Kitchen waste slurry fermentation wastewater treating method

A technology for food waste and fermented waste water, which is applied in the field of waste water treatment of food waste and waste water produced in other processes of food waste treatment, can solve the problems of high operating cost, accelerated membrane aging, unsatisfactory, etc., and avoid frequent Effects of cleaning, effective denitrification, and improvement of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

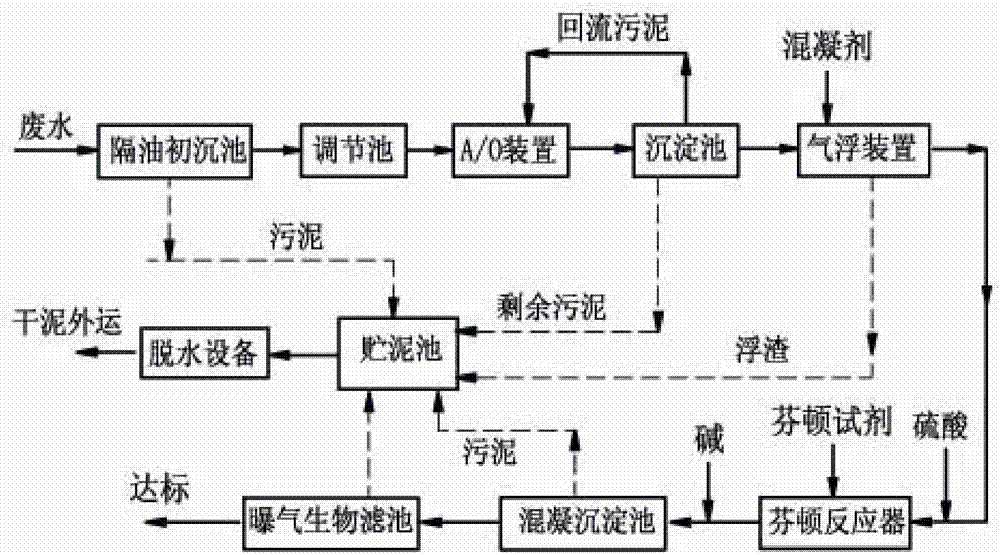

[0024] See the attached picture for a treatment scale of 100m 3 / d of kitchen waste wastewater as an example, the specific implementation is as follows:

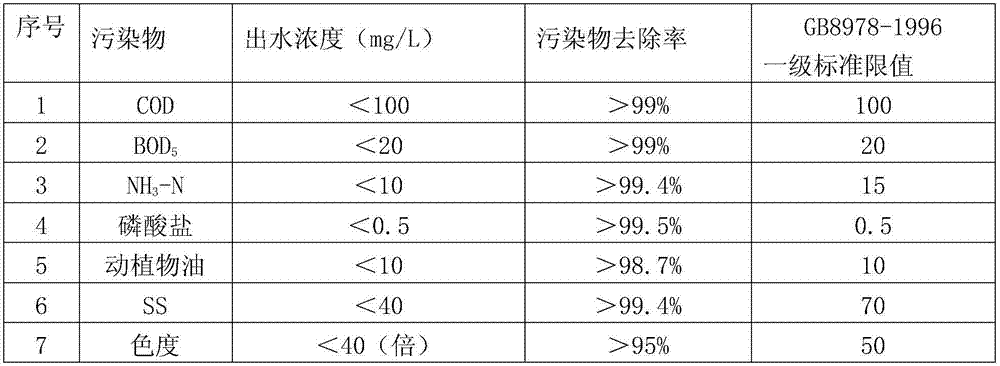

[0025] Wastewater after anaerobic digestion and dehydration of food waste slurry and waste water produced in other processes of food waste treatment Water quality: COD: 12000-15000mg / L, BOD 5 : 4500~5000mg / L, TN: 2100~2400mg / L, NH 3 -N: 1800~2000mg / L, TP: 110~130mg / L, SS: 7000~10000mg / L, animal and vegetable oil: 800~1000mg / L, pH: 7.5~8, chromaticity: 800~1000 times.

[0026] a. The waste water after anaerobic digestion and dehydration of the kitchen waste slurry and the waste water produced in other processes of the kitchen waste treatment, first enters the oil separation primary sedimentation tank for the oil separation primary sedimentation treatment, and the slick oil in the waste water is separated, and the waste water in the waste water Large particles of impurities and large particles of suspended matter are separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com