Liquid addition and atomization device for mine nitrogen-filling process

A liquid addition and atomization device technology, applied in safety devices, mining equipment, earthwork drilling and mining, etc., can solve problems such as liquid addition and atomization that are difficult to meet, achieve wide practicability, reduce excessive resistance, and move flexibly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

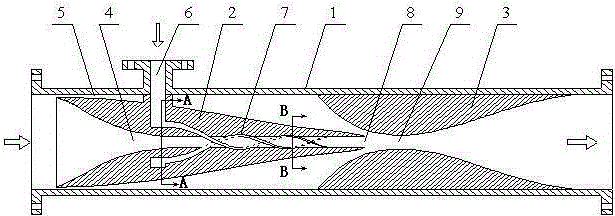

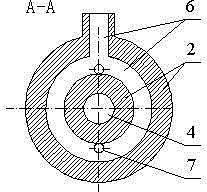

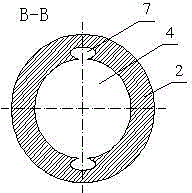

[0013] exist figure 1 Among them, a diversion atomizer 2 is provided at the front end of the cylinder body 1, a tapered air guide channel 4 is provided inside the diversion atomizer 2, and a bypass channel 5 is provided between the outside of the diversion atomizer 2 and the cylinder body 1 , the side of the diversion atomizer 2 is provided with a liquid inlet channel 6, and the liquid inlet channel 6 is connected to the liquid guide groove 7; the rear end of the cylinder 1 is provided with a Venturi mixer 3, and the jet port 8 of the diversion atomizer 2 is facing Mixing channel 9 of Venturi mixer 3.

[0014] The air guiding channel 4 is provided with 2~6 liquid guiding grooves 7, the liquid guiding grooves 7 are arranged in a spiral shape and each liquid guiding groove 7 has the same spiral direction, the liquid guiding grooves 7 are recessed on the inner wall of the air guiding channel 4 and the section is from Then it gradually decreases until it disappears.

[0015] Wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com