Spraying equipment with spray gun dredging structure

The technology of spraying equipment and spray gun is applied in the field of spraying equipment with spray gun dredging structure, which can solve problems such as reducing glue dispensing efficiency, and achieve the effect of preventing frequent cleaning and improving dispensing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

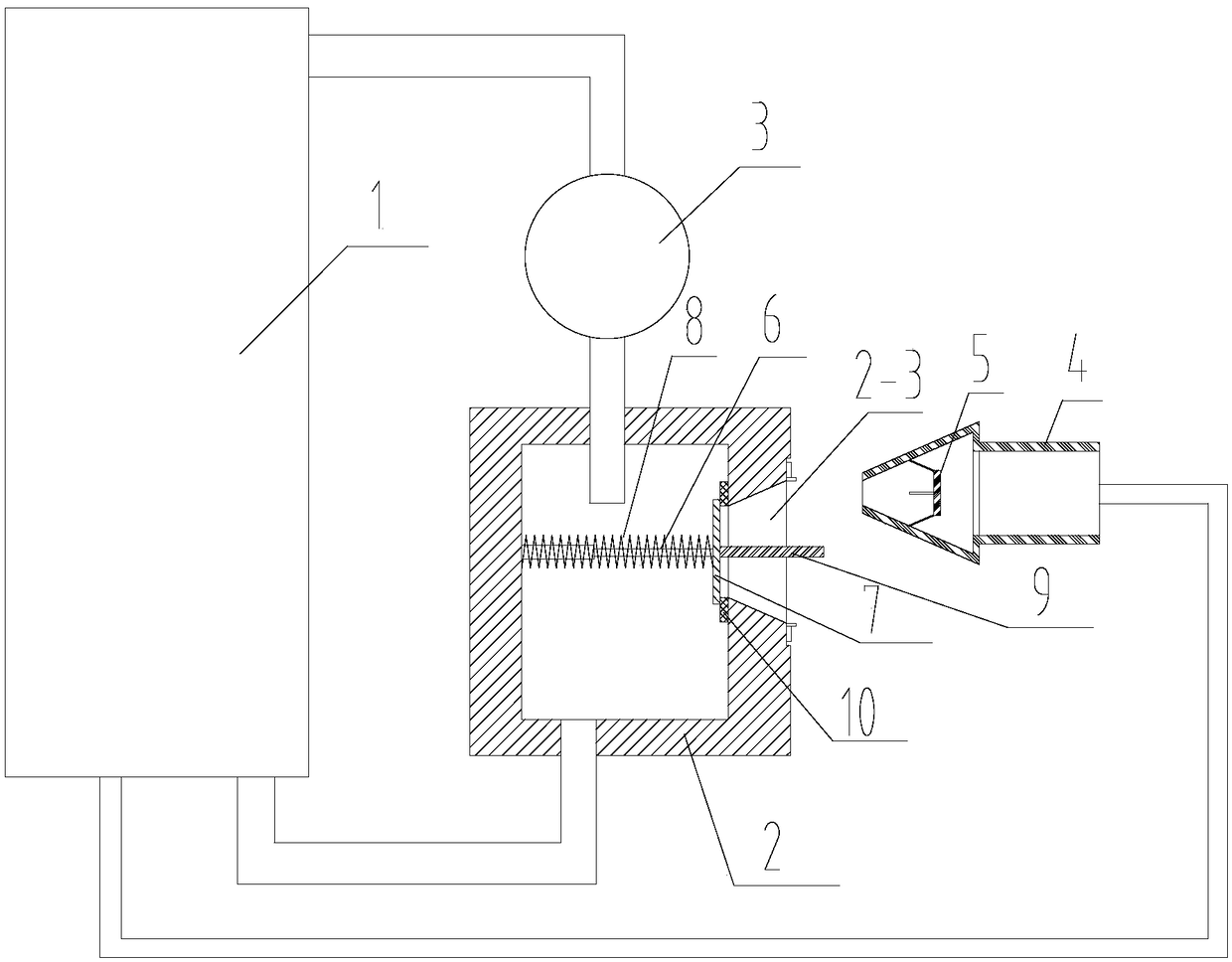

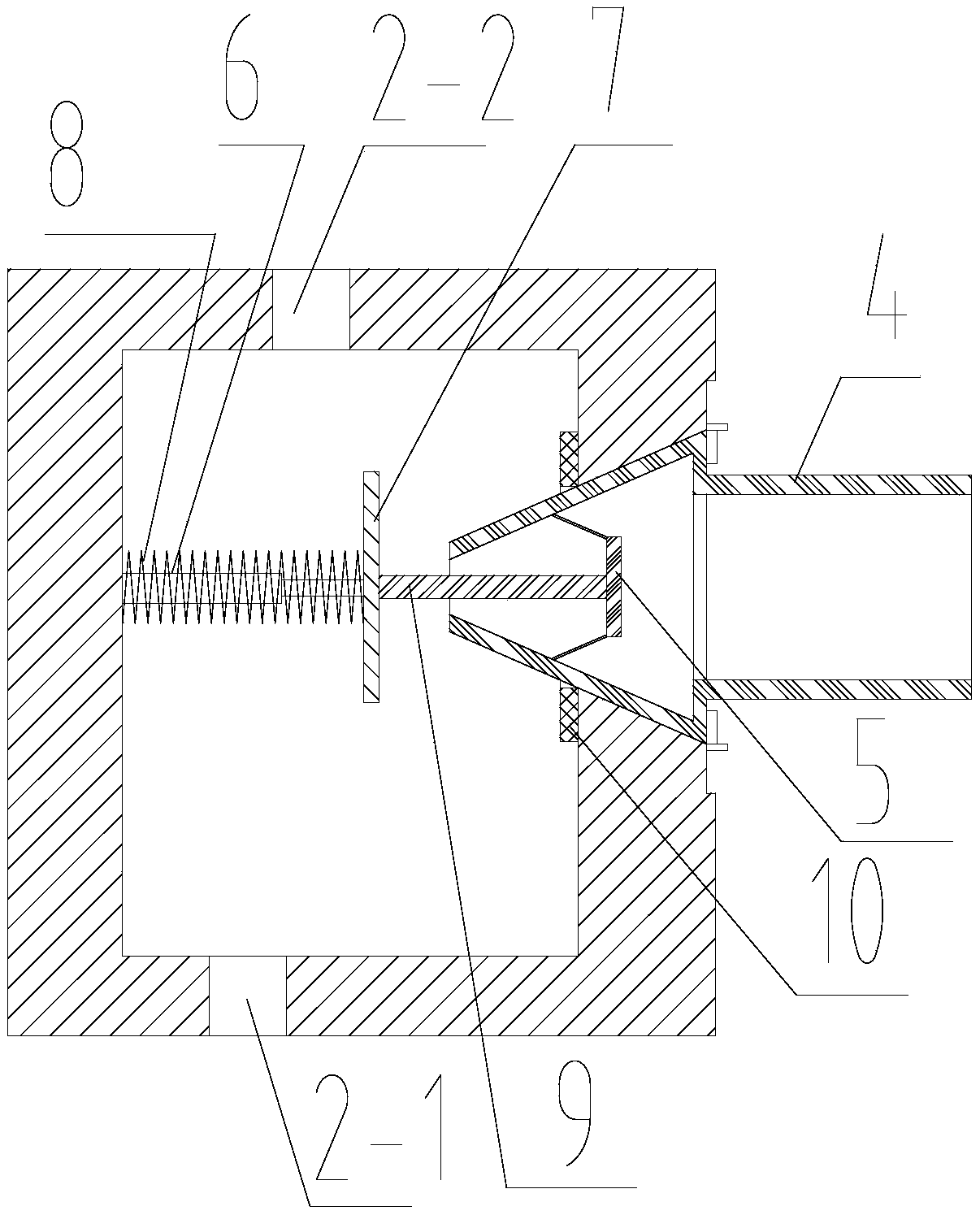

[0018] refer to figure 1 , a kind of spraying equipment that the present invention proposes is provided with spray gun dredging structure, comprises: material box 1, confluence box 2, backflow pump 3 and nozzle 4, material box 1 connects nozzle 4 through hose, so that nozzle 4 extracts material box 1 The conductive adhesive inside is dispensed.

[0019] The confluence box 2 is provided with an input port 2-1 and a return port 2-2. The input port 2-1 is connected to the material box 1 through a pipeline, and the return port 2-2 is connected to the material box 1 through the return pump 3. The material box 1 and the confluence Tank 2 and return pump 3 constitute a circulation loop. In this way, after the backflow pump 3 works, the conductive glue in the material box 1 flows into the combiner box 2, and then returns to the material box 1 after the reflux pump 3, so as to realize the dynamic circulation of the conductive glue in the material box 1, so as to avoid the internal lea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com