Furnace end structure capable of avoiding coking

A burner and nozzle technology, which is applied to household stoves/stoves, burners for burning powder fuel, combustion methods, etc., can solve problems such as clogging of nozzles, quality affecting stove burners, and easy coking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

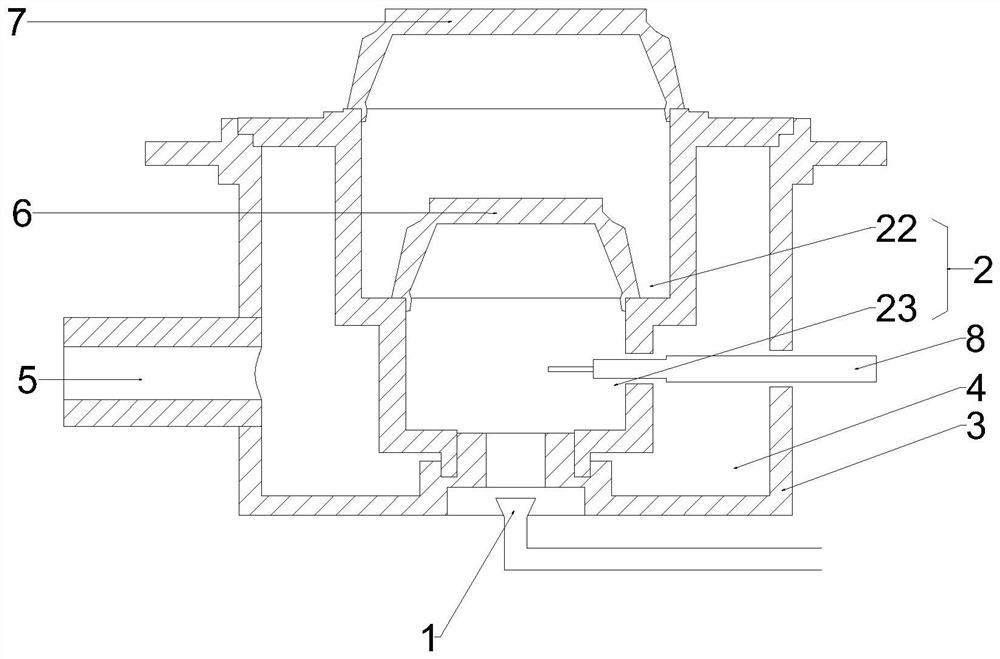

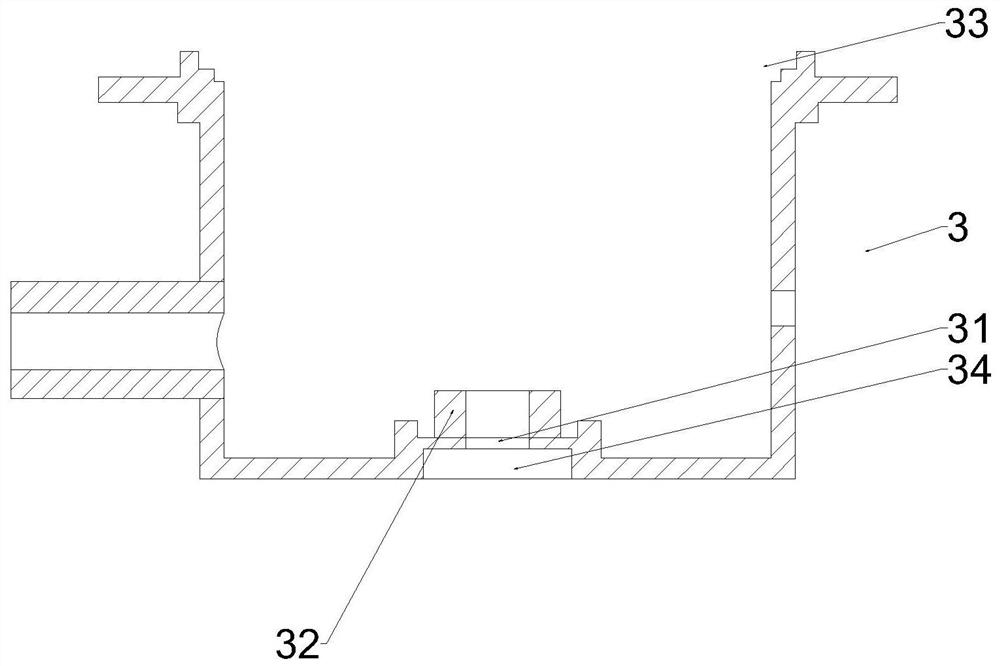

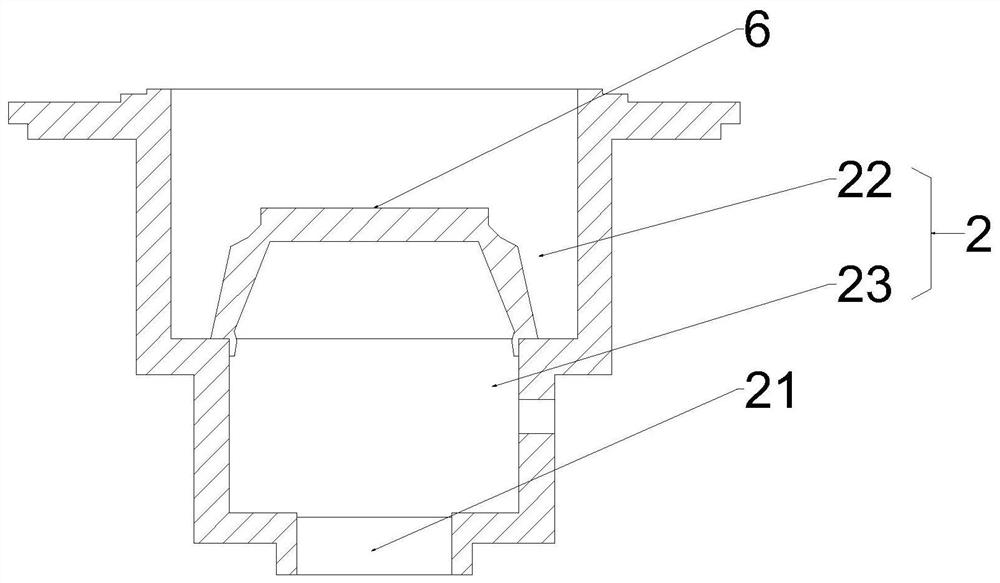

[0024] see Figure 1 to Figure 3 , the present application provides a burner structure for avoiding coking, including: a nozzle 1, a burner shell 3 and a burner liner 2; the burner liner 2 is arranged in the burner shell 3, and the burner The cavity formed between the outer wall of the head liner 2 and the inner wall of the burner shell 3 is a combustion chamber 4, which is connected to the air intake pipe; the side wall of the burner liner 2 is provided with Air holes, the burner inner container 2 communicates with the combustion-supporting chamber 4 through the air holes; the bottom of the burner inner container 2 is provided with a first fuel through hole 21, and the bottom of the burner shell 3 is provided with a second The fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com