Nail ordering machine for steel nails and control method thereof

A technology of nail arranging machine and steel nails, which is applied to conveyors, mechanical equipment, conveyor objects, etc., can solve the problems of low degree of automation of steel nail arranging machines, damage to workers' bodies, dim nails, etc., to avoid Dull nails, labor cost saving, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

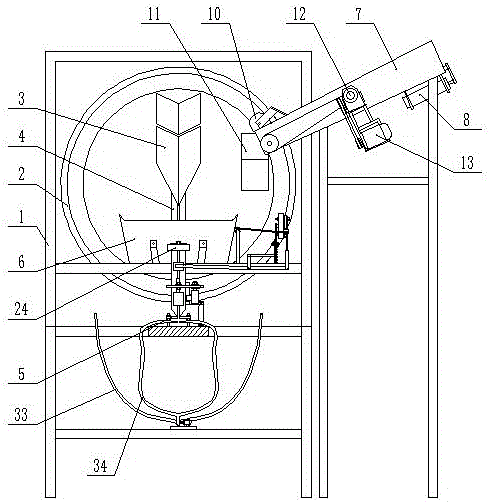

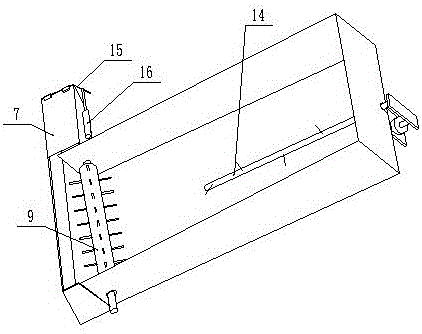

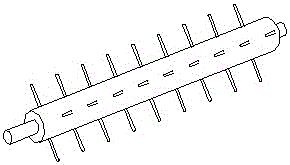

[0034] Such as Figure 1-Figure 8As shown, the steel nail arranging machine of the present invention comprises a bracket 1, a feeding drum 2, a chute 3, an oblique nail track 4, a flat track 5, a glue discharge device and a nail cutting device, and the feeding drum 2 is fixed on the bracket 1, and the inner wall of the feeding drum 2 is evenly distributed in the axial direction with a plurality of feeding partitions, the chute 3 is arranged in the feeding drum 2, and the end of the chute 3 is connected with the inclined nail track 4 , the oblique nailing track 4 is arranged obliquely, one end of which is located inside the feeding drum 2, and the other end is connected to the horizontally arranged flat track 5. Through the hole in the middle of the baffle 6, the baffle 6 is fixed on the bracket 1, and its bottom extends into the feeding drum 2, the glue outlet of the glue outlet is arranged on both sides of the flat track 5, and the nail cutting device is installed on the The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com