Electronic irradiating crosslinked polyethylene foaming machine

A technology of cross-linked polyethylene and foaming equipment, which is applied in the field of electronic irradiation cross-linked polyethylene foaming equipment, can solve the problems of unqualified products, low production efficiency and yield rate, high equipment failure rate, etc., and achieve temperature gradient distribution Uniformity, improved production efficiency, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

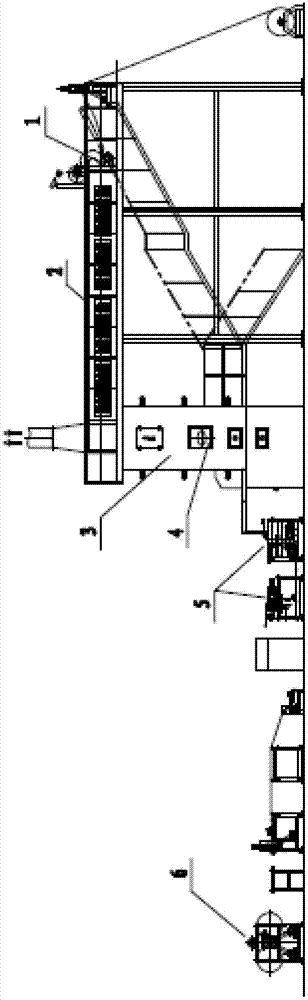

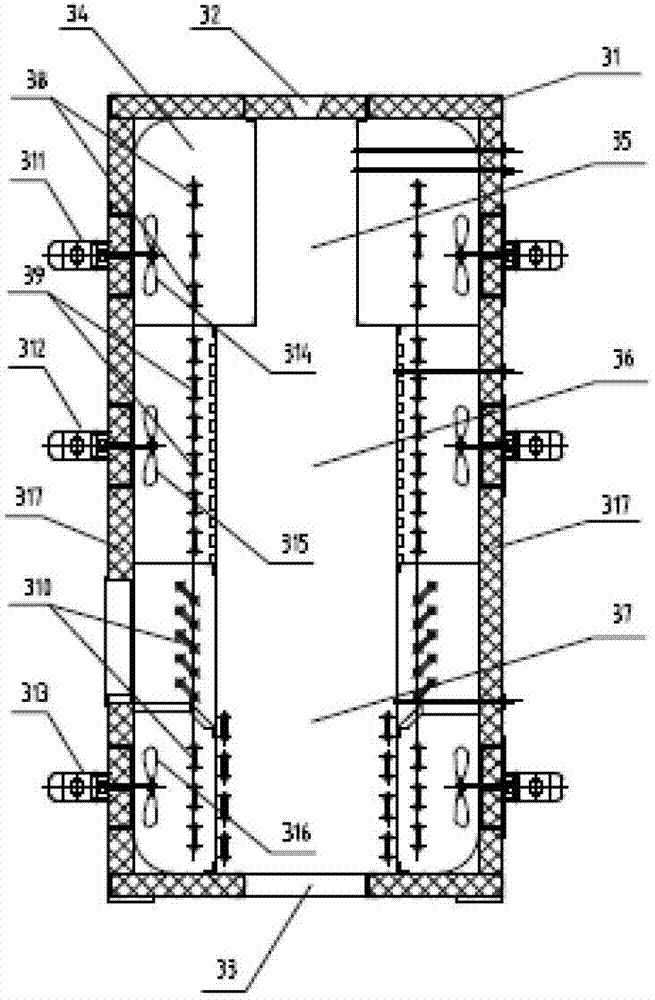

[0041] As shown in the figure, an electronic radiation cross-linked polyethylene foaming equipment includes a horizontal conveying device 1, a horizontal preheating device 2, a vertical foaming device 3, an unfolding device 4, a front and back calendering device 5, and Rewinding device 6.

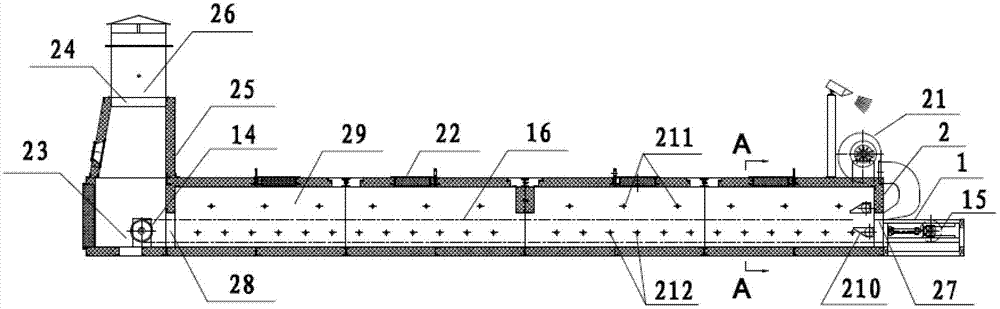

[0042] The horizontal conveying device 1 is arranged in the horizontal preheating device 2 and both ends of the horizontal conveying device 1 extend out of the horizontal preheating device 2 respectively. The horizontal conveying device 1 includes a straight-shaft mesh belt 11, a steel mesh 12, and a parallel guide rail. 13. The driving mechanism 16 is composed of a driving sprocket 14 and a passive sprocket 15. The driving sprocket 14 is connected to the motor 17, the driving sprocket 14 is located at one end of the parallel guide rail 13, and the passive sprocket 15 is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com