Shock absorber

A shock absorber, hollow technology, applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., can solve problems such as noise, reduced quality satisfaction, and reduced durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

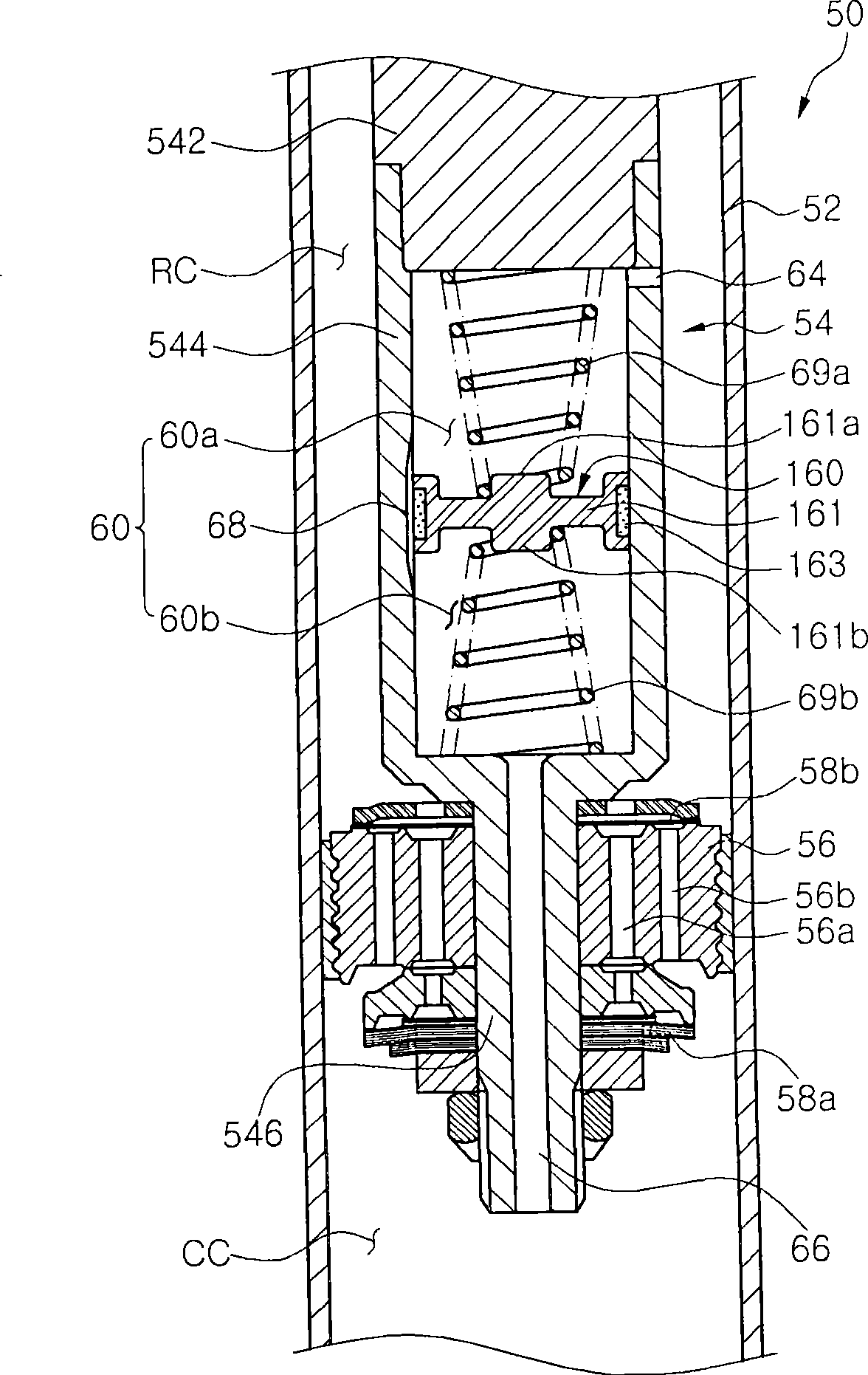

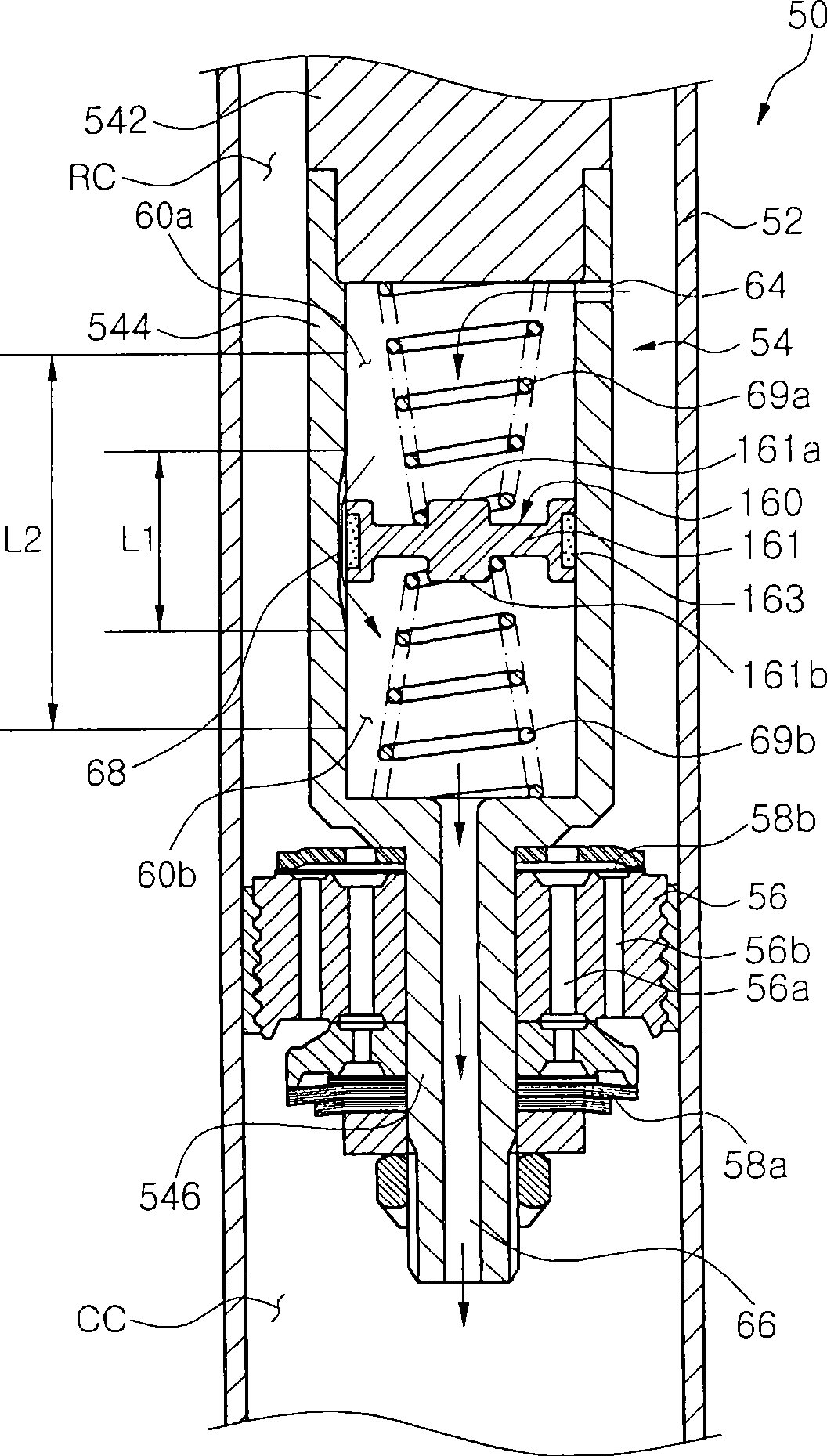

[0027] Exemplary embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

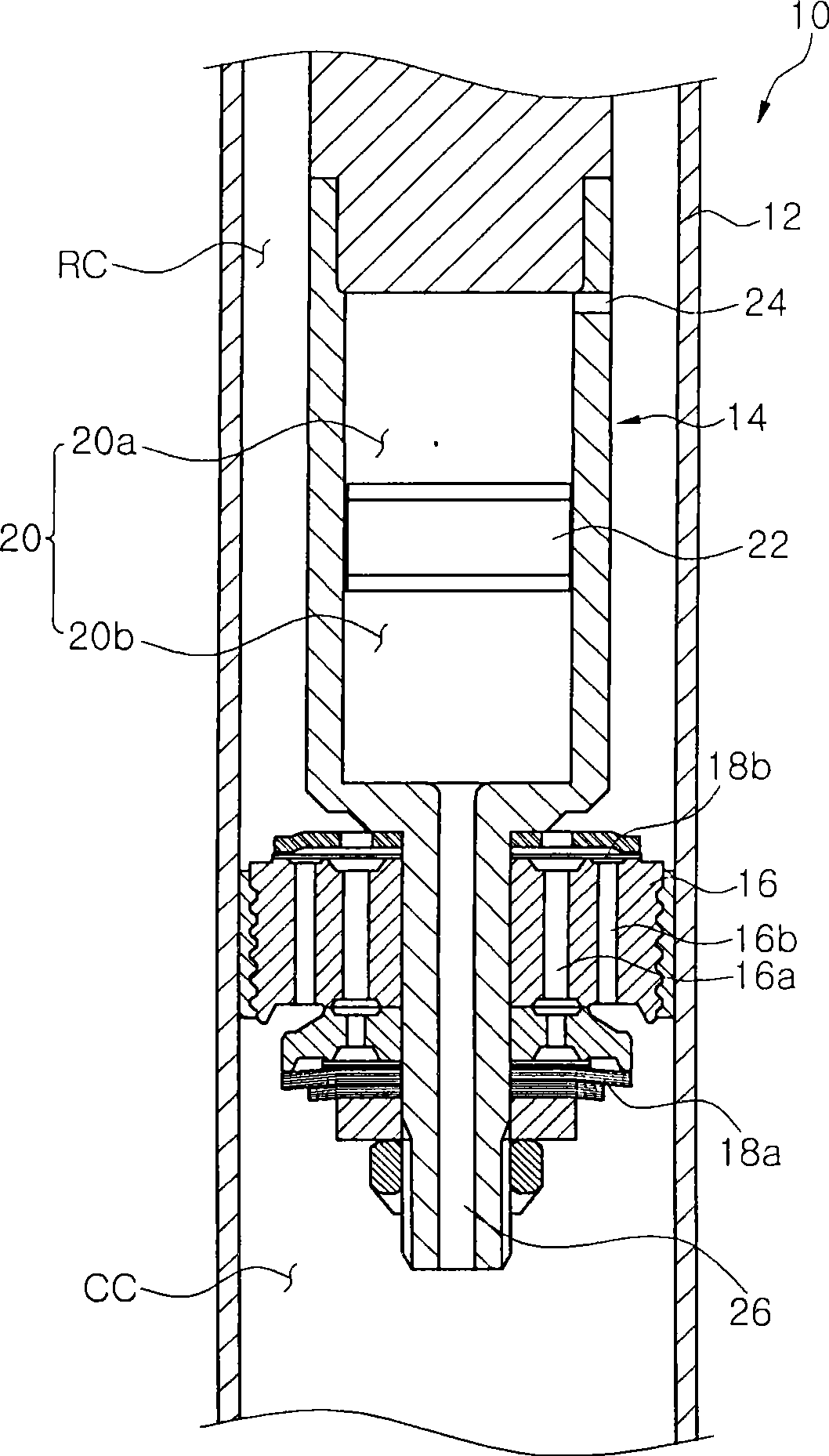

[0028] figure 2 is an enlarged sectional view of a part of the shock absorber according to the first embodiment of the present invention.

[0029] figure 2 Among them, the shock absorber 50 according to the first embodiment of the present invention includes a cylinder 52 connected to an axle of a vehicle and a piston rod 54 connected to a vehicle body side. A piston rod 54 is disposed within the cylinder 52 to reciprocate therein and includes a piston valve 56 disposed at one end of the piston rod 54 so as to divide the interior of the cylinder 52 into a compression chamber CC and a tensile chamber RC. The piston valve 56 is formed with a stretch hole 56a and a compression hole 56b through which the stretch chamber RC communicates with the compression chamber CC. In addition, a plurality of disk valves 58a and 58b are located on the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com