Patents

Literature

38results about How to "Avoid coke clogging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial production method for separating boron isotope product based on methyl-phenoxide-boron trifluoride complex

ActiveCN104209003AAvoid cloggingLess side effectsIsotope separationBoron halogen compoundsChemical reactionBoron trifluoride

The invention discloses an industrial production method for separating a boron isotope product based on a methyl-phenoxide-boron trifluoride complex, belonging to the technical field of separation of isotope. The industrial production method mainly aims to solve the problem that a methyl-phenoxide-boron trifluoride complex chemical reaction exchange rectifying method is serious during vacuum material carrying and the like. The industrial production method comprises the following steps: firstly, performing gas stripping and drying treatment to the methyl-phenoxide-boron trifluoride complex, continuously adding the methyl-phenoxide-boron trifluoride complex from a gas stripping tower kettle into a first exchange rectifying tower kettle, continuously extracting liquid in the fore exchange rectifying tower kettle into the next tower top, condensing steam at the top of the next tower top, and continuously entering the fore tower kettle; under pressure-reduced heating distillation, enabling a boron trifluoride gas and methyl ether gas to enter shell passes of a condenser and a catcher, enabling a coolant to travel the shell passes of the condenser and the catcher, wherein a minus 60DEG C methyl ether solution pump is conveyed to a spray device so as to spray a boron trifluoride gas, the boron trifluoride gas and the methyl ether gas are converted into the methyl-phenoxide-boron trifluoride complex. The industrial production method has the advantage of being capable of solving the problem of vacuum material carrying.

Owner:浙江创世雷博科技有限公司

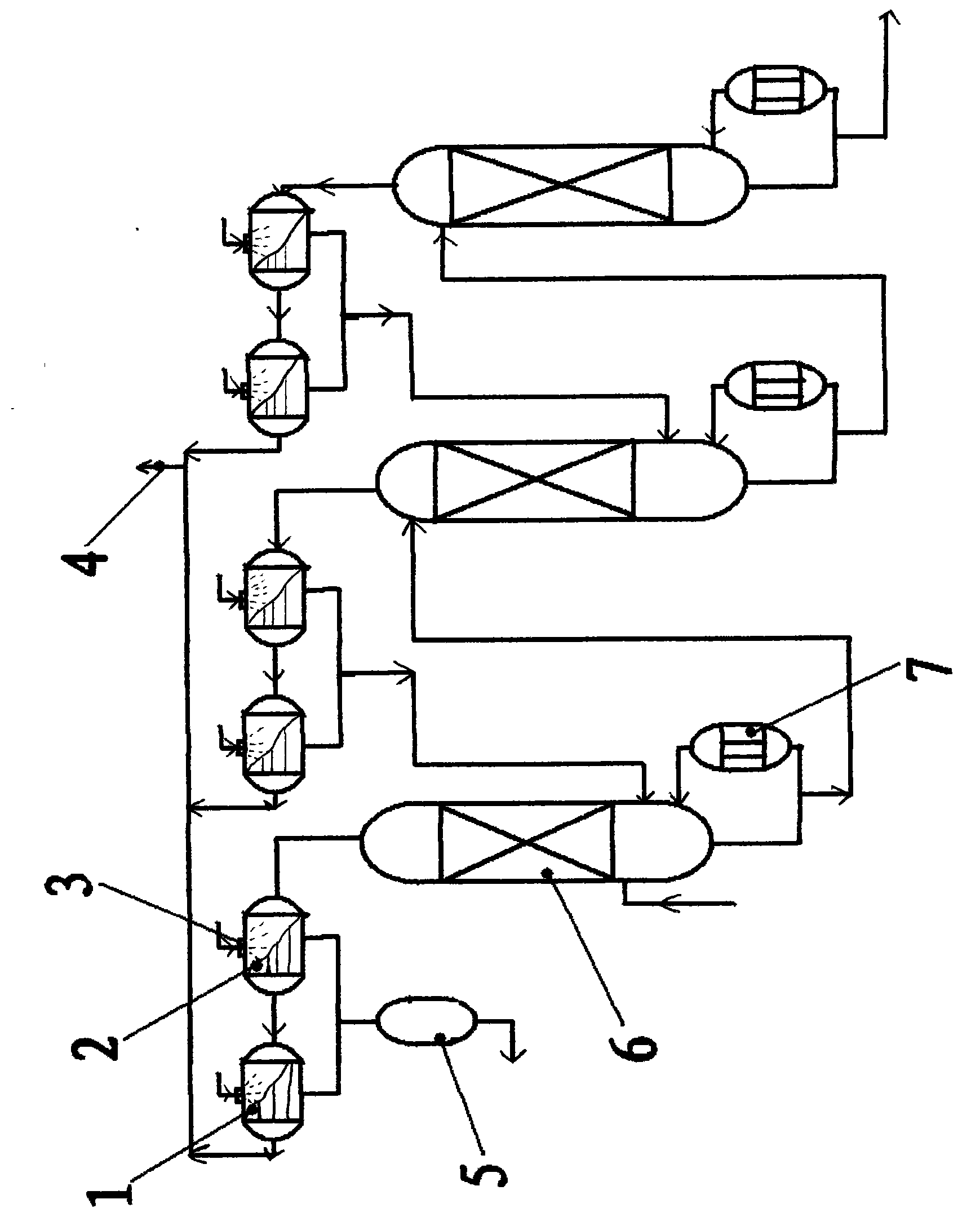

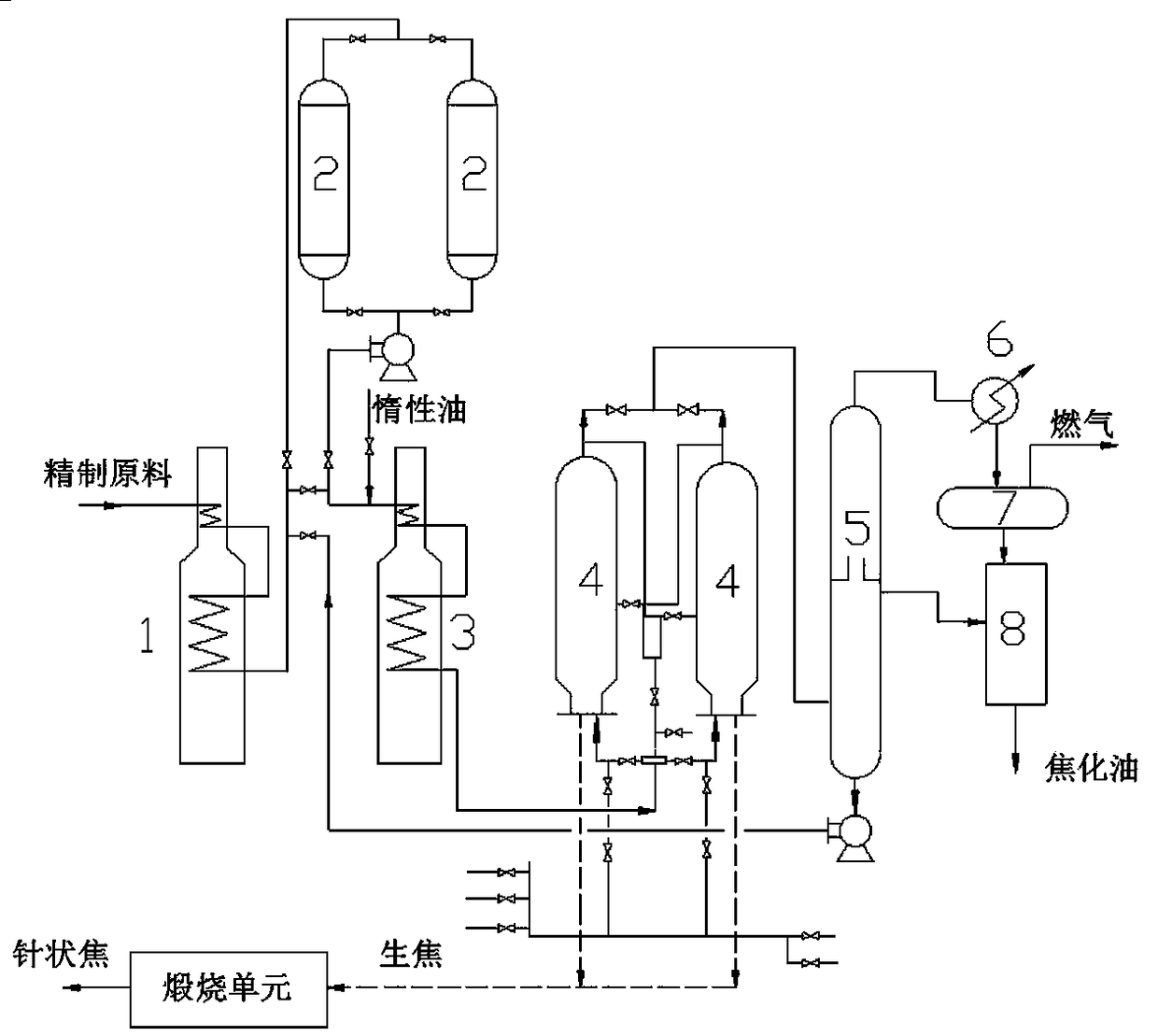

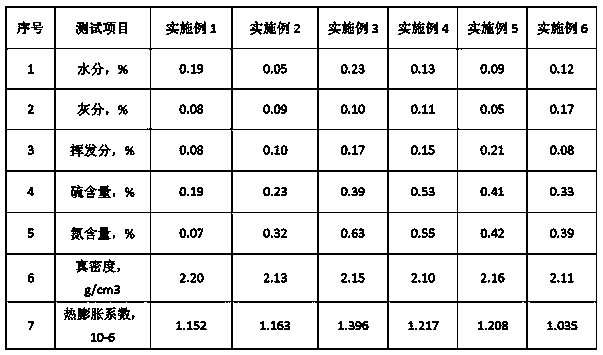

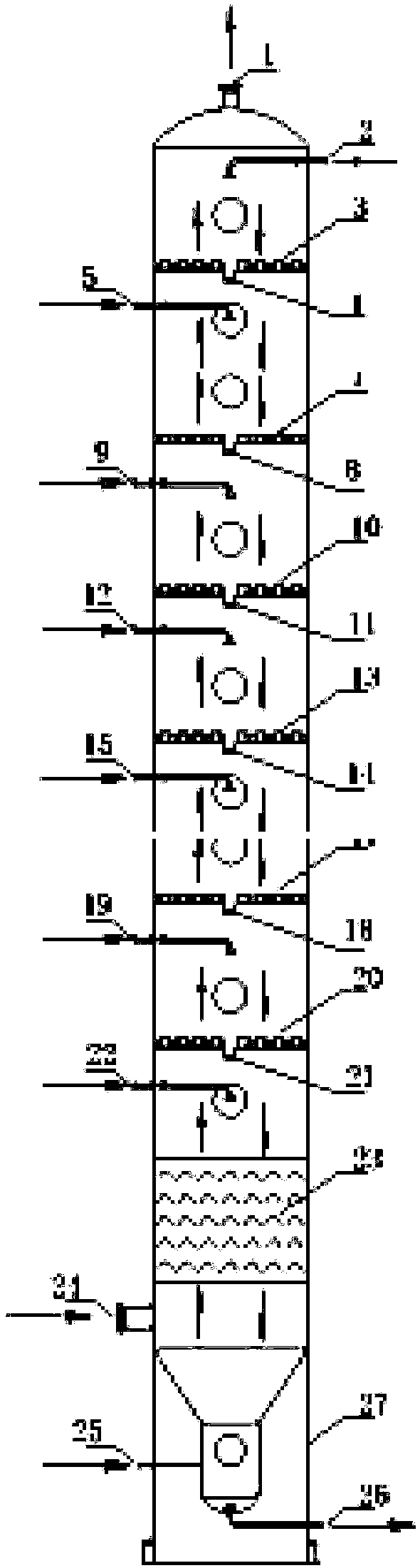

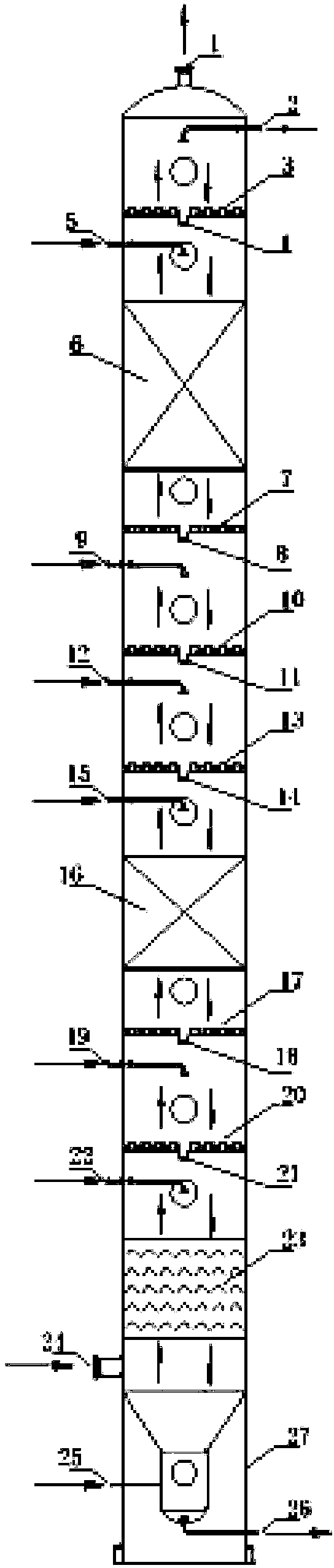

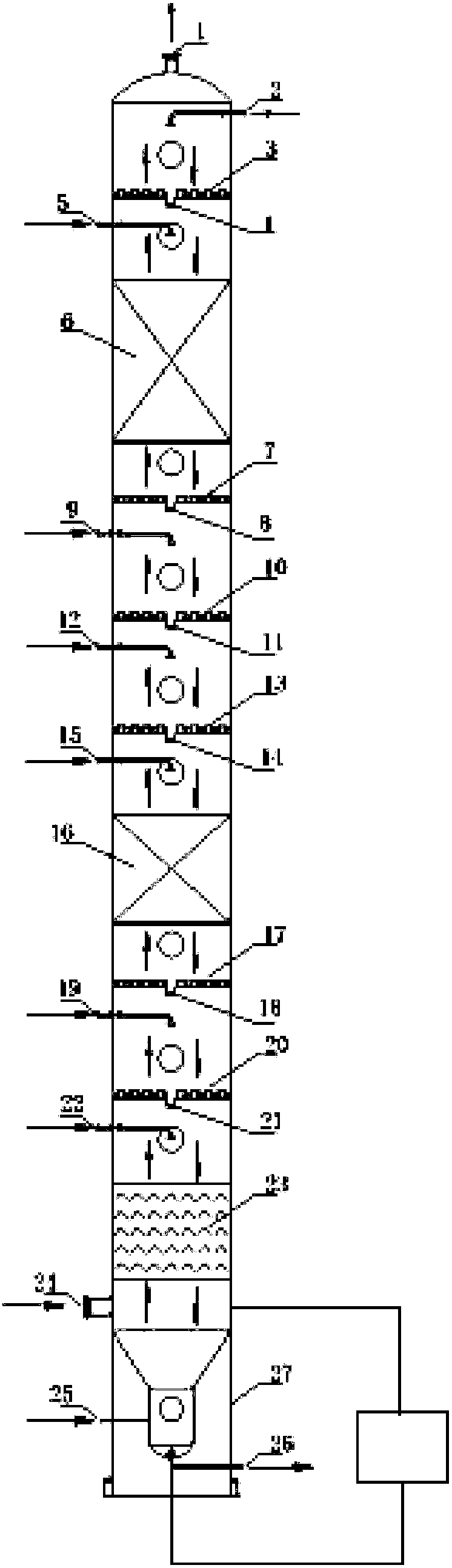

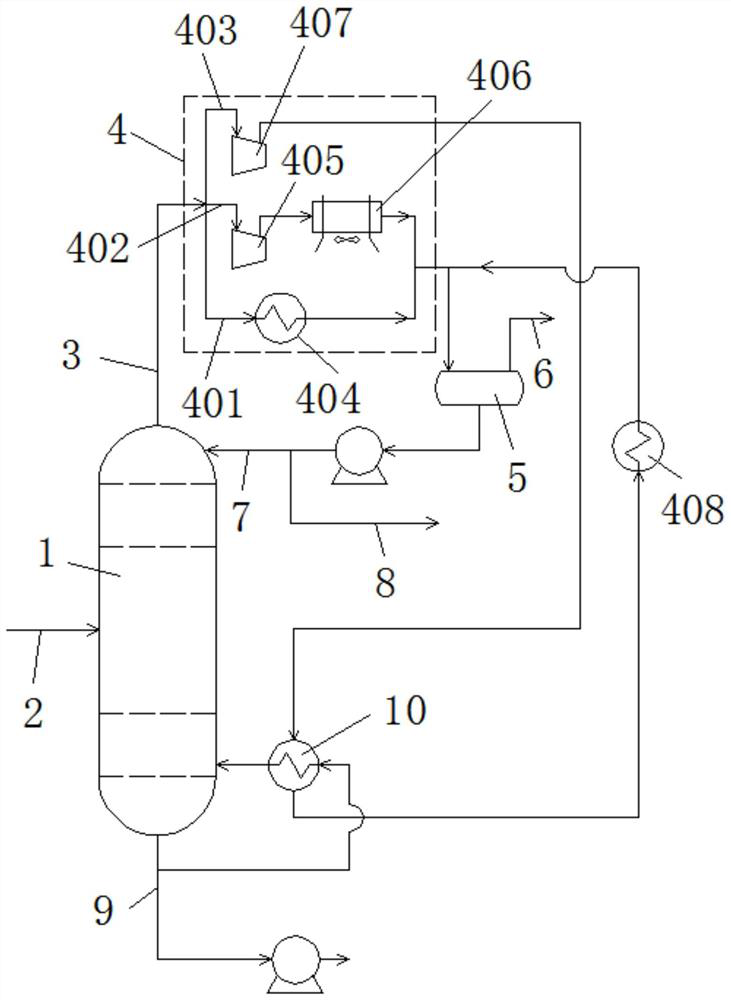

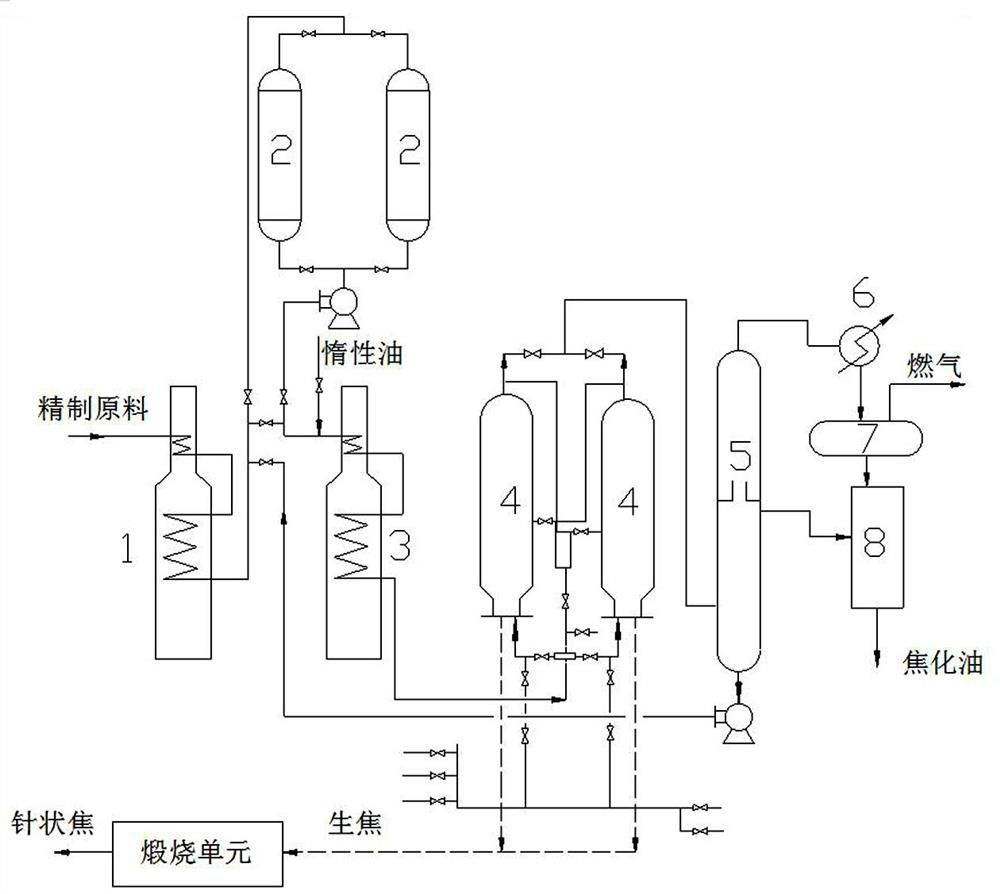

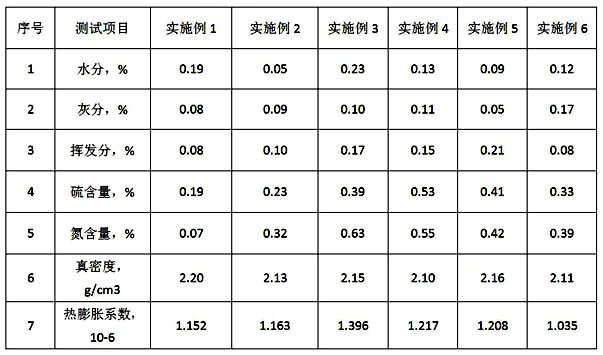

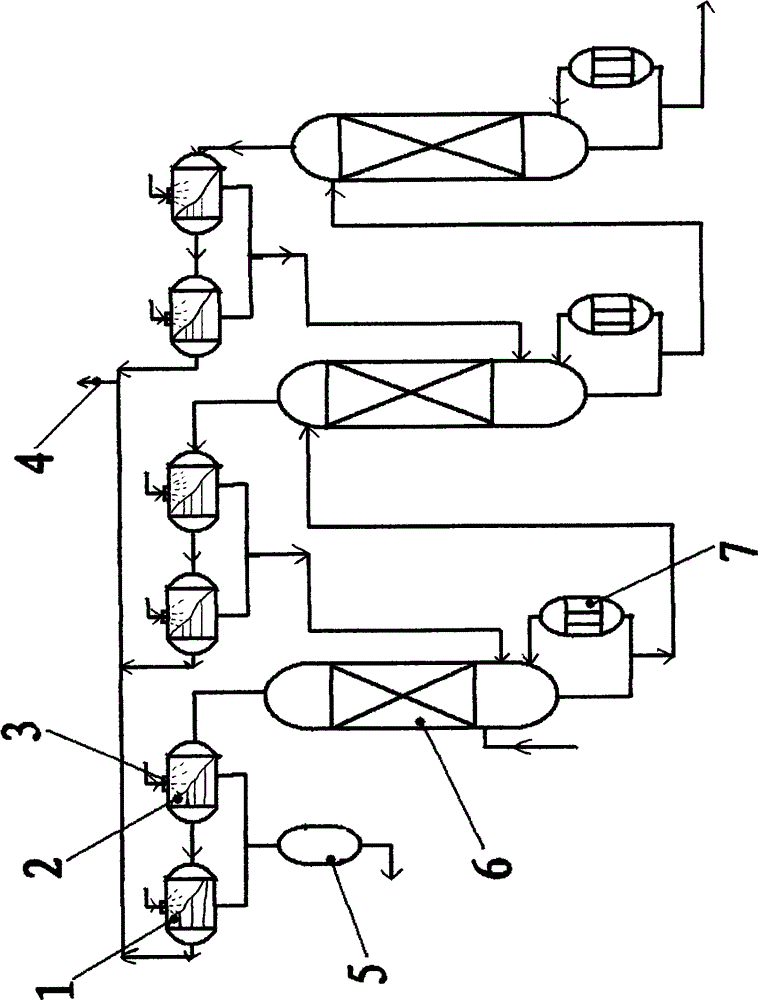

Delayed coking process for preparing coal-based needle coke

ActiveCN109370642AAvoid coke cloggingAccurately control the degree of coking reactionTreatment with plural serial stages onlyCoking carbonaceous materialsPre treatmentProcess engineering

The invention belongs to the technical field of needle coke preparation, and relates to a delayed coking process for preparing coal-based needle coke, in particular to a multi-tower delayed coking process with a heat polycondensation tower and a coking tower. The technical scheme includes that the coking process includes the steps: pretreating coal tar, coal pitch, modified pitch and the like to obtain finished raw materials; heating the finished raw materials, and enabling the heated raw material to enter a heat polymerization tower; polymerizing the raw materials to generate an intermediatephase in the inertness or reduction atmosphere; rapidly heating materials containing the intermediate phase and inert oil when the content of the intermediate phase of the materials reaches 30-60%; conveying the heated mixture into the coking tower to generate coke, and calcining the coke to obtain the needle coke. High-temperature oil and gas of the coking tower is divided into fuel gas and coking oil by a fractionating tower, the coking tower serves as a product output system, the process can accurately control coking reaction degree of coal-based needle coke raw materials, coking and jamming of a device pipeline are avoided, and long-period stable operation of coal-based needle coke production is achieved.

Owner:山西中科化美科技有限责任公司

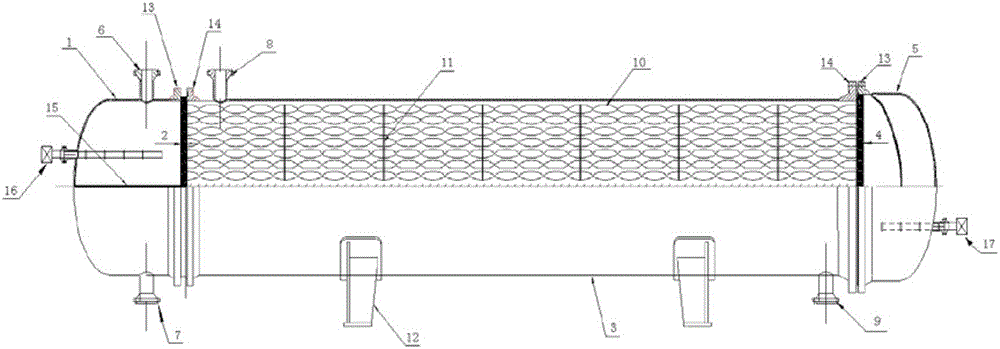

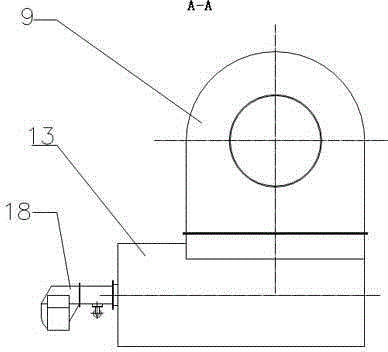

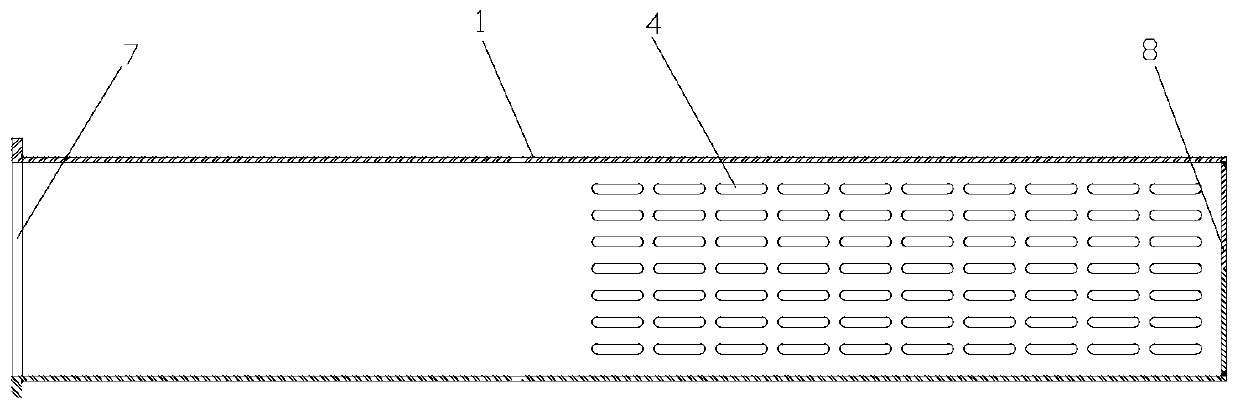

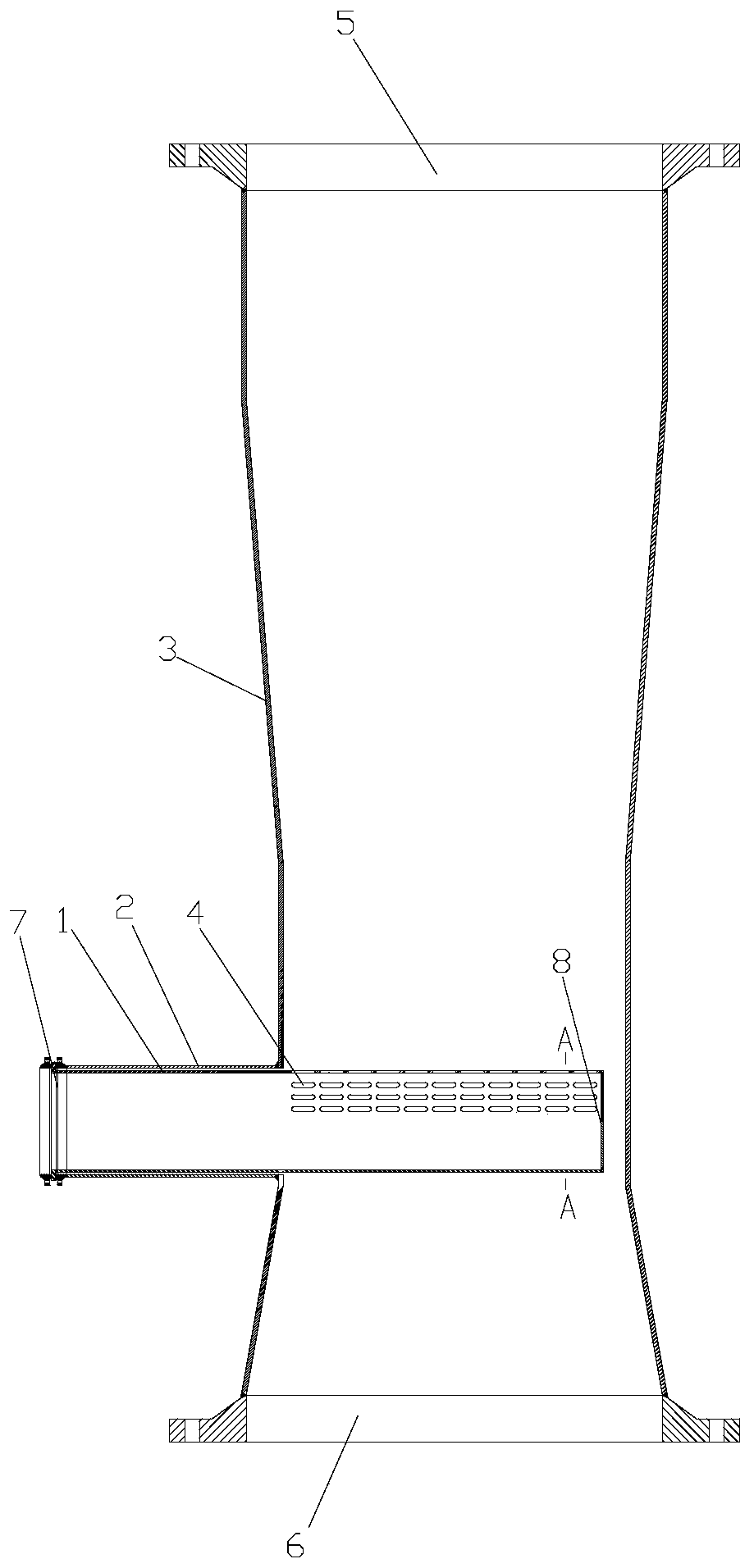

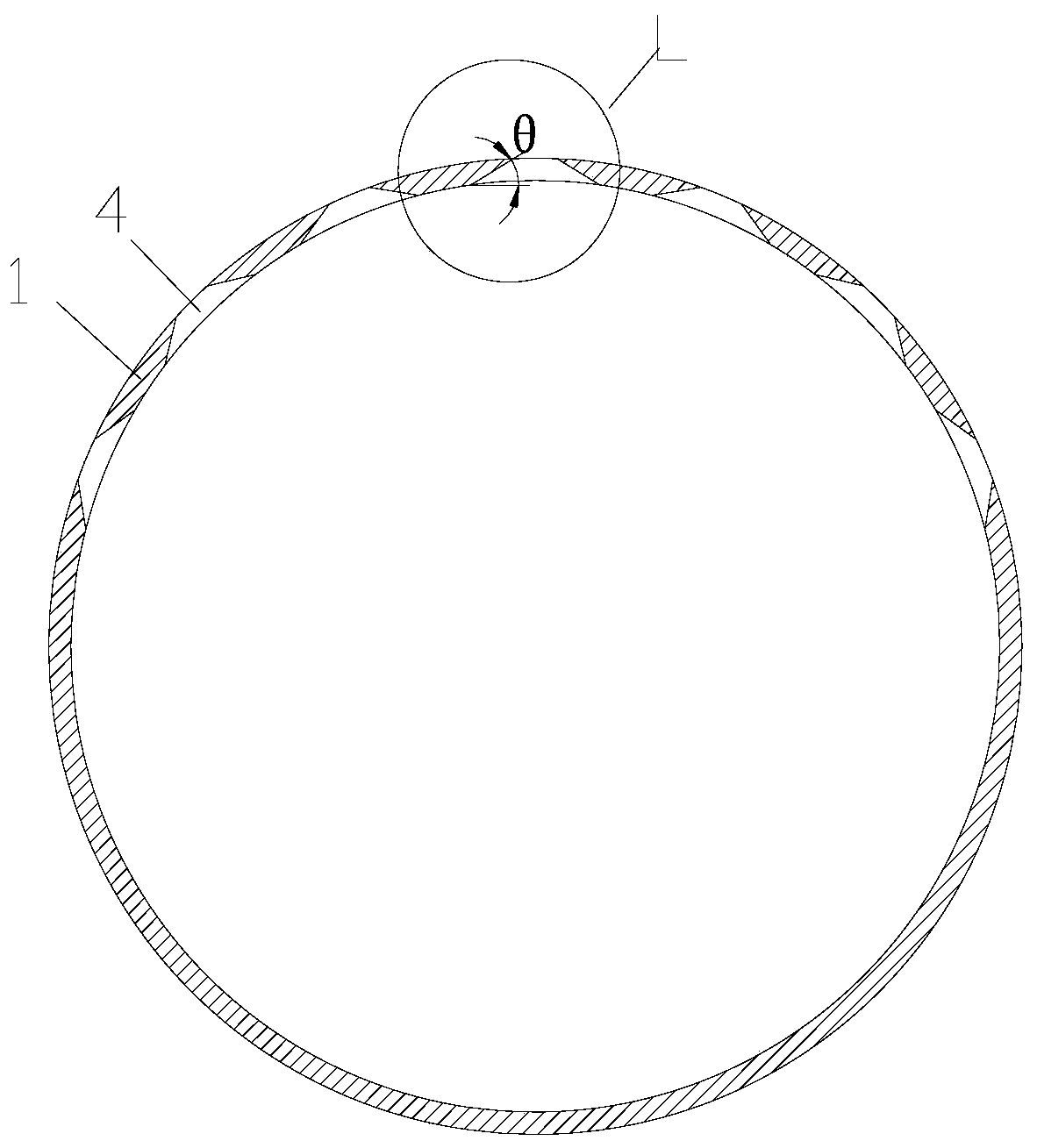

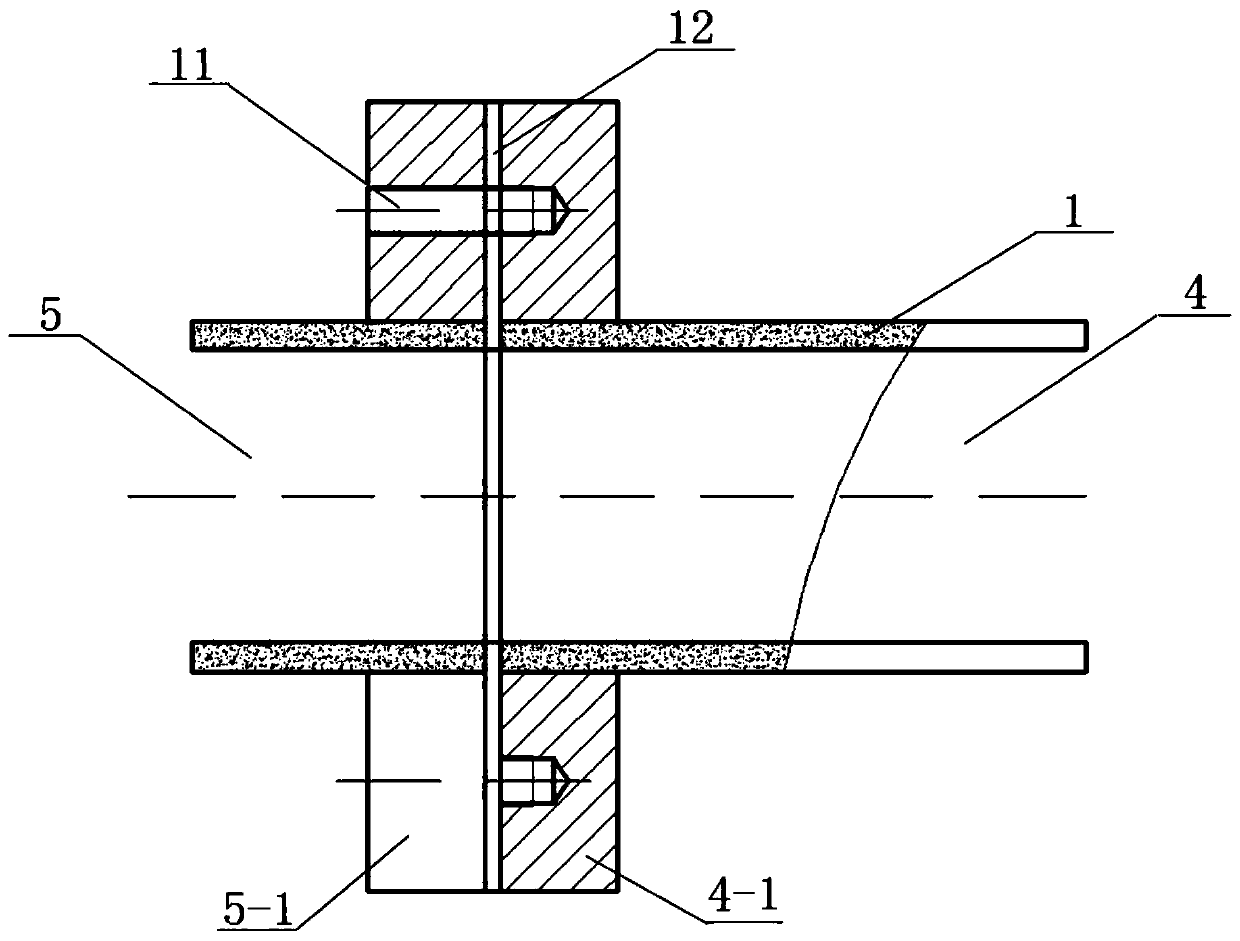

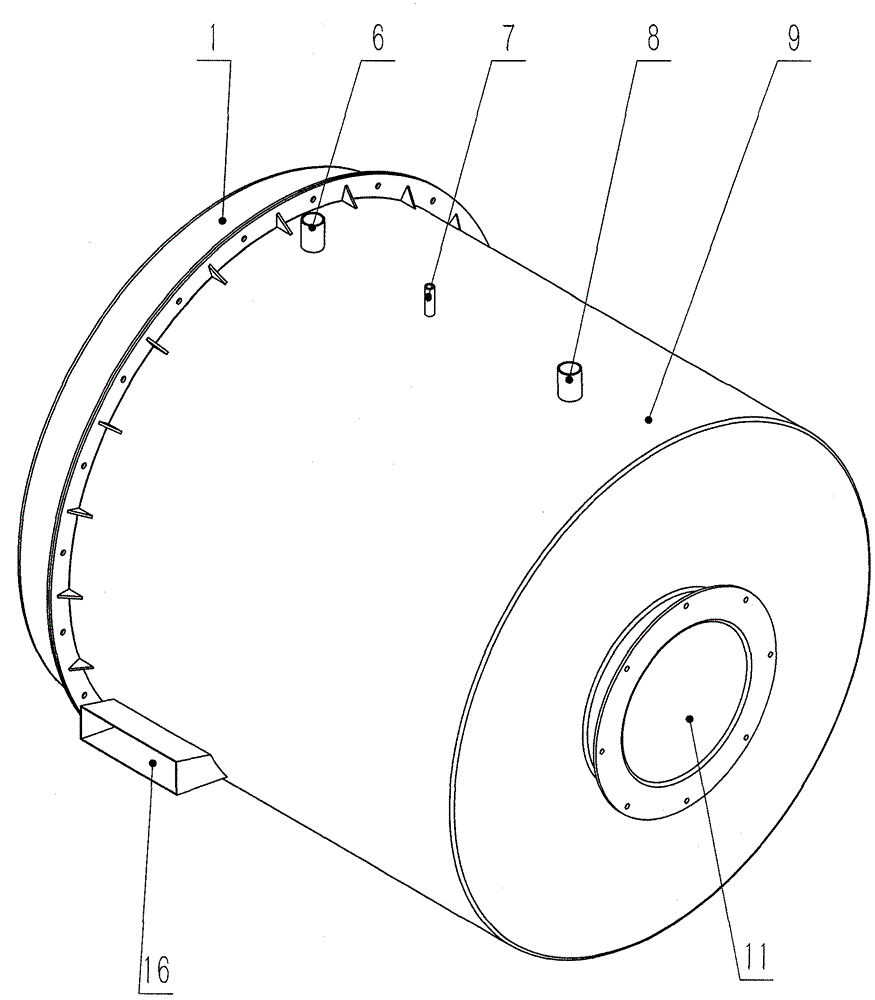

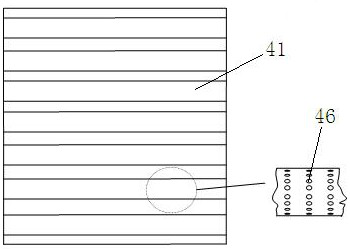

Ultrasonic spiral flat tube heat exchanger

InactiveCN106123635APrevent scalingAvoid coke cloggingCleaning heat-transfer devicesCorrosion preventionBiomedical engineeringUltrasound

The invention discloses an ultrasonic spiral flat tube heat exchanger. The ultrasonic spiral flat tube heat exchanger comprises a left end face end socket, a left tube plate, a heat exchanger shell, a right tube plate and a right end face end socket which are connected in sequence. Spiral flat tubes are horizontally arranged in the heat exchanger shell. A baffling baffle is horizontally arranged in the left end face end socket. A first ultrasonic generation device is horizontally arranged on the upper portion of the baffling baffle and fixed to the side wall of the left end face end socket. One end of the first ultrasonic generation device is located outside the left end face end socket, and the other end of the first ultrasonic generation device is located in the left end face end socket. A second ultrasonic generation device is horizontally arranged on the lower right portion of the right end face end socket. One end of the second ultrasonic generation device is located outside the right end face end socket, and the other end of the second ultrasonic generation device is located in the right end face end socket. According to the ultrasonic spiral flat tube heat exchanger, scaling in the tube walls can be prevented, coking and blockage in the tube walls are avoided, the equipment maintenance period is prolonged, and the ultrasonic spiral flat tube heat exchanger is suitable for the technical field of industrial heat exchange.

Owner:CHINA NAT OFFSHORE OIL CORP +1

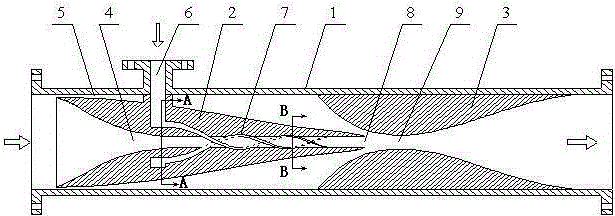

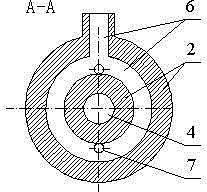

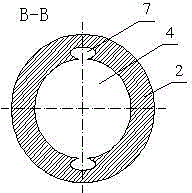

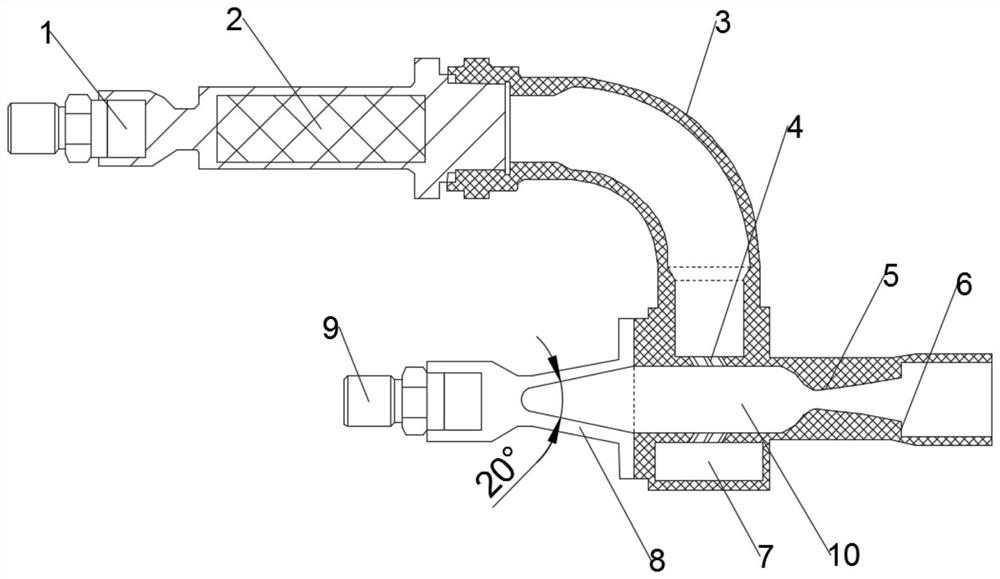

Liquid addition and atomization device for mine nitrogen-filling process

ActiveCN103195462BStable nebulized nitrogen flowReduce excessive resistanceDust removalFire preventionViscous liquidInlet channel

The invention discloses a liquid addition and atomization device for a mine nitrogen-filling process. A flow-guide atomization device is arranged at the front end of a barrel body of the liquid addition and atomization device. A reducing gas-guide channel is reserved in the interior of the flow-guide atomization device. A bypass channel is arranged between the exterior of the flow-guide atomization device and the barrel body. A flow inlet channel is arranged on a lateral side of the flow-guide atomization device, and is communicated with a liquid-guide groove. A Venturi mixer is arranged at the rear end of the barrel body; and an injection orifice of the flow-guide atomization device is opposite to a mixture channel of the Venturi mixer. The liquid addition and atomization device is simple in structure, large in atomization amount, small in occupied space, flexible in movement, convenient to assemble, capable of effectively preventing blocking and working continuously, suitable for viscous liquid, free of electric elements, safe, reliable, and wide in practicability, is applicable to fire preventing and suppression in gob area of a mine or a closed space, and especially is applicable to adding fire-proof inhibitor solution in a mine nitrogen-filling process for fire preventing and suppression.

Owner:CHINA UNIV OF MINING & TECH

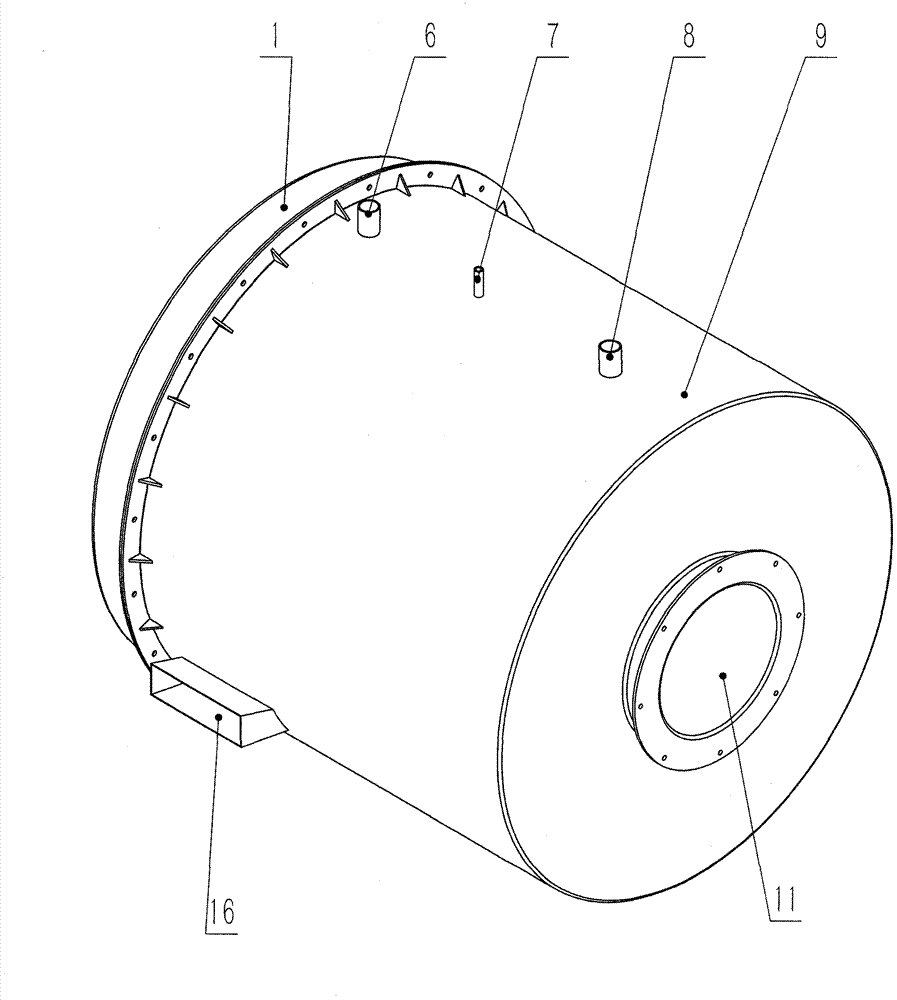

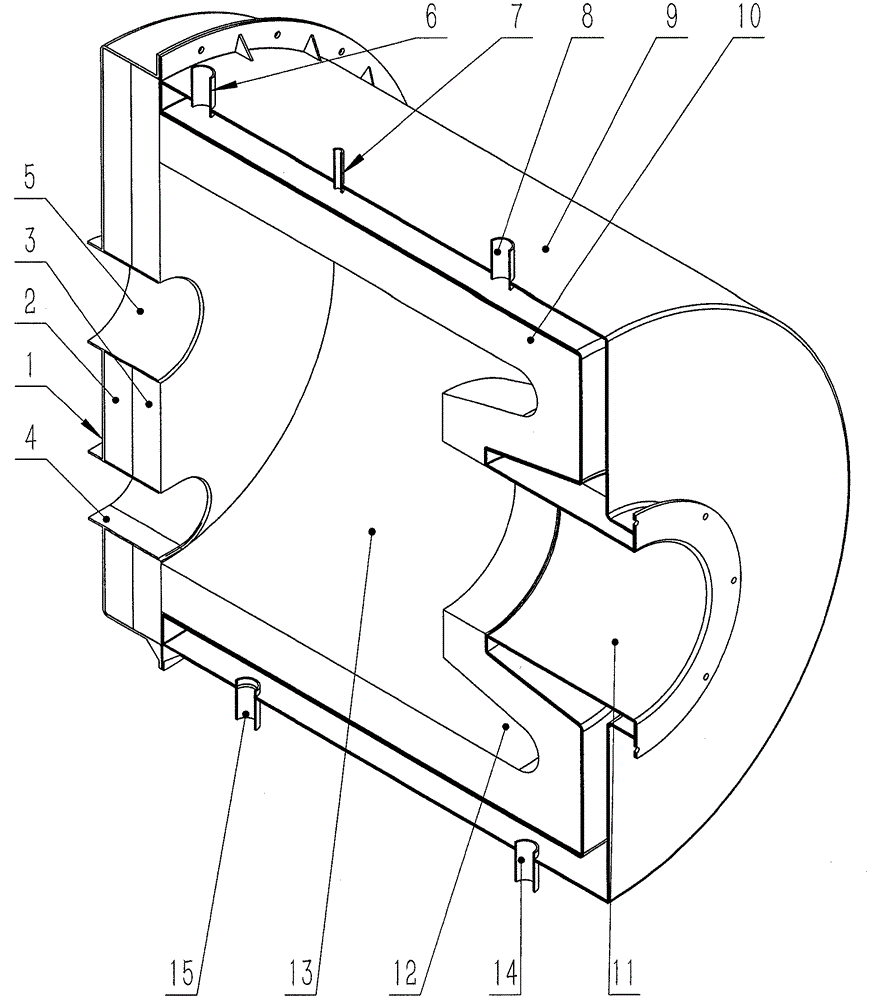

Cyclone type biomass powder combustor

InactiveCN103175201ASpeed up the flowSolve the blockagePulverulent fuel combustion burnersCycloneFurnace temperature

The invention relates to a high-efficiency cyclone type biomass powder combustor used for a boiler and a kiln. The combustor is composed of a water cooling sleeve, an end cover and the like. No hole that disturbs rotational flow is arranged between two ends of a cyclone combusting chamber. Biomass powder is put into the combustion chamber through a feeding hole and dispersed and pushed by cyclone of a cyclone hole so that wall-attached combustion and floating combustion are achieved. Raging fire erupts out of a fire and air hole. Ash is pulled out from an ash outlet hole. Coal particles are carbonized to be ash in a carbonization pool. A water exiting pipe, an air exhausting pipe, a water entering pipe, a sewage draining pipe and a water temperature sensor penetrate into the water cooling sleeve. The water cooling sleeve is used for regulating furnace temperature, recycling heat and safety protection. An igniter starts a combustion process. Combustion situations are observed from a fire observation hole. A safety valve ensures safety. A furnace temperature sensor detects furnace temperature. The problems that a rotation flow field is disturbed due to blowing-in from multiple air holes, bunkers are not fully combusted; slag short out and escaping happen, residues are condensed and formed at the air holes and the problems of coal particle coking, insufficient combustion and dust pollution caused by material particles, furnace temperature, flow speed, communication of the feeding hole and the fire and air hole and the like are basically solved.

Owner:HUBEI HUABAO ECOLOGICAL ENERGY TECH CO LTD +1

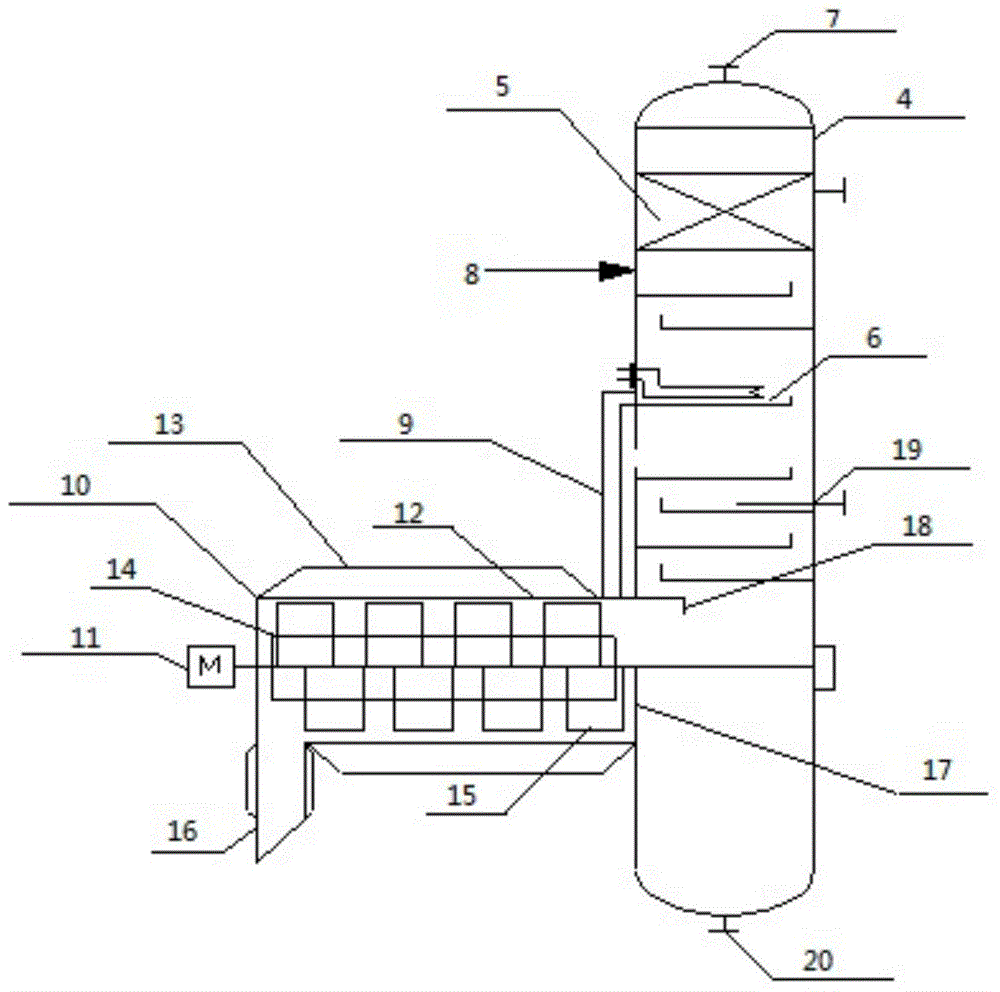

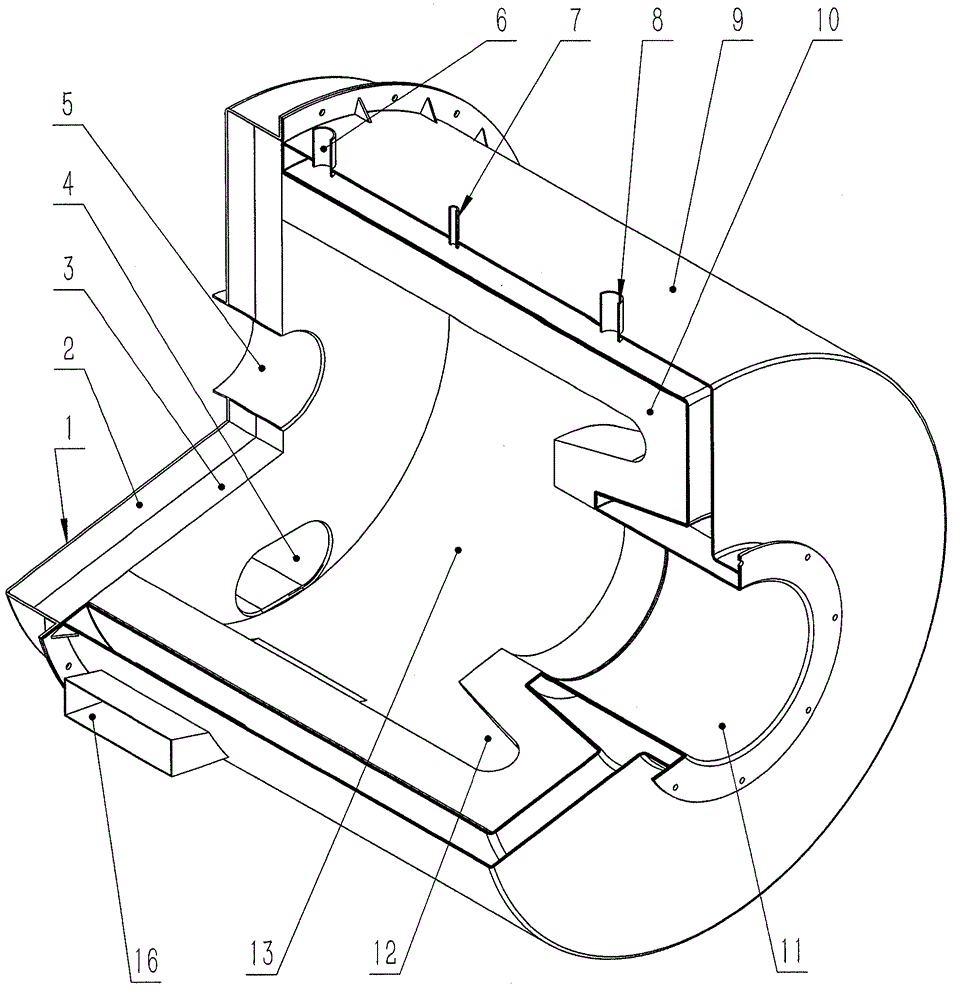

Hybrid heating equipment and application thereof

ActiveCN104694138AReduce lossesHigh thermal efficiencyHorizontal chamber coke ovensSpecial form destructive distillationSlagEngineering

The invention relates to heating equipment, in particular to hybrid heating equipment and application thereof. The hybrid heating equipment comprises a three-layer cylinder structure consisting of an outer cylinder (1), a heating cylinder (4) and a slag return cylinder (5) from outside to inside sequentially, wherein the outer cylinder (1) is supported by a supporting device (12), and driven to rotate by a transmission device (11); a first supporting piece (3) is arranged between an inner wall of the outer cylinder (1) and an outer wall of the heating cylinder (4); a second supporting piece (6) is arranged between an inner wall of the heating cylinder (4) and an outer wall of the slag return cylinder (5); an air inlet cover (17) and an air outlet cover (7) are respectively arranged at the two ends of the outer cylinder (1); the air inlet cover (17) is connected with a heating furnace (13) by a flange; the flange on the heating furnace (13) is connected with a burner (18); one end of the heating cylinder (4) is connected with a feeding airlock (8); and the other end of the heating cylinder (4) is connected with a discharge airlock (15).

Owner:JIANGSU PENGFEI GROUP

Igniter capable of being ignited repeatedly and ignition method

PendingCN111720241AControl injection timeAchieve repetitive ignitionRocket engine plantsCombustion chamberPtru catalyst

The embodiment of the invention discloses an igniter capable of being ignited repeatedly and an ignition method. The igniter comprises a hydrogen peroxide catalyst bed, wherein a hydrogen peroxide nozzle is installed at one end of the hydrogen peroxide catalyst bed, a transition section is installed at the other end of the hydrogen peroxide catalyst bed, the bottom end of the transition section communicates with a collecting distribution cavity, and the connecting surfaces of a premixing chamber and the collecting distribution cavity are provided with oxygen-enriched gas nozzles; and a fuel nozzle is installed on one side of the premixing chamber through a tapered structure section, a premixing chamber outlet throat is installed on the other side of the premixing chamber, and a step structure is installed on the outer side of the premixing chamber outlet throat. Hydrogen peroxide with a concentration of no less than 82% is decomposed by catalysts to produce high-temperature oxygen-enriched gas, then the high-temperature oxygen-enriched gas is mixed with hydrocarbon fuel in the premixing chamber, the temperature of fuel is improved, the ignition delay time is shortened, automatic ignition and initial reaction are realized, and then flames are jetted into a combustion chamber to ignite an engine.

Owner:合肥中科重明科技有限公司 +1

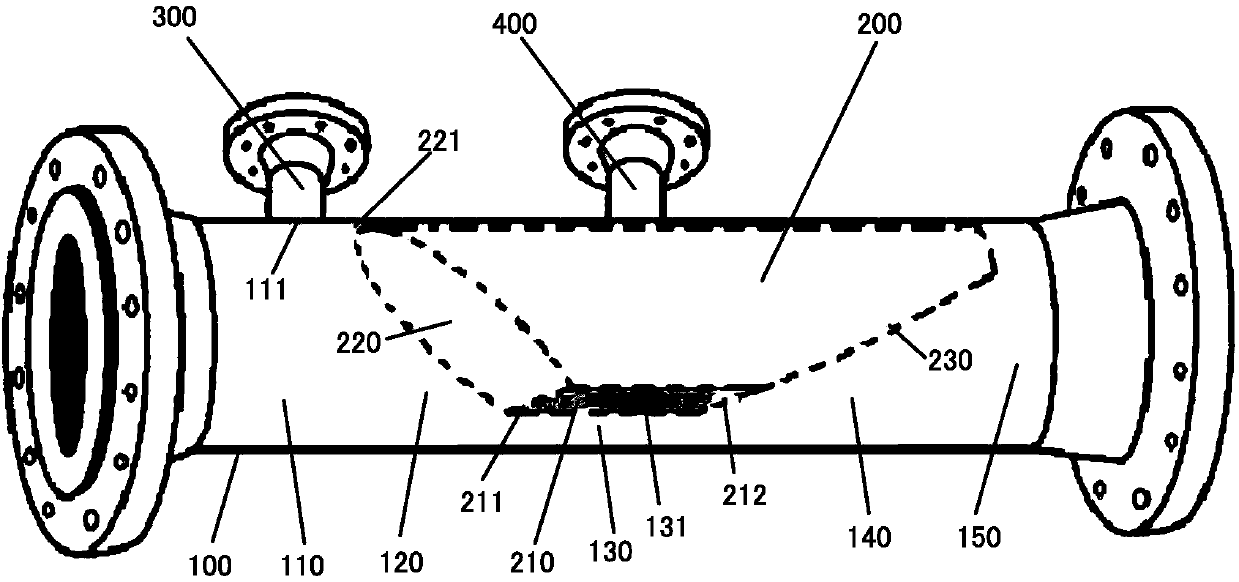

Rectangular flowmeter

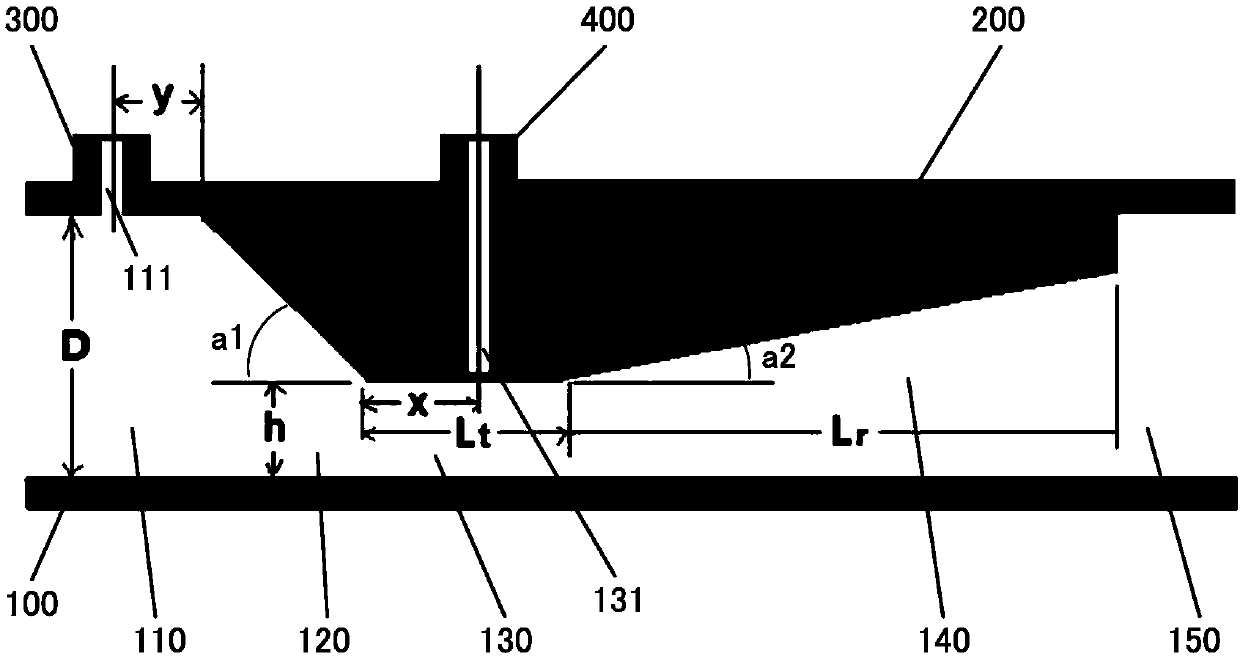

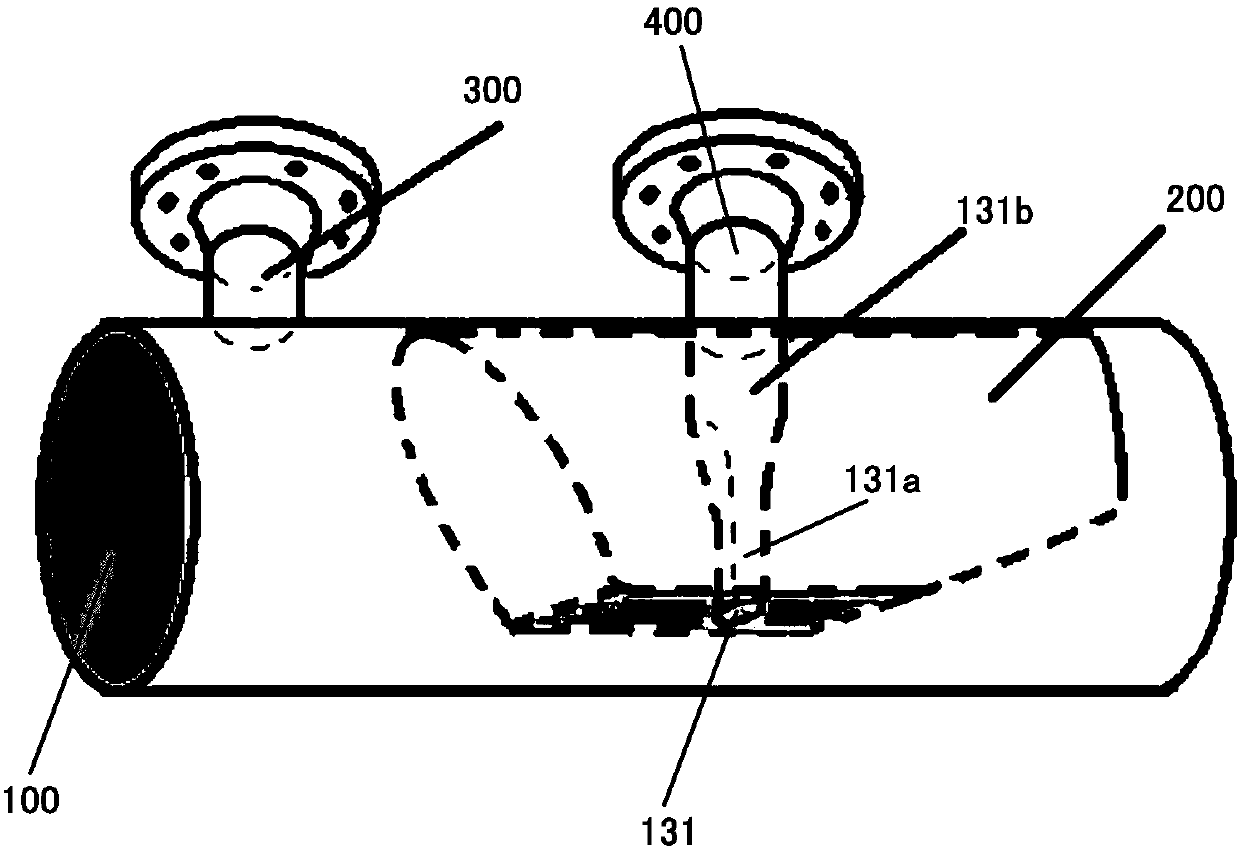

PendingCN107764345AHigh precisionShorten the lengthVolume/mass flow by differential pressureStraight tubeStream flow

The invention discloses a rectangular flowmeter, and belongs to the field of flow measurement. The rectangular flowmeter comprises a measuring pipeline and a throttling block. The top of the throttling block is connected with the top wall of the measuring pipeline in a fastened mode. The bottom of the throttling block is a rectangular throttling face parallel to the down-flow axial direction of the measuring pipeline, the head end and the tail end of the throttling face extend towards the two ends of the measuring pipeline to the top wall of the measuring pipeline to form a contracted flow face and a recovery face, the throttling block divides the measuring pipeline into a straight pipe section, a contracted flow section, a throttling section, a recovery section and an extension section which are communicated in sequence, a negative pressure obtaining hole for extracting negative pressure is upwards formed in the throttling face of the throttling block, the center position of the negative pressure obtaining hole meets the following relation expressions that 1 / 2Lt<x<Lt, wherein x is the distance between the head end of the throttling face and the center position of the negative pressure obtaining hole, and Lt is the length of the throttling section. According to the rectangular flowmeter, the structure of the rectangular flowmeter is improved, and the measuring accuracy can be improved.

Owner:王子平

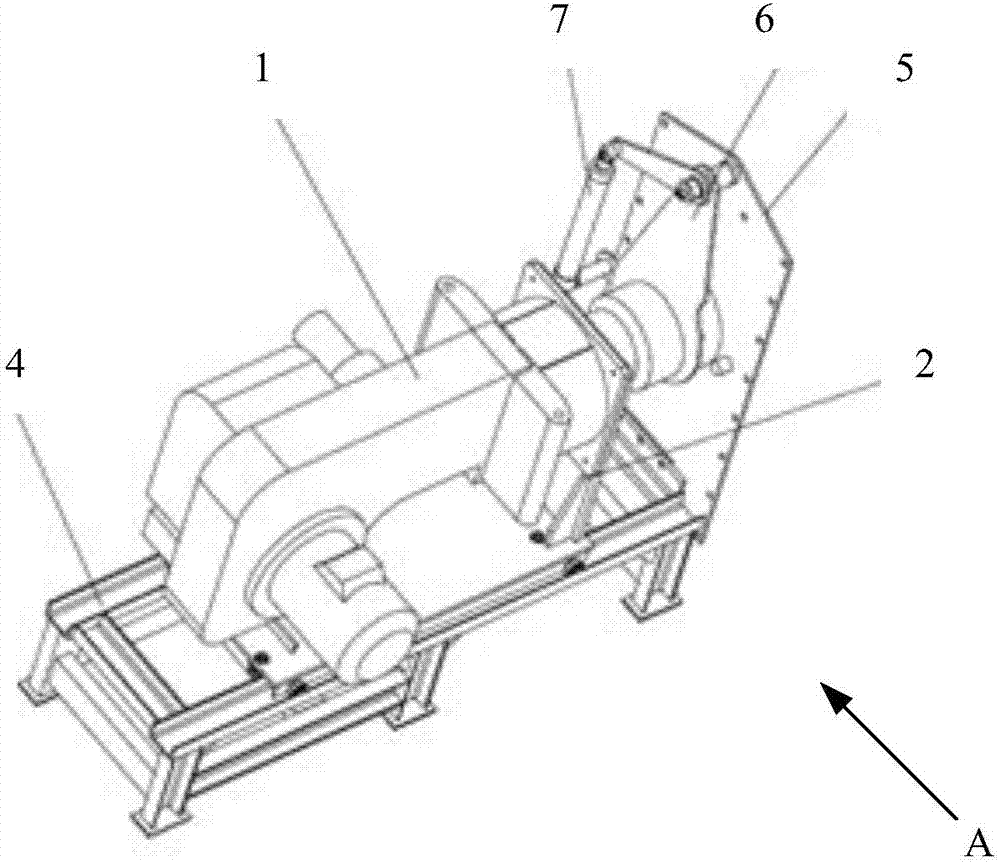

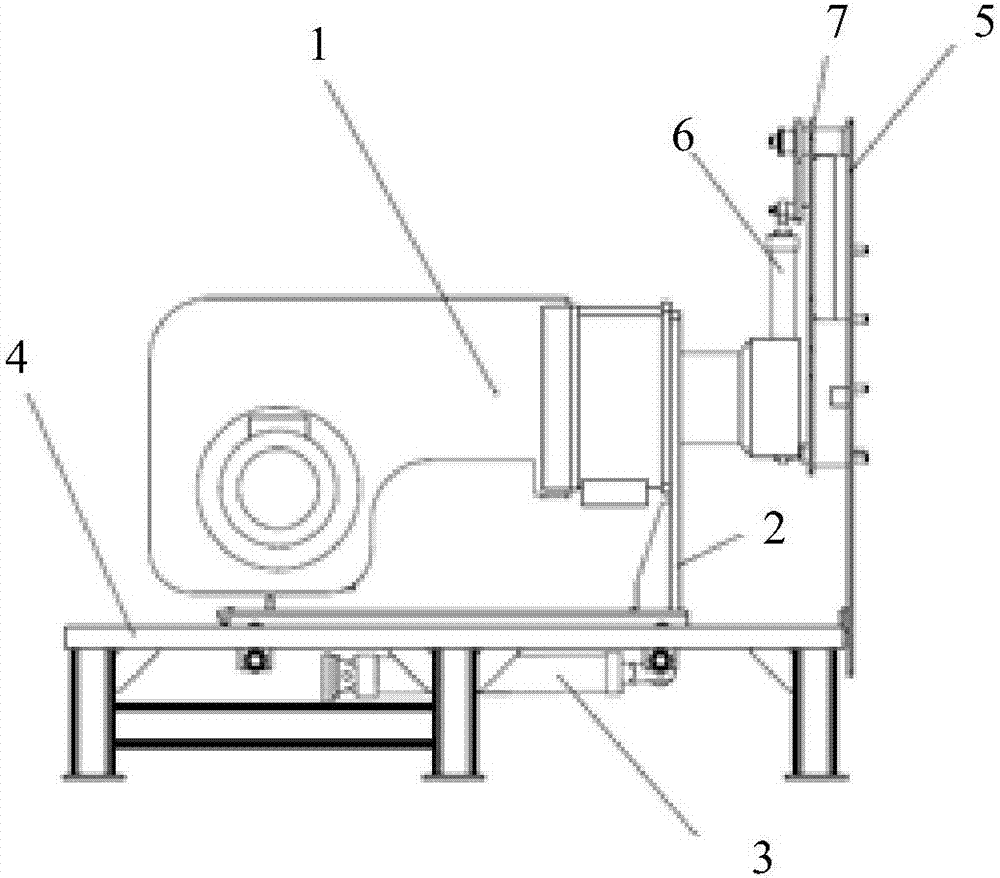

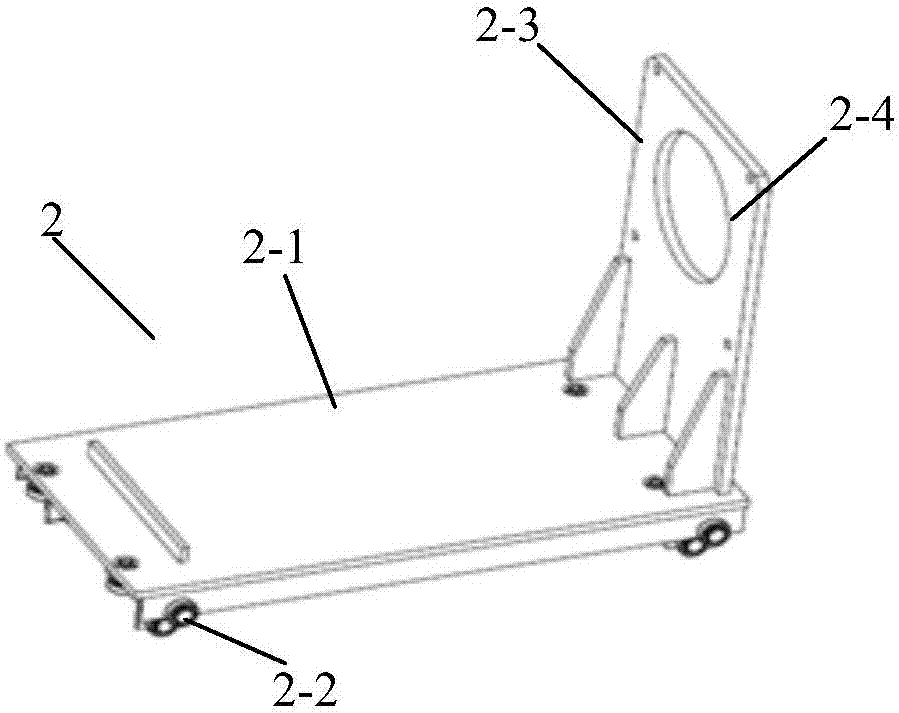

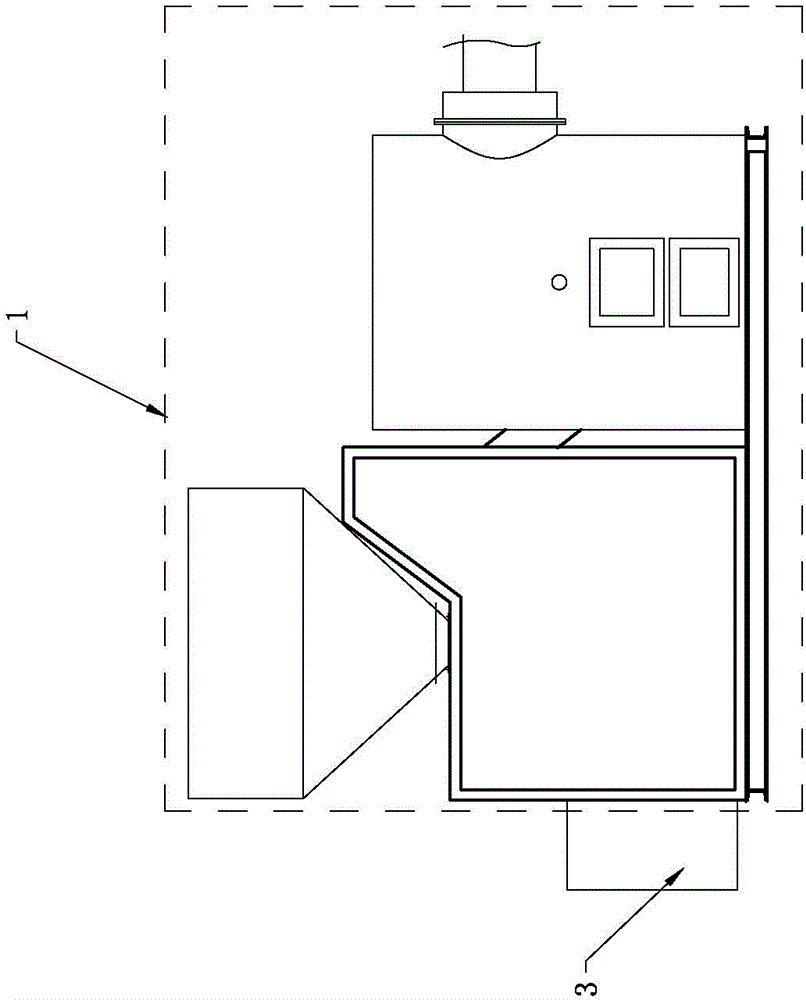

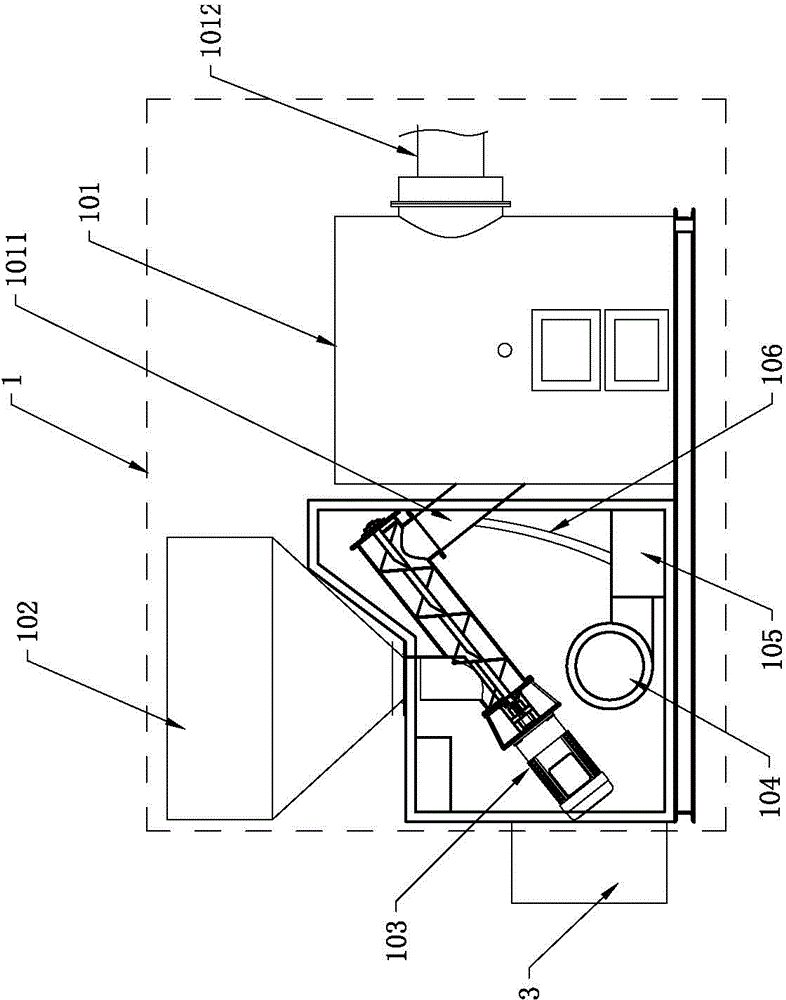

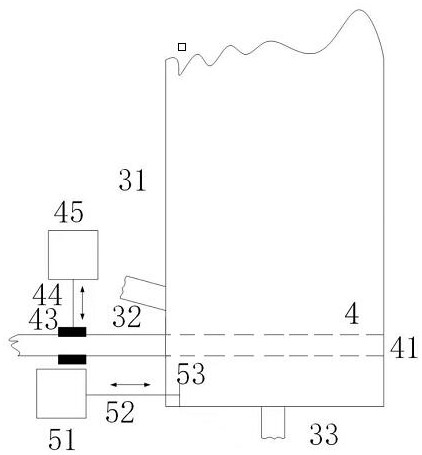

Burner propelling system

InactiveCN107289452AReduce labor costsReduce energy consumptionIncinerator apparatusAutomatic controlAutomotive engineering

The present invention provides a combustor propulsion system, the system includes a combustor; a propulsion mechanism, the propulsion mechanism includes a sliding device and a sliding driving device, the sliding device is fixedly connected with the combustor, and drives the combustor Moving back and forth in the direction of the combustion chamber, the sliding drive device drives the sliding device to move or stop; and a control module, the control module automatically controls the propulsion mechanism so that the sliding drive device drives the The sliding device drives the burner to move forward or backward, wherein the forward movement causes the nozzle of the burner to enter the combustion chamber, and the backward movement causes the nozzle of the burner to exit the combustion chamber . According to the burner propulsion system of the present invention, the burner can be taken out in time when the burner is not running, and the burner can be sent into the combustion chamber in time when the burner needs to be operated, avoiding the tediousness of frequent manual taking out and reducing labor costs.

Owner:EVERBRIGHT ENVIRONMENTAL TECH RES INST NANJING CO LTD +3

Biomass burning device for butt-jointed boilers, heat exchangers and heat supply systems

InactiveCN103557516AIncrease burn rateHigh calorific valueSolid fuel combustionNon-combustible gases/liquids supplyCarbonizationVapor generator

The invention discloses a biomass burning device for butt-jointed boilers, heat exchangers and heat supply systems. The biomass burning device comprises a burner body, a carbonizing machine and a vapor generator, wherein the carbonizing machine is used for producing fuel required by burning of the burner body; and a vapor output pipe of the vapor generator is communicated with a burning chamber of the burner body. Tar is separated out of raw biomass materials through preliminary cracking by the carbonizing machine, so that the obtained biomass fuel is low in tar content, and the phenomenon of coking inside the burning chamber during burning is effectively avoided. Meanwhile, water vapor is used for supporting burning, so that coking elimination can be facilitated, and the fire temperature of burning flames, the biomass fuel rate and the heat value can be increased. According to the biomass burning device, the carbonizing machine, the vapor generator and the burner body are combined organically, so that the problems that traditional biomass burners are low in burning rate, easy to coke, low in work efficiency, unstable in operation and the like are solved. The biomass burning device can be used for the butt-jointed boilers, the heat exchangers and the heat supply systems as well as other equipment or systems using open fire for heating, such as large thermal motors and the like.

Owner:黎明 +1

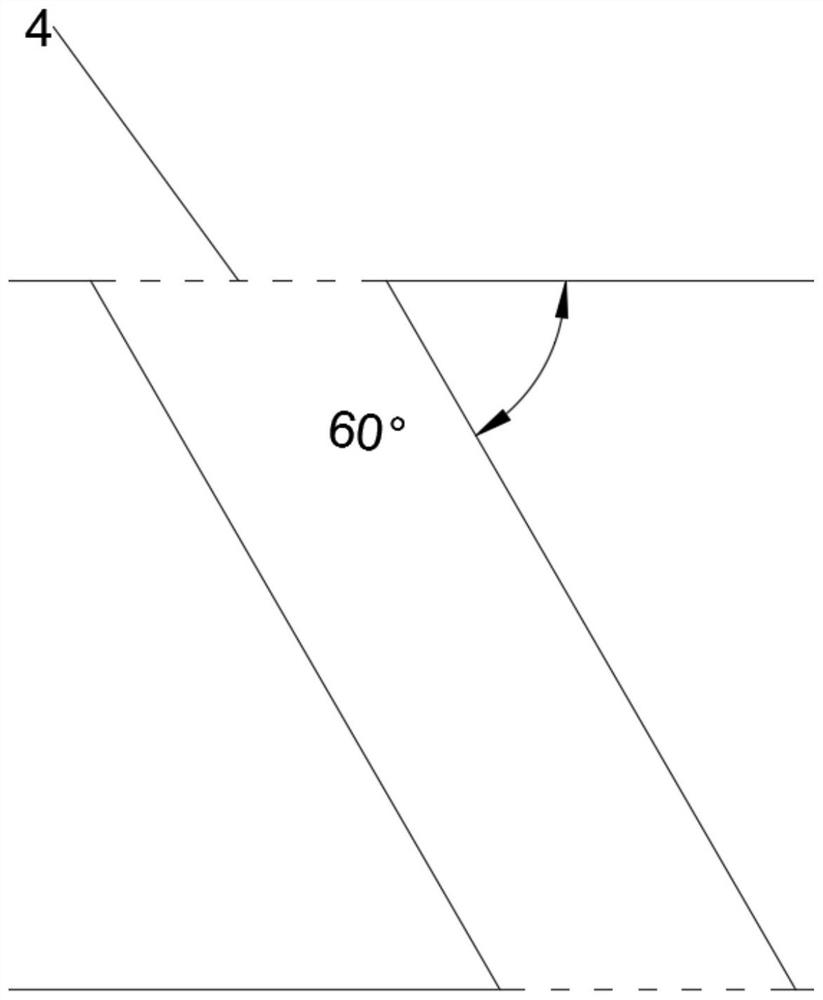

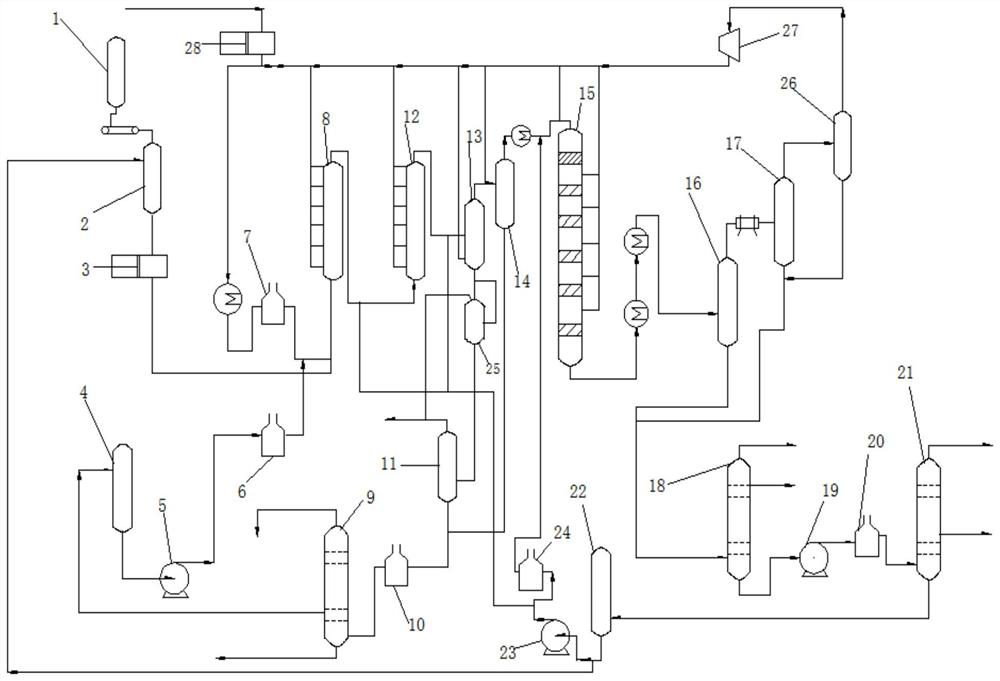

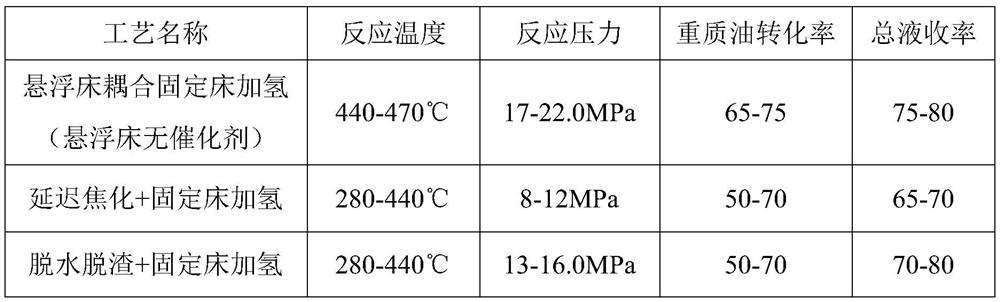

Coal tar suspended bed coupled fixed bed hydrocracking process and device

PendingCN113214861AAvoid coke cloggingSolve wear and tearHydrocarbon oil crackingTreatment with hydrotreatment processesProcess engineeringPhencyclone

The invention discloses a coal tar suspended bed coupled fixed bed hydrocracking process and a device, the device comprises a catalyst storage tank, the catalyst storage tank is connected with a catalyst mixing tank, and the catalyst mixing tank is connected with a catalyst feed pump; and also comprises a coal tar buffer tank, wherein the coal tar buffer tank is connected with an oil slurry feeding pump, the oil slurry feeding pump is connected with a first heating furnace, the first heating furnace is connected with a hydrogen heating furnace, and the hydrogen heating furnace is connected with the first suspended bed reactor; the coal tar buffer tank is also connected with a first vacuum tower, the first vacuum tower is connected with a second heating furnace, the second heating furnace is connected with a hot low-pressure separator, the first suspended bed reactor is connected with a second suspended bed reactor, an outlet of the second suspended bed reactor is connected with a hot high-pressure separator, and the hot high-pressure separator is connected with a cyclone separator and a hot medium-pressure separator; the cyclone separator is connected with the fixed bed reactor. The process is short in technological process, high in conversion rate and light oil yield and low in energy consumption, the interior of the reactor and a feeding and mixing system are not prone to being blocked, and a pressure reduction system is not prone to being abraded.

Owner:YANAN UNIV

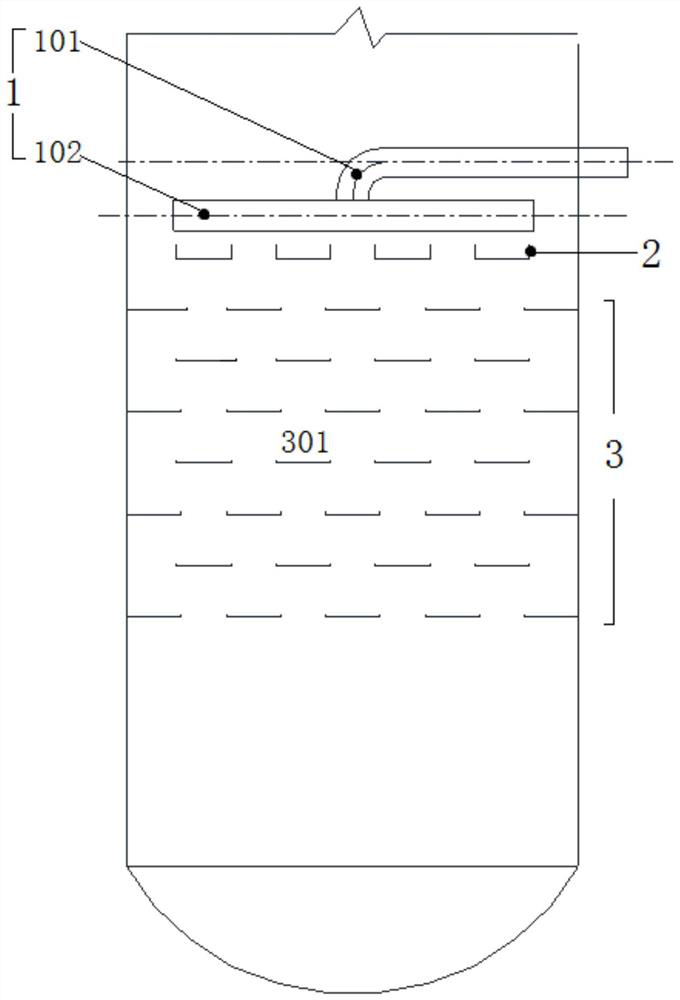

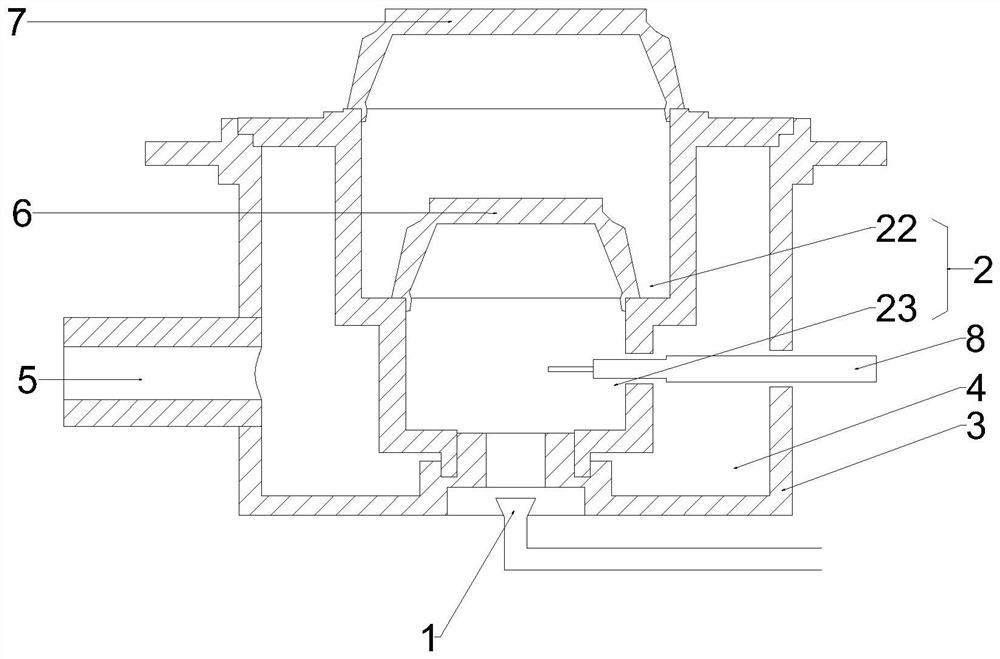

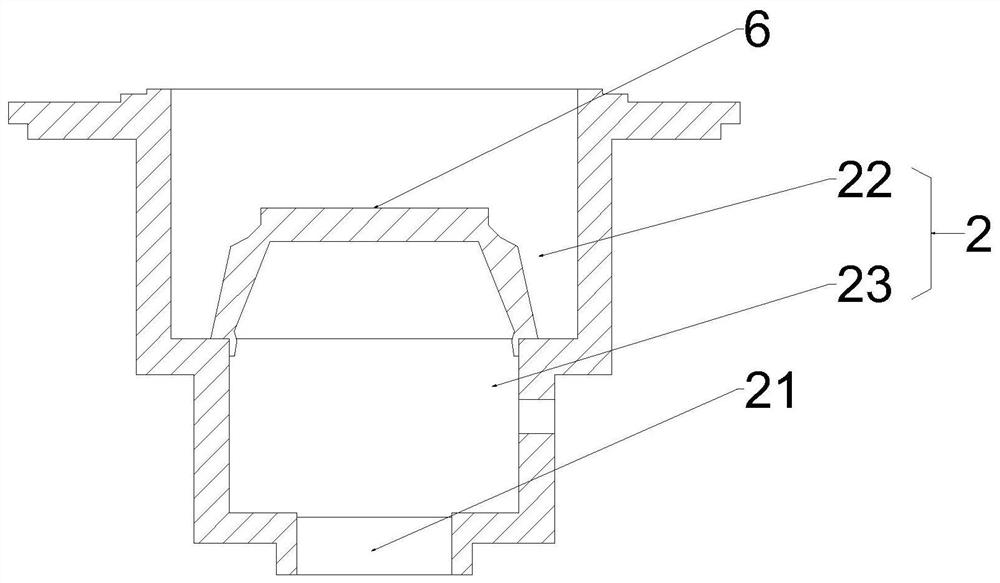

Gas-phase naphthalene feeder of phthalic anhydride device

The invention provides a gas-phase naphthalene feeder of a phthalic anhydride device. The gas-phase naphthalene feeder of the phthalic anhydride device comprises a feeding pipe (1), an outer sleeve (2) and a Venturi mixer (3); the outer sleeve (2) is fixedly connected onto the outer wall of the Venturi mixer (3); the feeding pipe (1) is sleeved in the outer sleeve (2), and one end the feeding pipe(1) stretches out of the outer sleeve (2) and enters the Venturi mixer (3); the end portion of one end, located in the Venturi mixer (3), of the feeding pipe (1) is sealed; long-strip holes (4) are formed in a part, located in the Venturi mixer (3), of the feeding pipe (1); the openings of the long-strip holes (4) face towards the low-pressure area of the Venturi mixer (3). According to the gas-phase naphthalene feeder of the phthalic anhydride device, uniform mixing of gas-phase naphthalene and air can be ensured; the reaction efficiency can be improved while the stability and safety of an oxidation reaction are improved; the product quality is improved; the oxidation yield is improved.

Owner:邢台旭阳化工有限公司

A scraped rectification tower for refining adiponitrile and adiponitrile refining process

ActiveCN103977591BAvoid entrainmentAvoid cloggingCarboxylic acid nitrile purification/separationFractional distillationForeign matterFluid phase

The invention provides a scraper rectifying column and process for refining adiponitrile. The scraper rectifying column comprises a column body and a liquid blanking pipe, as well as a scraper evaporator, a material circulating hole, a liquid phase outlet and a circulating pump, wherein the tower body internally comprises a filler layer and a plate type layer; the scraper evaporator is mounted at the outer part of the column body in a sealing manner and below the last column plate of the plate type layer; the material circulating hole is formed in the plate type layer and outside the column body; the liquid phase outlet connected with the material circulating hole through the circulating pump is formed in the bottom part of the tower body. The scraper rectifying column and process for refining adiponitrile have the beneficial effects that a special column structure is adopted, adiponitrile is separated from other dissolved foreign matters by adopting a crystal separation method, and thus the adiponitrile product can be recovered to the maximum while high-purity adiponitrile products are obtained, the problem of coking and blocking at the bottom part of a traditional rectifying column can be effectively solved, the purity of the product is improved, and the adiponitrile products can be recovered to the maximum.

Owner:CHINA TIANCHEN ENG +2

Vacuum tower for waste lubricating oil pretreatment

PendingCN108251152ASolve easy cokingAchieve rectification effectLubricating oils distillationHydrocarbon oils treatmentSprayerFractionation

The invention provides a vacuum tower for waste lubricating oil pretreatment. The vacuum tower is of a cylinder vertical structure; a tower tray is not arranged in the vacuum tower; a tower skirt, a feeding port, a baffle, an over-vaporized oil production section, a distillate oil production section, a diesel production section and a gas outlet are formed in the vacuum tower; two packing sectionscan be arranged among the diesel production section, the distillate oil production section and the over-vaporized oil production section according to the difficulty of separation of distillate oil ineach of the production sections; further, backflow spray distributors are respectively arranged on the three oil production sections and the packing sections. According to the vacuum tower in the scheme of the invention, the tower tray and fillers are directly replaced by utilizing a sprayer, the pressure drop is reduced in a manner of spray fractionation, the separation effect is good, and the process is simple, convenient and practical; moreover, according to the fraction separation difficulty, whether the fillers are provided or not can be freely selected, the heat and mass transfer efficiency is enhanced, and flexible and variable effects are realized, Importantly, the technical scheme of the invention solves the problem of influence on continuous production due to coking in all positions in the vacuum tower.

Owner:深圳至诚环境科技有限公司

Tower internal component for fractionating tower

PendingCN113117367AIncrease the itineraryExtend the stroke so that the gas-liquid contact areaFractional distillationPtru catalystFractionating column

The invention discloses an internal component for a fractionating tower, and belongs to the field of petroleum equipment. The tower internal component comprises a fluid distribution pipe, fluid distribution grooves and a baffle mechanism which are sequentially distributed at intervals from top to bottom; the baffle mechanism comprises at least three layers which are arranged at intervals from top to bottom, adjacent upper and lower layers of baffles are arranged in a staggered mode, each layer of baffles comprises a plurality of baffles arranged at intervals, and the distance between every two adjacent baffles in the same layer of baffles is smaller than the width of the baffles; the fluid distribution pipe is used for distributing fluid into the fluid distribution groove; the fluid distribution grooves are used for distributing fluid to the topmost baffle of the baffle mechanism, the multiple fluid distribution grooves are arranged at intervals, and a balance groove is formed between every two adjacent fluid distribution grooves and used for enabling the liquid levels of the multiple fluid distribution grooves to be consistent. The tower internal component can obviously increase the gas-liquid contact area, is beneficial to enhancing the heat and mass transfer effect, prevents oil gas from coking and blocking, reduces the gas resistance drop, and obviously improves the washing effect of catalyst powder.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

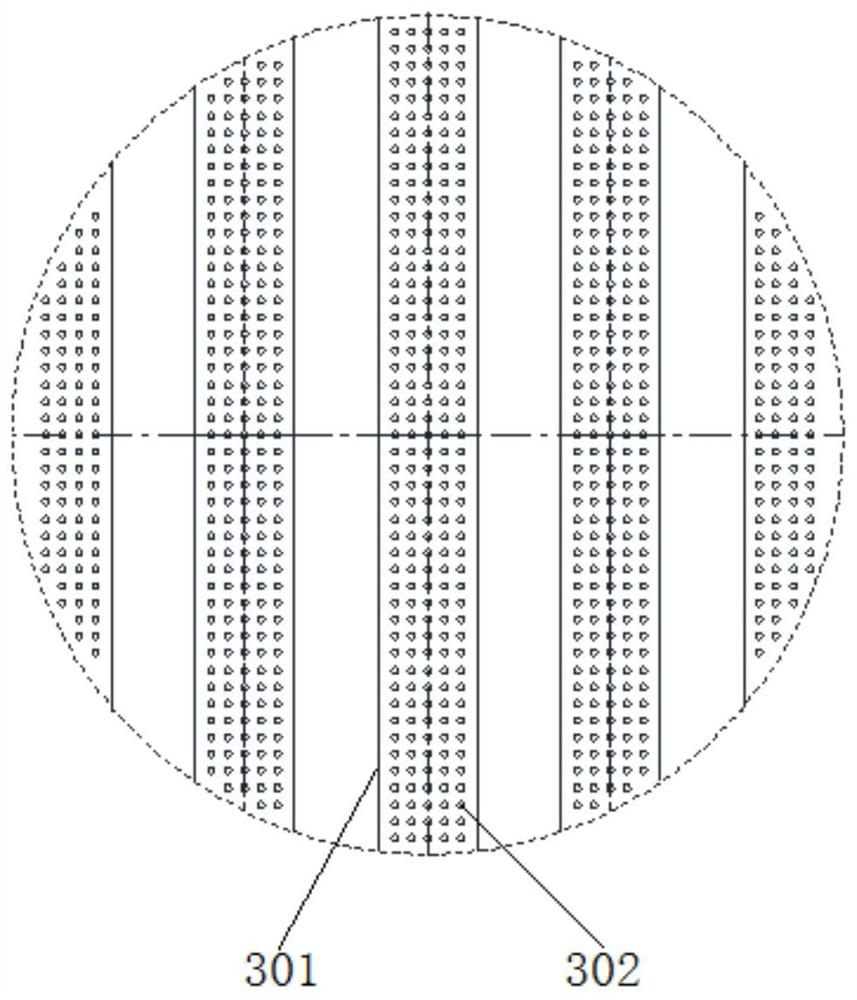

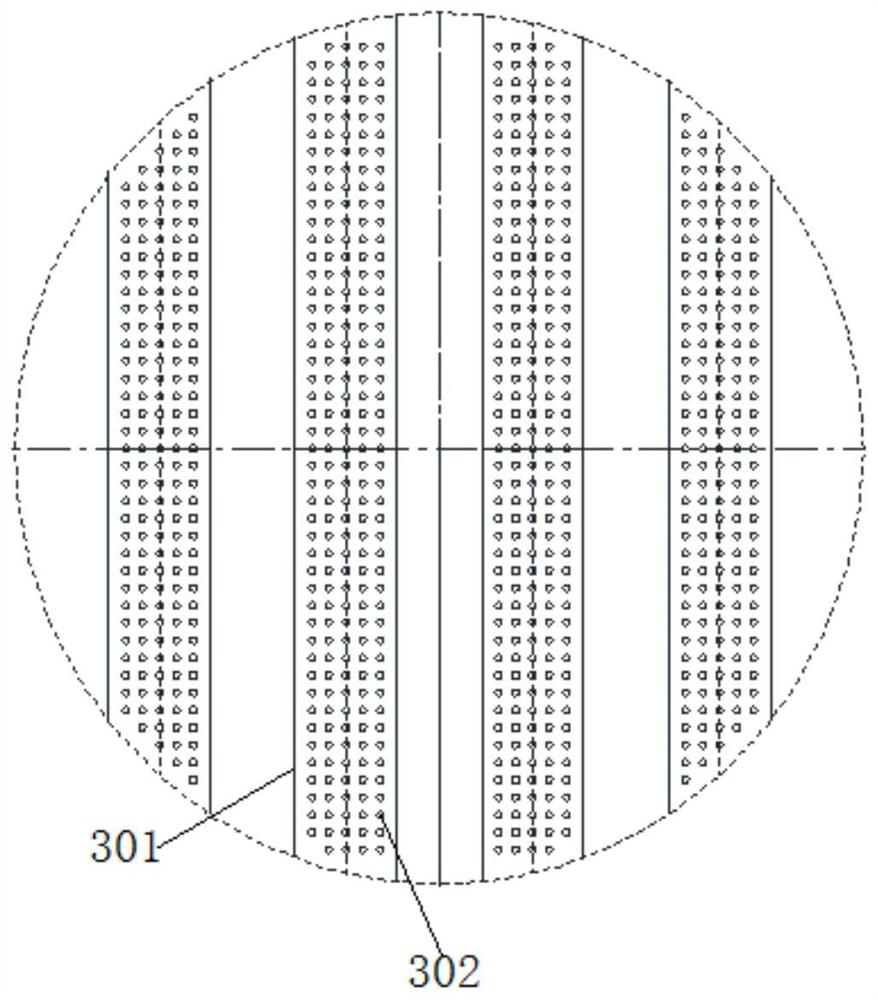

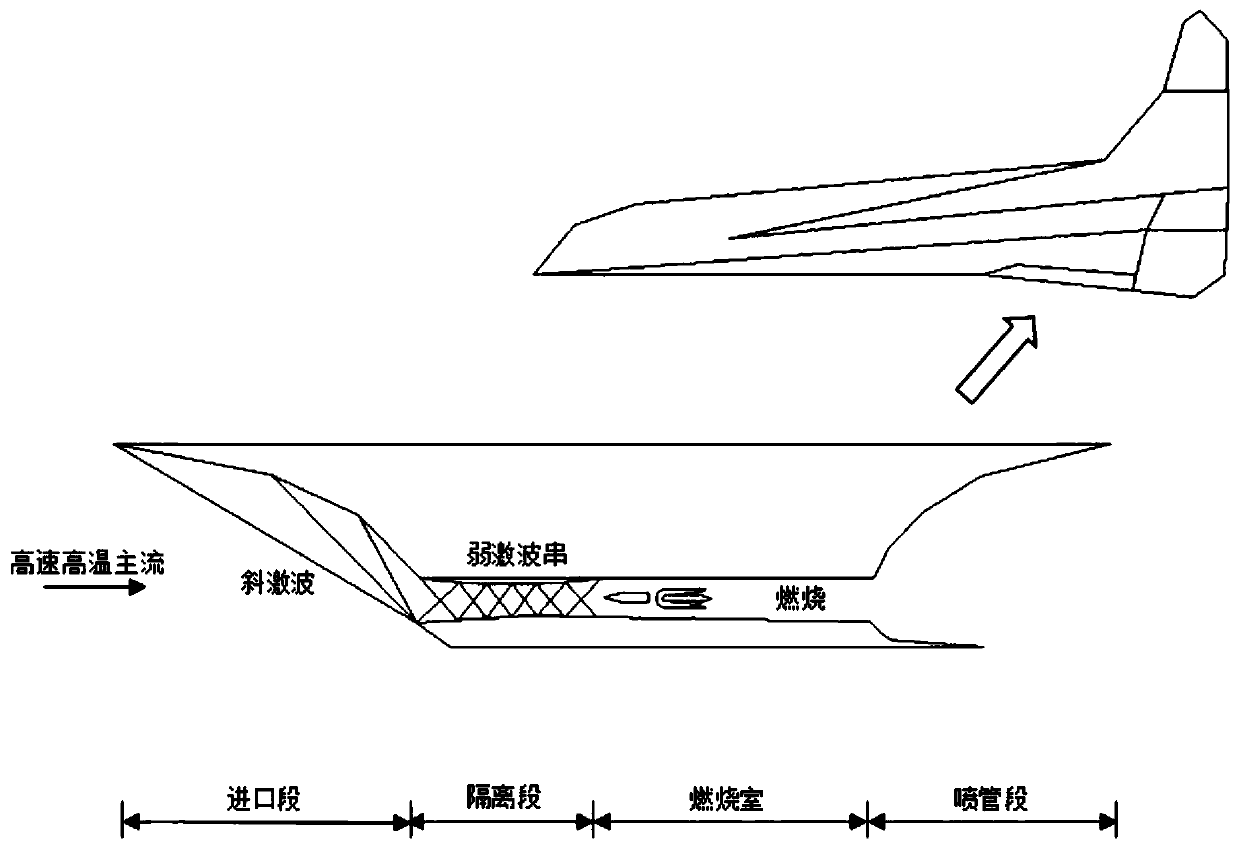

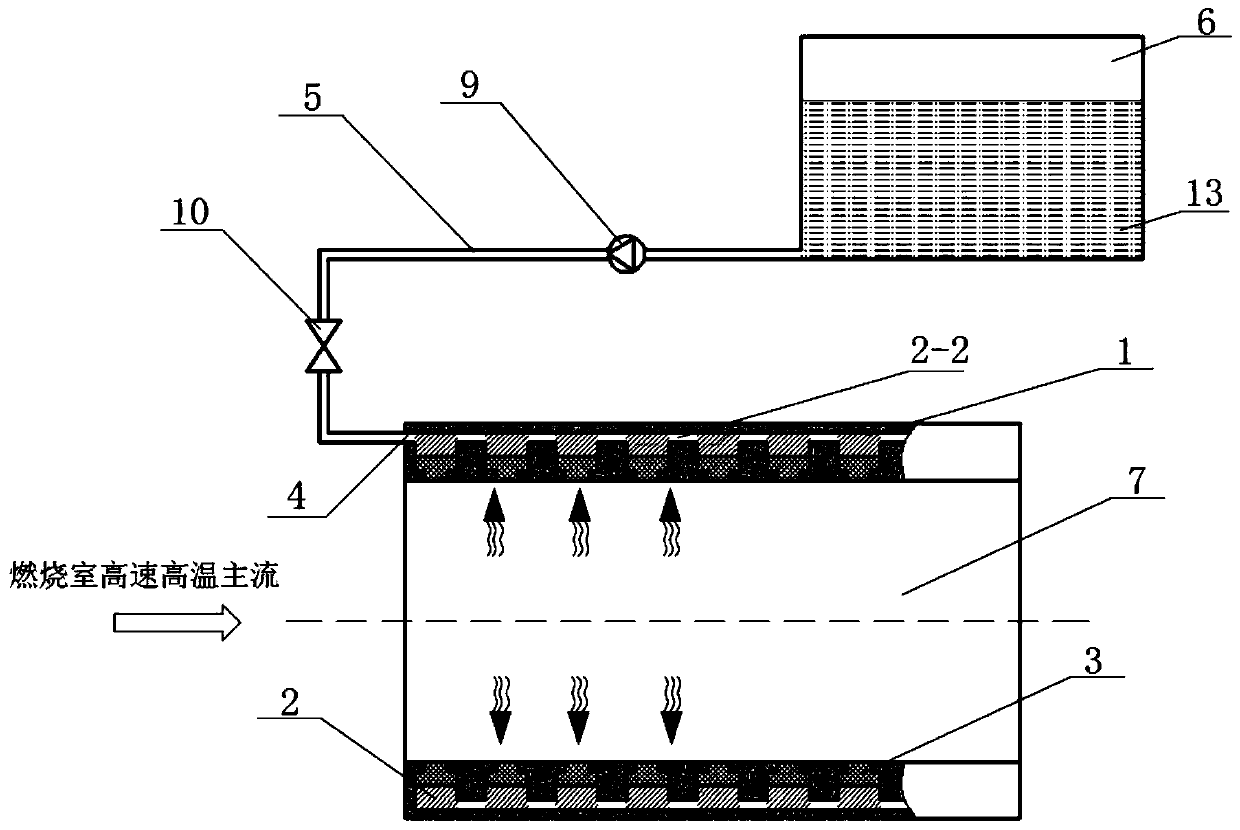

Combustion chamber heat protection wall structure using fuel self-suction sweat cooling

ActiveCN110566999BRealize adaptive adjustmentAchieve recyclingContinuous combustion chamberCombustion chamberFuel tank

Owner:TSINGHUA UNIV

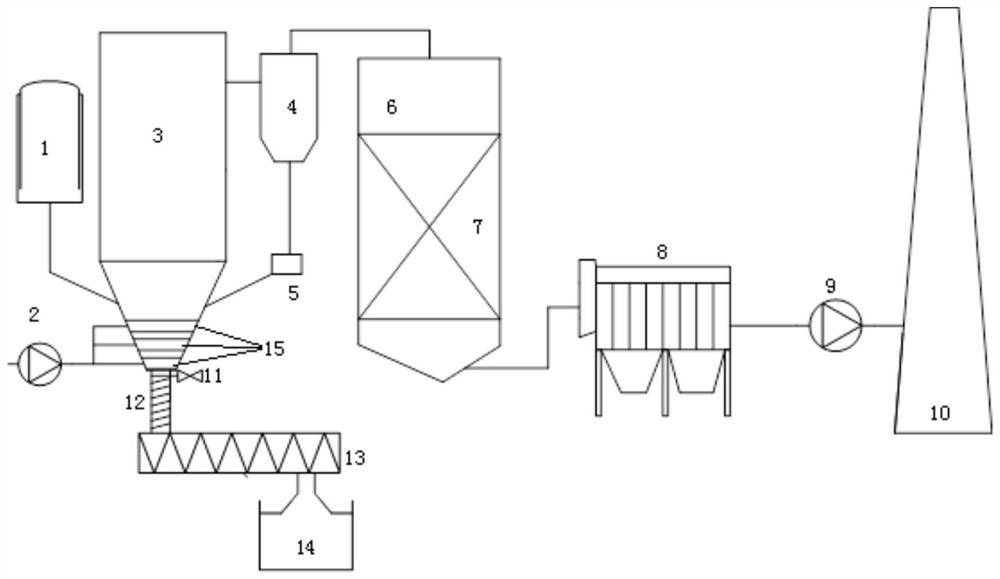

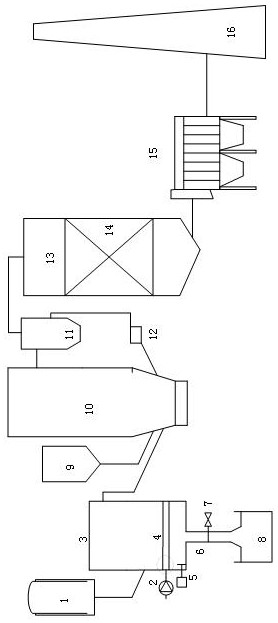

Fluidized bed industrial solid waste incinerator adopting tubular air distribution and working method thereof

PendingCN112146103AAvoid coke cloggingImprove running stabilityFluidized bed combustionIncinerator apparatusSlagFlue

The invention discloses a fluidized bed industrial solid waste incinerator adopting tubular air distribution and a working method thereof, and belongs to the technical field of solid waste disposal. The lower part of a furnace body is a conical section, a solid waste inlet and a material returning inlet are formed in the conical section, the solid waste inlet is connected with a feeding system, and the material returning inlet is connected with a material returning device; a smoke outlet is formed in the upper portion of the furnace body and connected with a separation device, a bottom outletof the separation device is connected with the material returning device, and an upper outlet of the separation device is connected to a tail flue; a bottom slag outlet in the bottom of the conical section is connected with a slag falling pipe and is provided with a slag discharging valve; a plurality of layers of fluidization air distribution pipes are arranged in the conical section and are connected with a fluidization air system; gaps for slag falling are reserved between the adjacent fluidization air distribution pipes and between the fluidization air distribution pipes and the wall surface of the conical section; and a plurality of air outlet holes are formed in the fluidization air distribution pipes. The industrial solid waste incinerator is reasonable and flexible in structural design, particularly suitable for industrial solid waste disposal, high in application value and easy to industrialize.

Owner:华能长江环保科技有限公司 +1

Cyclone Biomass Powder Burner

InactiveCN103175201BSpeed up the flowSolve the blockagePulverulent fuel combustion burnersFurnace temperatureCyclone

The invention relates to a high-efficiency cyclone type biomass powder combustor used for a boiler and a kiln. The combustor is composed of a water cooling sleeve, an end cover and the like. No hole that disturbs rotational flow is arranged between two ends of a cyclone combusting chamber. Biomass powder is put into the combustion chamber through a feeding hole and dispersed and pushed by cyclone of a cyclone hole so that wall-attached combustion and floating combustion are achieved. Raging fire erupts out of a fire and air hole. Ash is pulled out from an ash outlet hole. Coal particles are carbonized to be ash in a carbonization pool. A water exiting pipe, an air exhausting pipe, a water entering pipe, a sewage draining pipe and a water temperature sensor penetrate into the water cooling sleeve. The water cooling sleeve is used for regulating furnace temperature, recycling heat and safety protection. An igniter starts a combustion process. Combustion situations are observed from a fire observation hole. A safety valve ensures safety. A furnace temperature sensor detects furnace temperature. The problems that a rotation flow field is disturbed due to blowing-in from multiple air holes, bunkers are not fully combusted; slag short out and escaping happen, residues are condensed and formed at the air holes and the problems of coal particle coking, insufficient combustion and dust pollution caused by material particles, furnace temperature, flow speed, communication of the feeding hole and the fire and air hole and the like are basically solved.

Owner:HUBEI HUABAO ECOLOGICAL ENERGY TECH CO LTD +1

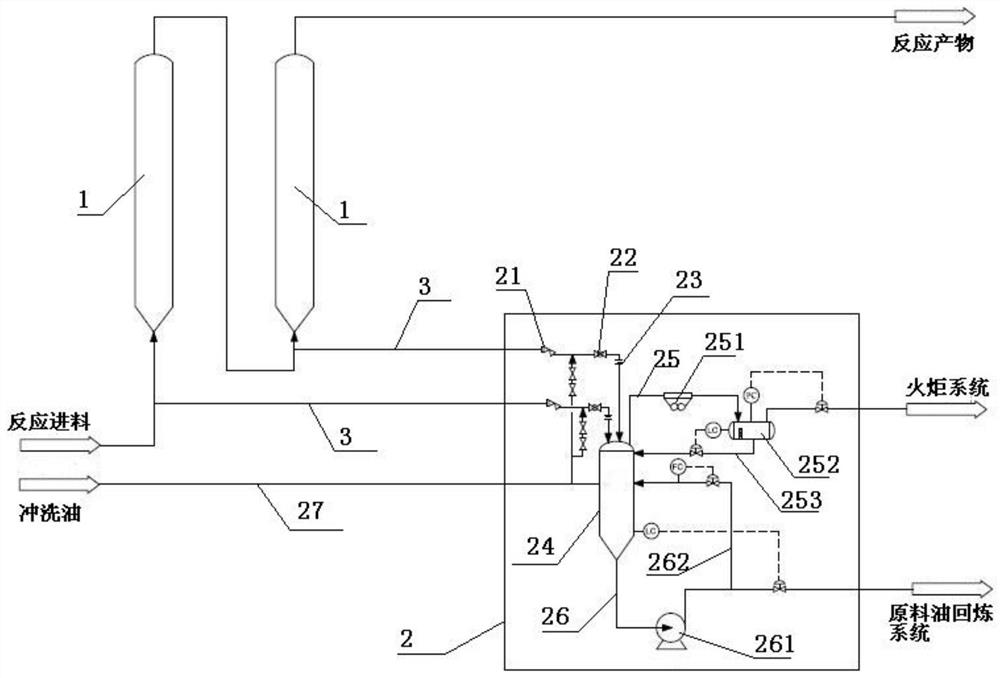

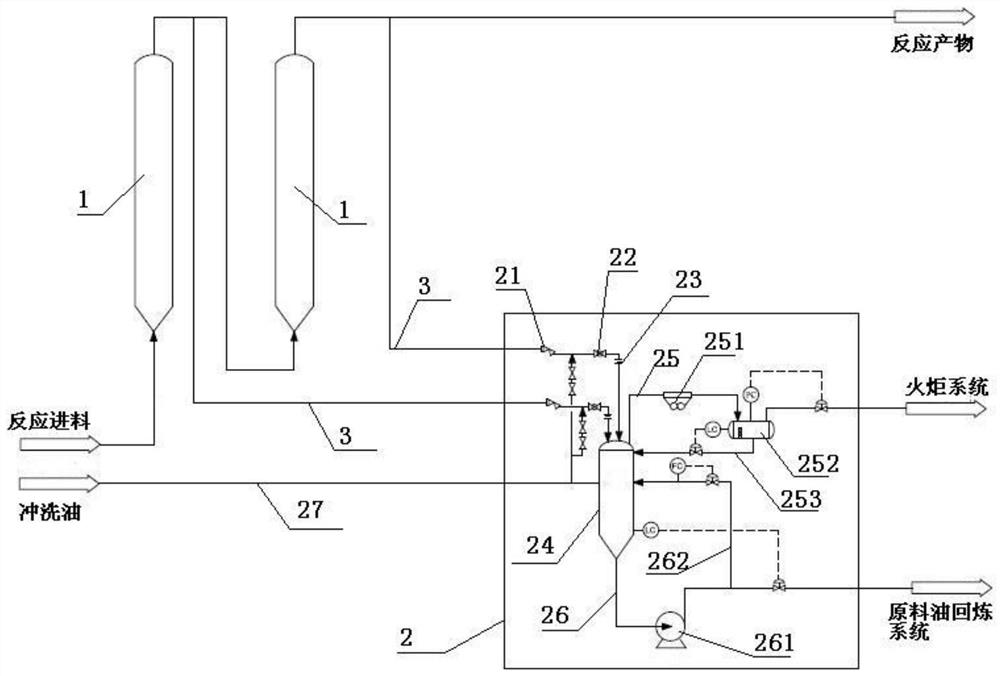

A Suspension Bed Hydrogenation Bleeding System

ActiveCN107805519BUniform densityAvoid the re-boost processHydrocarbon oil crackingChemical/physical processesFluid phaseHeat torch

The invention provides a suspended bed hydrogenation discharge system, which comprises a suspended bed hydrogenation reactor, wherein the top portion of the suspended bed hydrogenation reactor is connected to a reaction product pipeline, the bottom portion of the suspended bed hydrogenation reactor is connected to a reaction material inlet pipeline and a discharge pipeline, the discharge pipelineis connected to a cooling separation system, and the cooling separation system is respectively connected to a torch system and a raw oil recycling system. According to the present invention, the liquid phase and the catalyst solid in the suspended bed hydrogenation reactor are rapidly discharged during the emergency discharge to stop the occurrence of the reaction and ensure the uniform density ofthe reaction material in the reactor, such that the heavy component deposition phenomenon cannot occur, the thermal runaway of the suspended bed hydrogenation reactor can be avoided, the temperaturein the reactor can be effectively controlled, the safety can be improved, the pressure of the suspended bed hydrogenation reactor can be stabilized at the high pressure, the equipment fatigue caused by the frequent pressure increase and pressure reduce can be avoided, and the energy consumption and the cost can be reduced.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

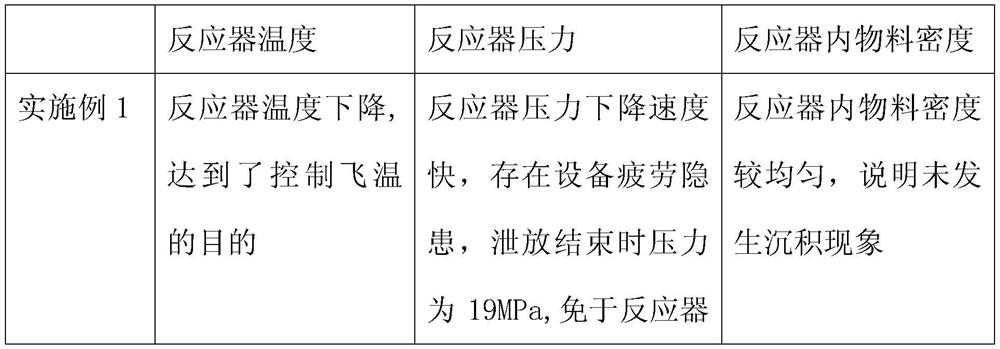

High-temperature oil pump flushing oil and instrument isolation liquid supply system and working method thereof

PendingCN111207298AGuaranteed uptimeStable flushing mediumPositive displacement pump componentsPipeline systemsOil pumpPressure detection

The invention relates to a high-temperature oil pump flushing oil and instrument isolation liquid supply system and a working method thereof. The high-temperature oil pump flushing oil and instrumentisolation liquid supply system comprises a flushing oil main loop, a flushing oil user branch and an isolation liquid user branch, wherein the flushing oil main loop is composed of a flushing oil mainpipe, a flushing oil groove, a flushing oil pump, a pressure regulating valve, a pressure transmitter I and a flow limiting hole plate I; and the flushing oil user is a high-temperature oil pump, andthe isolation liquid user is a pressure detection instrument and / or a flow detection instrument. According to the high-temperature oil pump flushing oil and instrument isolation liquid supply systemand the working method thereof, a stable flushing medium can be provided for each high-temperature oil pump, and the flushing oil is used for cooling, lubricating, sealing and flushing a mechanical seal of a pump body, so that long-term stable operation of each pump is guaranteed; meanwhile, isolation liquid can be provided for an instrument pipeline provided with the pressure detection instrumentand the flow detection instrument, so that the situation that the detection instrument cannot work normally due to the fact that the detection instrument is in direct contact with a viscous and easily-coked process medium is avoided; and on the premise that normal work of the high-temperature oil pump and the detection instrument is guaranteed, the quality of a needle coke product is not influenced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Biomass combustion device for docking boilers, heat exchangers, heating systems

InactiveCN103557516BSmall molecular weightAvoid cokingSolid fuel combustionNon-combustible gases/liquids supplyCarbonizationBiomass fuels

Biomass combustion device for docking boilers, heat exchangers, and heating systems, including the burner body, the carbonization machine used to generate the fuel required for combustion of the burner body, and the steam generator. The steam output pipe of the steam generator is connected to the combustion The furnace of the machine body is connected. After the biomass raw material is initially cracked by the carbonization machine, tar is precipitated, and the resulting biomass fuel has a low tar content, which effectively avoids coking in the furnace during the combustion process. At the same time, the use of steam to support combustion can not only help to eliminate coking, but also improve the fire temperature of the combustion flame, the biomass fuel rate and the calorific value. The present invention organically combines the carbonization machine, the steam generator and the burner itself to improve Traditional biomass burners have problems such as low combustion rate, easy coking, low work efficiency and unstable operation. In addition to being used for docking boilers, heat exchangers, and heating systems, the present invention can also be applied to other equipment or systems that use open flame heating, such as large thermal motors.

Owner:黎明 +1

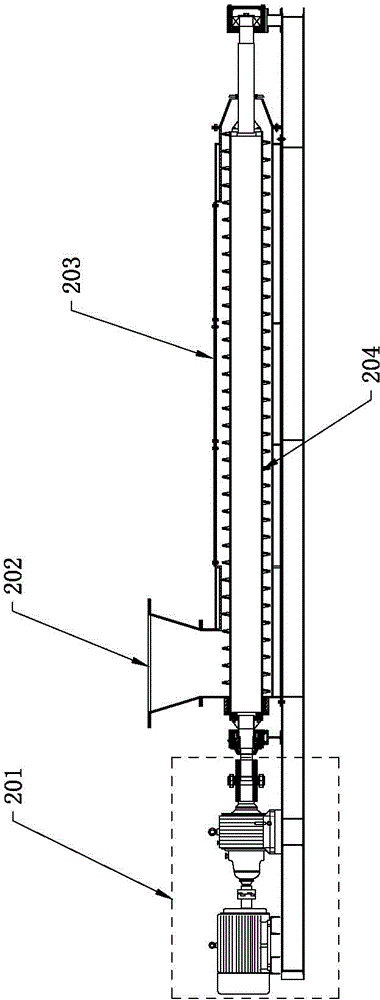

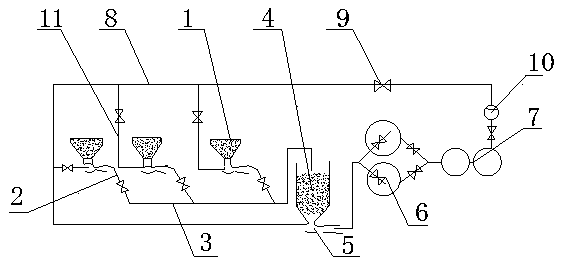

Pebble coal collecting system

InactiveCN104340684AAvoid coke cloggingImprove work efficiencyBulk conveyorsGrain treatmentsHigh pressureCoal

The invention discloses a pebble coal collecting system. The pebble coal collecting system is characterized in that the pebble coal collecting system comprises a plurality of water seal pebble coal buckets, material outlets of the water seal pebble coal buckets are connected with a main conveying pipeline respectively through branch pipelines, the tail end of the main conveying pipeline is connected with a pebble coal collecting bin, a hydraulic ejector is arranged at the bottom of the pebble coal collecting bin, a dewatering bin is disposed in rear of the pebble coal collecting bin, a water purifying treatment and storage device is arranged in rear of the dewatering bin, the water purifying treatment and storage device is connected with a main water pipeline, a valve and a high-pressure pump are disposed on the main water pipeline, and branch water pipelines which are connected with the water seal pebble coal buckets respectively are disposed on the main water pipeline. The pebble coal collecting system has the advantages that the structure is reasonable, pipe blockage is not prone to occur, and water consumption is small.

Owner:JIANGSU AEROSPACE ELECTRIC

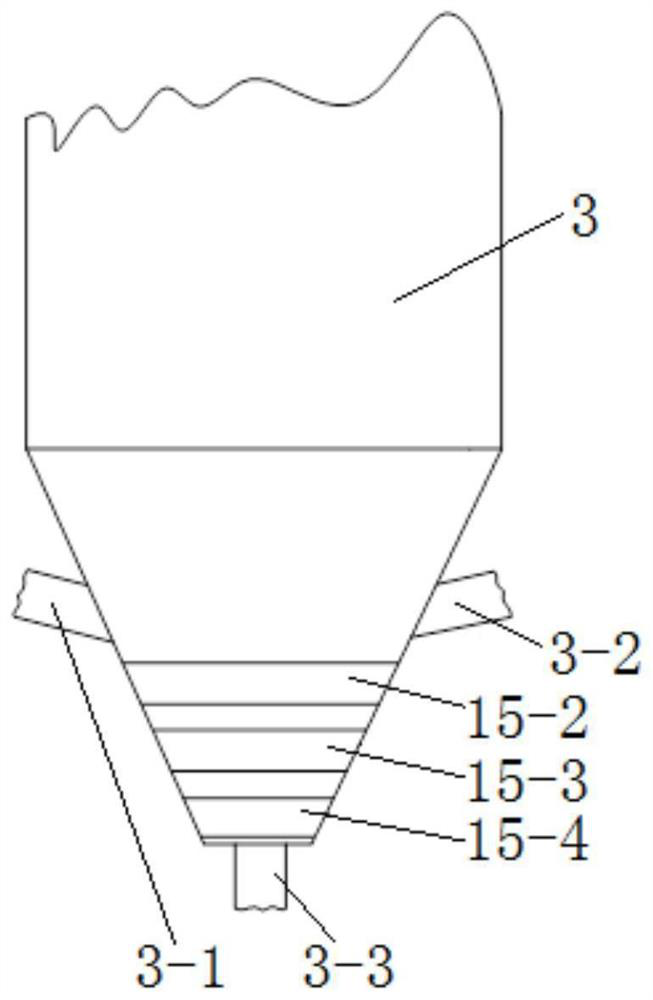

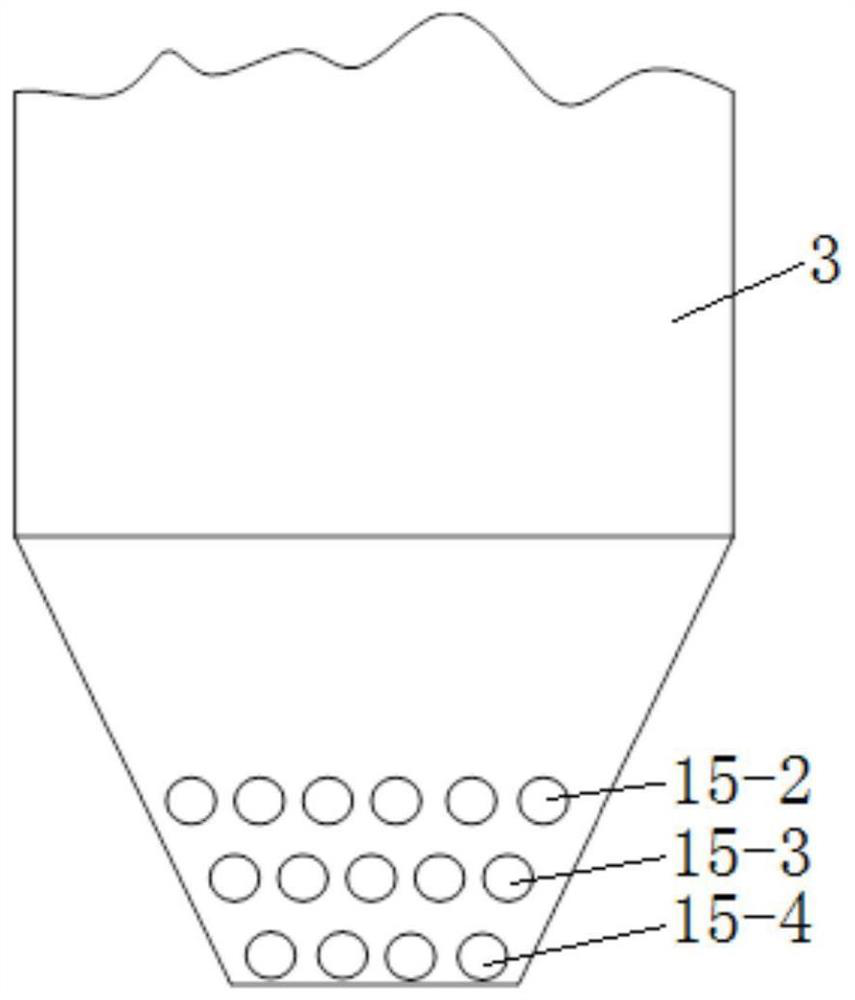

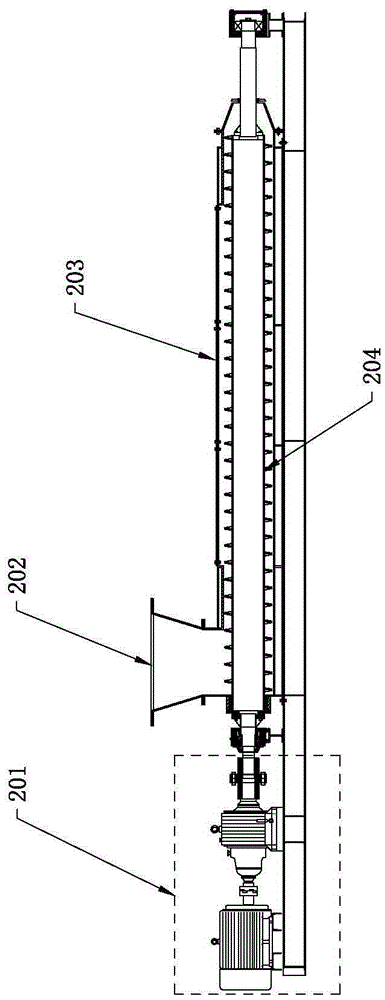

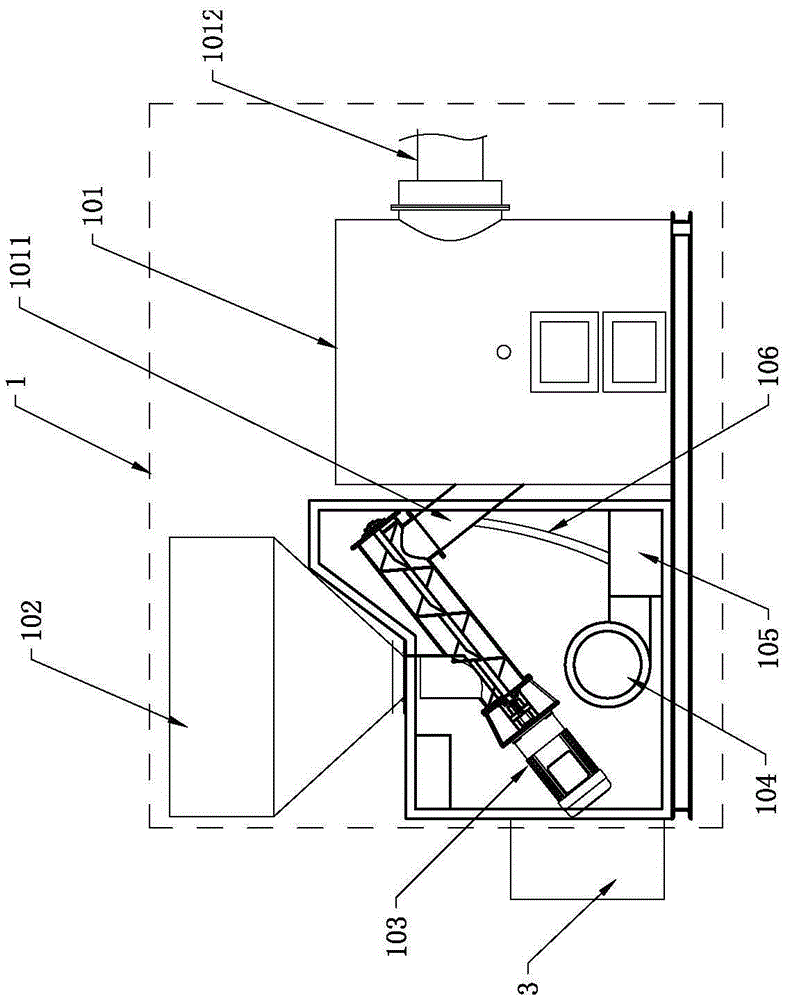

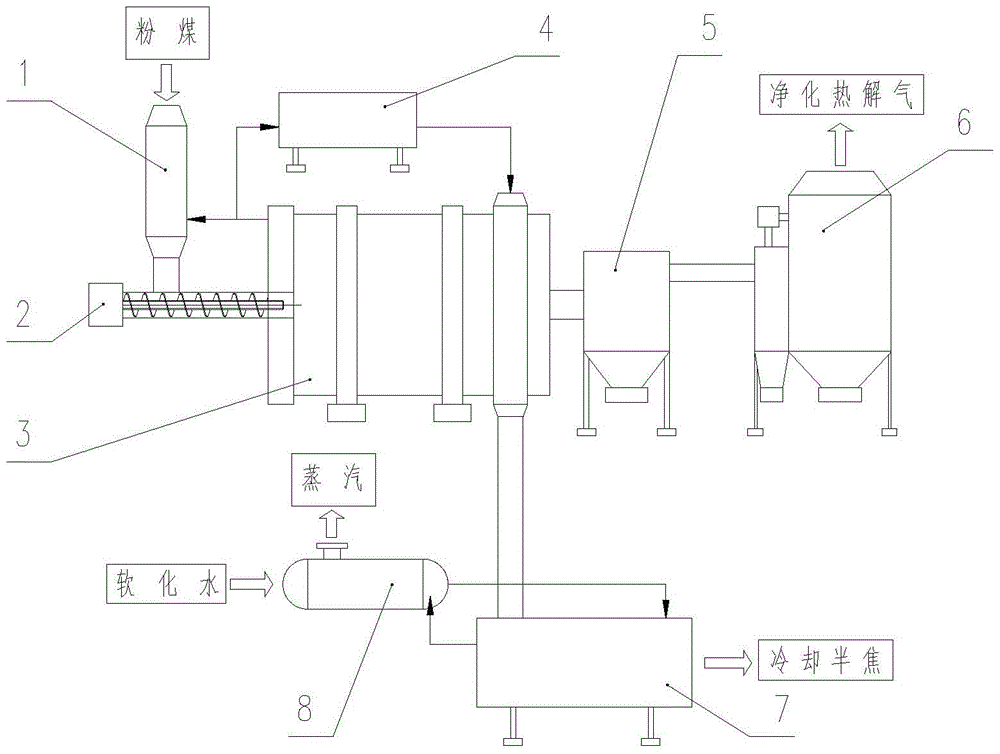

A large-scale low-rank pulverized coal low-temperature pyrolysis device and method

ActiveCN104593026BHigh content of active ingredientsHigh calorific valueEnergy inputSpecial form destructive distillationProduction lineSteam drum

The invention discloses a device and method for large-scale low-temperature pyrolysis of low-rank coal powder. A discharge opening of a vertical preheater is connected with a feed screw; the feed screw is connected with a pyrolysis kiln; a pyrolysis gas outlet of the pyrolysis kiln is connected with a settling connection box; the settling connection box is connected with a high-temperature filter device; a semicoke outlet of the pyrolysis kiln is connected with a semicoke cooling and waste heat recovering device; a steam outlet of the semicoke cooling and waste heat recovering device is connected with a steam pocket; an air outlet of a hot air heating furnace is connected with an air inlet of the pyrolysis kiln; and an exhaust outlet of the pyrolysis kiln is connected with an air inlet of the vertical preheater and an air inlet of the hot air heating furnace. The device is simple in system constitution, reasonable in technological structure, suitable for construction of a large-scale pyrolysis and deep processing production line and high in economic efficiency and environmental protection property.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

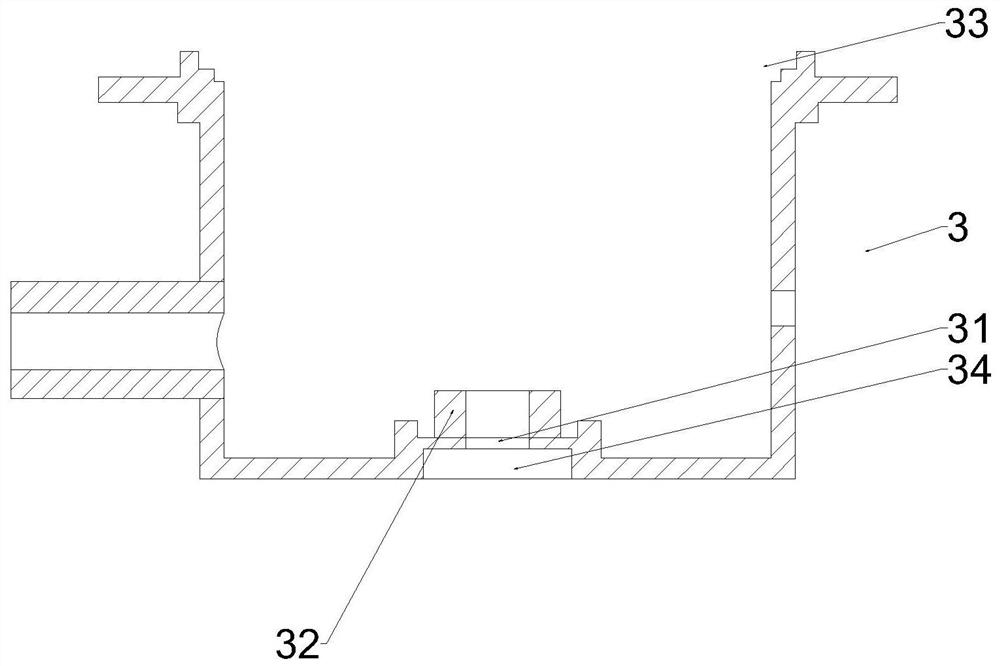

Separation device and separation method for preventing coking at bottom of catalytic depropanization tower

PendingCN113354504AAvoid coke cloggingReduce energy consumptionDistillation purification/separationThermodynamicsReboiler

The invention provides a separation device for preventing coking at the bottom of a catalytic depropanization tower. The device comprises a depropanization tower, an inlet pipeline is arranged in the middle of the depropanization tower, a tower top gas phase delivery pipeline is arranged at the top of the depropanization tower, and a tower top condensation mechanism and a tower top reflux tank are sequentially arranged on the tower top gas phase delivery pipeline along the gas phase flowing direction. According to the invention, a low-pressure depropanization process is adopted for separation, so that the operation temperature of the tower bottom is effectively reduced, the problem of coking and blocking at the bottom of the depropanization tower is fundamentally solved, and reduction of the processing load and non-planned shutdown of a catalytic gas separation device caused by the coking and blocking at the bottom of the depropanization tower are avoided; the temperature of the tower bottom is low, and a reboiler at the tower bottom can adopt hot water of 80-95 DEG C in a factory, waste heat of low-temperature process materials or low-pressure steam is used as a heat source, so that the steam consumption at the tower bottom of the depropanizing tower is saved, and the energy consumption of the device is reduced.

Owner:BEIJING OUYIDE TECH +2

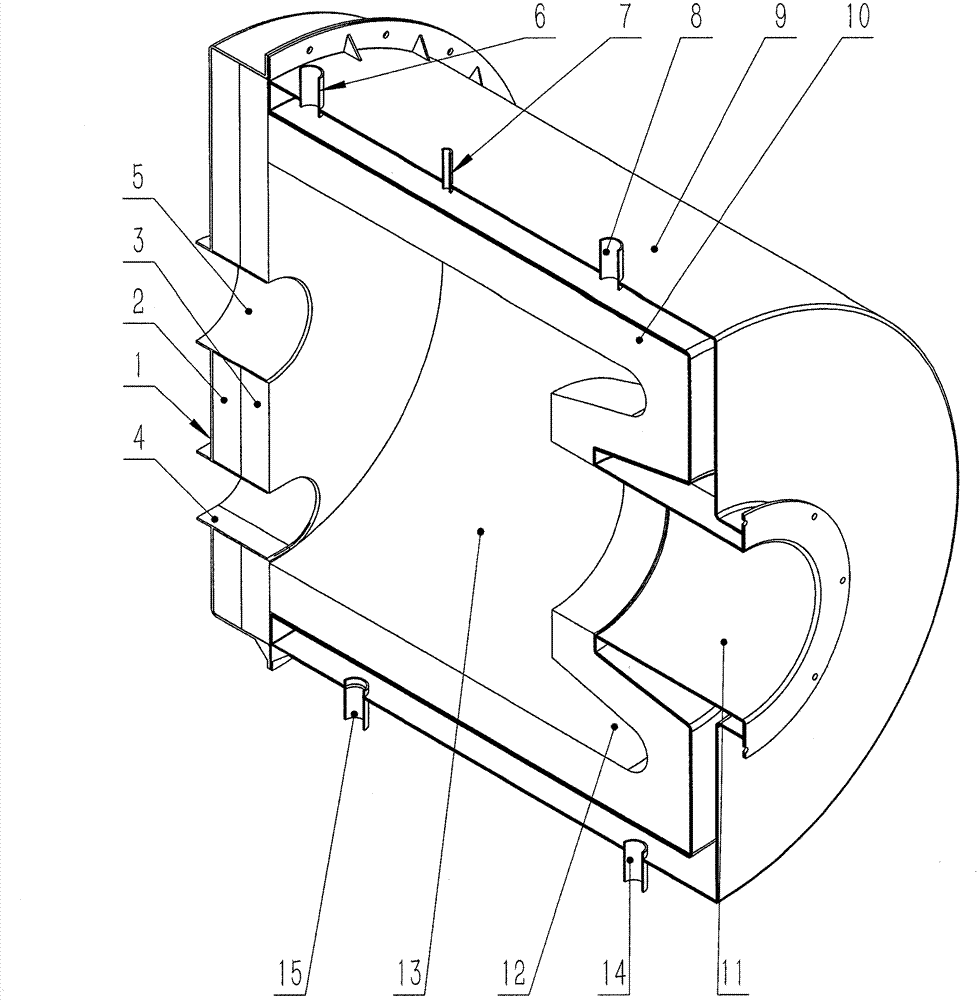

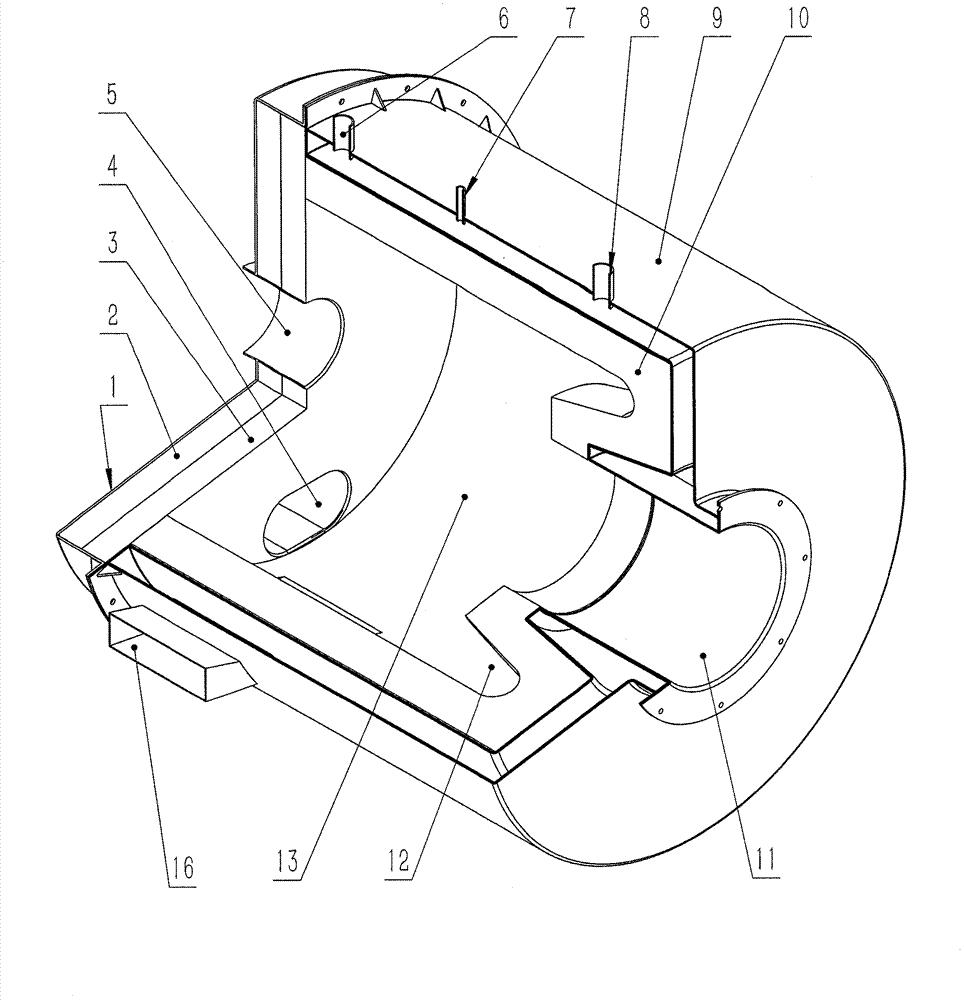

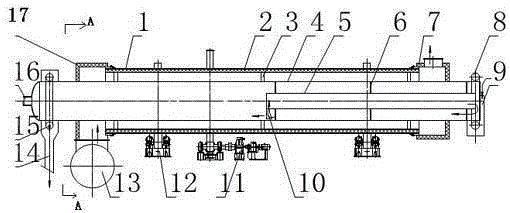

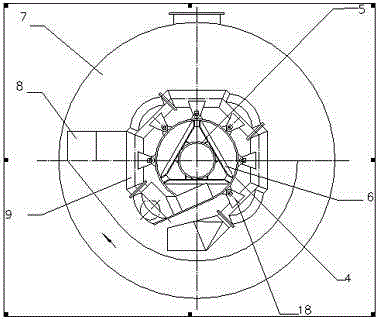

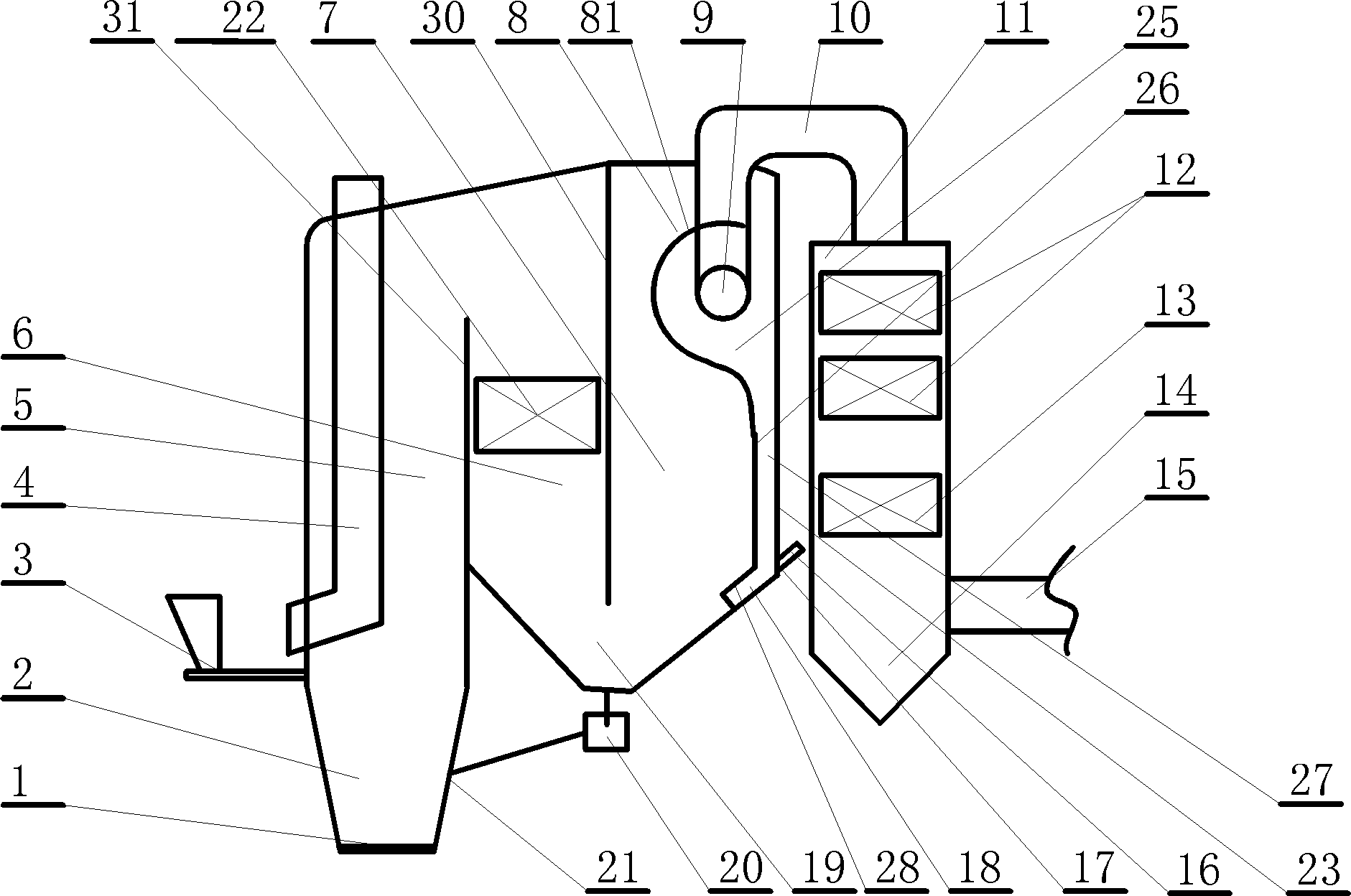

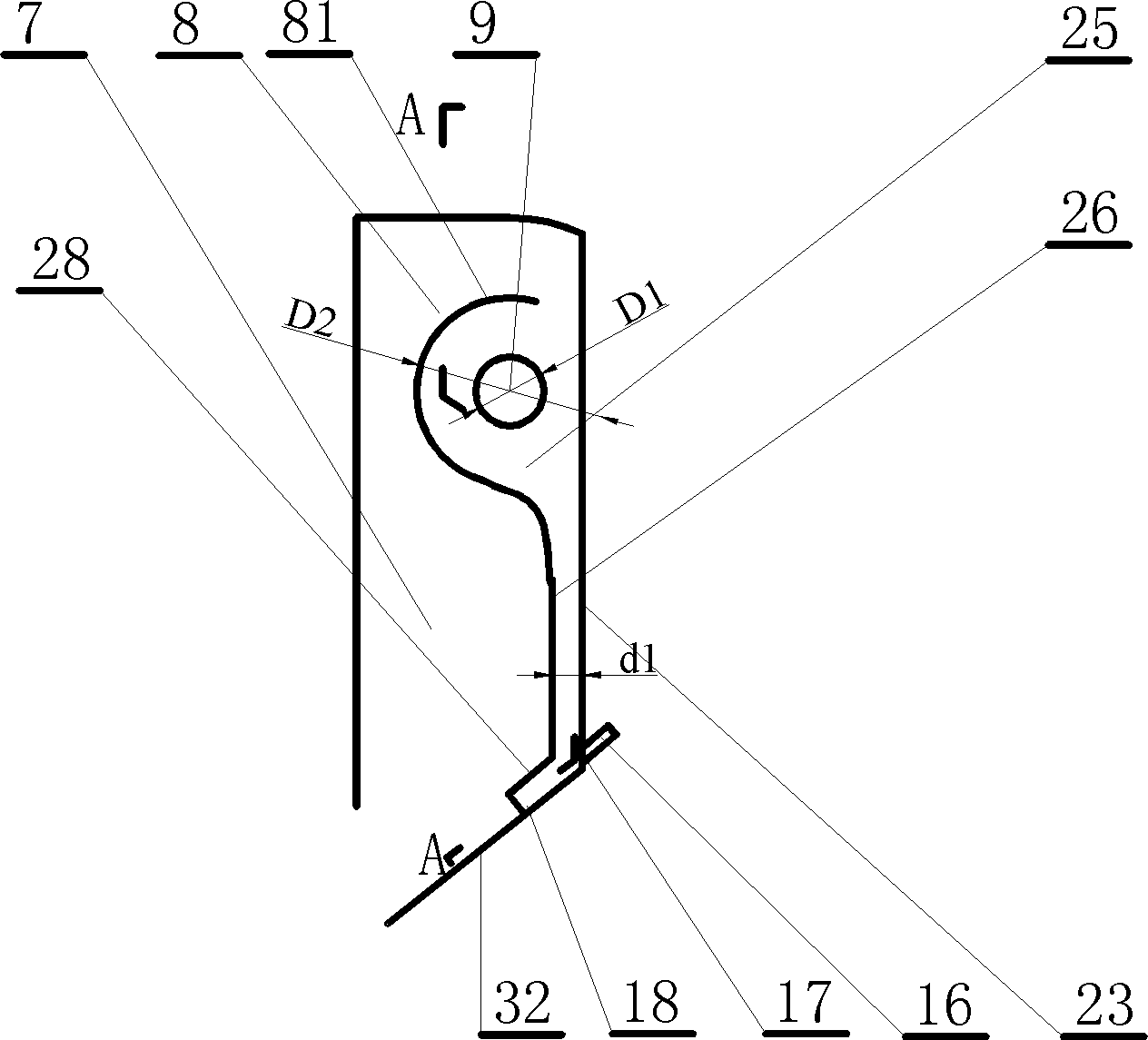

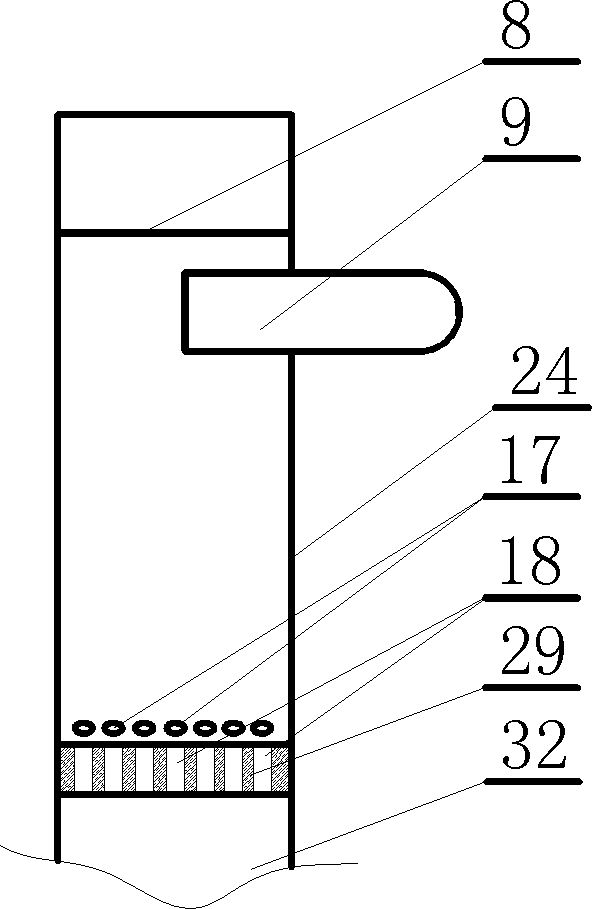

Horizontal type circulating fluidized bed boiler with horizontal cyclone separator

ActiveCN102537943BLow costReduce construction costsFluidized bed combustionApparatus for fluidised bed combustionCycloneCombustion chamber

A horizontal type circulating fluidized bed boiler with a horizontal cyclone separator comprises a main combustion chamber, a secondary combustion chamber (6), a burnout chamber (7) and a tail gas flue (11). A horizontal cyclone separator (25) is provided in the burnout chamber (7). An outer cylinder of the horizontal cyclone separator (25) is defined by a separator spacer (8), a burnout chamber rear water-cooled wall (23) and a burnout chamber side water-cooled wall (24). The separator spacer (8) is formed by a separator upper circular-arc section (81), a separator spacer lower vertical section (26) and a separator spacer inclined section (28). A middle cylinder (9) of the horizontal cyclone separator is inserted into the burnout chamber (7) from two sides or one side of the burnout chamber side water-cooled wall (24). The separator spacer lower vertical section (26), the burnout chamber rear water-cooled wall (23) and the burnout chamber side water-cooled wall (24) define a material returning channel (27). An aeration air nozzle (17) is provided at a lower part of the burnout chamber rear water-cooled wall (23). A V-shaped ash hopper wall (32), a material chute baffle plate (29), the separator spacer inclined section (28) and the burnout chamber side water-cooled wall (24) define a material chute (18). The aeration air nozzle (17) and the material chute (18) face each other in line arrangement. The horizontal type circulating fluidized bed boiler is particularly suitable for fluidized combustion of fuels like biomass with low ash content and coal gangue with high ash content.

Owner:TSINGHUA UNIV +1

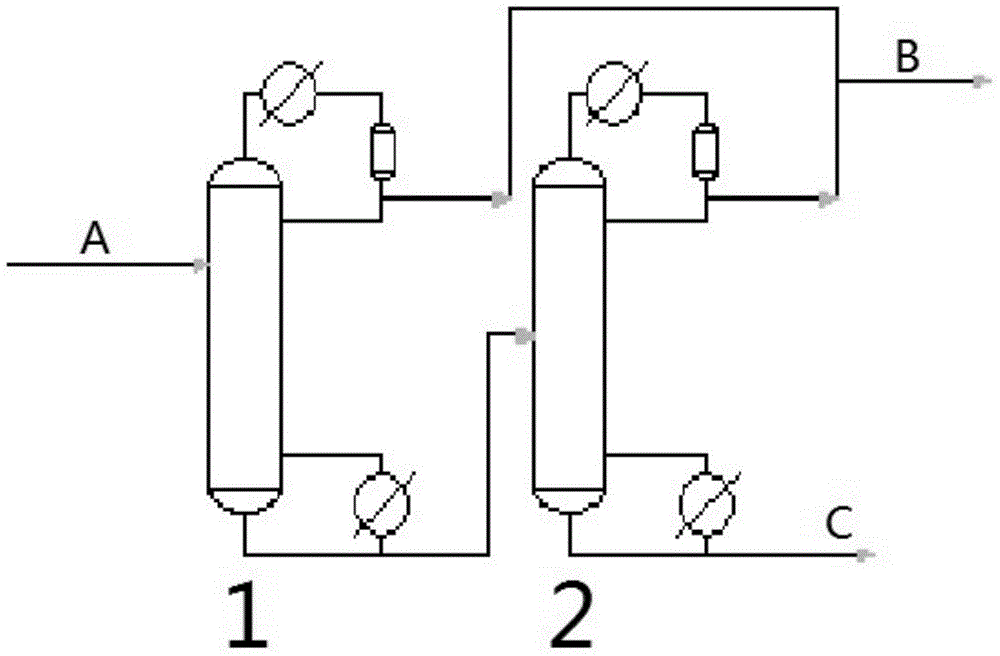

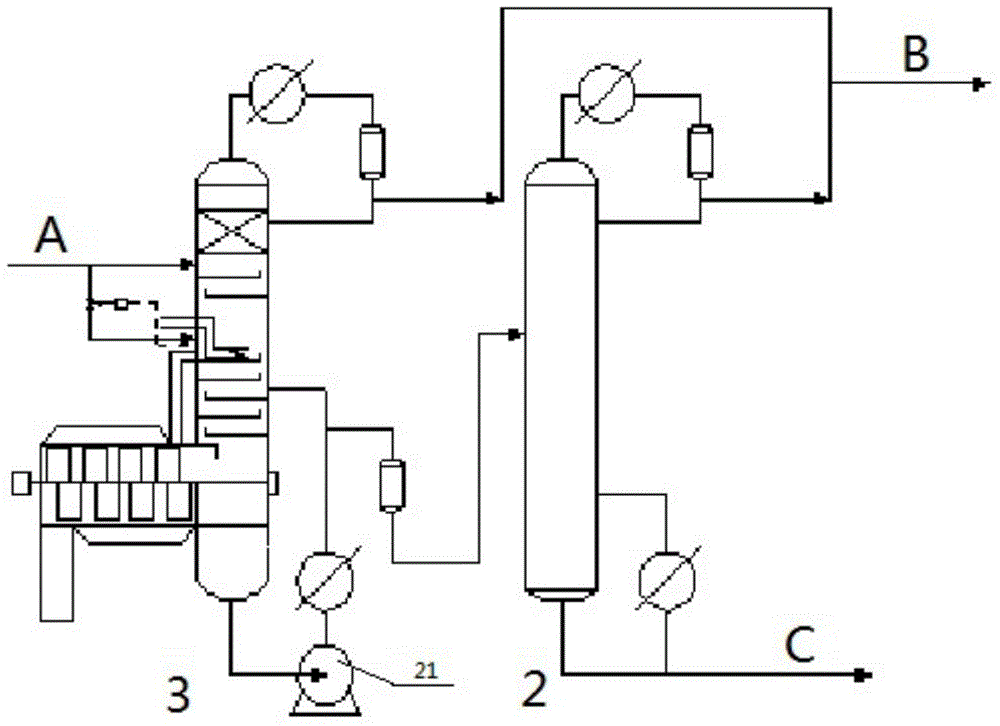

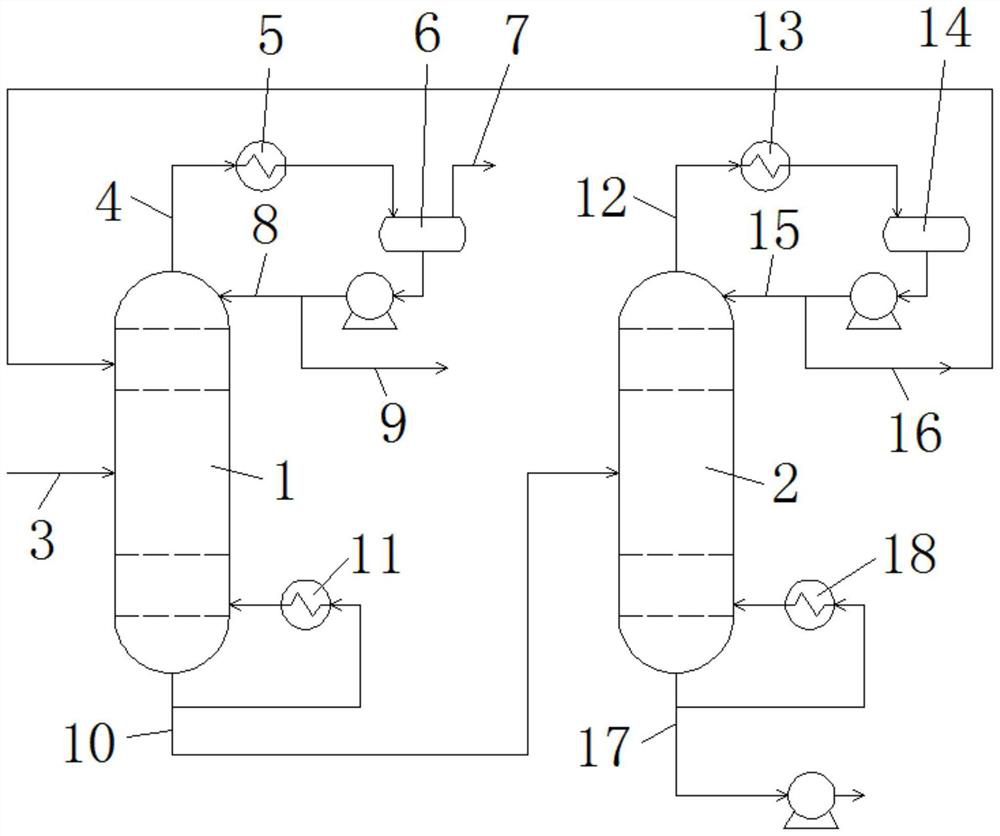

A delayed coking process for preparing coal-based needle coke

ActiveCN109370642BAccurately control the degree of coking reactionAvoid coke cloggingTreatment with plural serial stages onlyCoking carbonaceous materialsThermodynamicsCoke

The invention belongs to the technical field of needle coke preparation, and relates to a delayed coking process for preparing coal-based needle coke, in particular to a multi-tower delayed coking process with a heat polycondensation tower and a coking tower. The technical scheme includes that the coking process includes the steps: pretreating coal tar, coal pitch, modified pitch and the like to obtain finished raw materials; heating the finished raw materials, and enabling the heated raw material to enter a heat polymerization tower; polymerizing the raw materials to generate an intermediatephase in the inertness or reduction atmosphere; rapidly heating materials containing the intermediate phase and inert oil when the content of the intermediate phase of the materials reaches 30-60%; conveying the heated mixture into the coking tower to generate coke, and calcining the coke to obtain the needle coke. High-temperature oil and gas of the coking tower is divided into fuel gas and coking oil by a fractionating tower, the coking tower serves as a product output system, the process can accurately control coking reaction degree of coal-based needle coke raw materials, coking and jamming of a device pipeline are avoided, and long-period stable operation of coal-based needle coke production is achieved.

Owner:山西中科化美科技有限责任公司

Winnowing impurity removal and incineration disposal device for industrial solid waste

PendingCN113932222AAchieve separationAvoid coke cloggingGas current separationIncinerator apparatusFlueCoal

The invention discloses a winnowing impurity removal and incineration disposal device for industrial solid waste. The problems that at present, no mature solid waste coupling incineration boiler can realize long-period treatment operation of industrial solid wastes, and the solid wastes are prone to being coked due to metal impurities are solved. The winnowing impurity removal and incineration disposal device comprises a solid waste bin (1), an air separator (3), a coal bucket (9), a fluidized bed incinerator (10), a cyclone separator (11), a material returning device (12), a flue vertical shaft (13), a dust remover (15) and a chimney (16). The solid waste bin is connected with a solid waste inlet in the lower part of the air separator; a gas-solid outlet of the air separator is connected with a solid waste inlet of the lower conical section of the fluidized bed incinerator; and a smoke outlet in the upper part of the fluidized bed incinerator is connected with a smoke inlet of the cyclone separator, a coarse ash outlet is formed in the bottom of the cyclone separator and connected with an inlet of the material returning device, and an outlet of the material returning device is connected with a material returning opening formed in the lower conical section of the fluidized bed incinerator. The winnowing impurity removal and incineration disposal device is used for winnowing impurity removal and incineration treatment of industrial solid waste.

Owner:北京华能长江环保科技研究院有限公司 +1

Separation device and separation method for preventing coking at bottom of depropanization tower of catalytic gas fractionation device

PendingCN113354505AAvoid coke cloggingReduce energy consumptionDistillation purification/separationChemistryProcess engineering

The invention provides a separation device for preventing coking at the bottom of a depropanization tower of a catalytic gas fractionation device. The separation device comprises a high-pressure depropanization tower and a low-pressure depropanization tower. An inlet pipeline is arranged in the middle of the high-pressure depropanization tower, a first tower top gas phase delivery pipeline is arranged at the top of the high-pressure depropanization tower, and a first tower top condenser and a first tower top reflux tank are sequentially arranged on the first tower top gas phase delivery pipeline in the gas phase flowing direction. A high-low-pressure double-tower depropanization process is adopted, hot water of 80-95 DEG C in a factory, waste heat of a low-temperature process material or low-pressure steam is adopted as a heat source at the tower bottom, so that the operation temperature of the tower bottom of the depropanization tower is effectively reduced, and the problem that the tower bottom of the depropanization tower is coked and blocked is fundamentally solved; the problems of reduced processing load and unplanned shutdown of the catalytic gas separation device caused by coking and blockage of the tower bottom of the depropanization tower are avoided; and meanwhile, the steam consumption at the bottom of the depropanization tower is reduced, and the energy consumption of the device is reduced.

Owner:BEIJING OUYIDE TECH +1

Furnace end structure capable of avoiding coking

PendingCN112682777AAvoid coke cloggingDomestic stoves or rangesLiquid heating fuelCombustionEngineering

The invention provides a furnace end structure capable of avoiding coking. The furnace end structure is characterized in that a furnace end inner container is arranged in a furnace end shell, a cavity formed between the outer side wall of the furnace end inner container and the inner side wall of the furnace end shell is a combustion-supporting chamber, and the combustion-supporting chamber communicates with an air inlet pipe; air holes are formed in the side wall of the furnace end inner container, and the furnace end inner container communicates with the combustion-supporting chamber; a first fuel through hole and a second fuel through hole are formed in the bottom of the furnace end inner container and the bottom of the furnace end shell respectively, a gap surrounding a spray head by a circle is formed between the spray head and the second fuel through hole, and fuel sprayed out of the spray head enters the furnace end inner container through the first fuel through hole and the second fuel through hole; and the spray head is connected with the furnace end shell through a fixing piece. The spray head is separated from the furnace end inner container and the furnace end shell, so that the spray head is not in contact with the furnace end inner container and the furnace end shell; and after the furnace end structure is used, high temperature on the furnace end inner container and the furnace end shell cannot be conducted to the spray head, meanwhile, fuel located in the spray head and on the surface of the spray head cannot be catalyzed by the high temperature, and the problem that the spray head is coked and blocked is avoided.

Owner:谢常英

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com