Coal tar suspended bed coupled fixed bed hydrocracking process and device

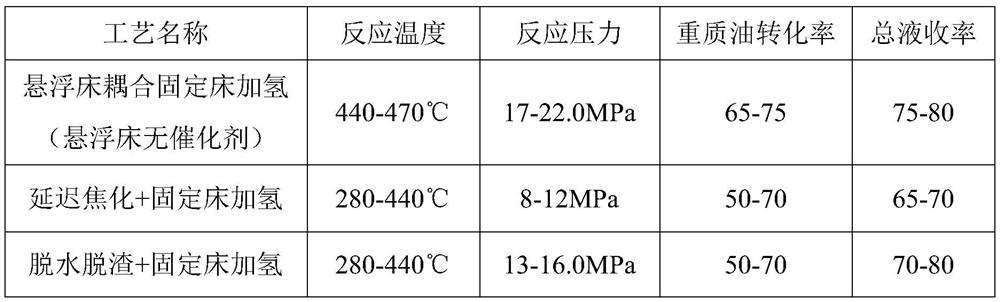

A hydrocracking and suspended bed technology, applied in hydrotreating process, hydrocarbon oil cracking, petroleum industry, etc., can solve the problem of low coal tar conversion rate, low light oil yield, easy blockage of feeding system, and easy decompression system. Abrasion and other problems, to avoid coking blockage, reduce energy consumption, and reduce investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

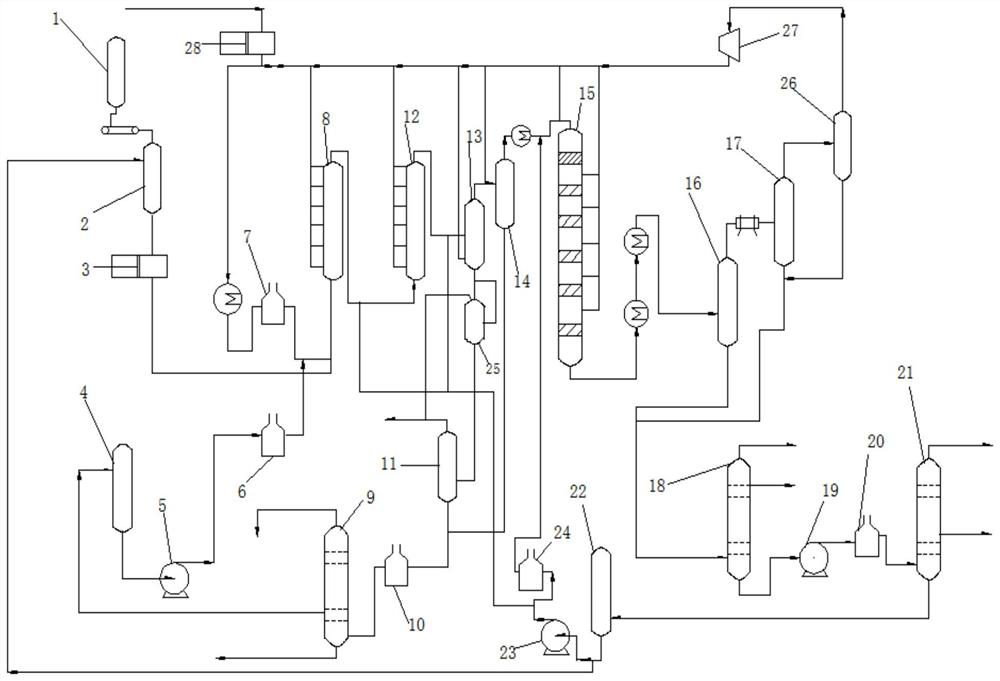

[0051] A coal tar suspended bed coupling fixed bed hydrocracking process of the present invention is specifically implemented according to the following steps:

[0052] Step 1, mixing the coal tar suspended bed hydrocracking catalyst with the raw material to obtain a catalyst oil slurry; the catalyst oil slurry is mixed with the hydrogenated tail oil at the bottom of the fixed-bed vacuum fractionation tower 21 and then entered into the catalyst mixing tank 2 for thorough mixing , to obtain catalyst mixed raw material;

[0053] The raw material is coal tar;

[0054] The mass ratio of coal tar suspended bed hydrocracking catalyst to coal tar is 0.005:1;

[0055] The coal tar suspended bed hydrocracking catalyst is the catalyst disclosed in the Chinese patent (application number 202010265211.3, publication number CN111420671A);

[0056] Step 2, the catalyst mixed raw material obtained in step 1 is boosted to 22.0MPa through the catalyst feed pump 3; the raw material oil in the ...

Embodiment 2

[0067] A coal tar suspended bed coupling fixed bed hydrocracking process of the present invention is specifically implemented according to the following steps:

[0068] Step 1, mixing the coal tar suspended bed hydrocracking catalyst with the raw material to obtain a catalyst oil slurry; the catalyst oil slurry is mixed with the hydrogenated tail oil at the bottom of the fixed-bed vacuum fractionation tower 21 and then entered into the catalyst mixing tank 2 for thorough mixing , to obtain catalyst mixed raw material;

[0069] The raw material is coal tar;

[0070] The mass ratio of coal tar suspended bed hydrocracking catalyst to coal tar is 0.01:1;

[0071] The coal tar suspended bed hydrocracking catalyst is the catalyst disclosed in the Chinese patent (application number 202010265211.3, publication number CN111420671A);

[0072]Step 2, the catalyst mixed raw material obtained in step 1 is boosted to 22.0MPa through the catalyst feed pump 3; the raw material oil in the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com