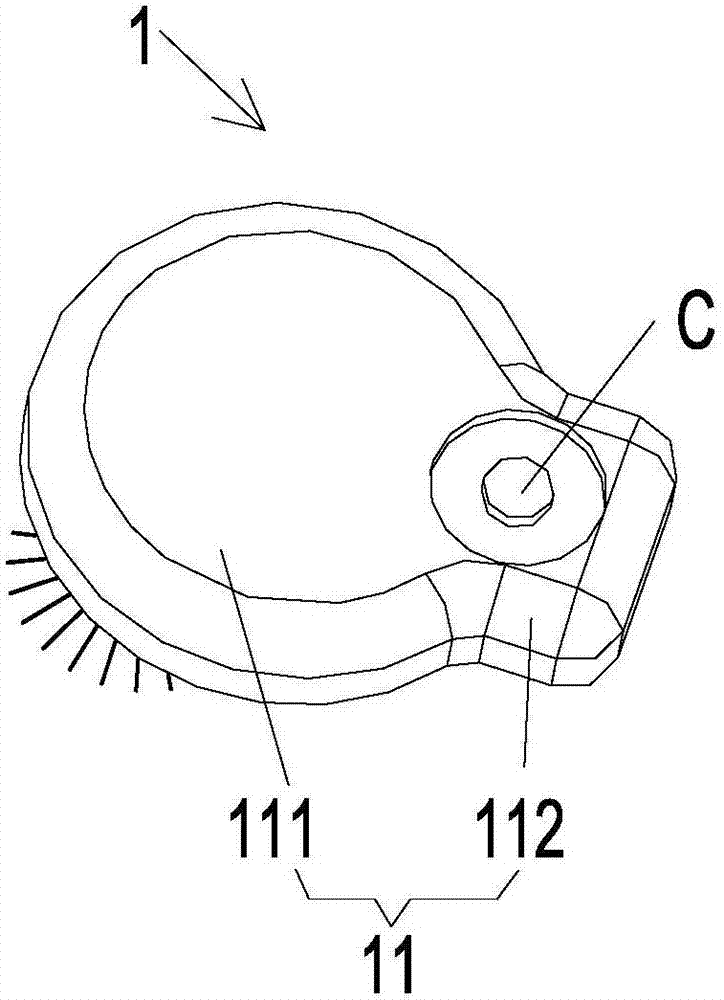

Low-temperature baking cigarette withdrawing tool

PendingCN108669658AResidue reductionAvoid frequent cleaningTobacco pipesTobacco devicesEngineeringSmoke

The invention discloses a low-temperature baking cigarette withdrawing tool. The low-temperature baking cigarette withdrawing tool comprises a heating tip and an electric rod assembly for supplying power to the heating tip, wherein a heating body for heating a cigarette is arranged in the heating tip; a cigarette withdrawing body used for supporting the cigarette is movably arranged on the heatingbody; the cigarette withdrawing body is provided with a through hole matched with the heating body; the cigarette withdrawing body has a first position and a second position; when the cigarette withdrawing body is positioned at the first position, the heating body passes through the through hole, enters the cigarette and heats the cigarette; when the cigarette withdrawing body is positioned at the second position, the heating body exits from the through hole in order to be separated from the cigarette. According to the low-temperature baking cigarette withdrawing tool, the cigarette withdrawing body in the tool is used for supporting the cigarette, so that residue on the heating body can be scraped in conjunction with the through hole of the heating body after finishing of heating, separation of the cigarette and the heating body is realized, the situation of cigarette residue in the tool due to direct pull and insertion of the cigarette is avoided, and frequent cleaning of the cigarette is avoided effectively.

Owner:CHONGQING CHINA TOBACCO IND CO LTD

Upright vacuum cleaner

InactiveCN107440620AAvoid frequent cleaningBig spaceCarpet cleanersFloor cleanersEngineeringOperating time

The invention relates to the field of electric cleaning appliances and discloses an upright vacuum cleaner, comprising intelligent sweeper (1) having a dust collection box and an upright unit (2) having a duct cup. The vertical unit (2) is releasably arranged above the intelligent sweeper (1); with the vertical unit (2) arranged above the intelligent sweeper (1), the dust collection box can be communicated with the dust cup so that dust in the dust collection box can be sucked into the dust cup. The upright vacuum cleaner has the advantages that frequent cleaning of the dust collection box of the intelligent sweeper is avoided, and manual operating time is saved; in addition, the upright unit and the intelligent sweeper can be combined together for use and be split for use, and larger space is provided for a user to make flexible options as work requires; the upright vacuum cleaner can provide comprehensive cleaning with less time consumed when split for use; when assembled for storage, the upright vacuum cleaner occupies small area so that user experience is greatly improved.

Owner:JIANGSU MIDEA CLEANING APPLIANCES

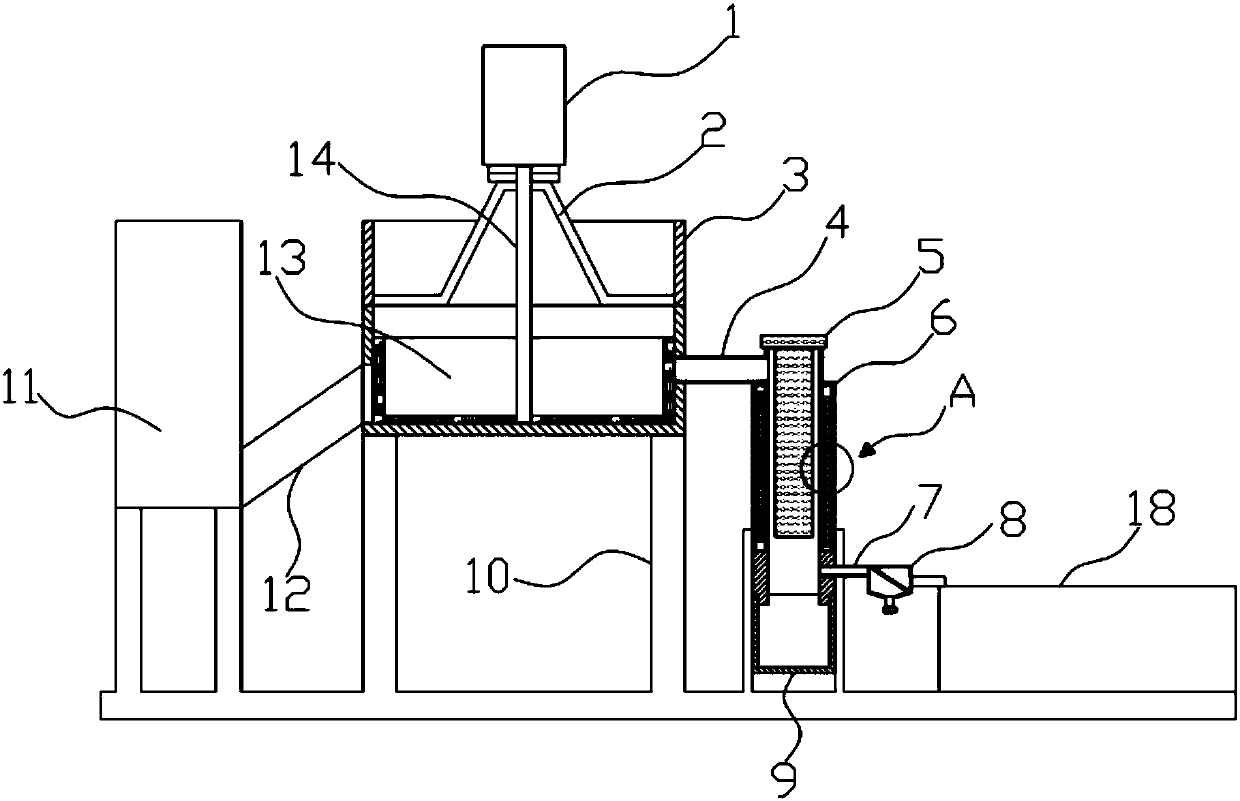

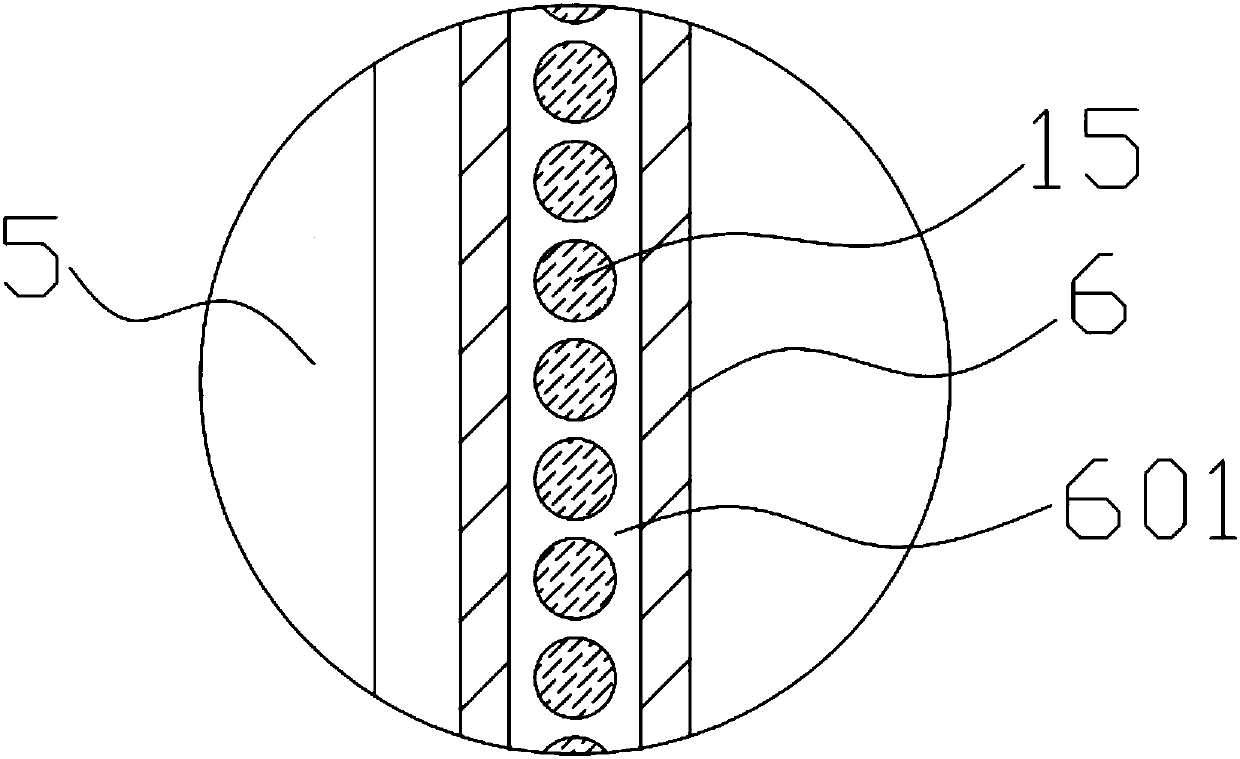

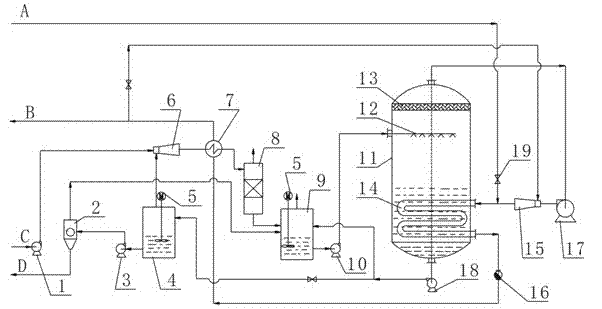

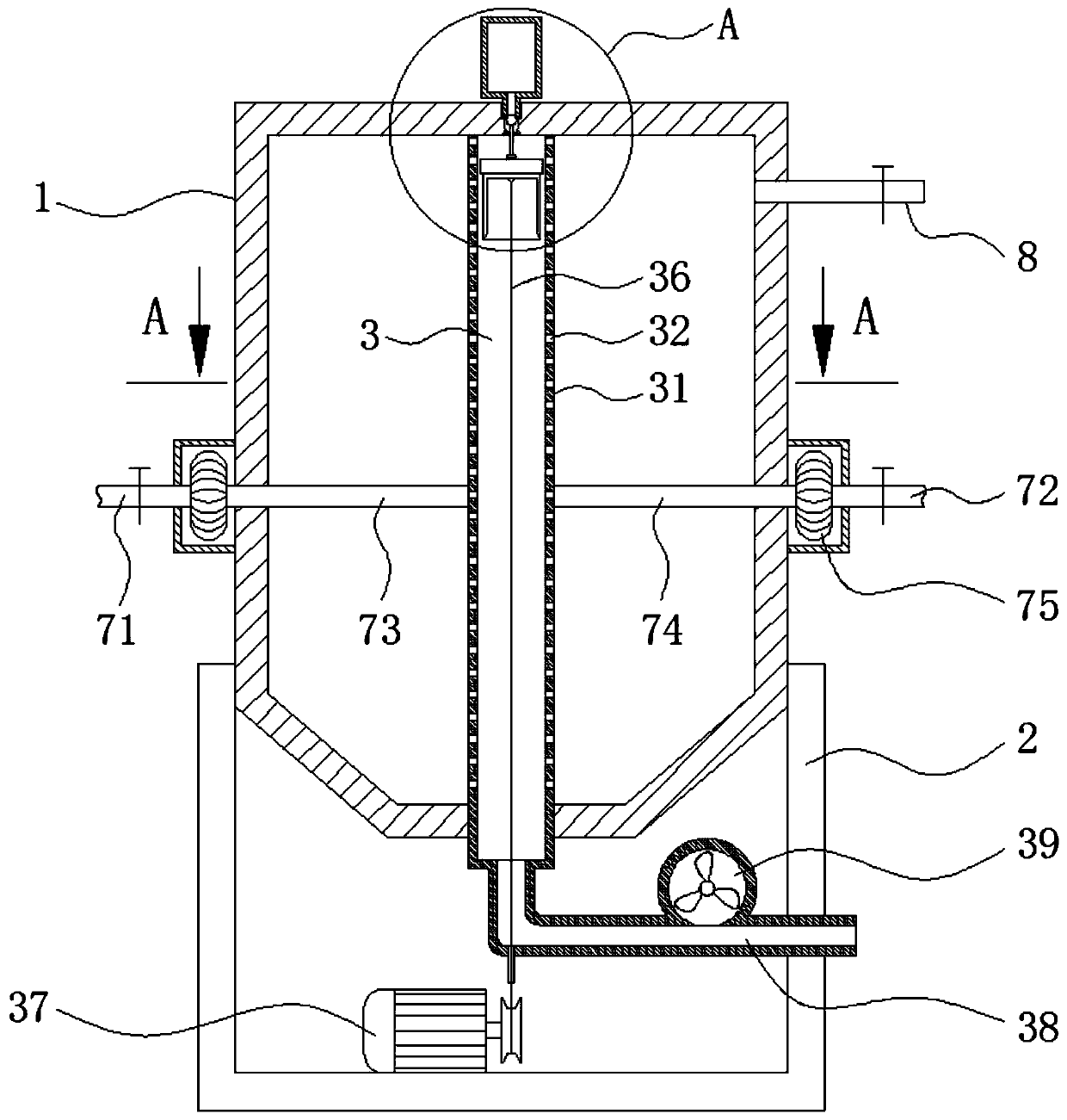

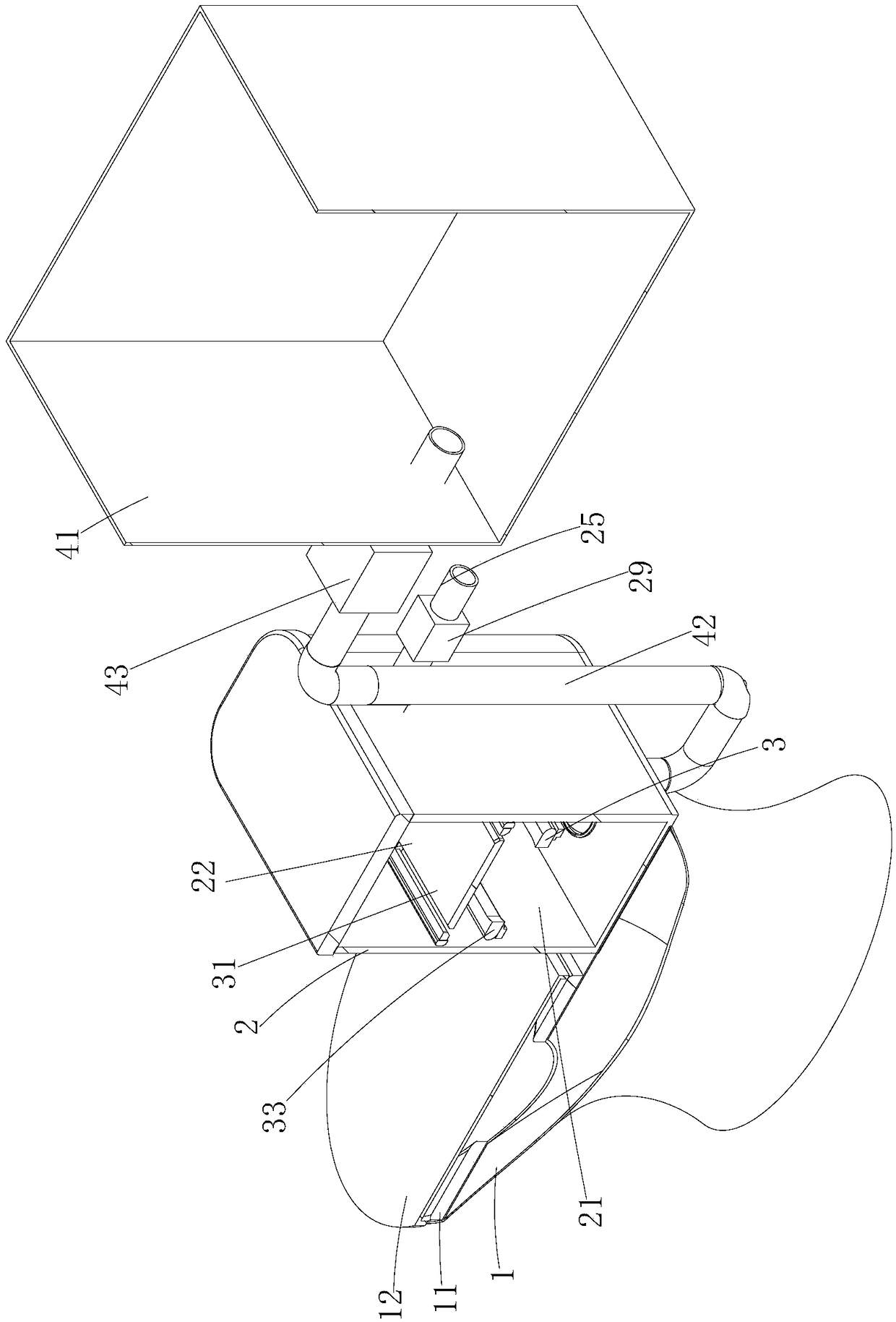

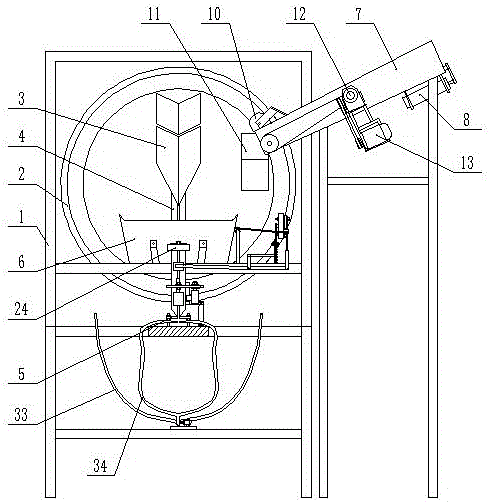

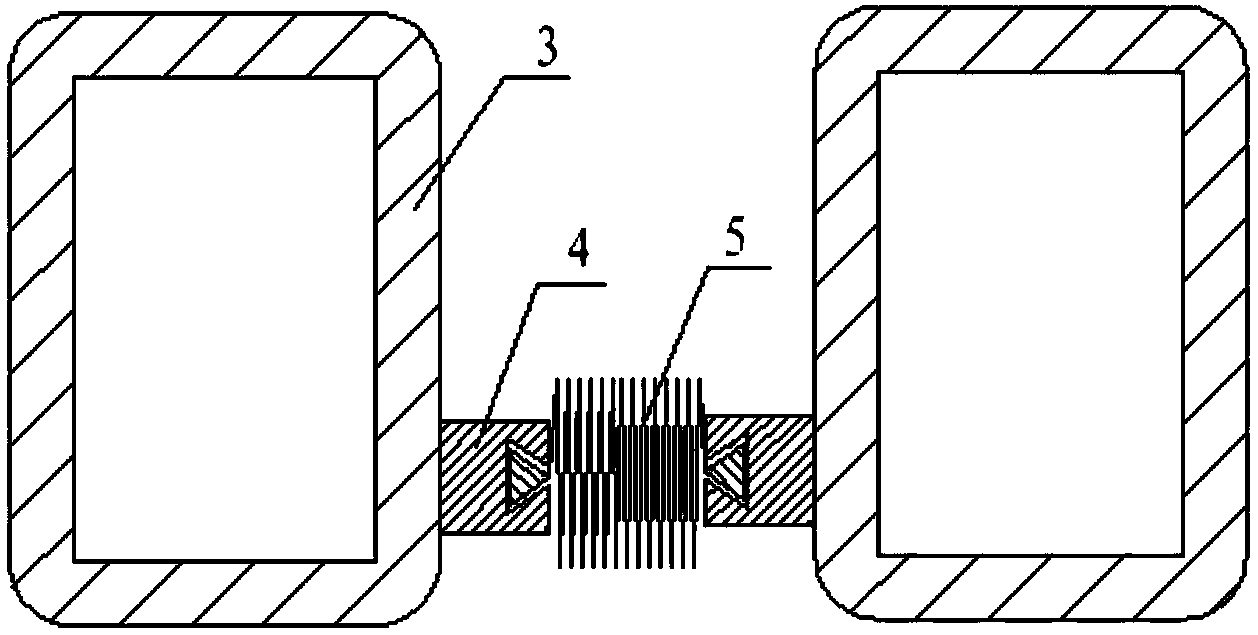

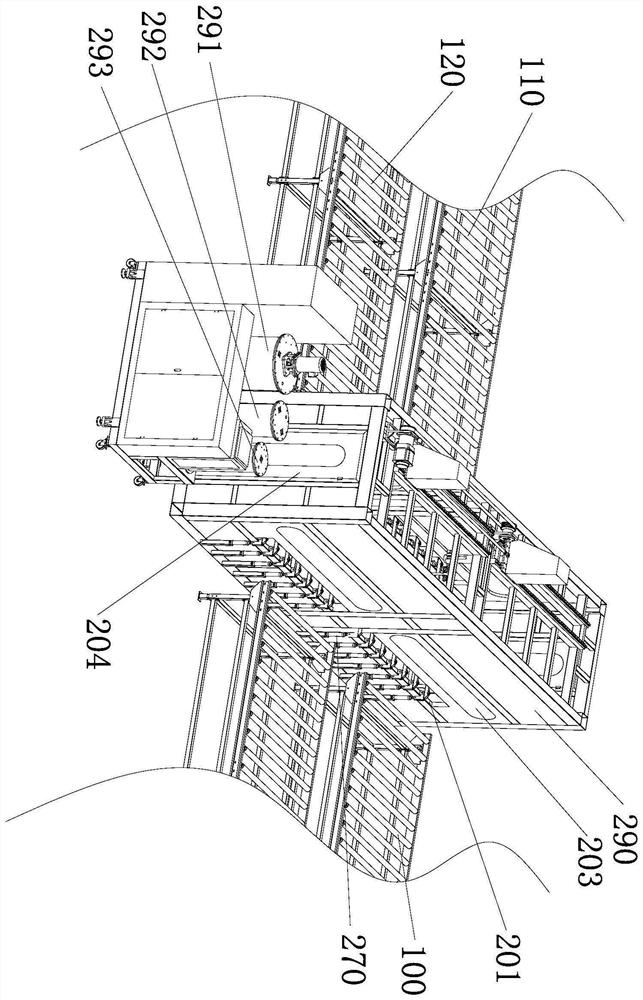

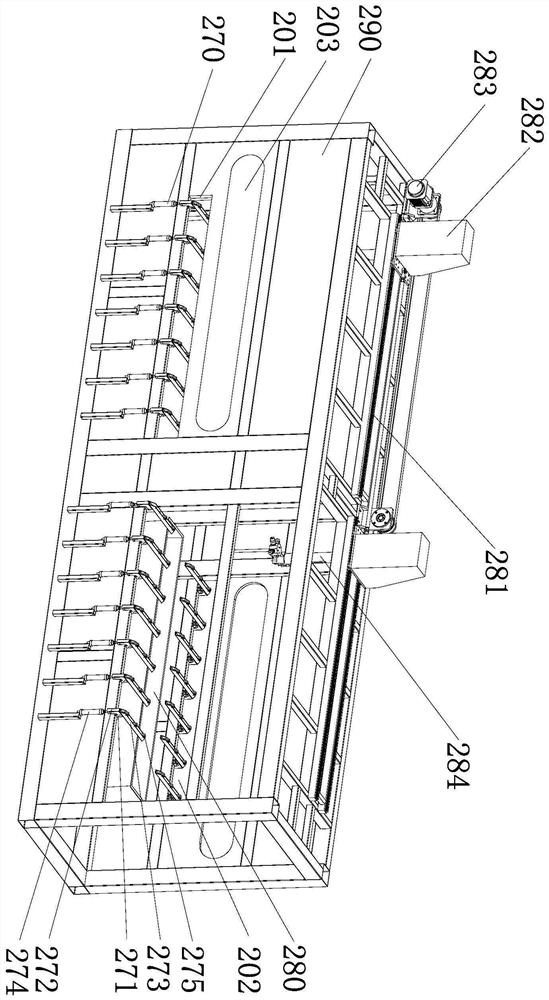

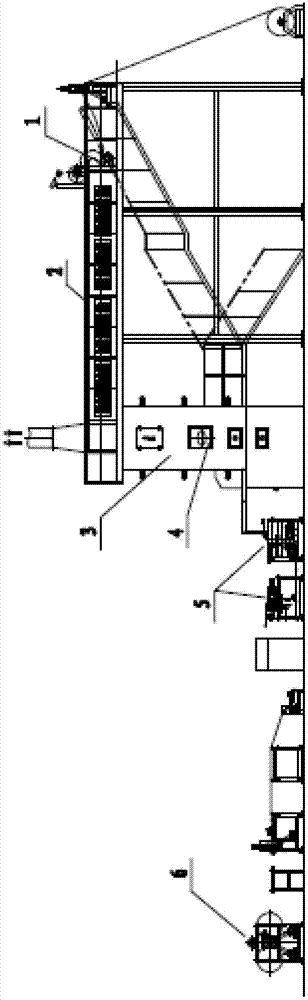

Device for treating kitchen waste slurry fermentation wastewater

InactiveCN107265791AAvoid frequent cleaningPrevent sinkingWater treatment parameter controlSludge treatmentBiological filterOil separation

The invention discloses a device for treating kitchen waste slurry fermentation wastewater, and relates to devices for treating wastewater obtained after anaerobic digestion and dehydration are carried out on kitchen waste slurry and wastewater generated in other working procedures. The device has the advantages that the kitchen waste slurry fermentation wastewater is sequentially treated by an oil separation primary settling tank (1), a regulating tank (2), an A / O (anaerobic / oxic) biochemical treatment device (3), a settling tank (4), an air flotation device (5), a Fenton reactor (6), a coagulating settling tank (7) and an aeration biological filter tank (8), accordingly, requirements on effectively removing pollutants such as COD (chemical oxygen demand), BOD<5> (biochemical oxygen demand <5>) and SS (suspended solids) in the kitchen waste slurry fermentation wastewater can be met, TN (total nitrogen) and TP (total phosphorus) can be effectively removed, the chromaticity of the kitchen waste slurry fermentation wastewater can be effectively lowered, and the TN and TP removal rates can be increased; requirements of 'primary standards' of the Comprehensive Wastewater Discharge Standards (GB8978-1996) on pollutants such as the COD, the BOD<5>, NH3-N and the TP in the treated kitchen waste slurry fermentation wastewater and the chromaticity of the treated kitchen waste slurry fermentation wastewater can be stably met.

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

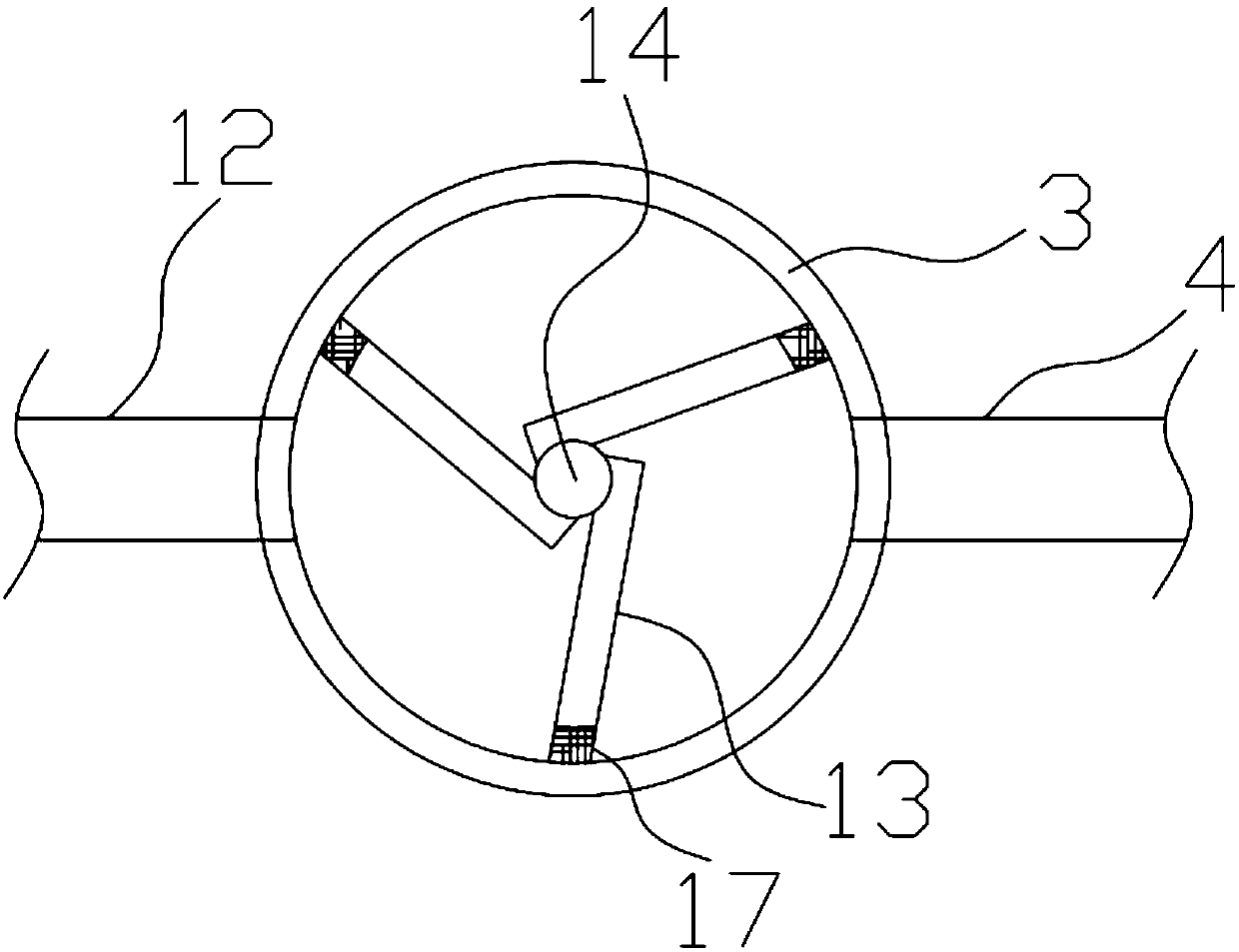

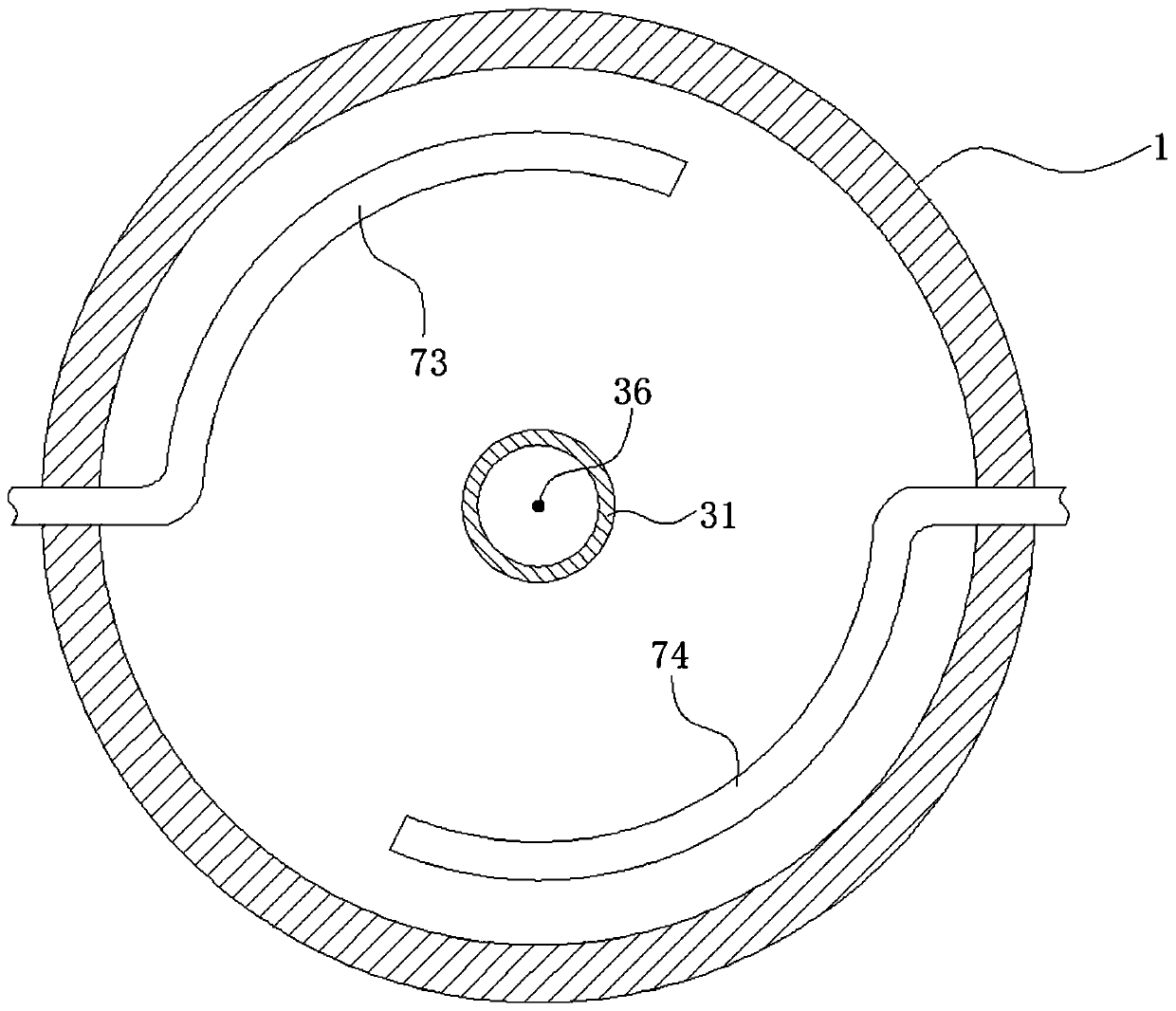

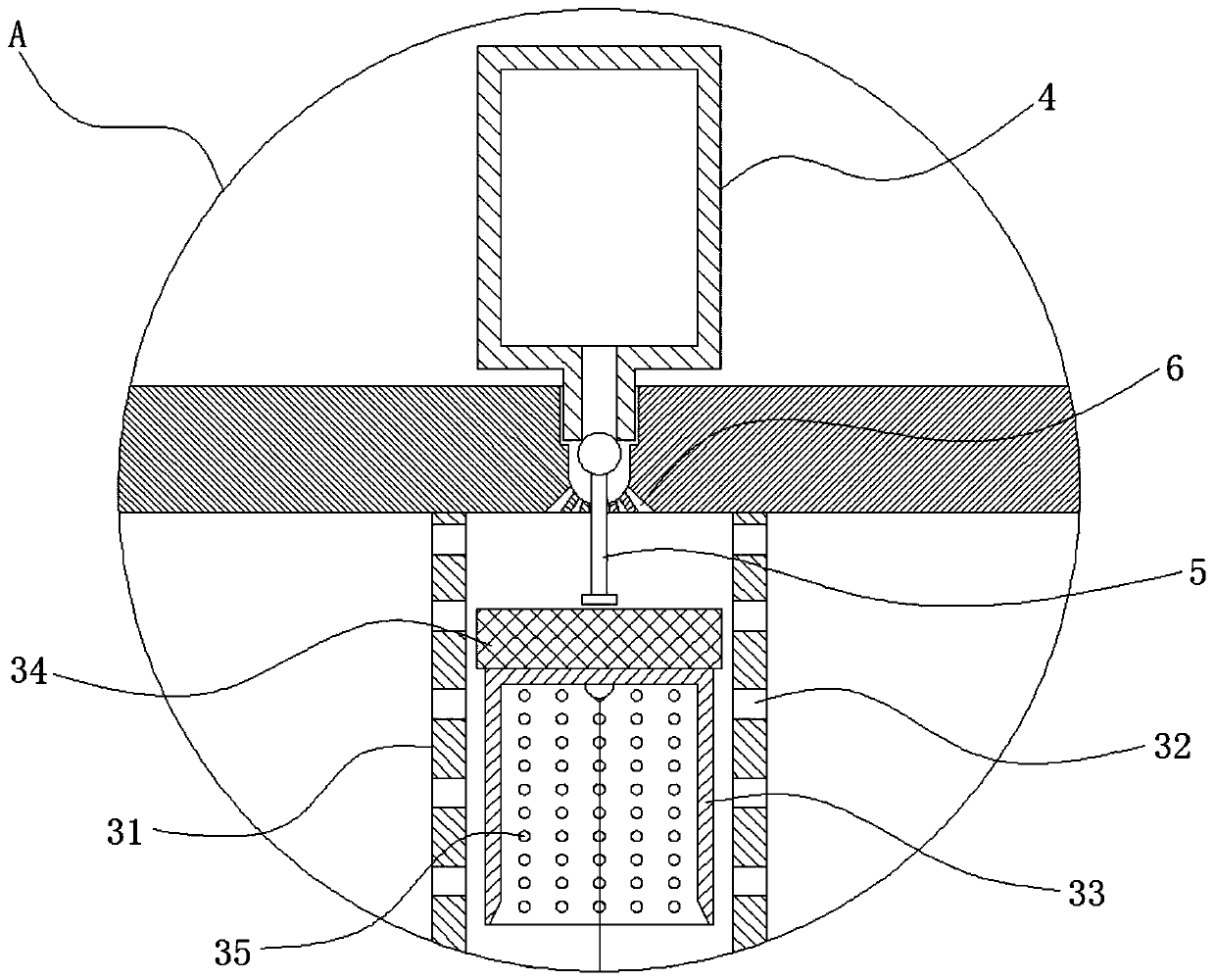

Centrifugal force based rotary sewage pre-treatment device

ActiveCN110282785AAvoid frequent cleaningReduce usageWater/sewage treatment by centrifugal separationTreatment involving filtrationCurrent limitingAdhesive

The invention provides a centrifugal force based rotary sewage pre-treatment device, and relates to the technical field of water pollution treatment. The centrifugal force based rotary sewage pre-treatment device includes a tank, wherein the bottom of the tank is fixedly provided with a support; a filtering device is fixedly installed in the tank; a potion bottle is in threaded connection with the top of the tank; a current-limiting rod is in sliding connection onto a position below the potion bottle on the top of the tank; leaking holes are formed below the current-limiting rod at the top of the tank; two swirling device are fixedly connected with two sides of the tank. According to the centrifugal force based rotary sewage pre-treatment device provided by the invention, centrifugal force is adopted to collect and clean impurities; repetitive work can be performed; no cleaning is needed; labor conservation and effectiveness are realized; inertia of the sewage itself is adopted to replace traditional stirring devices, the device is not easy to damage and energy is saved; a certain number of adhesive is automatically added into the tank, so that waste of adhesive is avoided.

Owner:南京本森自动化设备有限公司

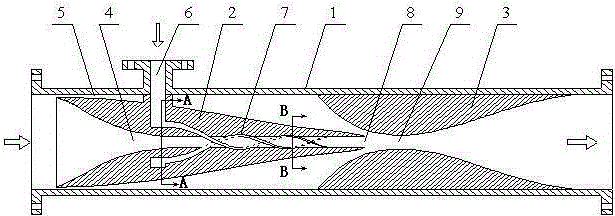

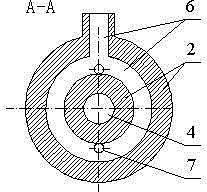

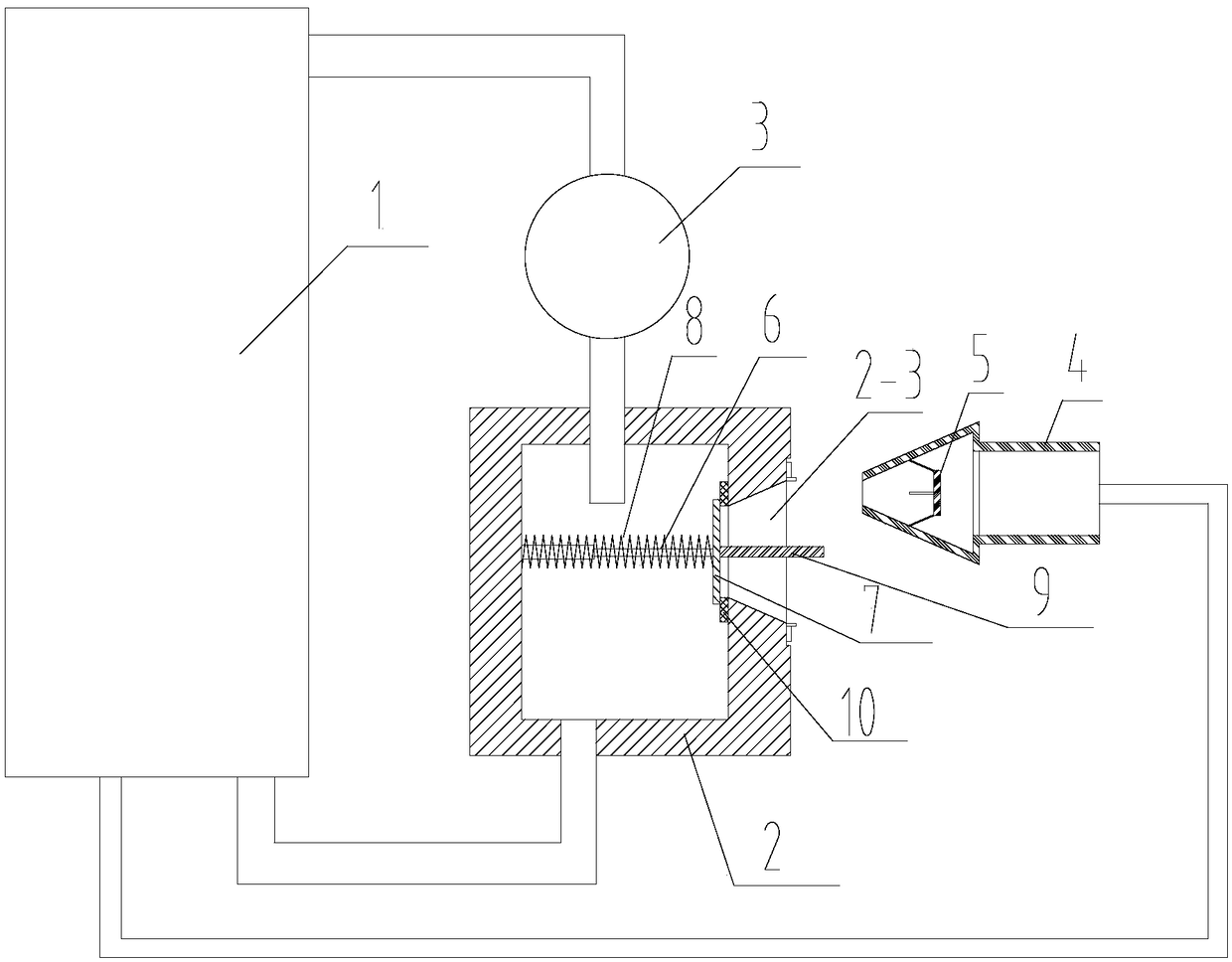

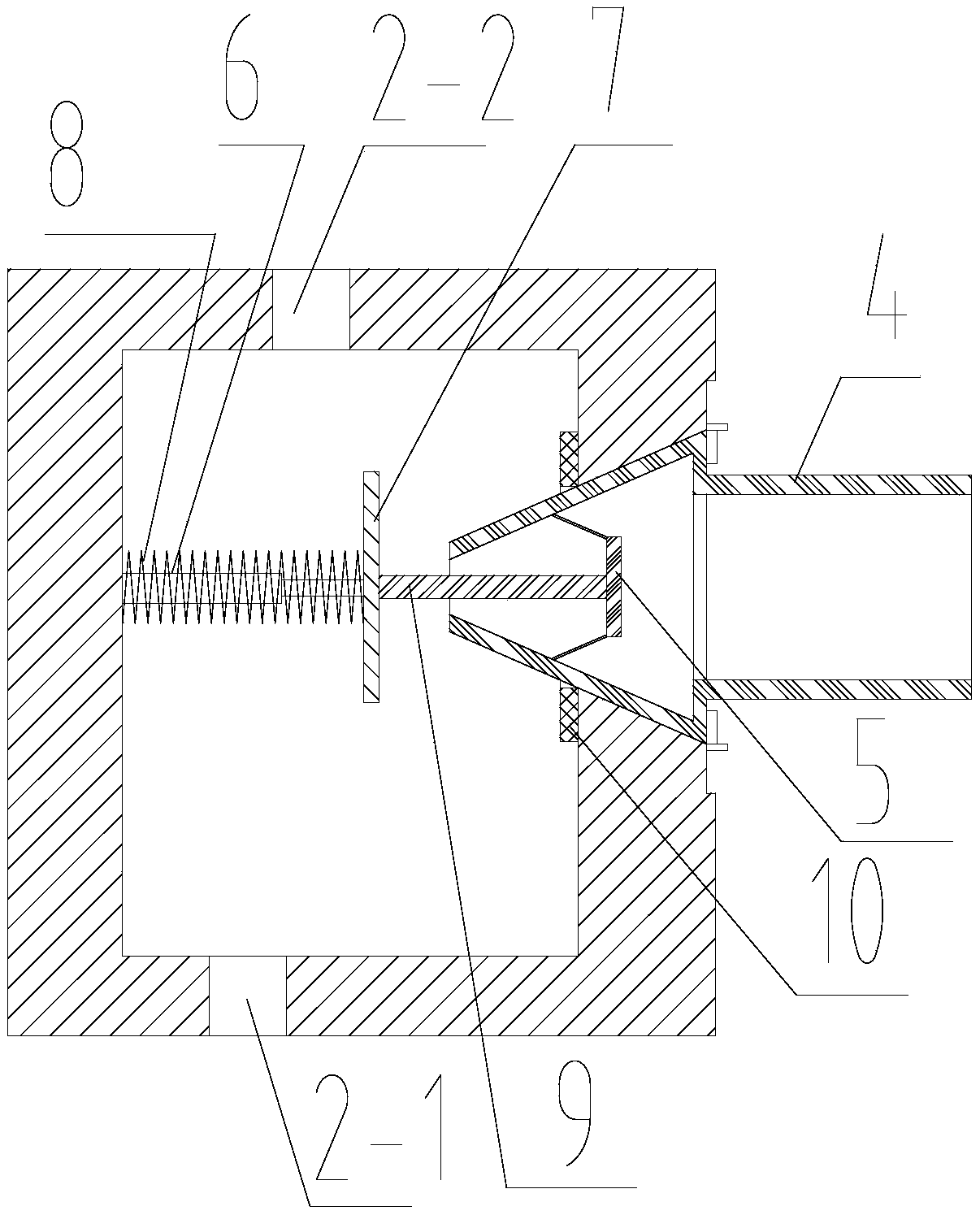

Liquid addition and atomization device for mine nitrogen-filling process

ActiveCN103195462BStable nebulized nitrogen flowReduce excessive resistanceDust removalFire preventionViscous liquidInlet channel

The invention discloses a liquid addition and atomization device for a mine nitrogen-filling process. A flow-guide atomization device is arranged at the front end of a barrel body of the liquid addition and atomization device. A reducing gas-guide channel is reserved in the interior of the flow-guide atomization device. A bypass channel is arranged between the exterior of the flow-guide atomization device and the barrel body. A flow inlet channel is arranged on a lateral side of the flow-guide atomization device, and is communicated with a liquid-guide groove. A Venturi mixer is arranged at the rear end of the barrel body; and an injection orifice of the flow-guide atomization device is opposite to a mixture channel of the Venturi mixer. The liquid addition and atomization device is simple in structure, large in atomization amount, small in occupied space, flexible in movement, convenient to assemble, capable of effectively preventing blocking and working continuously, suitable for viscous liquid, free of electric elements, safe, reliable, and wide in practicability, is applicable to fire preventing and suppression in gob area of a mine or a closed space, and especially is applicable to adding fire-proof inhibitor solution in a mine nitrogen-filling process for fire preventing and suppression.

Owner:CHINA UNIV OF MINING & TECH

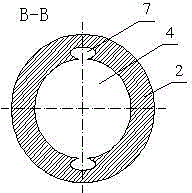

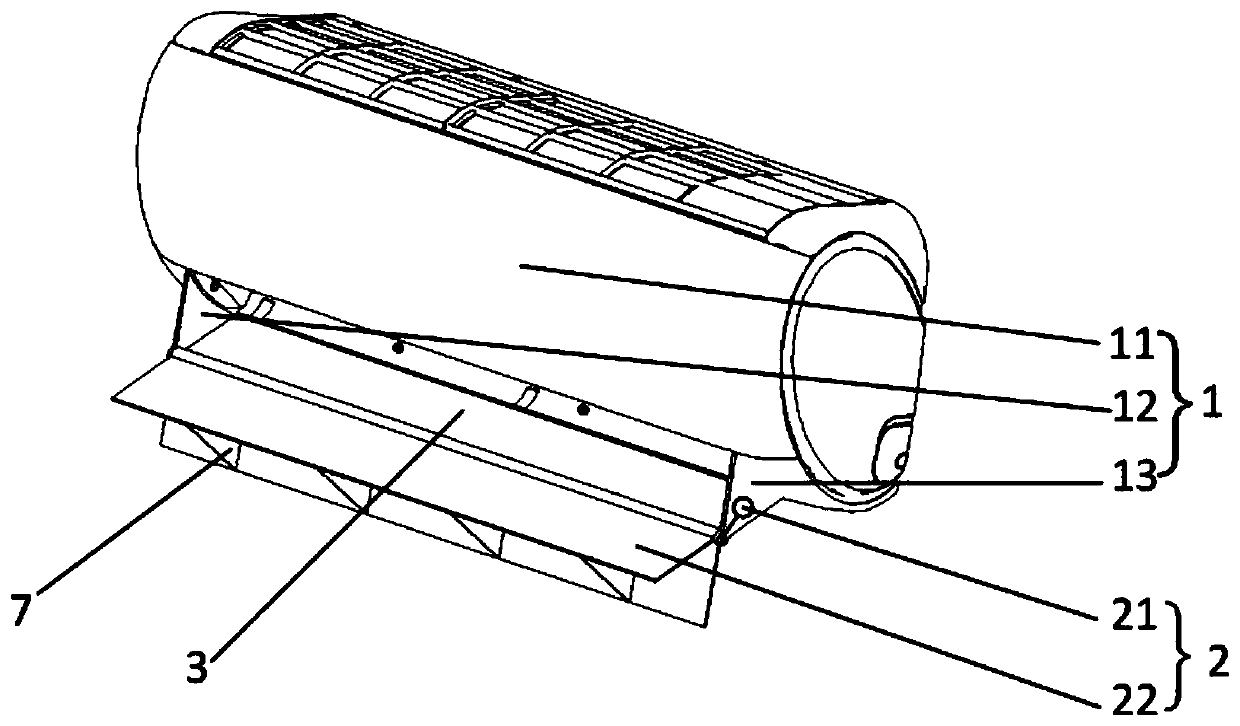

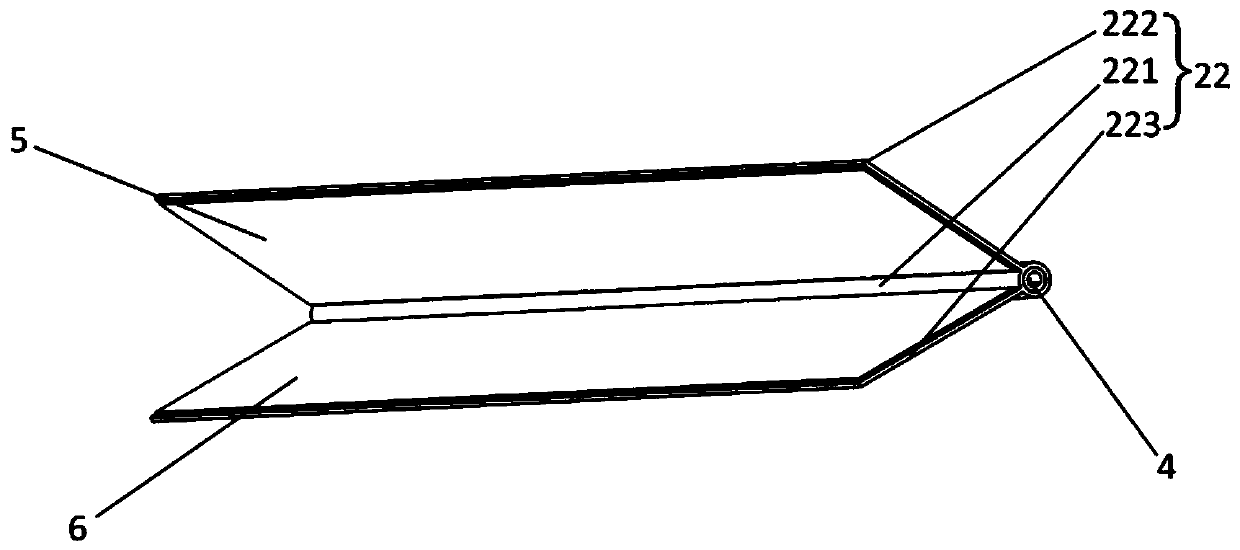

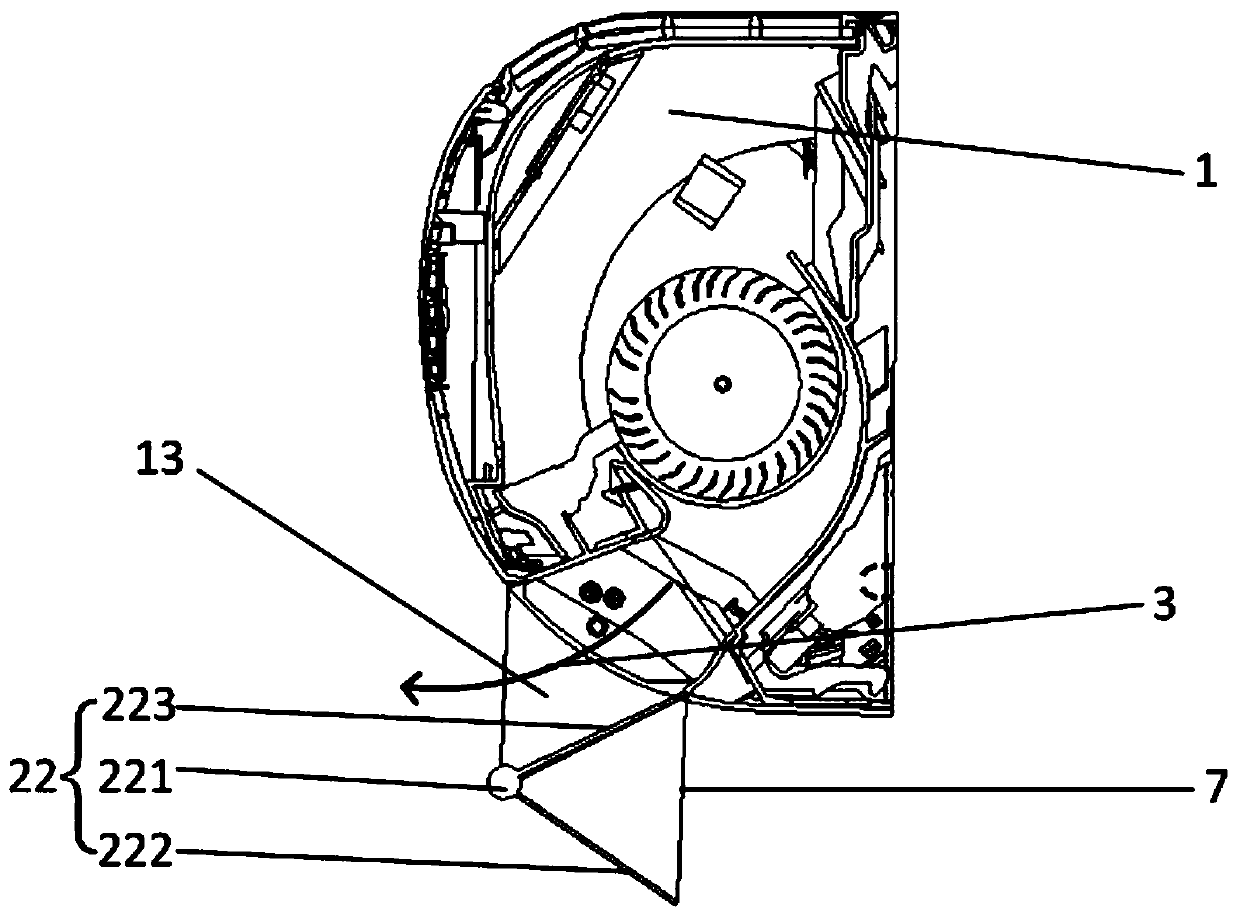

Indoor unit of air conditioner

ActiveCN110486800AUniform temperature distributionAvoid blowingLighting and heating apparatusAir conditioning systemsRefrigerationElectrical and Electronics engineering

The invention belongs to the technical field of air conditioners and aims to solve the problems that the temperature of air discharged from an existing indoor unit of an air conditioner is not distributed uniformly and a user is easily blown straightly. For the purpose, the invention provides an indoor unit of an air conditioner. The indoor unit of the air conditioner comprises a housing and a rotary air guide mechanism which is arranged on the housing; the housing is provided with an air outlet; the rotary air guide mechanism is arranged at the air outlet; the rotary air guide mechanism is configured to rotate to a first position when the air conditioner executes a refrigeration mode so that the air discharged from the indoor unit can be guided out upwards, rotate to a second position when the air conditioner executes a heating mode so that the air discharged from the indoor unit is guided out downwards and rotate to a third position when the air conditioner executes a straight-blow-preventing mode so that the air discharged from the indoor unit is guided out after being divided up and down. According to the indoor unit provided by the invention, when the air conditioner is in a refrigeration mode or in a heating mode, the temperature of discharged air is distributed uniformly; moreover the user can make the air conditioner execute a straight-blow-preventing mode when the useris close to the indoor unit, so the user is prevented from straight blowing and is prevented from feeling uncomfortable.

Owner:CHONGQING HAIER AIR CONDITIONER CO LTD +2

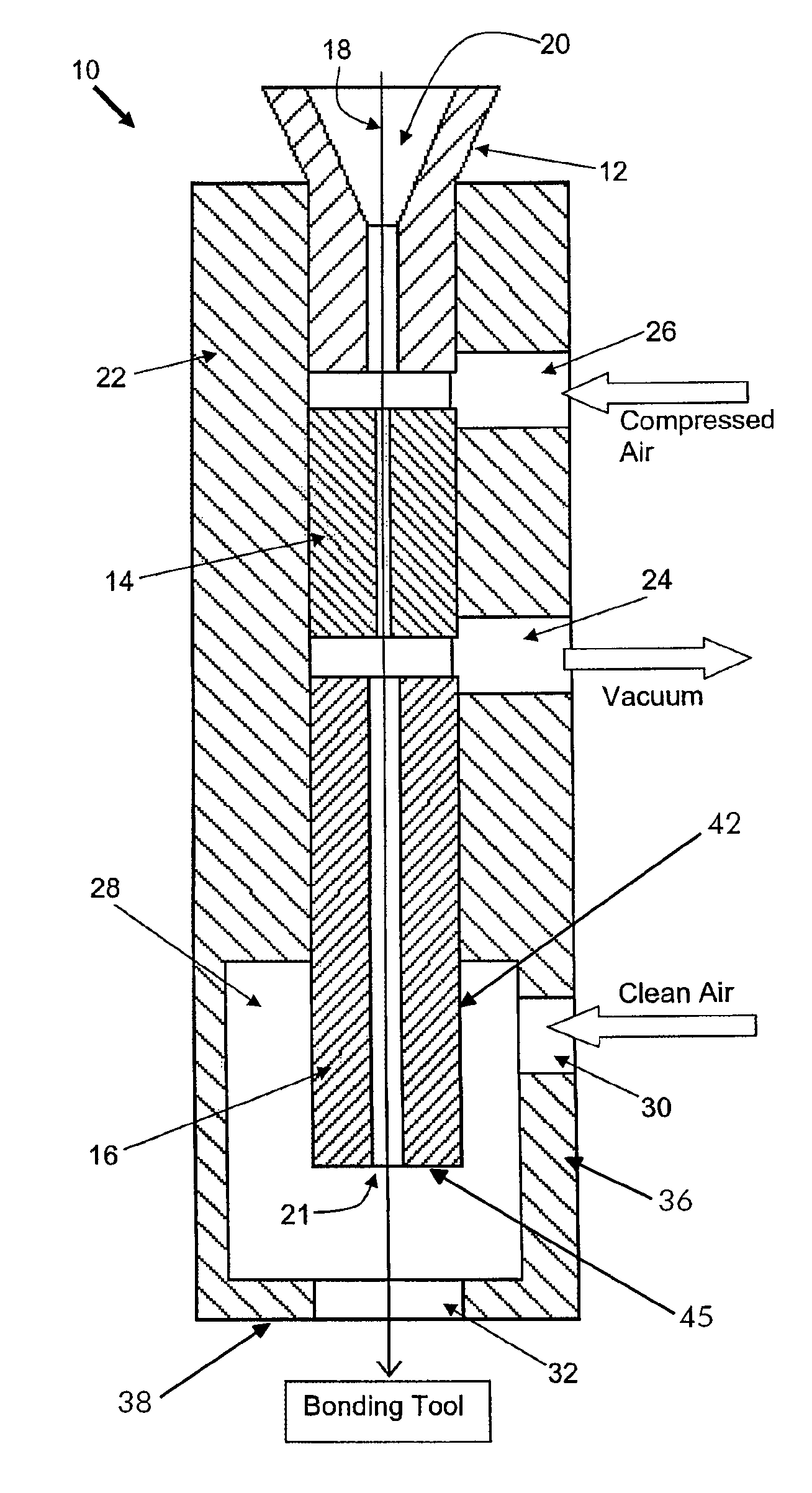

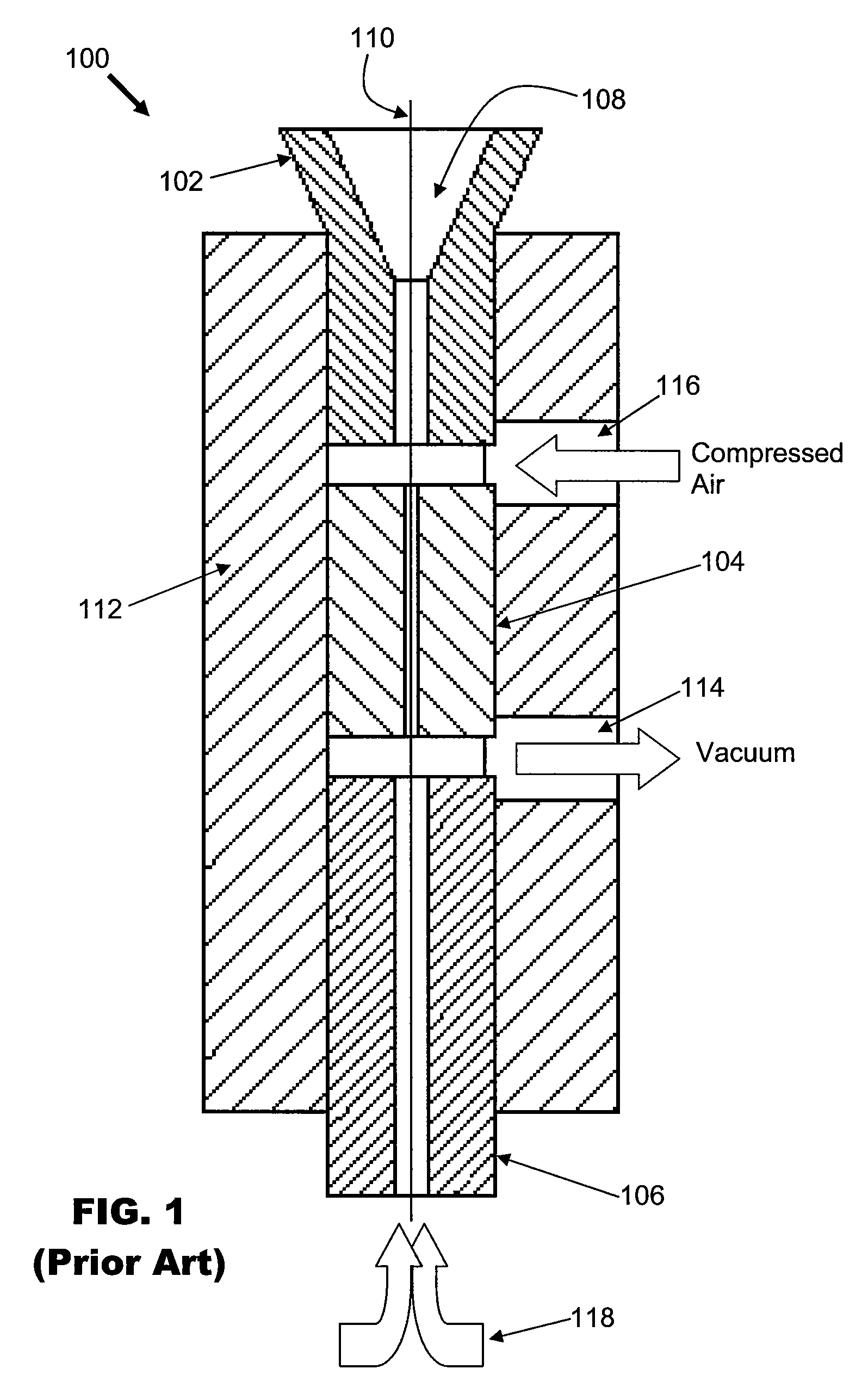

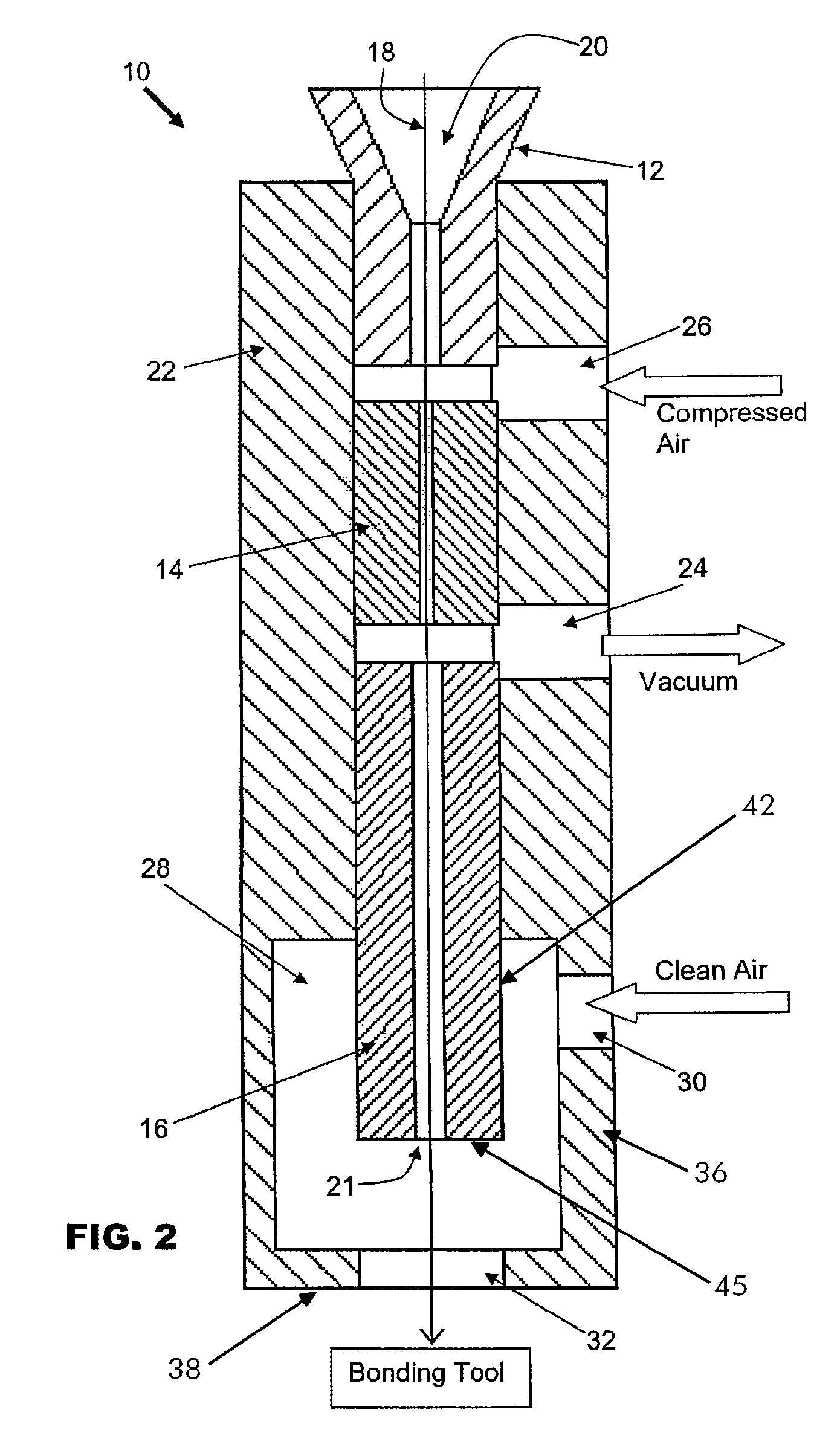

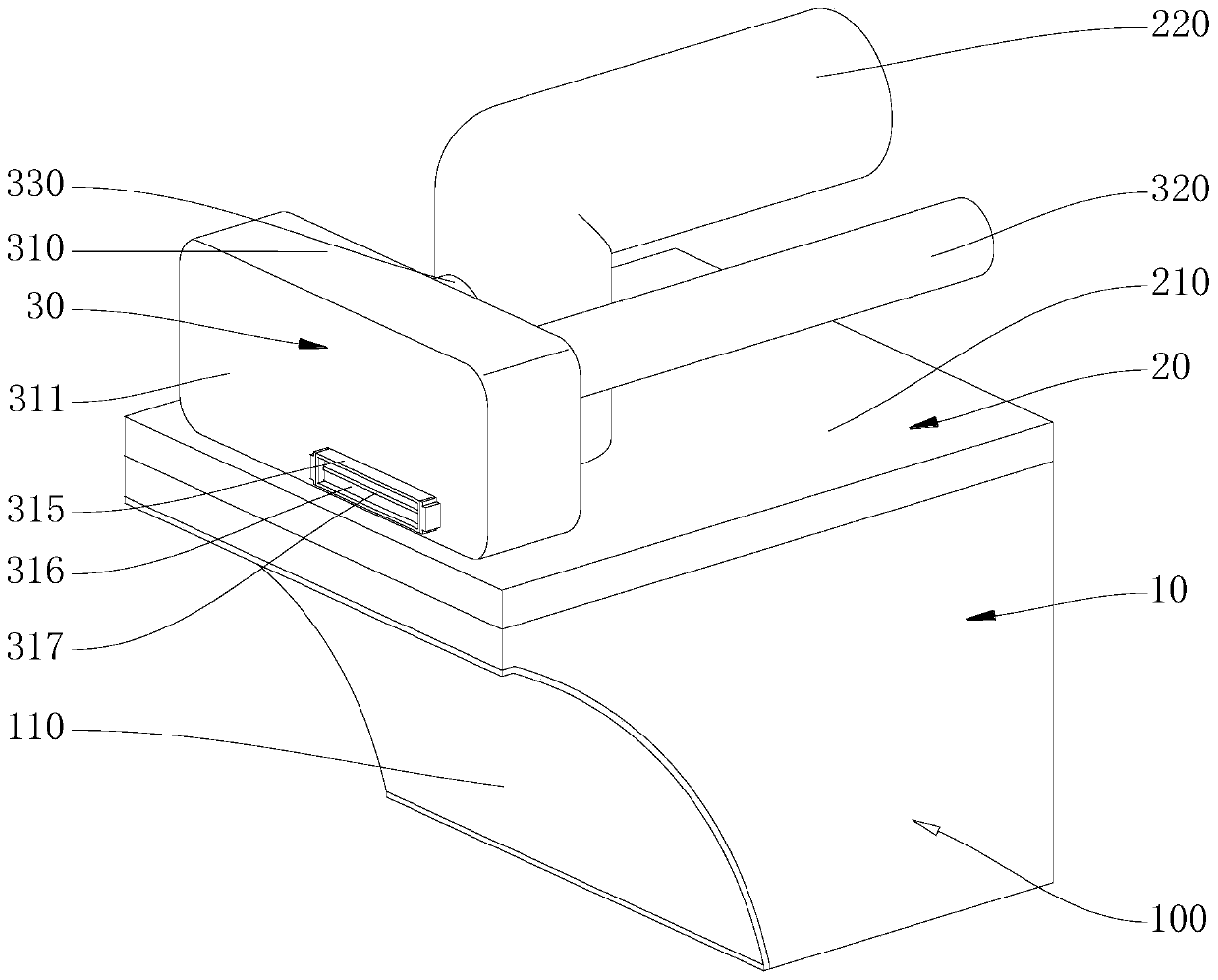

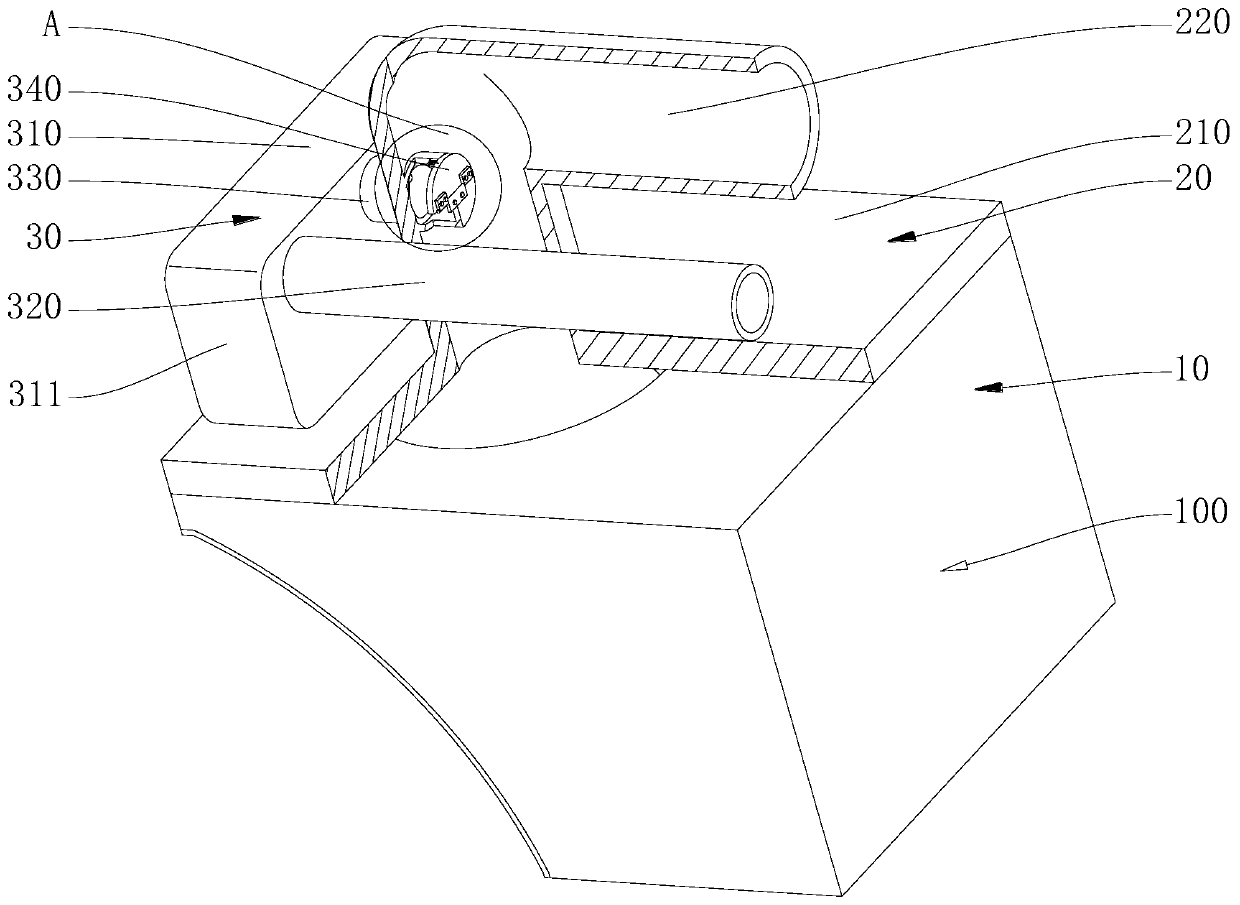

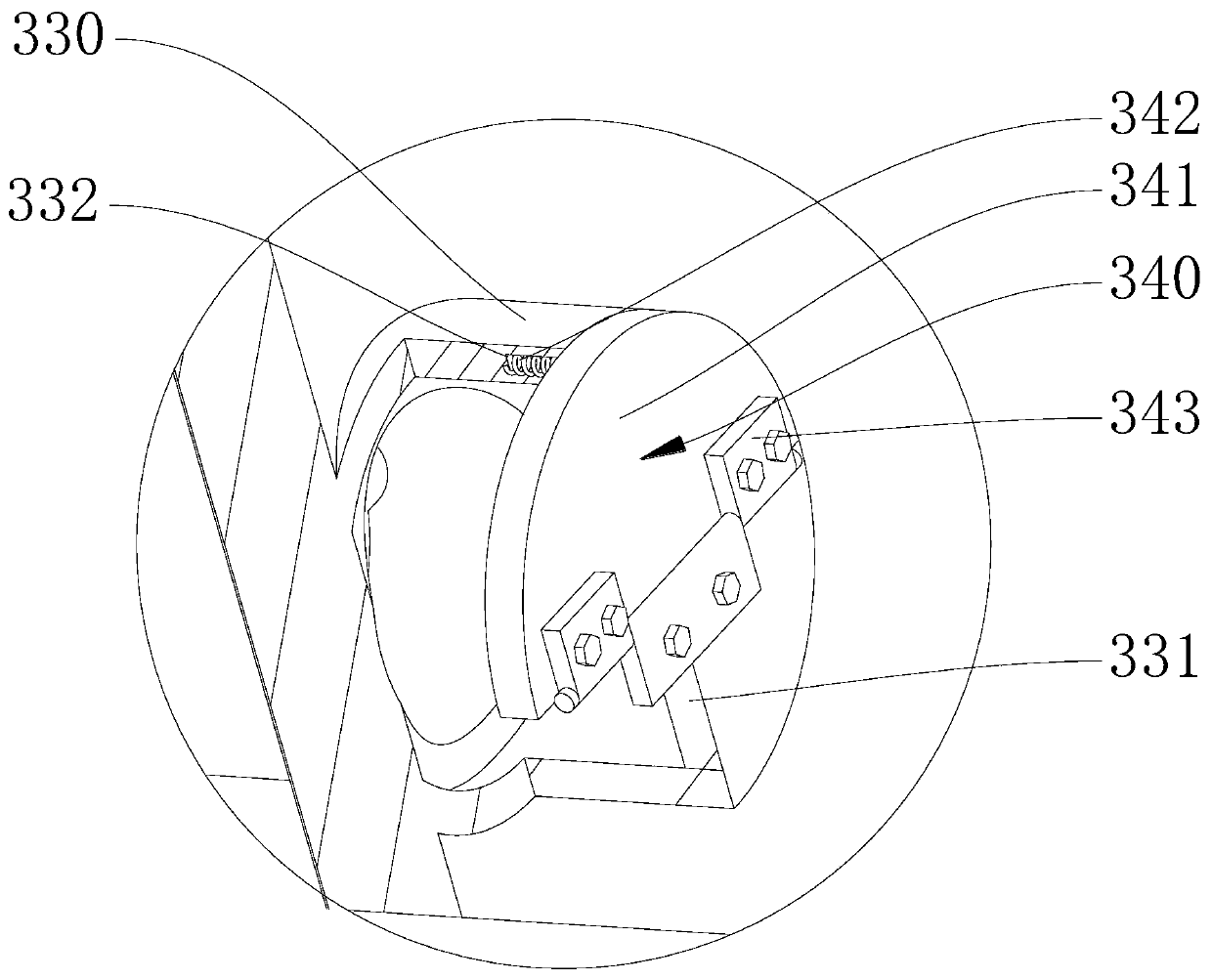

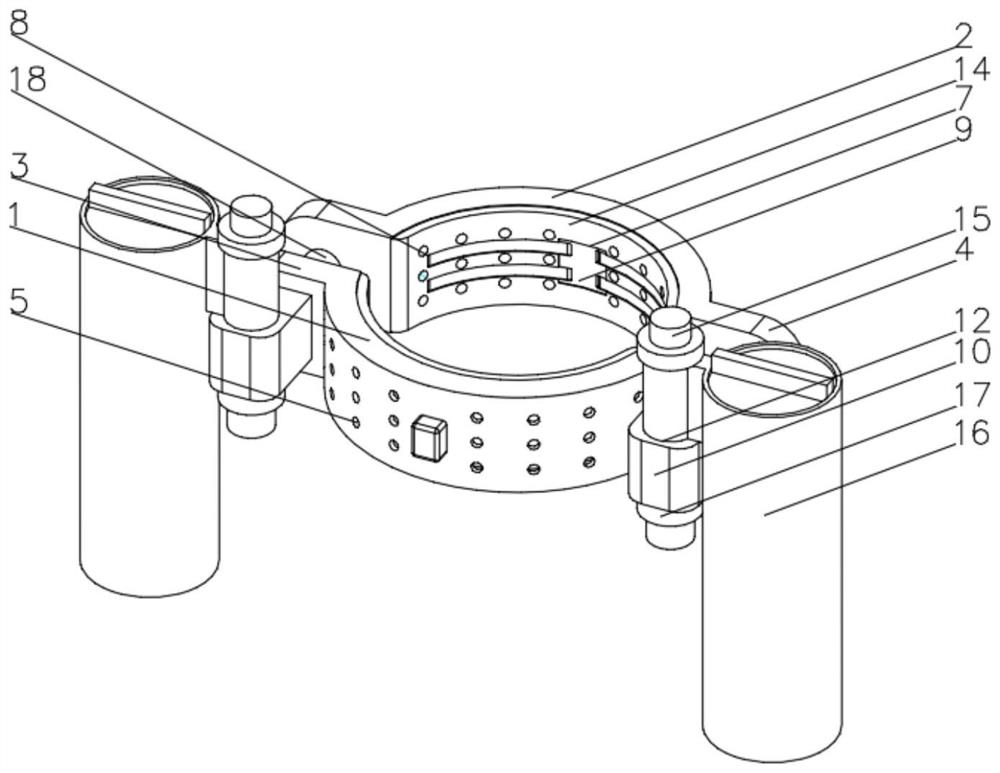

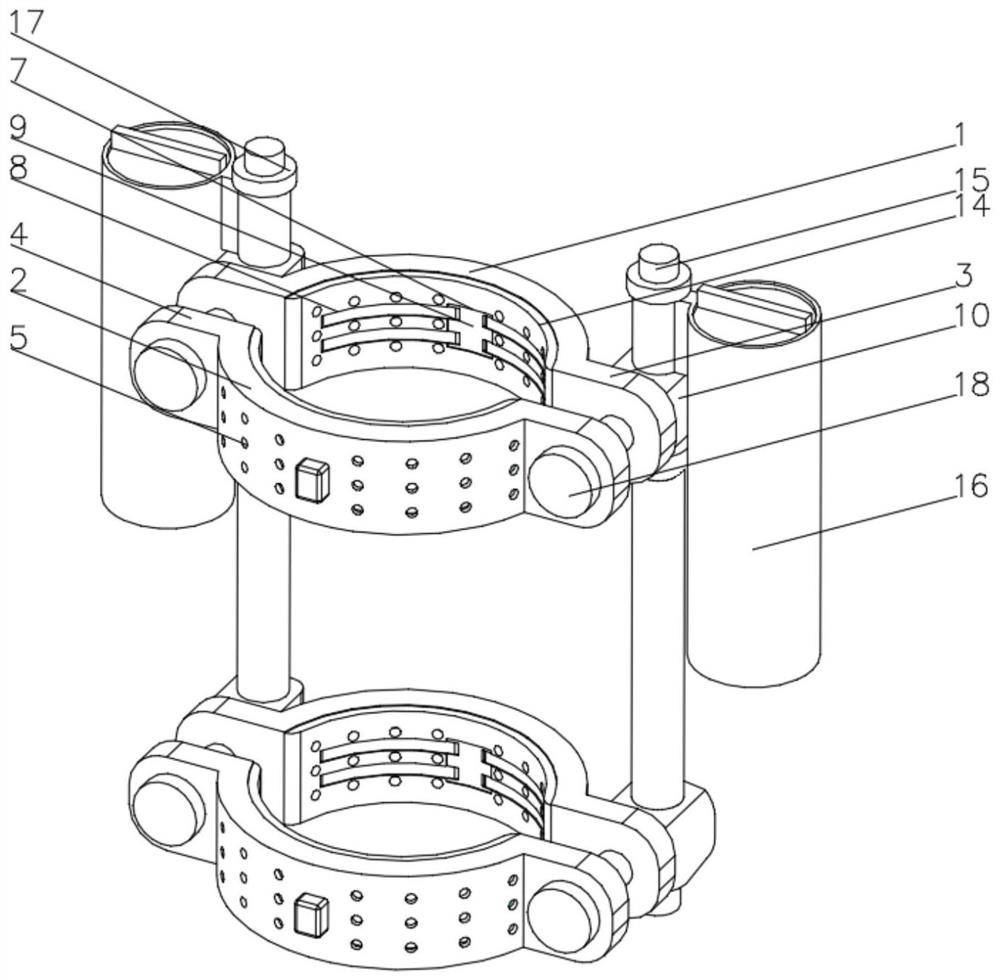

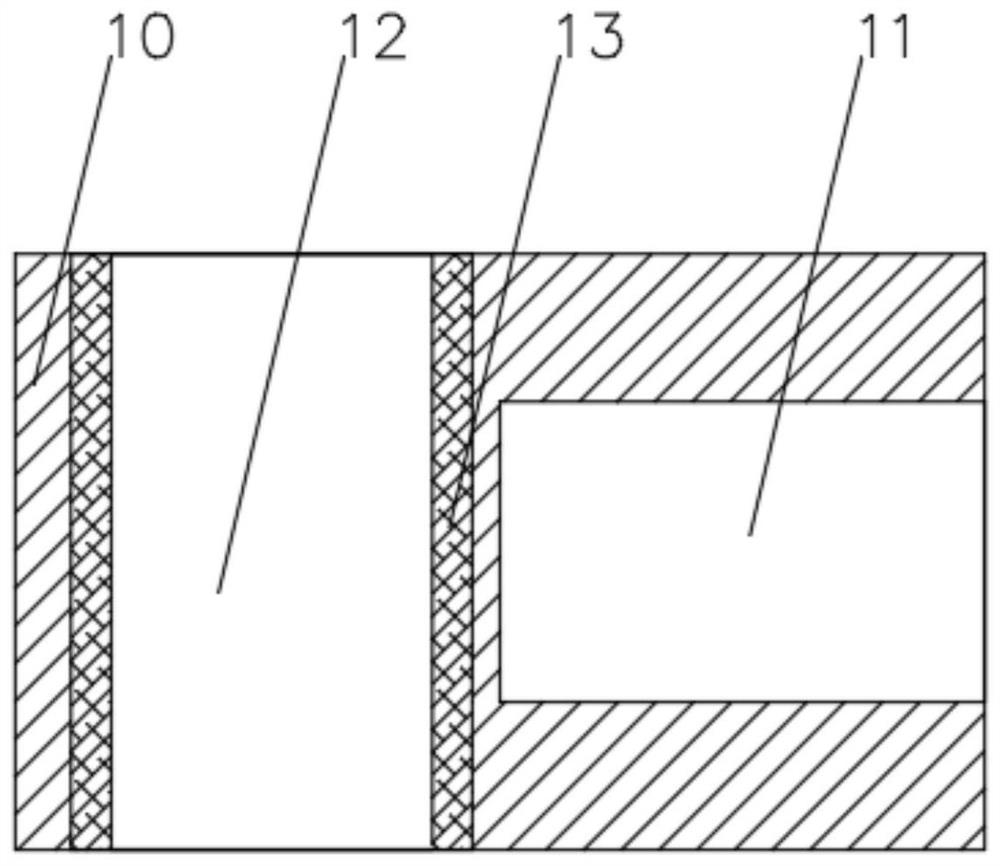

Vacuum wire tensioner for wire bonder

ActiveUS7954689B2Reduce introductionAvoid frequent cleaningSolid-state devicesWelding/cutting auxillary devicesEngineeringMechanical engineering

Owner:ASMPT SINGAPORE PTE LTD

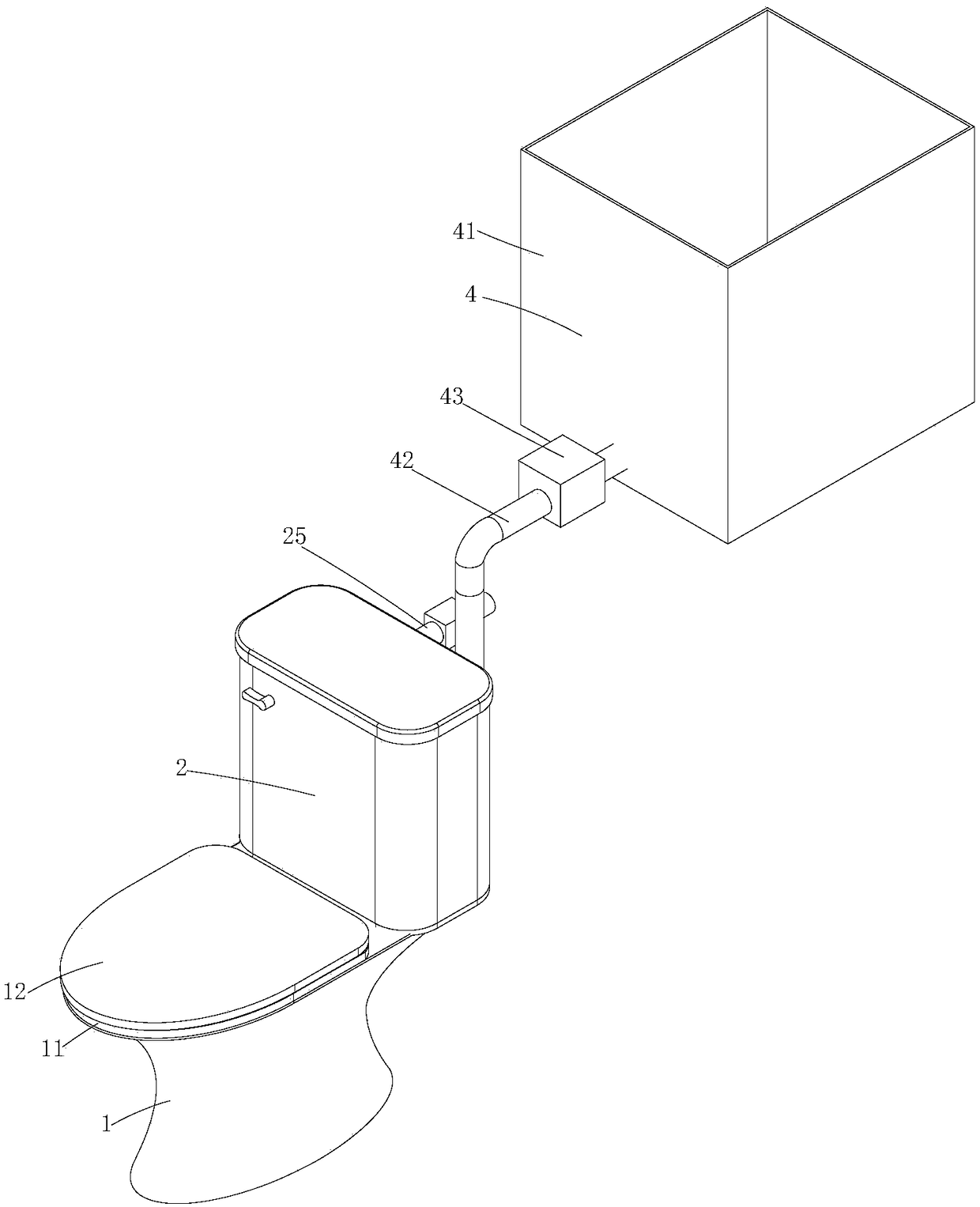

Ultraviolet light disinfection toilet

InactiveCN108951807AImprove convenienceImprove cleanlinessWater closetsFlushing devicesUltraviolet lightsUv disinfection

The invention discloses an ultraviolet light disinfection toilet. The ultraviolet light disinfection toilet comprises a toilet cylinder with an edge on the upper portion, a water tank connected with the toilet cylinder and a dividing structure used for dividing the water tank into a first water feeding cavity and a second water feeding cavity which are used for conveying domestic wastewater into the toilet cylinder, and the second water feeding cavity stores clear water and flushes the inner wall of the first water feeding cavity and the inner wall of the toilet cylinder after the domestic wastewater in the first water feeding cavity is discharged. The water tank of the ultraviolet light disinfection toilet is divided into the first water feeding cavity and the second water feeding cavity,the domestic wastewater is utilized, and therefore water resource waste is reduced; by arranging an ultraviolet light disinfection structure in a conveying pipe, the wastewater is disinfected instantly when used, the disinfection effect is good, bacteria are effectively prevented from breeding in the second water feeding cavity again, and it is guaranteed that the wastewater is in a sterile state.

Owner:杭州国瑞数码科技有限公司

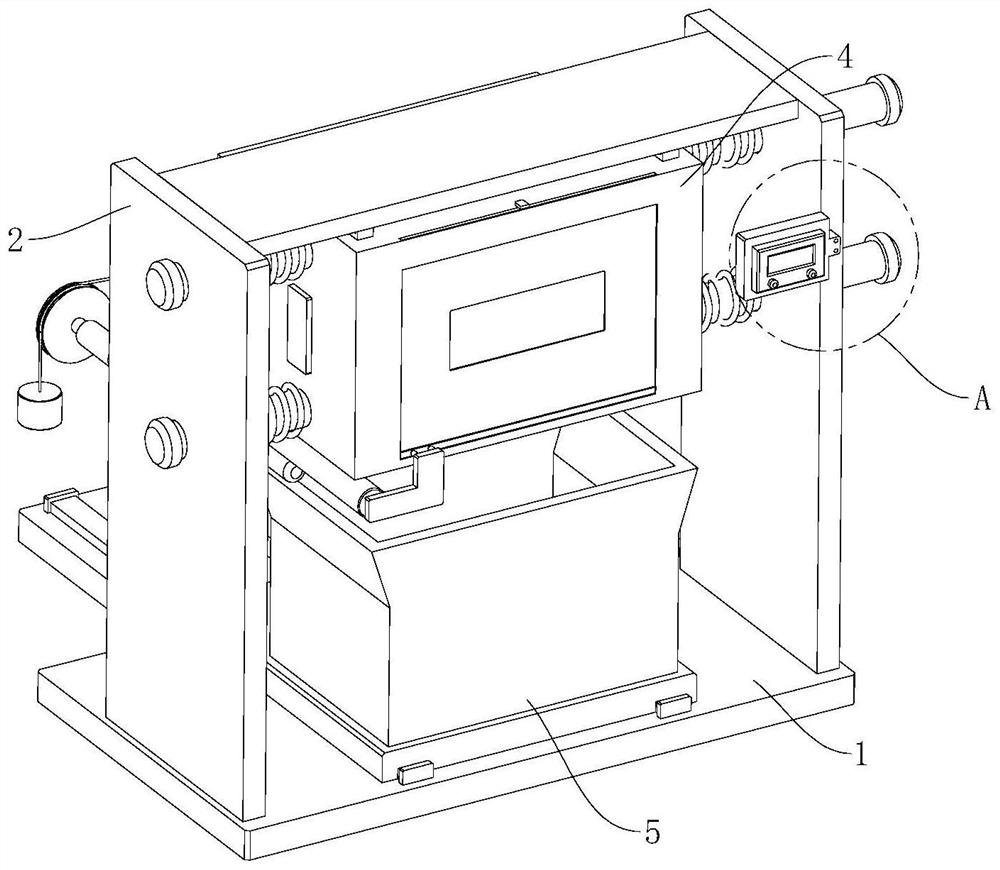

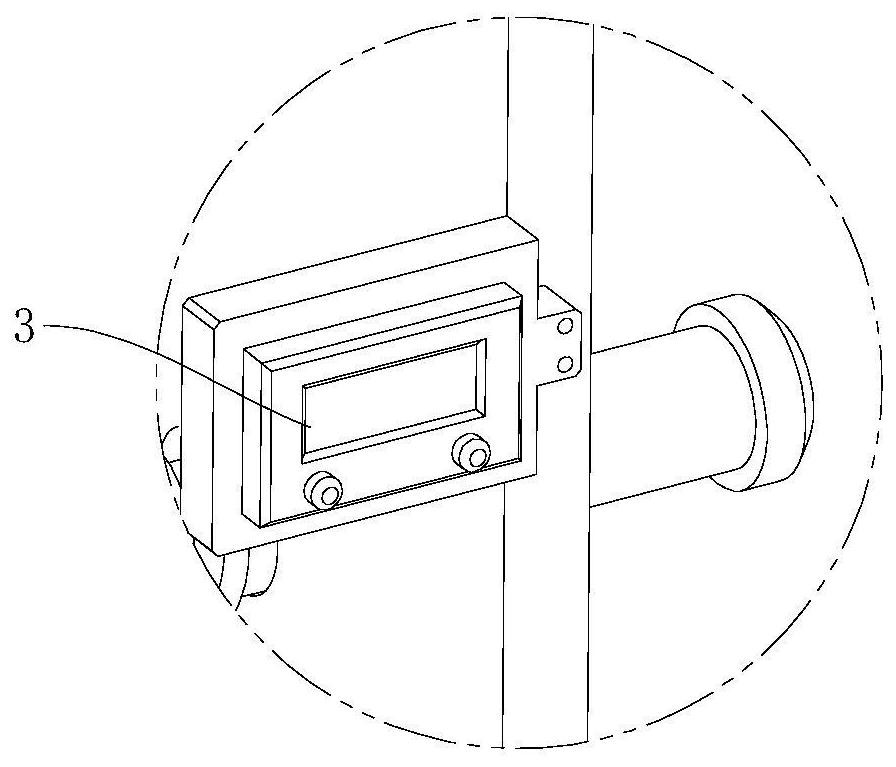

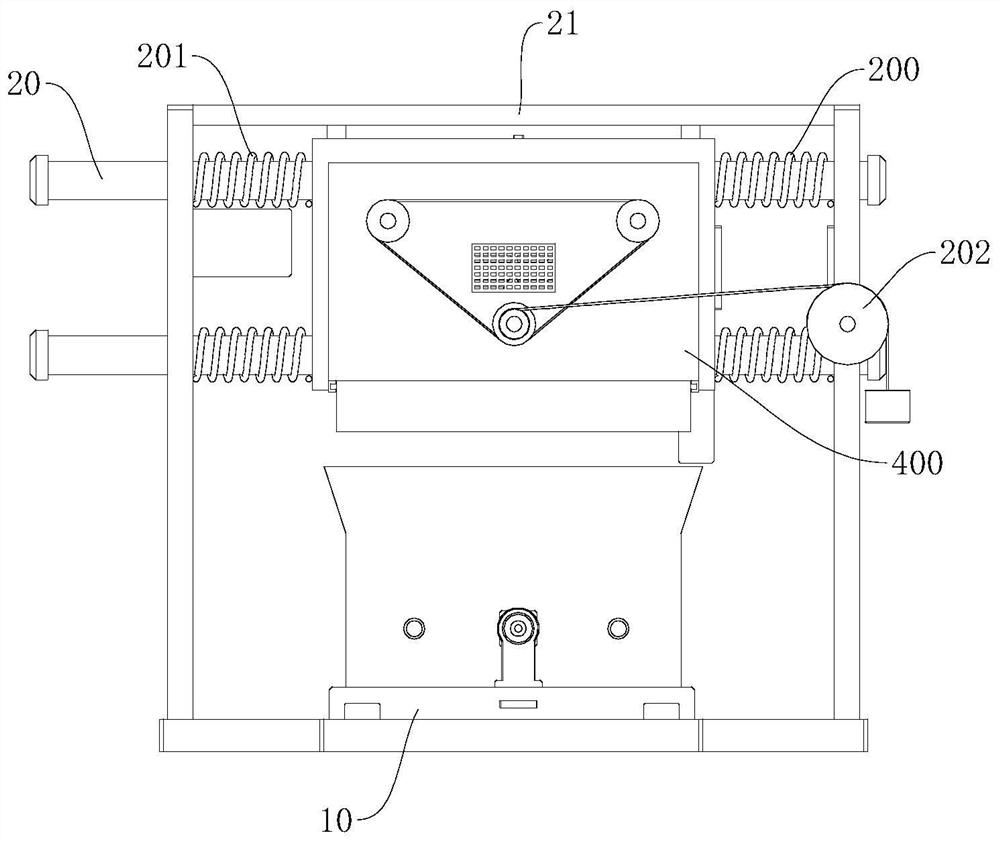

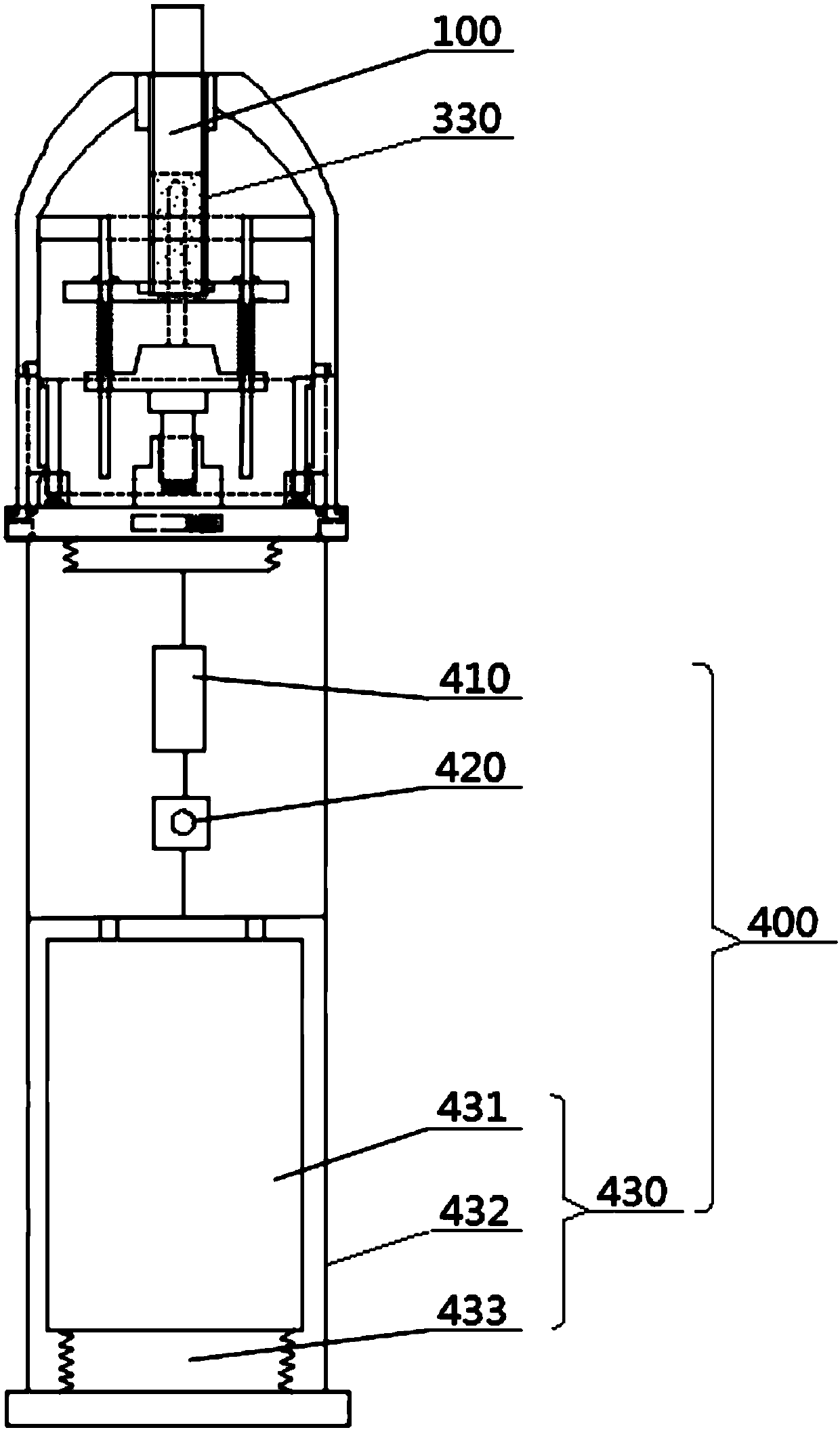

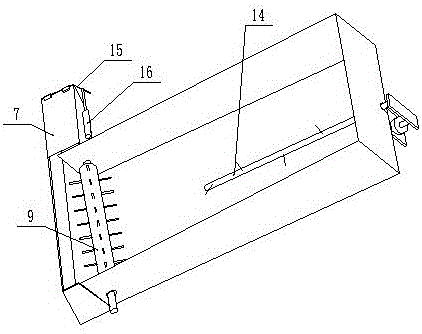

Nail ordering machine for steel nails and control method thereof

InactiveCN105775698AReduce labor intensityQuality improvementLiquid surface applicatorsConveyorsAutomatic controlEngineering

The invention discloses a nail ordering machine for steel nails and a control method thereof, and belongs to the technical field of nail ordering machines. The technical problem to be solved is to provide a nail ordering machine for steel nails, which is high in automation degree and high in finished product quality. The following technical scheme is adopted: according to the nail ordering machine for the steel nails, a charge drum is fixed on a support; an inclined groove is arranged in the charge drum; the tail end of the inclined groove is connected with an inclined nail ordering rail; one end of the inclined nail ordering rail is located in the charge drum, and the other end of the inclined nail ordering rail is connected with a horizontally-arranged flat rail; a baffle is arranged at the middle of the inclined nail ordering rail; adhesive outlet ports of an adhesive outlet device are arranged in the two sides of the flat rail; and a nail cutting device is installed at the tail end of the flat rail. The nail ordering machine for the steel nails further comprises a nail receiving mechanism, a nail filling device and a nail beating mechanism, wherein an automatic control mechanism is further arranged in the adhesive outlet device. The nail ordering machine for the steel nails, which is disclosed by the invention, realizes high automation, and operation and control for one machine can be easily completed only by one person, thus the labour intensity of workers is reduced, the labour cost is saved, and the finished product quality is further improved.

Owner:李翊朝

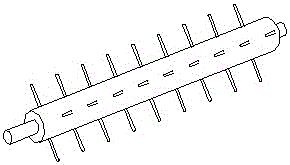

Roller pin coarse grinding device and application method thereof

PendingCN109277936AReduce the cushioning forceIncrease air pressureEdge grinding machinesPolishing machinesPulp and paper industryAir blower

The invention discloses a roller pin coarse grinding device. The device comprises a roller and a driving gear arranged at the tail end of the roller, wherein the head end of the roller is opened. Thedevice is characterized in that a dust collection sleeve is arranged on the outer side of the roller, dust exhaust holes are formed in the side wall of the roller and penetrate through the roller wallof the roller to communicate with an inner cavity of the dust collection sleeve, a barrel cover is arranged in an opening of the head end of the roller, and an adjusting platform, an air blower and the like are further arranged. Compared with the prior art, the roller pin coarse grinding device has the following advantages that fragments produced in the coarse grinding process can be separated from roller pins, the buffering effect of the fragments in the coarse grinding process is reduced, and the coarse grinding efficiency is improved; through an air supply pipe, airflow in the roller penetrates through the dust exhaust holes to increase the dust exhaust speed, heat is taken away, and the operating safety is improved; by arranging a vibrator, dust is fast exhausted with the aid of the vibrator, and frequent cleaning is avoided; and feeding and discharging are convenient, the coarse grinding process is uniform, and the product quality is improved.

Owner:NANJING RENHENG BEARING ROLLING ELEMENTS CO LTD

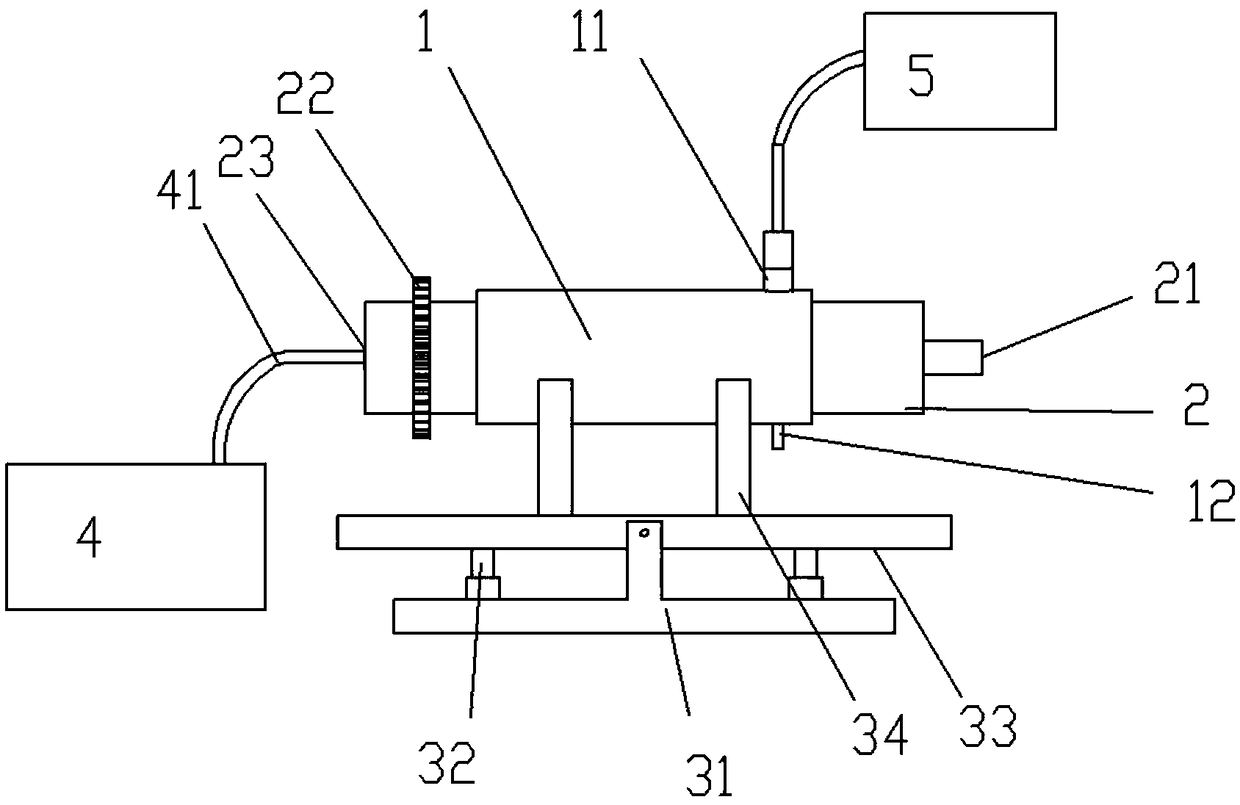

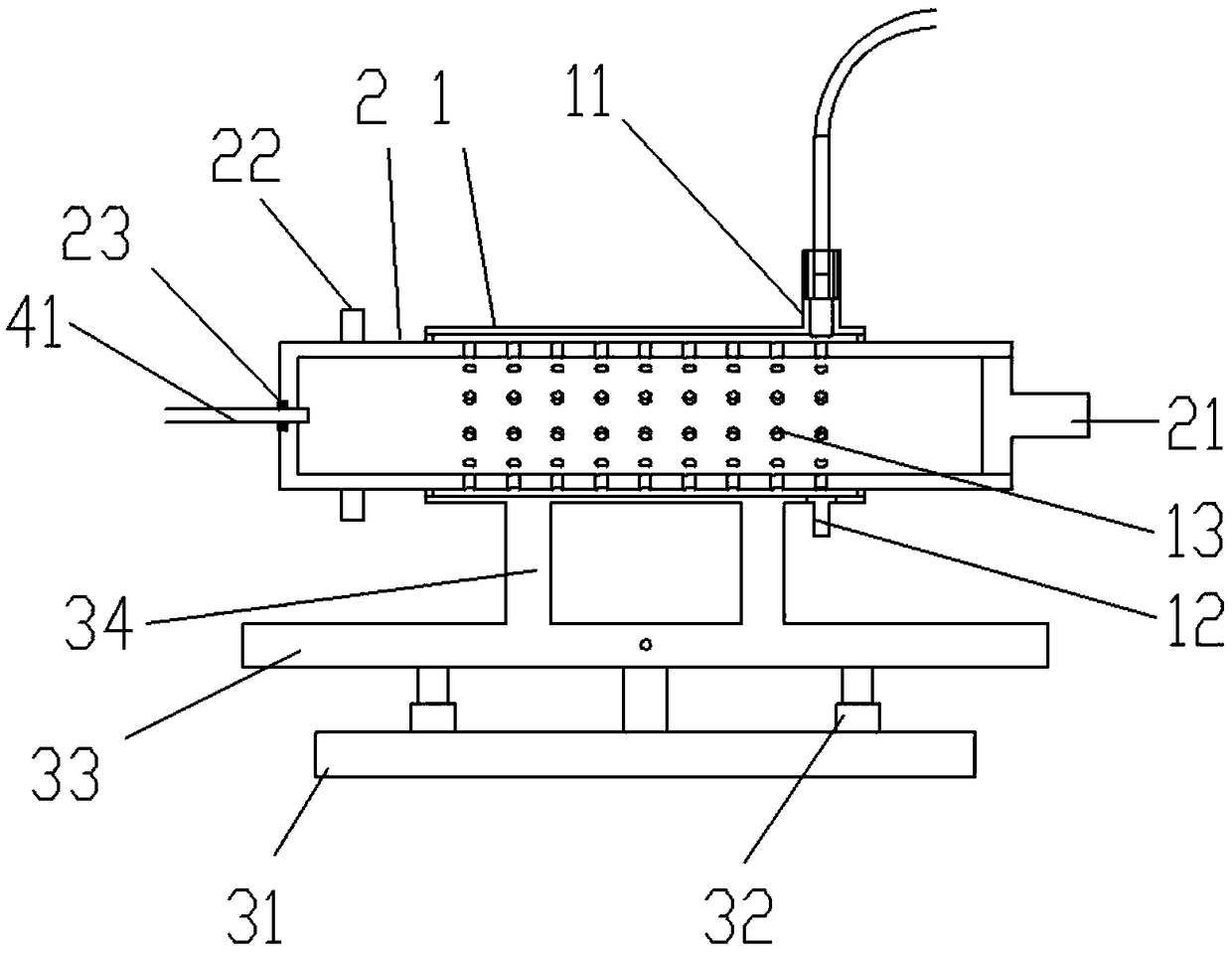

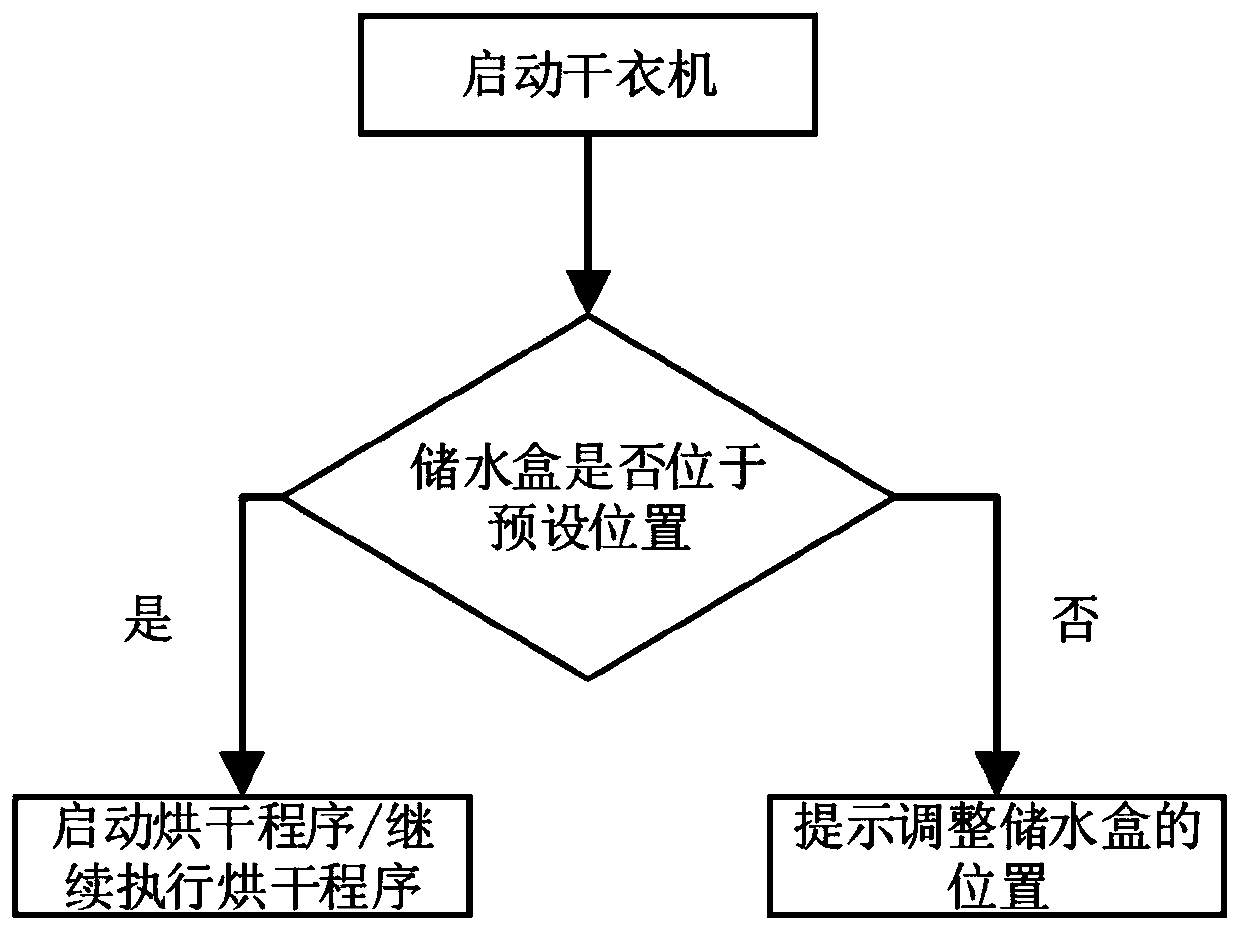

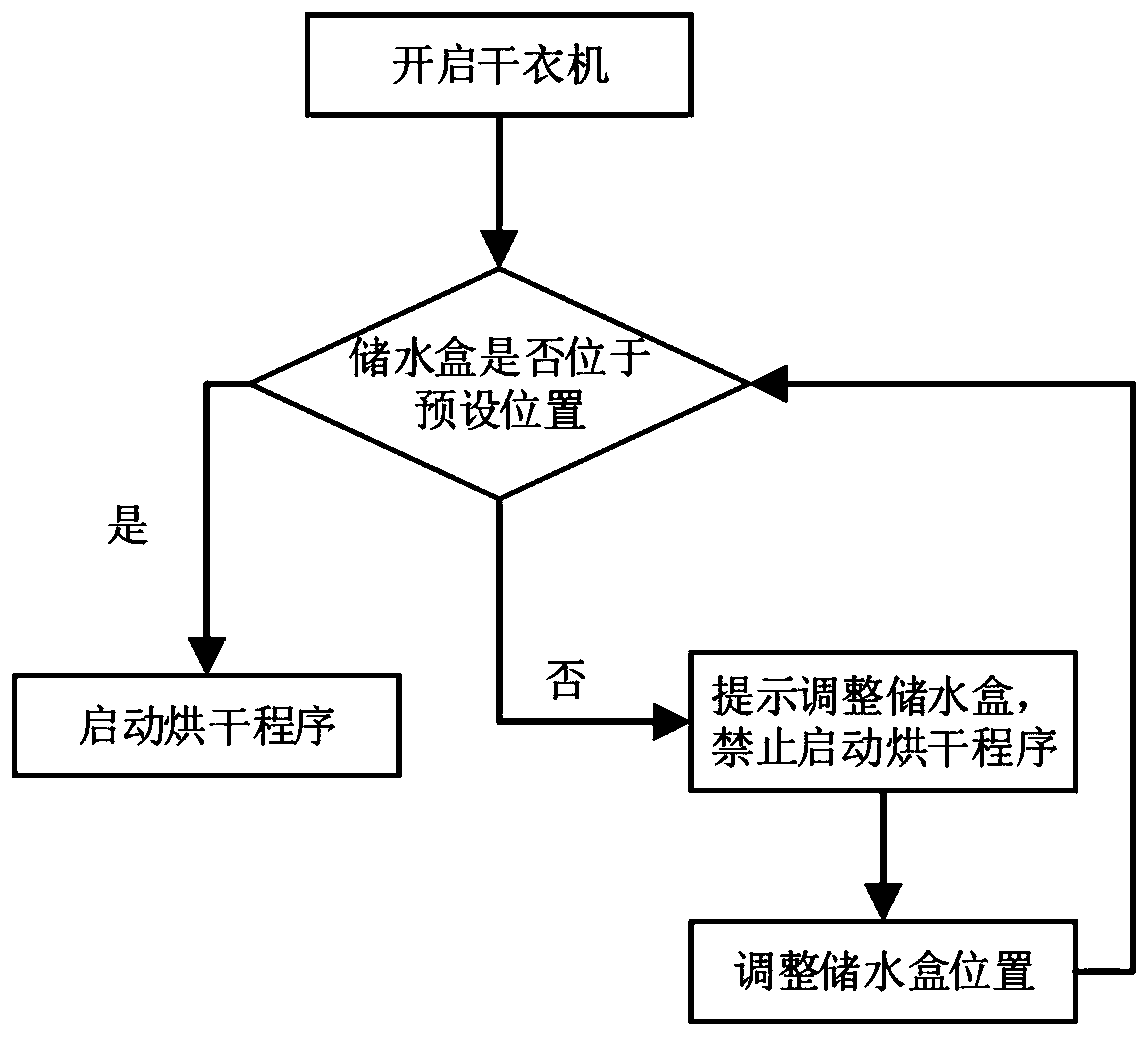

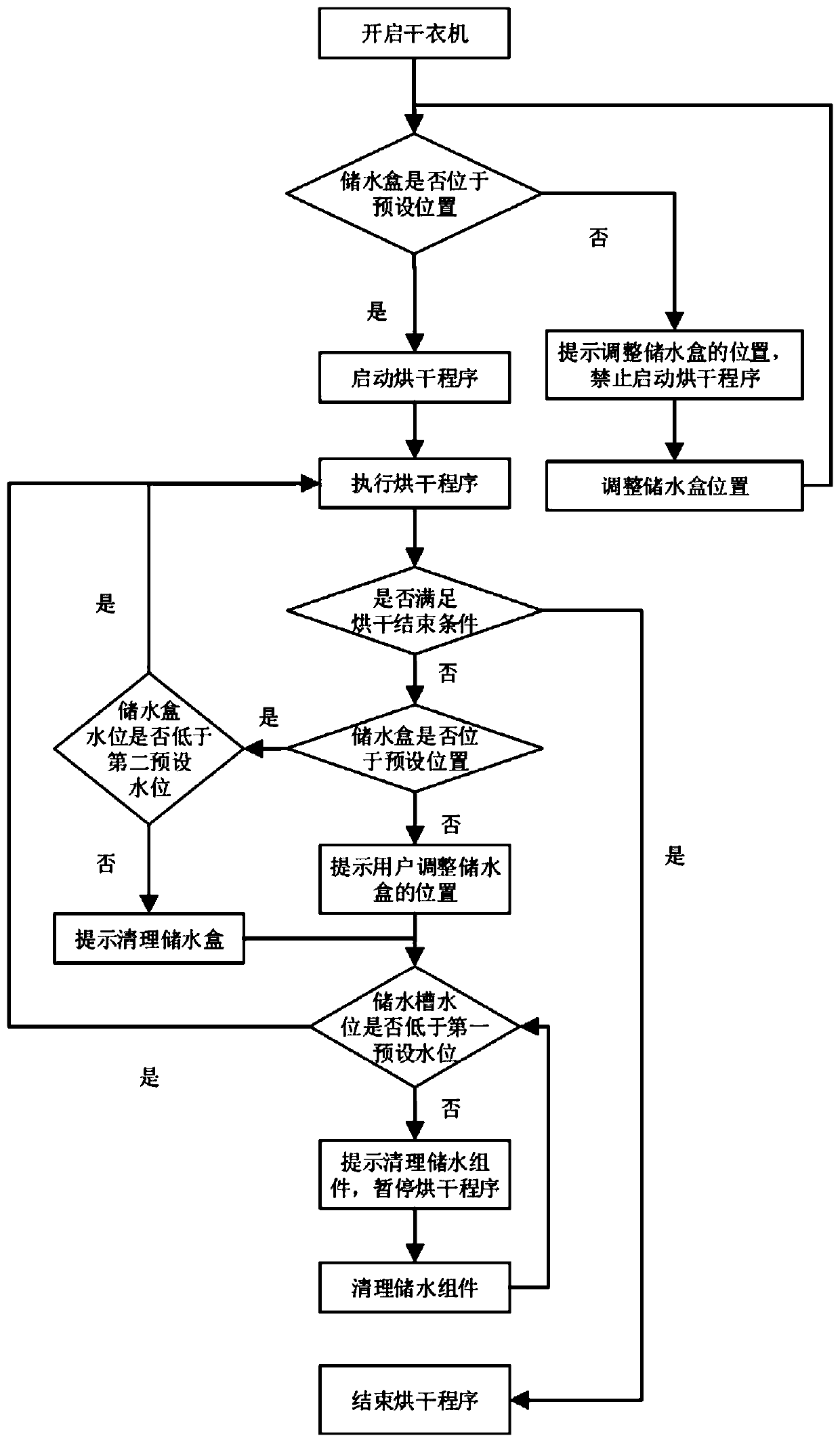

Clothes drying method and clothes dryer

PendingCN110485133AImprove satisfactionGuaranteed inflowTextiles and paperLaundry driersWater storageWater storage tank

The invention relates to the technical field of household appliances, in particular to a clothes drying method and a clothes dryer. The clothes drying method comprises the steps that after the clothesdryer is started, whether a water storage box is located at a preset position or not is detected; if the water storage box is not located at the preset position, a user is reminded to adjust the position of the water storage box. The clothes drying method has the function of detecting whether the water storage box is installed in place or not, and if the water storage box is not installed in place, the user can receive a corresponding prompt. The user can select to adjust the position of the water storage box according to the prompt so that condensed water can be pumped into the water storagebox from a water storage tank, and the water in the water storage box can enter the water storage tank after overflowing. When the clothes dryer detects that a water storage assembly is full of the water, the water storage box and the water storage tank are both filled with the condensed water. The situation that a machine mistakenly prompts to clean the water storage box is avoided, the situation that the water storage box is frequently cleaned by the user under the condition that the water storage box is not full is avoided, the clothes drying efficiency is ensured, and the satisfaction degree of the user is improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

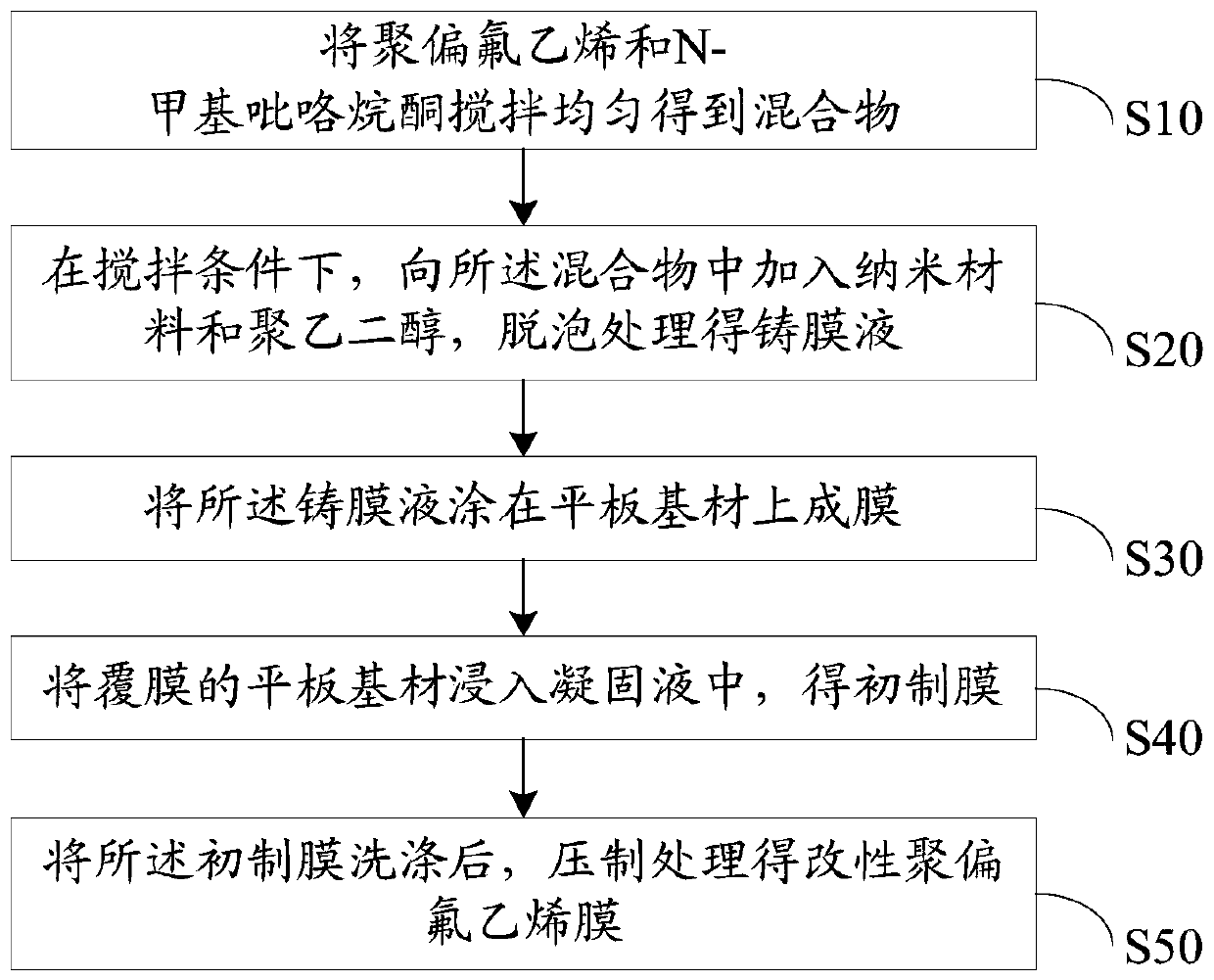

Preparation method of modified PVDF (polyvinylidene fluoride) membrane

InactiveCN110075725AImprove hydrophilicityImprove anti-pollution performanceSemi-permeable membranesMembranesHigh probabilityWastewater

The invention discloses a preparation method of a modified PVDF (polyvinylidene fluoride) membrane and relates to the technical field of wastewater treatment. The preparation method of the modified PVDF membrane comprises steps as follows: PVDF and NMP (N-methyl pyrrolidone) are stirred uniformly to obtain a mixture; a nanomaterial and PEG (polyethylene glycol) are added to the mixture under the stirring condition, defoaming treatment is performed, and a membrane casting solution is obtained; the membrane casting solution is applied to a flat plate substrate to form a membrane; the flat platesubstrate covered with the membrane is soaked in a solidification liquid, and a first prepared membrane is obtained; the first prepared membrane is washed and then pressed, and the modified PVDF membrane is obtained. The invention aims to prepare the modified PVDF membrane to solve the problem about high probability of pollution of existing PVDF membranes.

Owner:WUHAN POLYTECHNIC UNIVERSITY

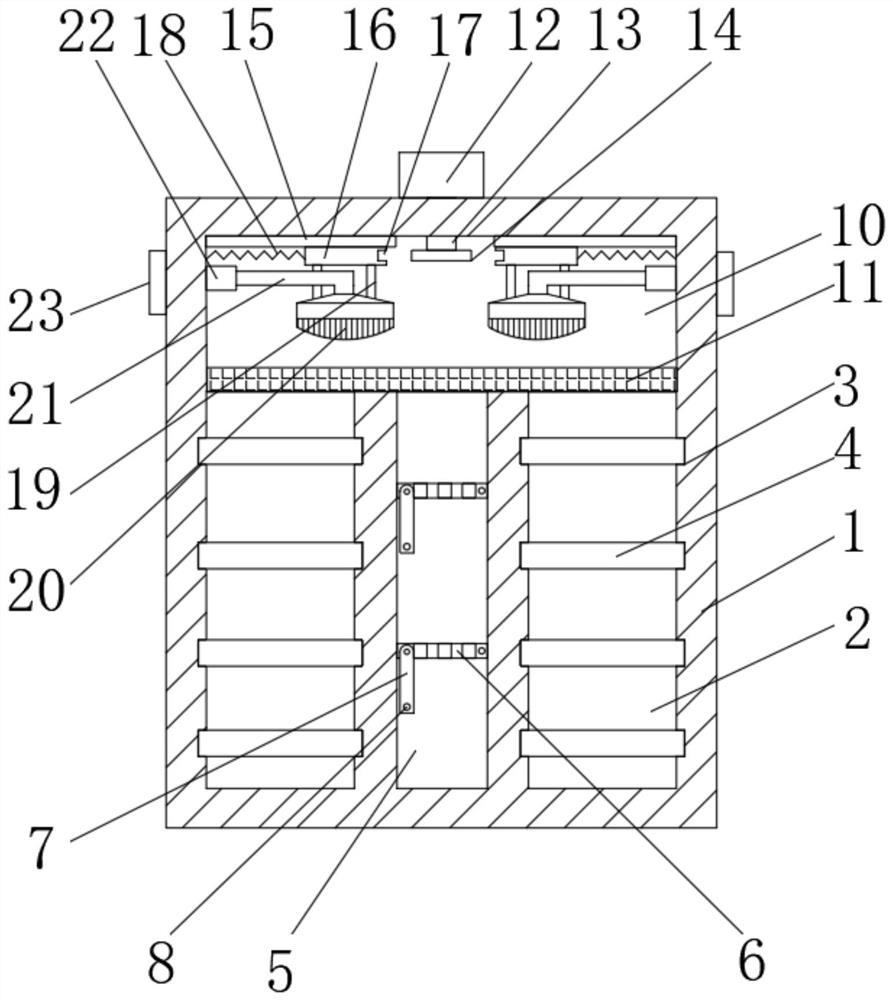

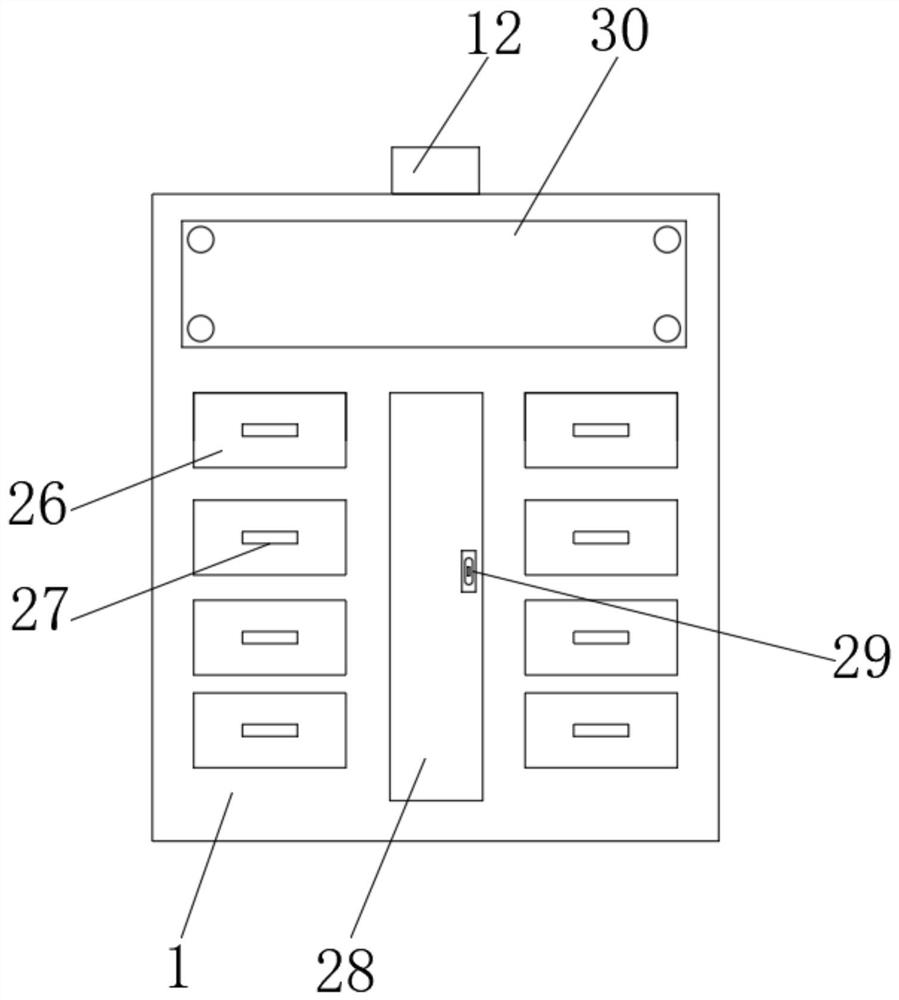

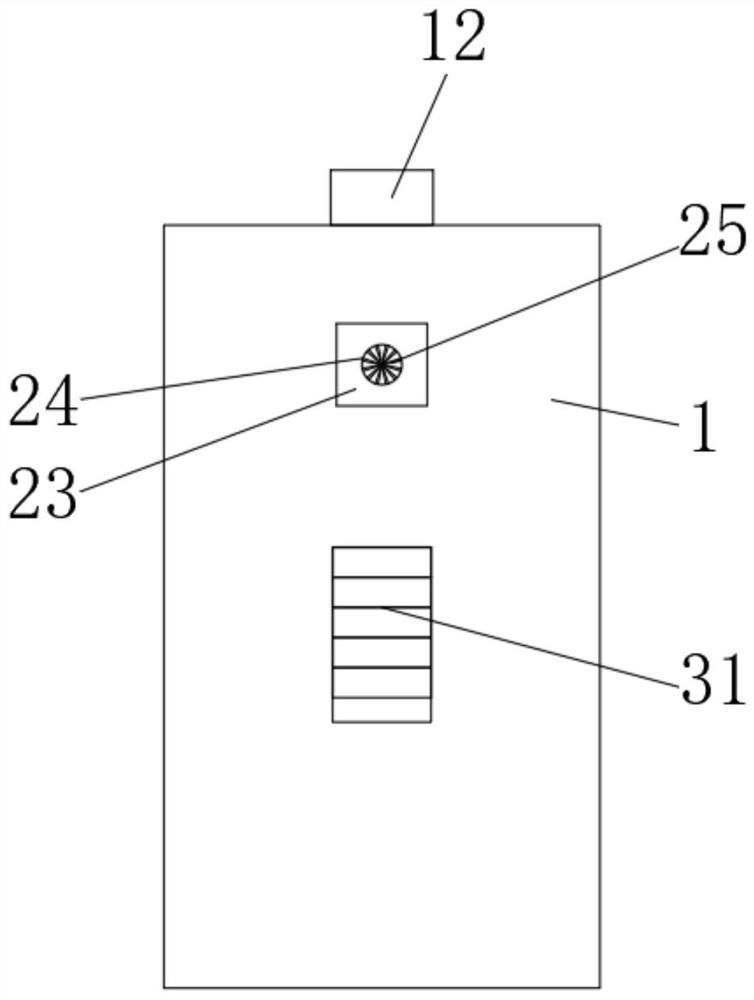

GCS type low-voltage draw-out switch cabinet

PendingCN111711103AGuaranteed efficiencyGuaranteed cleanlinessBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationStructural engineeringDevice chamber

The invention provides a GCS type low-voltage draw-out switch cabinet, and relates to the field of switch cabinets. The GCS type low-voltage draw-out switch cabinet comprises a device body. Device cavities are formed in the device main body and are close to the two sides. A plurality of sliding grooves are formed in two inner side walls of the device chamber. A plurality of drawing plates are arranged in the device chamber. A cable chamber is formed in the device main body and is positioned between the device chambers, and a plurality of limiting plates are fixedly connected to the interior ofthe cable chamber, wire fixing plates are hinged to the surfaces of the limiting plates, an air exhaust chamber is formed in the position, close to the top, of the interior of the device body, the air exhaust chamber communicates with the device cavity and the cable chamber, and sliding rails are arranged at the position, close to the two sides, of the inner top of the air exhaust chamber. By means of the multifunctional structural design, the switch cabinet can rapidly dissipate heat when generating large heat in the working process, and overhauling is more convenient.

Owner:襄阳双龙威机电科技有限公司

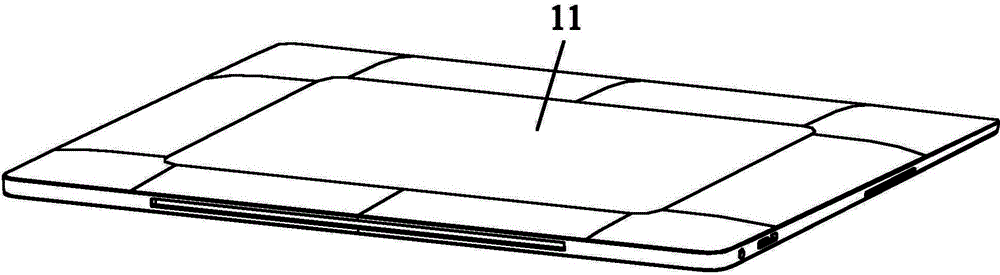

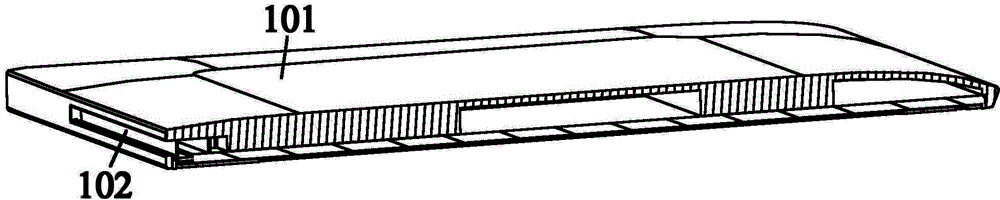

Plug-in mounting device and electronic device

InactiveCN105589516AAvoid frequent cleaningEnsure normal plug-in assemblyDigital data processing detailsPersonal computerElectric equipment

The invention discloses a plug-in mounting device. The plug-in mounting device comprises a first body and a slot blocking apparatus, wherein the first body is provided with a slot; the slot blocking apparatus is arranged on the first body; the slot blocking apparatus has a first use state and a second use state; in the first use state, the slot blocking apparatus blocks the slot; and in the second use state, the slot blocking apparatus opens the slot. In the plug-in mounting device, the slot blocking apparatus can block and open the slot of the first body as required so as to guarantee the first body and the second body to be normally plugged in and assembled and avoid the condition that foreign materials enter the slot of the first body when the first body and the second body are separated, thereby avoiding frequent cleaning of the slot by a user, and facilitating use by the user. The invention also discloses an electronic device which comprises the plug-in mounting device. The first body is a tablet personal computer, and the second body is a mounting plate hinged to a host part of the electrode device. The slot of the tablet personal computer in the electronic device can be kept clean so as to avoid frequent cleaning by the user.

Owner:LENOVO (BEIJING) LTD

Range hood with air conditioning device

PendingCN110617541AKeep aliveAvoid condensationDomestic stoves or rangesLighting and heating apparatusEngineeringAir conditioning

The invention provides a range hood with an air conditioning device. The range hood is used in a kitchen. The range hood comprises a machine body, a smoke extraction device installed on machine body and the air-conditioning device installed on the smoke extraction device, wherein the smoke extraction device comprises a smoke outlet pipe communicating into the machine body, the smoke outlet pipe communicates to the outside of the kitchen, the air conditioning device comprises an air conditioner body, an air outlet pipe communicating into the air conditioner body and a single guide flow component arranged in the air outlet pipe, the air conditioner body comprises a shell and a condenser arranged in the shell, the air outlet pipe communicates with the shell and the smoke outlet pipe, the airoutlet pipe corresponds to the condenser, the single guide flow component comprises a sealing plate rotatably arranged at one end of the air outlet pipe, a return spring is telescopically arranged between the sealing plate and the air outlet pipe, and the sealing plate can be moved to open or close the air outlet pipe. According to the range hood, hot air discharged by the air conditioner body canbe guided into the smoke outlet pipe through the air outlet pipe corresponding to the condenser, oil drops in the smoke outlet pipe are heated, and oil drops are prevented from being condensed into oil stains in the smoke outlet pipe.

Owner:CHANGZHOU TEXTILE GARMENT INST

Spraying equipment with spray gun dredging structure

The invention discloses spraying equipment with a spray gun dredging structure. The spraying equipment comprises a material box, a convergence box, a reflux pump and a spray head, wherein the materialbox is connected with the spray head through a hose; the material box, the convergence box and the reflux pump define a circulating loop; the front end of the spray head is of a tapered structure; apressure plate which is fixedly mounted on the inner wall of the spray head is arranged on the inner part of the spray head; the pressure plate is perpendicular to the center shaft of the spray head;the opposite two sides of the pressure plate inside the spray head communicate with each other; a tapered hole which is matched with the front end of the spray head is formed in the side wall of the convergence box; a telescopic pole which is parallel to the axial direction of the tapered hole is mounted on the inner wall of the convergence box; the free end of the telescopic pole is close to thetapered hole; the free end of the telescopic pole is equipped with a sealing plate; a spring sleeves the telescopic pole; and one side, away from a spring, of the sealing plate is equipped with a pushing rod in the extending direction of the spring. The spraying equipment is beneficial for preventing the spray head from being cleared frequently as a result of condensation of conductive adhesive inthe spray head, so that dispensing efficiency of the spray head is improved.

Owner:ANQING JINGKE ELECTRONICS CO LTD

Method of reducing calcium content in high calcium sulfate content feed liquid

InactiveCN110578052AReduce contentSave human effortProcess efficiency improvementMaterial resourcesNuclear chemistry

The invention provides a method of reducing calcium content in a high calcium sulfate content feed liquid and belongs to the technical field of hydrometallurgy. The method of reducing calcium contentin the high calcium sulfate content feed liquid comprises the following steps: mixing the high calcium sulfate content feed liquid with calcium sulfate crystal seeds; and carrying out sedimentation treatment, ageing and solid-liquid separation, successively, wherein the content of calcium sulfate in the high calcium sulfate content feed liquid is 2.30-2.56 g / L, and the pH value is 4.0-4.5; and thegrain sizes of the calcium sulfate crystal seeds are 11-18 [mu]m. The calcium sulfate crystal seeds with special grain sizes are adopted to induce calcium sedimentation, so that the content of calcium sulfate in the feed liquid can be reduced effectively, a condition that calcium sulfate precipitates in an extraction tank are cleaned frequently in a follow-up extraction and calcium removal step is avoided, the manpower and material resources are saved, and the production efficiency is improved. In addition, the method provided by the invention is simple in step and high in operability, and facilitates scale production.

Owner:GANZHOU NONFERROUS METALLURGICAL RES INST

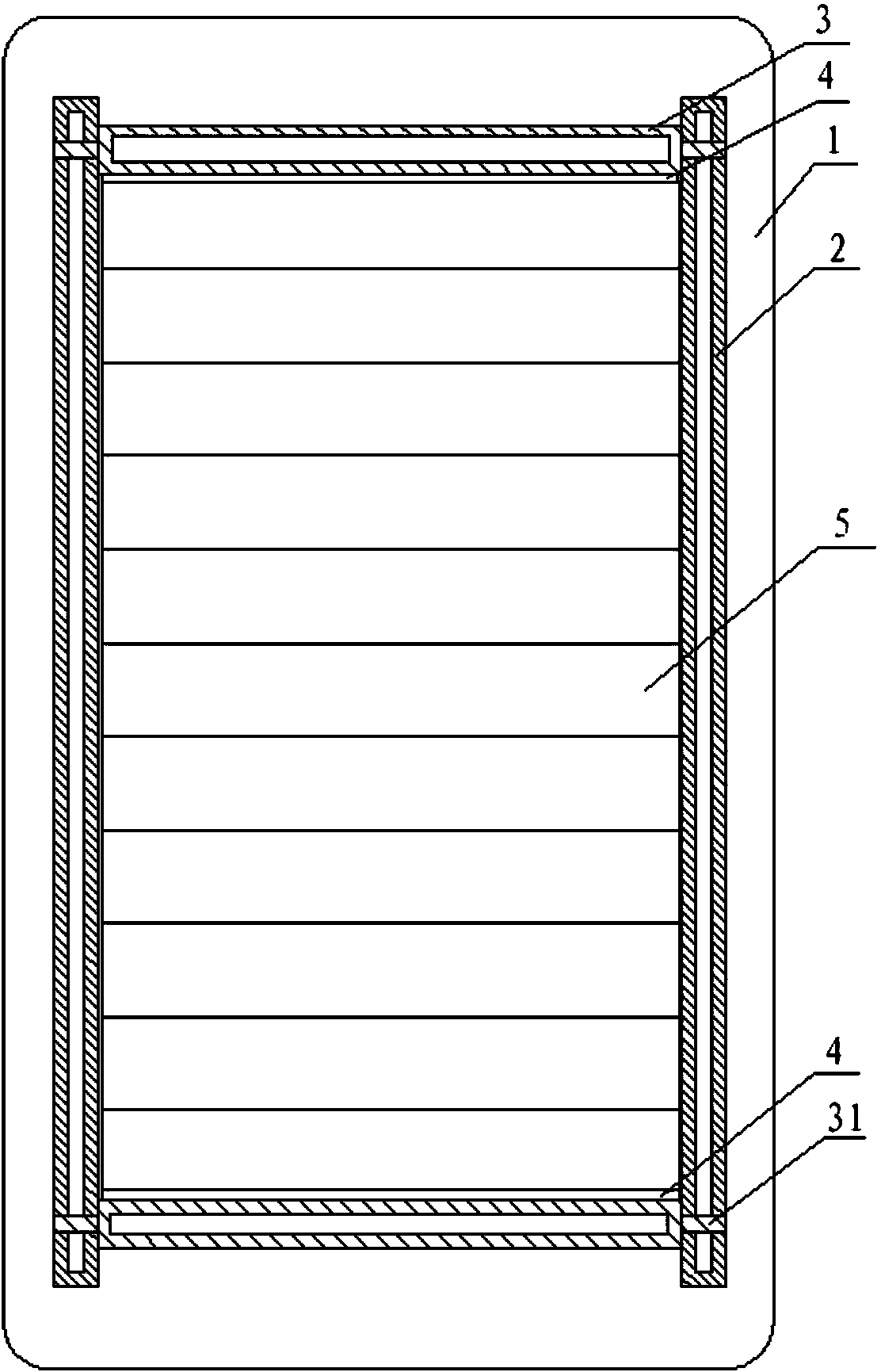

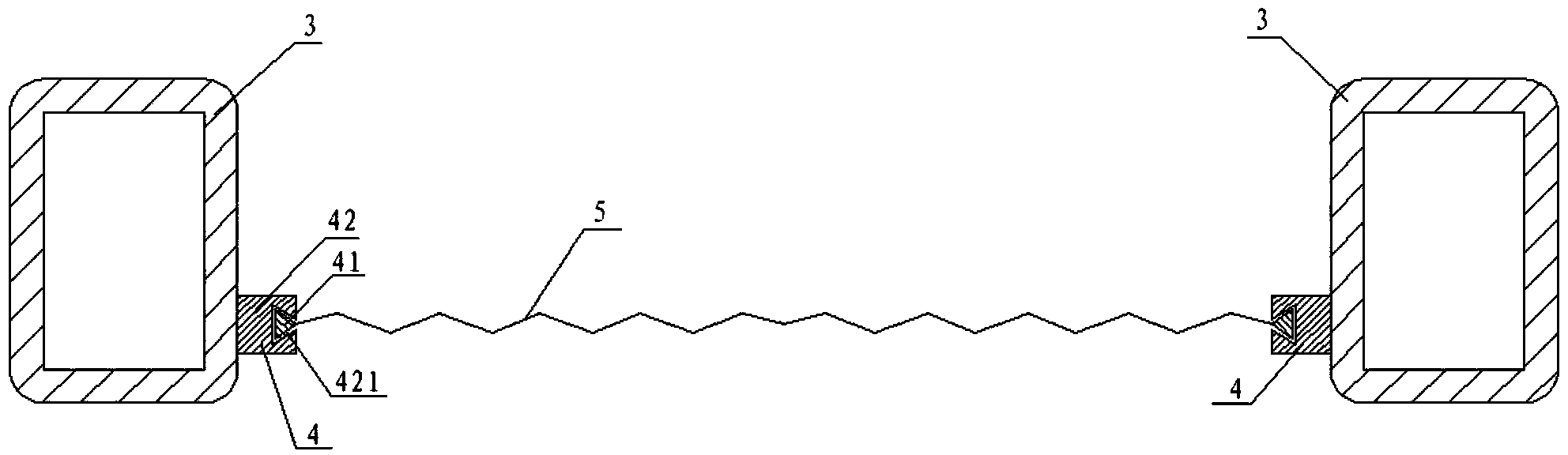

Car roof protection device

ActiveCN104369650AAvoid frequent cleaningAvoid damageRemovable external protective coveringsAutomotive engineeringSunlight

The invention discloses a car roof protection device connected with two longitudinal beams of a car roof luggage rack. The car roof protection device comprises two cross beams, two connection pieces and a foldable covering piece. The two ends of the covering piece are connected with the two cross beams respectively through the connection pieces, the cross beams are arranged between the two longitudinal beams of the luggage rack, and the two cross beams can be separated along the longitudinal beams, so that the covering piece is unfolded and laid on a car roof. The covering piece is made of light-proof materials, can shield sunlight for a car and achieves the sun-shading and heat insulation effects, so that heat energy absorbed by the car roof and conducted into the car is reduced, and it is avoided that a driver feels not comfortable due to overhigh temperature in the car and harmful gas emitted by objects in the car due to high temperature affects health of the driver; meanwhile, the covering piece is laid on the car roof and can block falling objects from directly falling on the car roof, falling objects are prevented from contaminating and damaging the surface of the car roof, and therefore the car is prevented from being cleaned frequently, the surface of the car roof is protected, the car maintenance expenses are reduced, and the car maintenance time is shortened.

Owner:CHERY AUTOMOBILE CO LTD

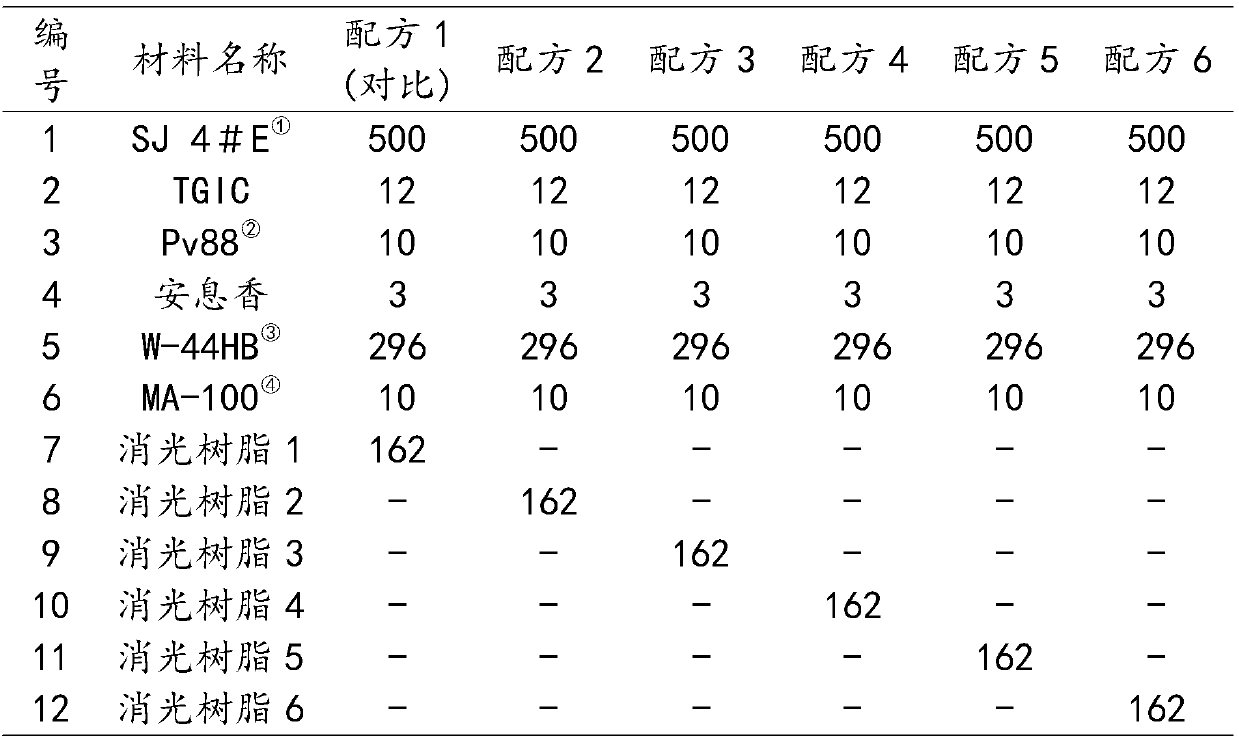

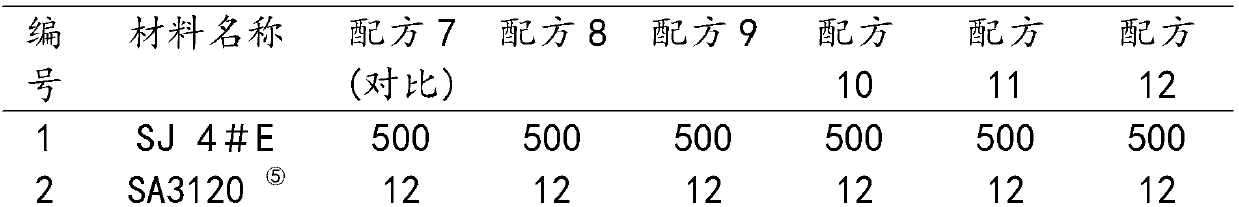

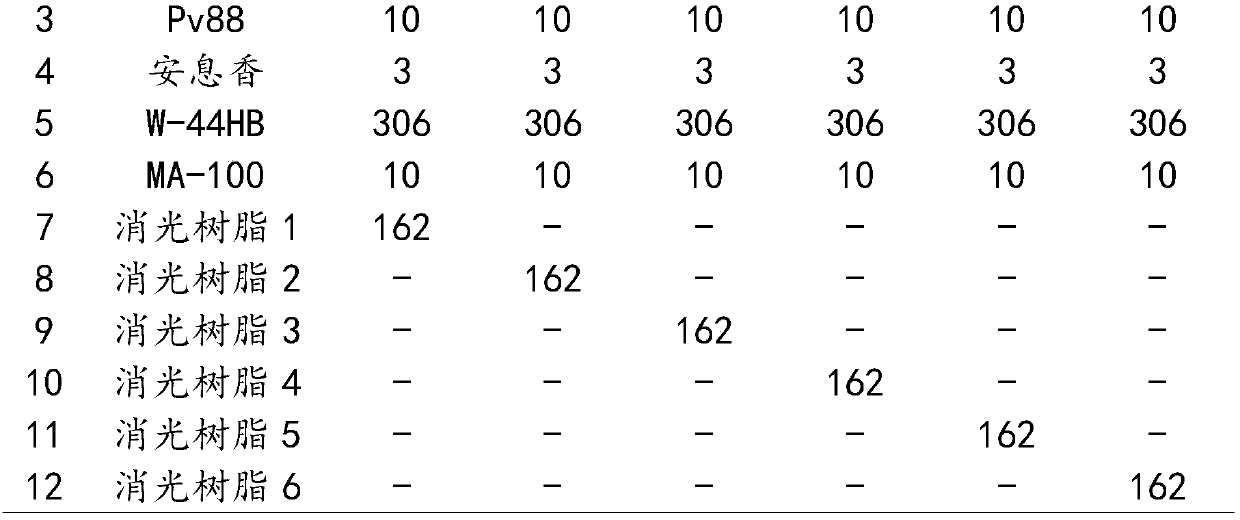

A kind of hydrophobic stain-resistant functional solid acrylic matting resin

ActiveCN106366233BImprove smoothnessAvoid frequent cleaningAntifouling/underwater paintsPaints with biocidesEpoxyPolymer science

The invention provides a solid acrylic matting resin with hydrophobic and antifouling functions. Other ethylenic monomers are free-radically copolymerized into modified solid epoxy-based acrylic matting resins. The modified solid epoxy-based acrylic type matting resin provided by the invention is used in outdoor powder coatings, and the resulting coating film can not only meet people's requirements for low-gloss appearance, but also improve the smoothness and hydrophobic stain resistance of the coating film. Significant improvement.

Owner:六安科瑞达新型材料有限公司

Automatic cat litter cleaning basin based on adsorption deodorization

InactiveCN112219725AAvoid pollutionAvoid affecting useDispersed particle separationAnimal housingLitterEngineering

The invention discloses an automatic cat litter cleaning basin based on adsorption deodorization. The automatic cat litter cleaning basin comprises a cat litter basin body, a storage box is fixedly connected to the center of the inner wall of the cat litter basin body, a rotating groove is formed in the top of one side of the storage box, and a sealing gasket is fixedly connected to the bottom ofthe inner wall of the rotating groove; rotating shafts are rotatably connected to the two sides of the inner wall of the rotating groove through bearings, cover plates are fixedly connected to the sides, close to the interior of the storage box, of the rotating shafts, a fixing ring is fixedly connected to the top of the inner wall of the storage box, a clamping groove is formed in the top of thefixing ring, and a pressing ring is slidably connected to the inner wall of the clamping groove; and leaking nets are fixedly connected to the sides, away from the cover plates, of the rotating shafts. The invention relates to the technical field of pet supplies. According to the automatic cat litter cleaning basin based on adsorption deodorization, odor generated when a pet cat urinates or afterthe pet cat urinates can be prevented from diffusing, the indoor environment is prevented from being polluted, and the automatic cat litter cleaning basin is convenient to use, good in deodorization effect and free of frequent cleaning.

Owner:许礼峰

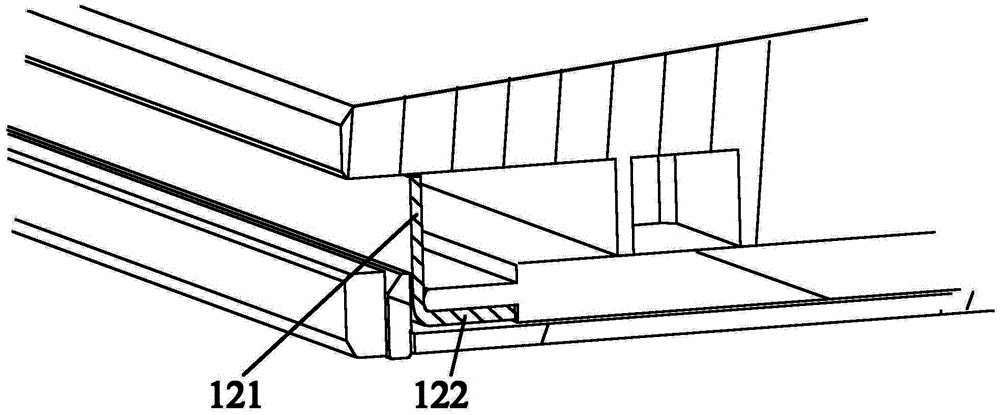

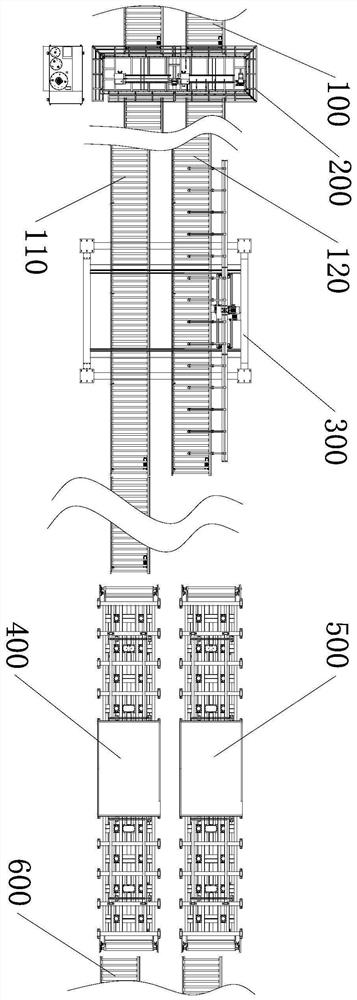

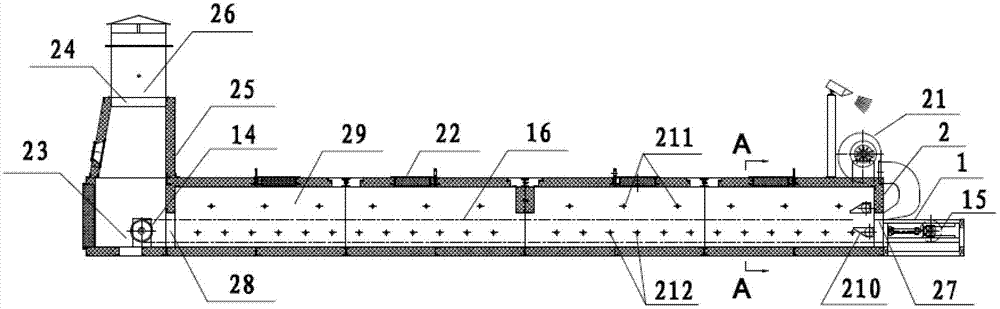

Composite board production line

InactiveCN113650397AAvoid frequent cleaningWill not affect the quality of spray glueLiquid surface applicatorsSpraying apparatusAdhesive glueProcess engineering

The invention provides a composite board production line which comprises a board feeding conveying device and a first glue spraying machine, one side of the first glue spraying machine is connected with a first conveying device and a second conveying device at the same time, and a board combining device is arranged beside the first conveying device. The end, away from the first glue spraying machine, of the first conveying device is connected with a first hot press, and a second hot press is arranged beside the first hot press side by side. And one end, relatively close to the first glue spraying machine, of the second hot press is provided with a board feeding ferry vehicle used for conveying a composite board located on the first conveying device to the second hot press. The conveying devices are arranged on the two sides of the first glue spraying machine, and compared with a traditional technical scheme that the conveying devices directly penetrate through the glue spraying machines, the situation that glue drips onto the conveying devices to affect the glue spraying quality is avoided, frequent cleaning of the conveying devices is also avoided, the glue spraying quality is relatively good, and the production efficiency is relatively high.

Owner:泉州市益达机械制造有限公司

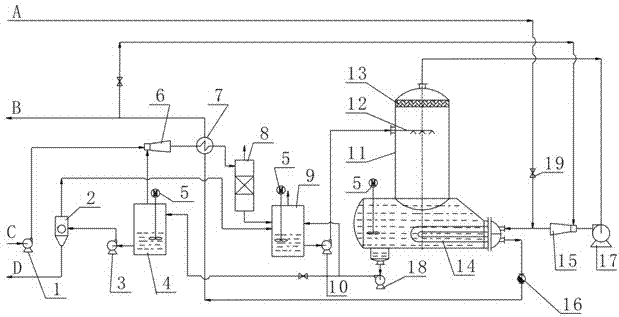

Kitchen waste slurry fermentation wastewater treating method

InactiveCN107352744AAvoid frequent cleaningImprove work efficiencyWater treatment parameter controlFatty/oily/floating substances removal devicesOil separationSedimentation

The invention provides a kitchen waste slurry fermentation wastewater treating method which is used for treating wastewater produced from kitchen waste slurry after anaerobic digestion and dewatering and wastewater produced in other procedures of kitchen waste treatment. The wastewater is subjected to oil-separation primary sedimentation, water quantity and water quality regulation, A / O biochemical treatment, sedimentation treatment, air floatation treatment, treatment in a Fenton reactor, treatment in a coagulative sedimentation tank and treatment in a biological aerated filter in sequence. With adoption of the method, pollutants such as COD (chemical oxygen demand), BOD5 (biochemical oxygen demand), SS (suspended solids) and the like in the wastewater are removed effectively, TN (total nitrogen) and TP (total phosphorus) can be removed effectively, wastewater chroma can be reduced effectively, TN and TP removal rate is increased, and the pollutants such as COD, BOD5, NH3-N, TP and the like in the treated wastewater as well as the chroma of the treated wastewater can stably meet requirements of level-1 in the integrated wastewater discharge standard (GB8978-1996).

Owner:CHINA MACHINERY INT ENG DESIGN & RES INST

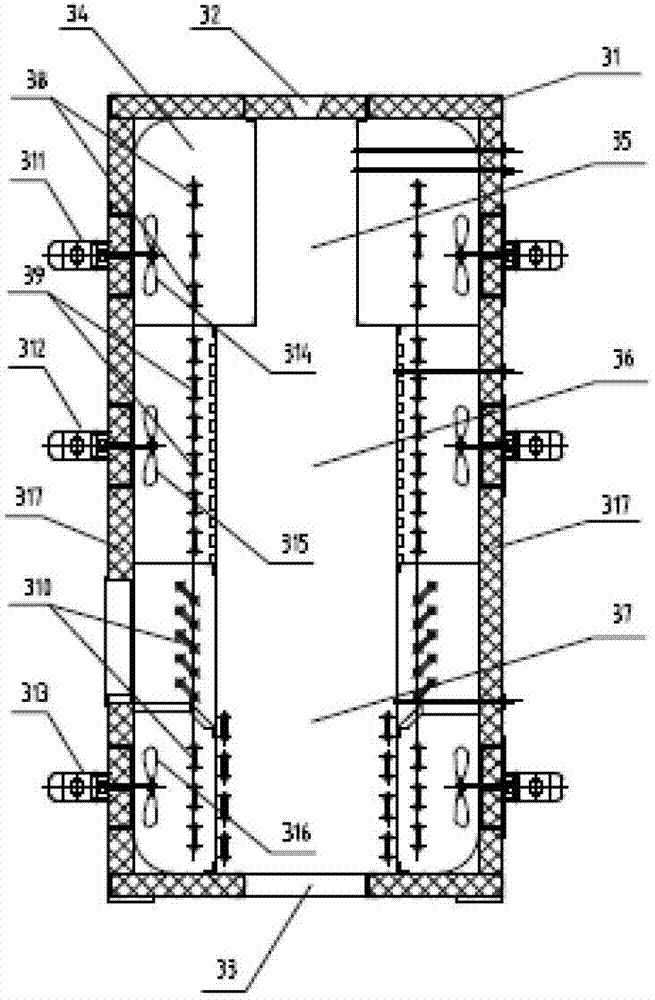

Electronic irradiating crosslinked polyethylene foaming machine

The invention relates to an electronic irradiating crosslinked polyethylene foaming machine, which comprises a horizontal conveying device, a horizontal preheating device, a vertical foaming device, an unfolding device, a positive and negative calendaring device and a coiling device which are successively arranged. The electronic irradiating crosslinked polyethylene foaming machine is characterized in that the vertical foaming device comprises a vertical foaming furnace; the vertical foaming furnace is provided with a transition area, a pre-foaming area and a foaming area; a plurality of first electric heating tubes, a plurality of second electric heating tubes, a plurality of third electric heating tubes, a plurality of first hot air circulating fans, a plurality of second hot air circulating fans and a plurality of third hot air circulating fans are arranged in the vertical foaming furnace; the first electric heating tubes and the first hot air circulating fans are located in the transition area; the second electric heating tubes and the second hot air circulating fans are located in the pre-foaming area; and the third electric heating tubes and the third hot air circulating fans are located in the foaming area. After the electronic irradiating crosslinked polyethylene foaming machine provided by the invention is adopted, the production efficiency and yield of the polyethylene foamed products are greatly increased.

Owner:宁波辉门科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com