A large-scale low-rank pulverized coal low-temperature pyrolysis device and method

A low-temperature pyrolysis and waste heat recovery device technology, applied in the field of coal chemical industry, can solve the problems of not equipped with pyrolysis gas high-temperature filtration, semi-coke cooling and waste heat recovery devices, no external preheater, and high tar impurity content, etc. , to achieve the effect of reducing water resource consumption and environmental pollution, good economy and environmental protection, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

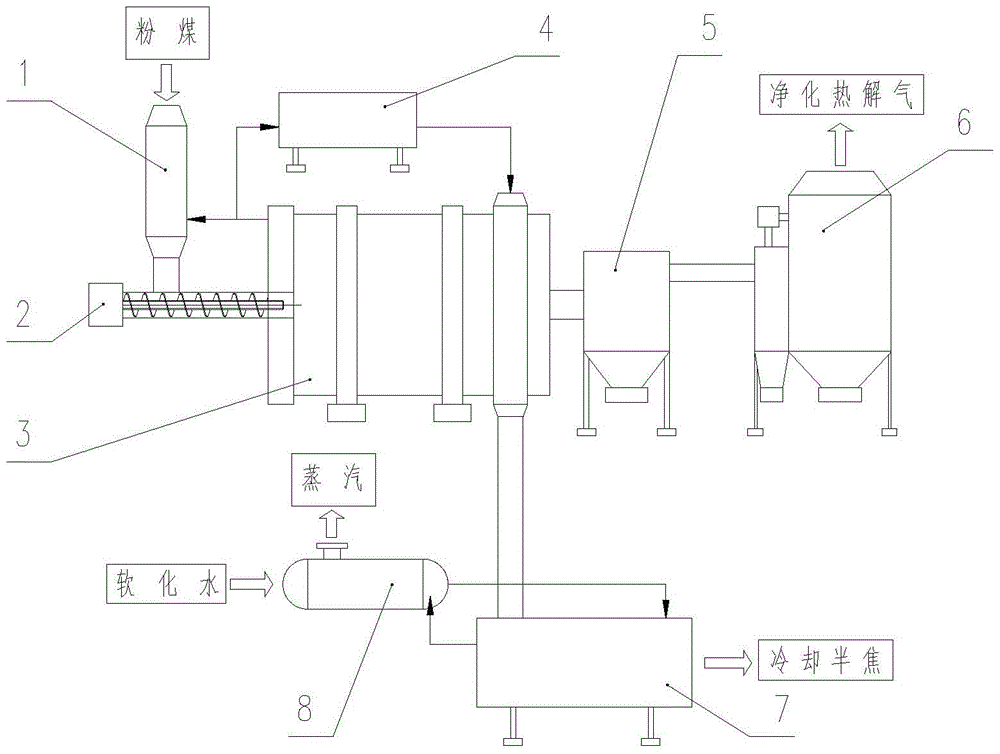

[0027] Such as figure 1 As shown, a large-scale low-grade pulverized coal low-temperature pyrolysis device includes a vertical preheater 1, a feeding screw 2, a pyrolysis kiln 3, a hot air heating furnace 4, a settling connection box 5, a high-temperature filter device 6, Semi-coke cooling waste heat recovery device 7 and steam drum 8, the discharge port of the vertical preheater 1 is connected to the feeding screw 2, and the feeding screw 2 is connected to the pyrolysis kiln 3, and the heat of the pyrolysis kiln 3 The degassing outlet is connected to the settling junction box 5, the settling junction box 5 is connected to the high-temperature filter device 6, the semi-coke outlet of the pyrolysis kiln 3 is connected to the semi-coke cooling waste heat recovery device 7, and the semi-coke cooling waste heat recovery device 7 The steam outlet of the st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com