Delayed coking process for preparing coal-based needle coke

A delayed coking and needle coke technology, applied in the multi-tower delayed coking process field, can solve the problems of solvent coking, uncontrollable reaction process of coal-based needle coke raw materials, difficult long-term stable operation of the process flow, etc., so as to avoid coking blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

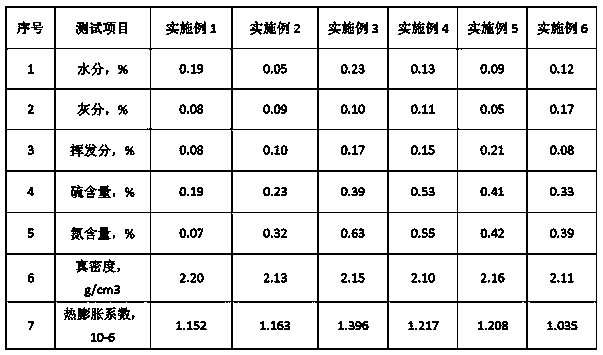

Embodiment 1

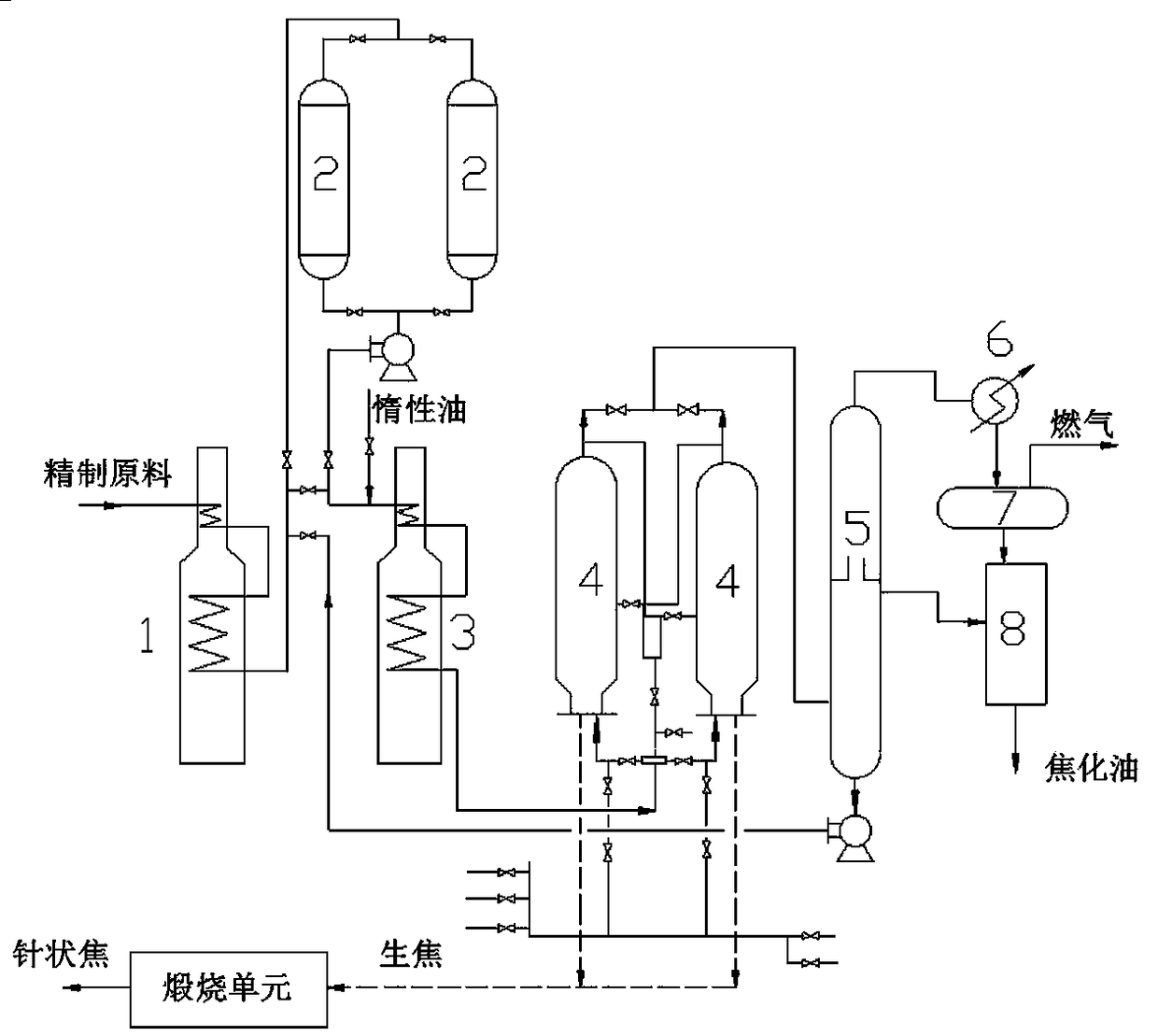

[0025] Such as Figure 1-2 As shown, a delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0026] 1. The refined raw material of medium-temperature coal tar pitch pretreated by solvent. The content of quinoline insoluble matter in the refined raw material is 0.08%. The refined raw material is heated to 395°C by low-temperature heating furnace 1 and sent to thermal polymerization tower 2. In a nitrogen atmosphere, Under the conditions of reaction temperature of 390°C and reaction pressure of 0.1MPa, stir for 3h;

[0027] 2. When the mesophase content of the material reaches 35%, send the mesophase-containing material obtained in the thermal polymerization kettle to the high-temperature heating furnace 3 together with diesel oil;

[0028] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 486°C, and send the mixed material to the coke tower;

[0029] 4. Control the temperature in the coke drum to 482...

Embodiment 2

[0033] A delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0034] 1. High-temperature coal tar refined raw material after solvent pretreatment, the content of quinoline insoluble matter in the refined raw material is 0.03%. The refined raw material is heated to 386°C by low-temperature heating furnace 1 and then sent to thermal polymerization tower 2. In a nitrogen atmosphere, Under the conditions of reaction temperature of 380°C and reaction pressure of 0.2MPa, stir for 1.5h;

[0035] 2. When the mesophase content of the material reaches 32%, the mixture of the mesophase-containing material, tetralin and diesel obtained in the thermal polymerization kettle is sent to the high-temperature heating furnace 3;

[0036] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 486°C, and send the mixed material to the coke tower;

[0037] 4. Control the temperature in the coke drum to 498°C, the coke generat...

Embodiment 3

[0041] A delayed coking process for preparing coal-based needle coke, the specific steps are as follows:

[0042] 1. The refined raw material of modified asphalt after solvent pretreatment. The content of quinoline insoluble matter in the refined raw material is 0.05%. The refined raw material is heated to 373°C by low-temperature heating furnace 1 and sent to thermal polymerization tower 2. In a nitrogen atmosphere, Under the conditions of reaction temperature of 370℃ and reaction pressure of 0.8MPa, stir for 1h;

[0043] 2. When the mesophase content of the material reaches 30%, send the mesophase-containing material obtained in the thermal polymerization kettle and liquid paraffin into the high-temperature heating furnace 3;

[0044] 3. Raise the temperature of the mixed material in the high-temperature heating furnace 3 to 510°C, and send the mixed material to the coke tower;

[0045] 4. Control the temperature in the coke drum to 460℃, the coke generation time to 33h, and the cok...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com