Zero-discharge treatment process for salt-containing waste water

A salty waste water and treatment process technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cycle rate, increased power consumption of circulating pumps, high flow rate, etc. problems, to achieve the effect of simple process, avoid frequent cleaning, and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A high-concentration salt-containing wastewater, total salt (TDS) content: 15000 mg / l, temperature 35°C, water volume 10t / h. It is required to achieve zero discharge after treatment, and the salt content of the reused water is less than 15 mg / l.

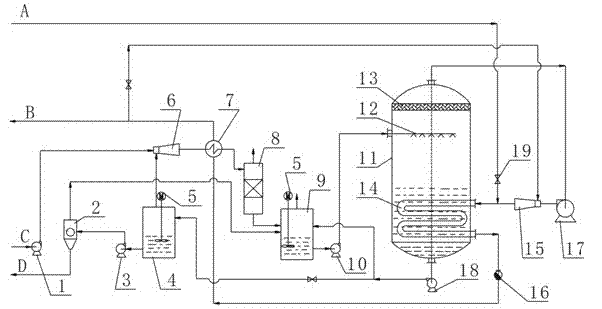

[0034] See figure 1 , The zero-discharge wastewater treatment process using vertical flash tower: including brine pump 1, centrifuge 2, concentrated brine pump 3, flash tank 4, agitator 5, water ejector 6, heat exchanger 7, degassing Tower 8, brine storage tank 9, flash tower feed pump 10, flash tower 11, brine distributor 12, demister 13, flash tower heater 14, steam ejector 15, steam trap 16, steam compressor 17. Concentrated brine pump at the bottom of the tower 18.

[0035] The flash tower 11 adopts a vertical method. The high-salinity wastewater C draws the flash steam from the flash tank 4 through the water ejector 6. The temperature of the wastewater is increased to about 40°C and enters the tube pass of the heat exchanger ...

Embodiment 2

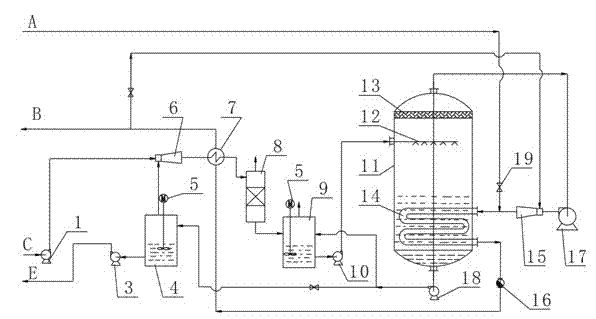

[0038] A high-concentration salt-containing wastewater, total salt (TDS) content: 15000 mg / l, temperature 35°C, water volume 10t / h. It is required that the water reuse rate after treatment is ≥85%, the salt content of the reused water is less than 15 mg / l, and the concentrated brine is sent to the evaporation pond.

[0039] See figure 2 Compared with Example 1, the only difference is: For dry climate areas, if there is enough space for the installation of evaporation ponds, from the perspective of energy saving, the centrifuge 2 is eliminated, and the concentrated brine E is directly sent to the evaporation pond for natural Evaporation can save energy by 15-20%.

Embodiment 3

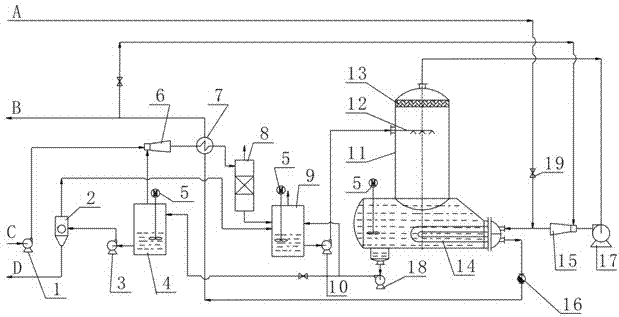

[0041] A high-concentration salt-containing wastewater, total salt (TDS) content: 15000 mg / l, temperature 35°C, water volume 30t / h. It is required to achieve zero discharge after treatment, and the salt content of the reused water is less than 15 mg / l.

[0042] See image 3 Compared with Example 1, only the vertical flash tower is changed to a combined flash tower. The combined tower is equipped with a stirrer 5. When the processing capacity is large, the combined flash tower is used, which is beneficial to the process Effective control of the process; in addition, the flash tower heater adopts the U-tube heat exchanger type, which is convenient for cleaning the tube bundle.

[0043] The salty wastewater zero-discharge treatment process of the present invention not only avoids frequent cleaning of the entire system, but also has simple process and low operating cost. Its popularization and application have positive significance for improving the efficiency of saline wastewater tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com