Industrial production method for separating boron isotope product based on methyl-phenoxide-boron trifluoride complex

A technology of boron trifluoride and complexes, which is applied in the field of rectification and separation of boron isotope products based on the chemical exchange reaction of methyl ether-boron trifluoride complexes, which can solve the problems of low production capacity, long equilibration time, and difficult operation, etc. problem, to achieve the effect of solving the problem of vacuum belt material, reducing equipment corrosion and prolonging the start-up cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

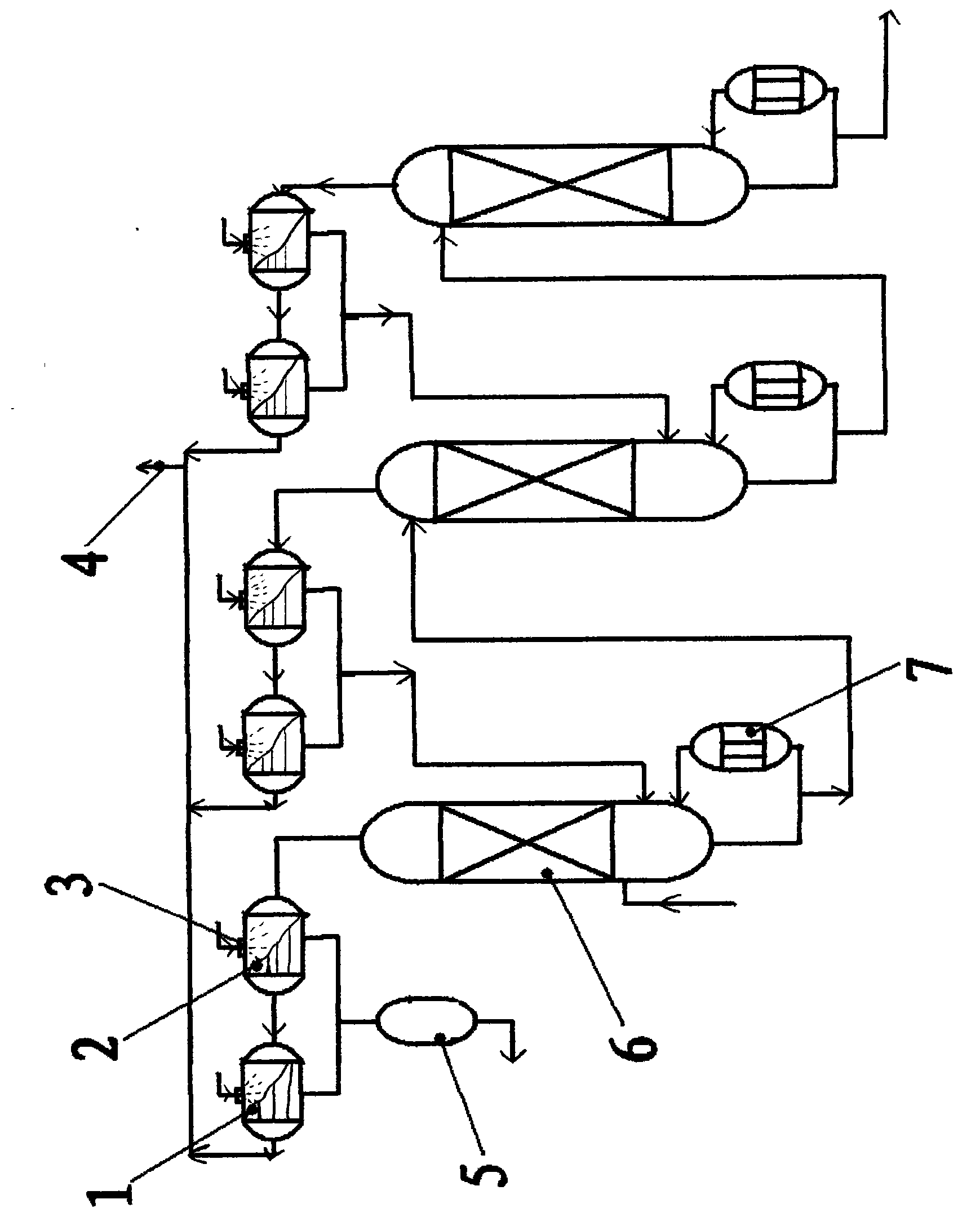

[0021] With reference to accompanying drawing, used equipment comprises several exchange rectification towers 6, and each exchange rectification tower is all equipped with column still reboiler 7 and tower top condenser 2, catcher 1, condenser and catcher They are all connected to the vacuum system 4, and sprinklers 3 are respectively installed on the shell tops of the condensers and traps, and boron trifluoride-11 product tanks 5 are also included;

[0022] Firstly, the methyl ether-boron trifluoride complex is stripped and dried by air, and the method is: pump the methyl ether-boron trifluoride complex to the top of the stripping tower, spray from top to bottom, and The nitrogen gas entering from the bottom of the stripping tower is contacted in countercurrent in the filler, and the moisture and HF in the complex are removed by nitrogen gas stripping. The nitrogen gas comes out from the top of the tower, absorbs boron trifluoride in methyl ether, and then vents. The methyl e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com