Preparation method of modified PVDF (polyvinylidene fluoride) membrane

A polyvinylidene fluoride film and a technology of polyvinylidene fluoride are applied in the field of preparation of modified polyvinylidene fluoride film, which can solve the problem of easy pollution of polyvinylidene fluoride film, avoid frequent cleaning of the film, improve hydrophobicity, The effect of improved anti-pollution performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

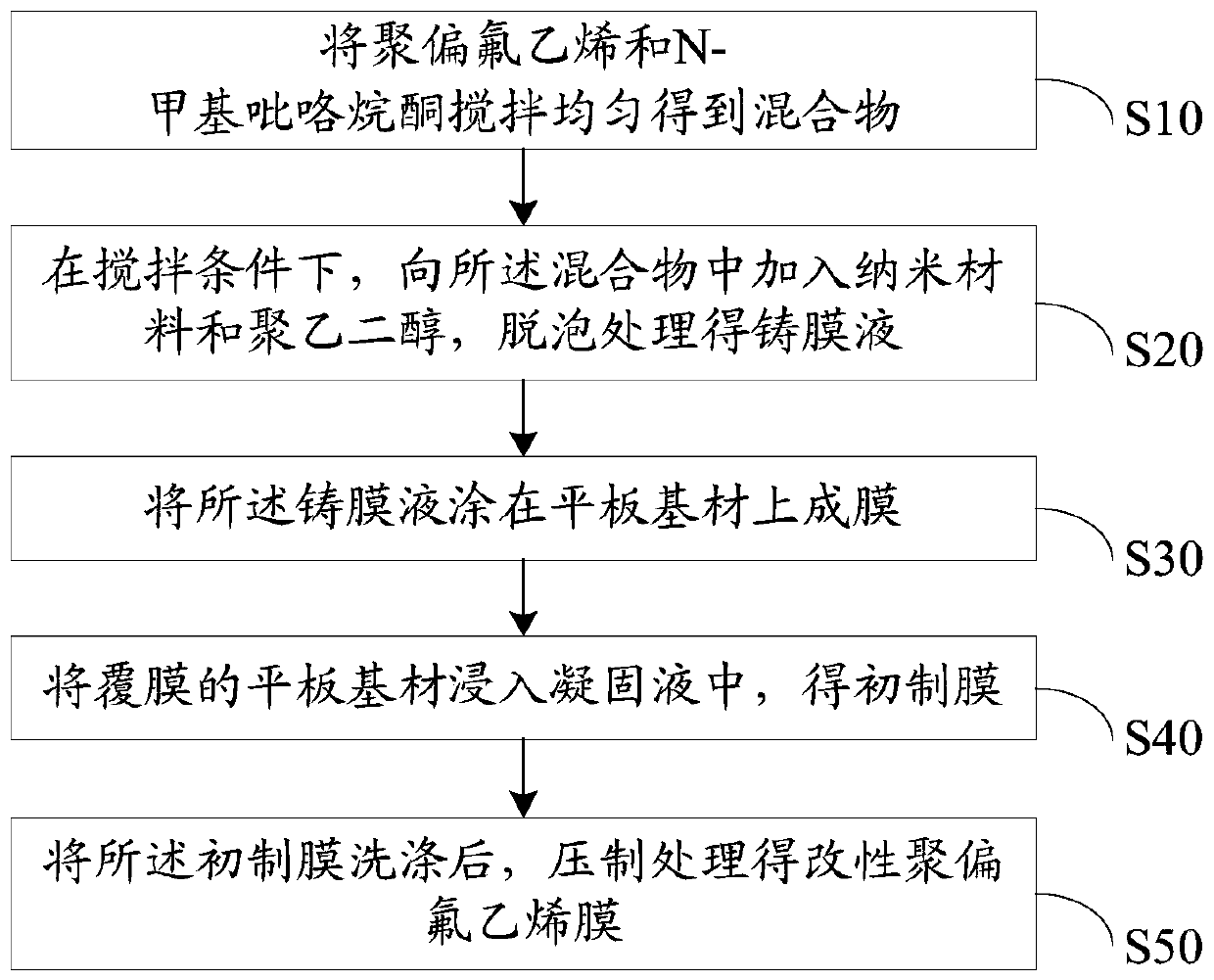

[0033] In view of this, the present invention proposes a method for preparing a modified polyvinylidene fluoride membrane, through which a modified polyvinylidene fluoride membrane can be prepared, and the modified polyvinylidene fluoride membrane can be used for waste water It has the advantages of good purification effect and strong anti-pollution performance. combine figure 1 The schematic flow chart of an embodiment of the preparation method of the shown modified polyvinylidene fluoride film, the preparation method of the modified polyvinylidene fluoride film comprises the following steps:

[0034] Step S10, stirring the polyvinylidene fluoride and N-methylpyrrolidone evenly to obtain a mixture.

[0035] In this example, N-methylpyrrolidone was added to polyvinylidene fluoride, and the two were mixed uniformly at a certain stirring speed to prepare a mixture. Wherein, the mass ratio of the polyvinylidene fluoride to the N-methylpyrrolidone used is 1:(2-6); the stirring s...

Embodiment 1

[0055] Put 10 g of polyvinylidene fluoride in a reactor, add 20 g of N-methylpyrrolidone, and stir at a stirring speed of 200 r / min to obtain a mixture. Under the condition of stirring at a speed of 200r / min, 0.75g of nano-titanium dioxide with a particle size of 50nm and 3g of polyethylene glycol were added to the mixture, and after being oscillated in an ultrasonic oscillator, vacuum defoaming was carried out at 30°C to obtain Casting solution.

[0056] After coating the casting solution on the flat substrate to form a film, immerse the film-coated flat substrate in an ethanol solution (60% by volume) at 20°C until the film solidifies and falls off, then put the peeled film in the coagulation solution Soak in medium for 16 hours to get the initial film. The initial film was taken out and washed in distilled water for 5 times, then pressed at 0.2 MPa for 2.5 hours to obtain a modified polyvinylidene fluoride film.

Embodiment 2

[0058] Put 5 g of polyvinylidene fluoride in the reactor, add 30 g of N-methylpyrrolidone, and stir at a stirring speed of 300 r / min to obtain a mixture. Under the condition of stirring at a rotating speed of 300r / min, 1.22g of nano-titanium dioxide and 1.75g of polyethylene glycol with a particle size of 30nm were added to the mixture, and after being vibrated in an ultrasonic oscillator, vacuum defoaming was carried out at 50°C to prepare Get the casting solution.

[0059] After coating the casting solution on the flat substrate to form a film, immerse the film-coated flat substrate in an ethanol solution (65% by volume) at 20°C until the film solidifies and falls off, and then put the peeled film in the coagulation solution Soak in medium for 24h to get the initial film. The initial film was taken out and washed 8 times in distilled water, then pressed at 0.26 MPa for 1.5 h to obtain a modified polyvinylidene fluoride film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com