Roller pin coarse grinding device and application method thereof

A technology of rough grinding and needle rolling, which is used in grinding machines, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc. The effect of quality improvement and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

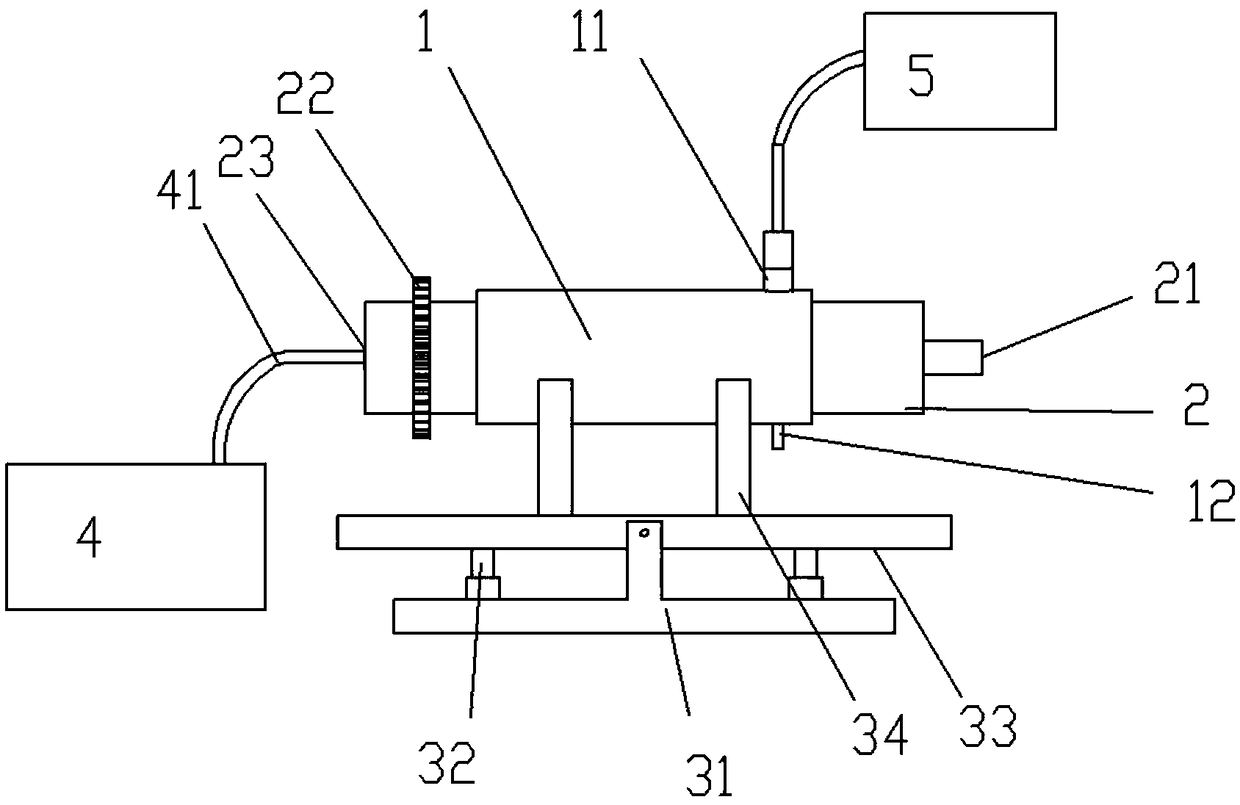

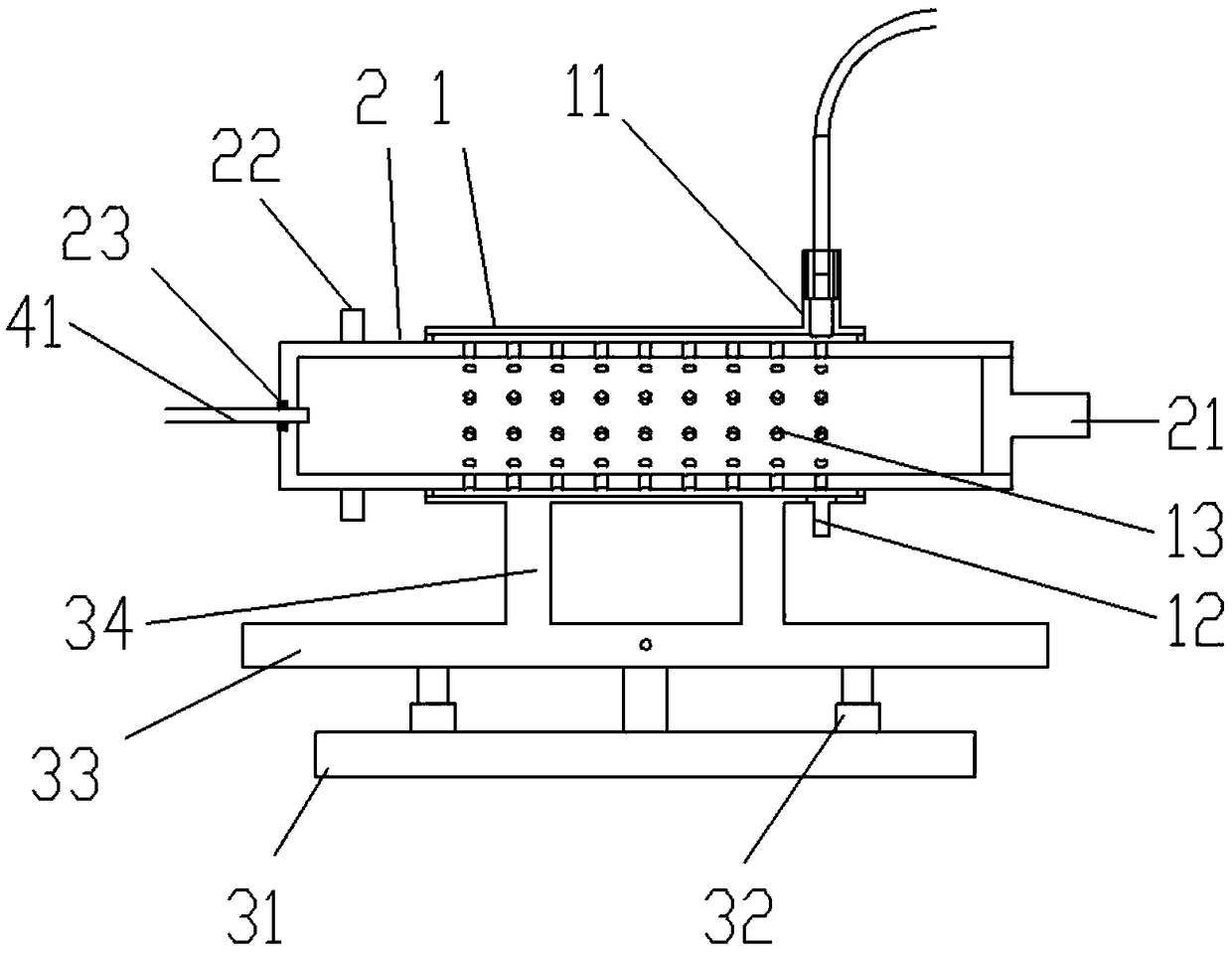

[0023] A needle rough grinding device, comprising a cylinder 2 with an open head end and a drive gear 22 disposed at the tail end of the cylinder 2, characterized in that a dust collection sleeve 1 is provided outside the cylinder 2, and on the side wall of the cylinder 2 An ash discharge hole 13 is provided, and the ash discharge hole 13 runs through the cylinder wall of the drum 2 and communicates with the inner cavity of the dust collection sleeve 1 , and a bucket cover 21 is provided at the opening of the head end of the drum 2 . The design of the ash discharge hole 13 and the dust collection sleeve 1 enables the debris generated during the coarse grinding process to be separated from the needle roller, reducing the buffering effect of the debris during the coarse grinding process and improving the efficiency of the coarse grinding.

[0024] The dust collection sleeve 1 is installed on the bracket 34 , and the drum 2 is rotatably connected with the dust collection sleeve 1 ...

Embodiment 2

[0032] An operation method of the above-mentioned needle rough grinding device, characterized in that the steps are as follows:

[0033] Step 1. Adjust the lifting actuator 32 so that the head opening of the drum 2 is inclined upward, open the barrel cover 21 and fill in the needle roller and abrasive, and then close the barrel cover 21;

[0034] Step 2, turn on the blower 4, and start the motor to drive the drum 2 to rotate through the drive gear 22;

[0035] Step 3, while keeping the drum 2 rotating, adjust the lifting actuator 32 so that the inclination angle of the drum 2 is constantly changing;

[0036] Step 4. After the coarse grinding is finished, close the price-raising actuator and the motor to stop the drum 2 from rotating, keep the blower 4 in working condition, and open the ash discharge port 12 to discharge debris and dust;

[0037] Step 5, turn off the blower 4, adjust the lifting actuator 32 to make the head opening of the drum 2 tilt downward, open the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com