Patents

Literature

37results about How to "Feed amount is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

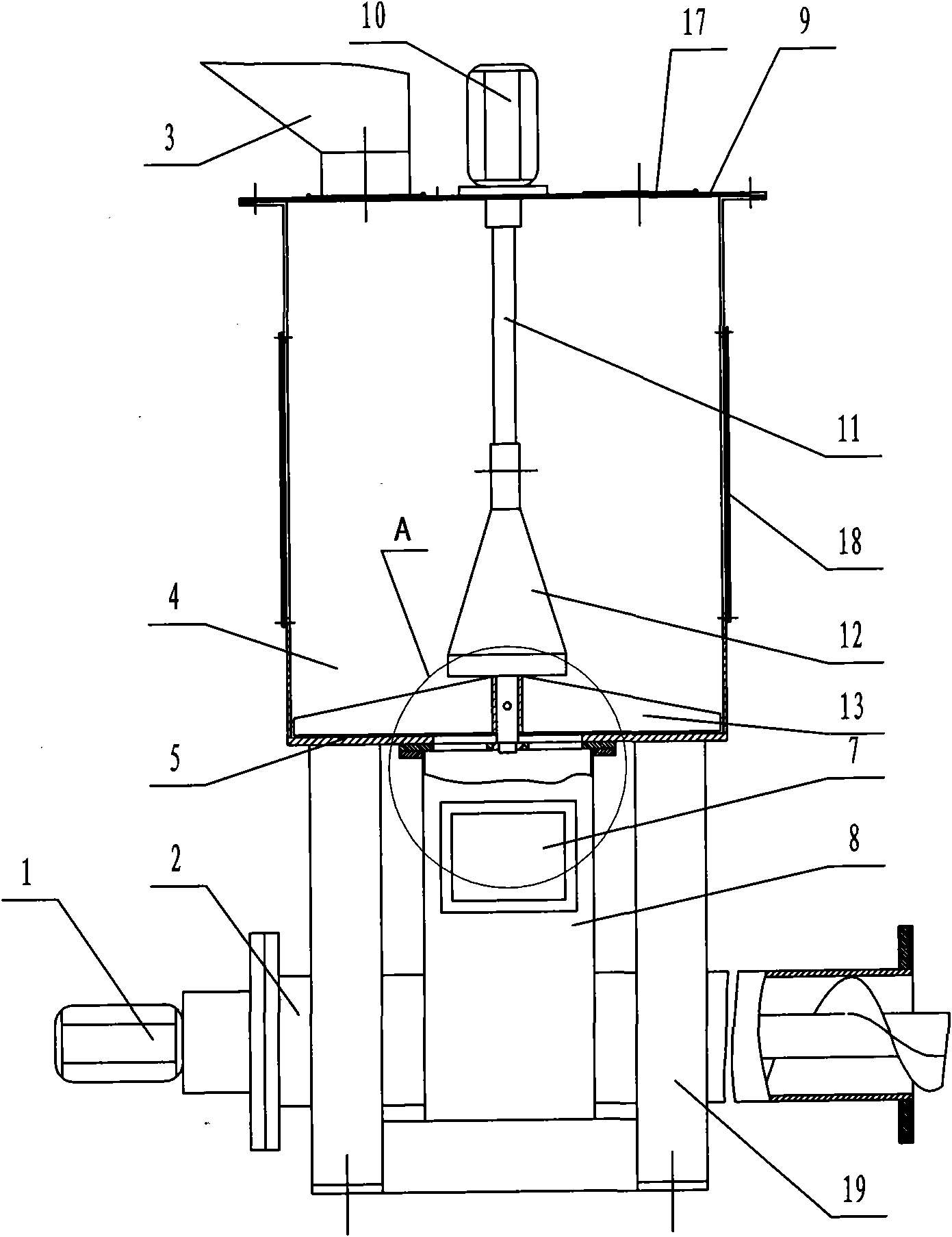

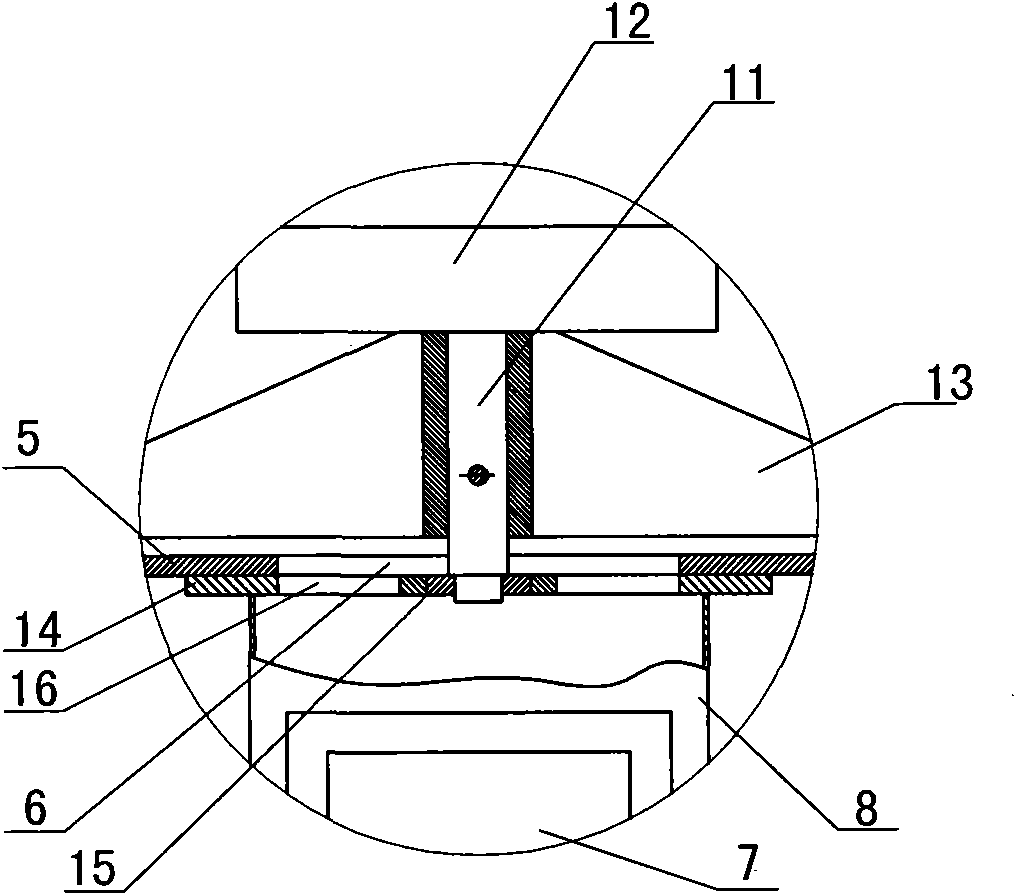

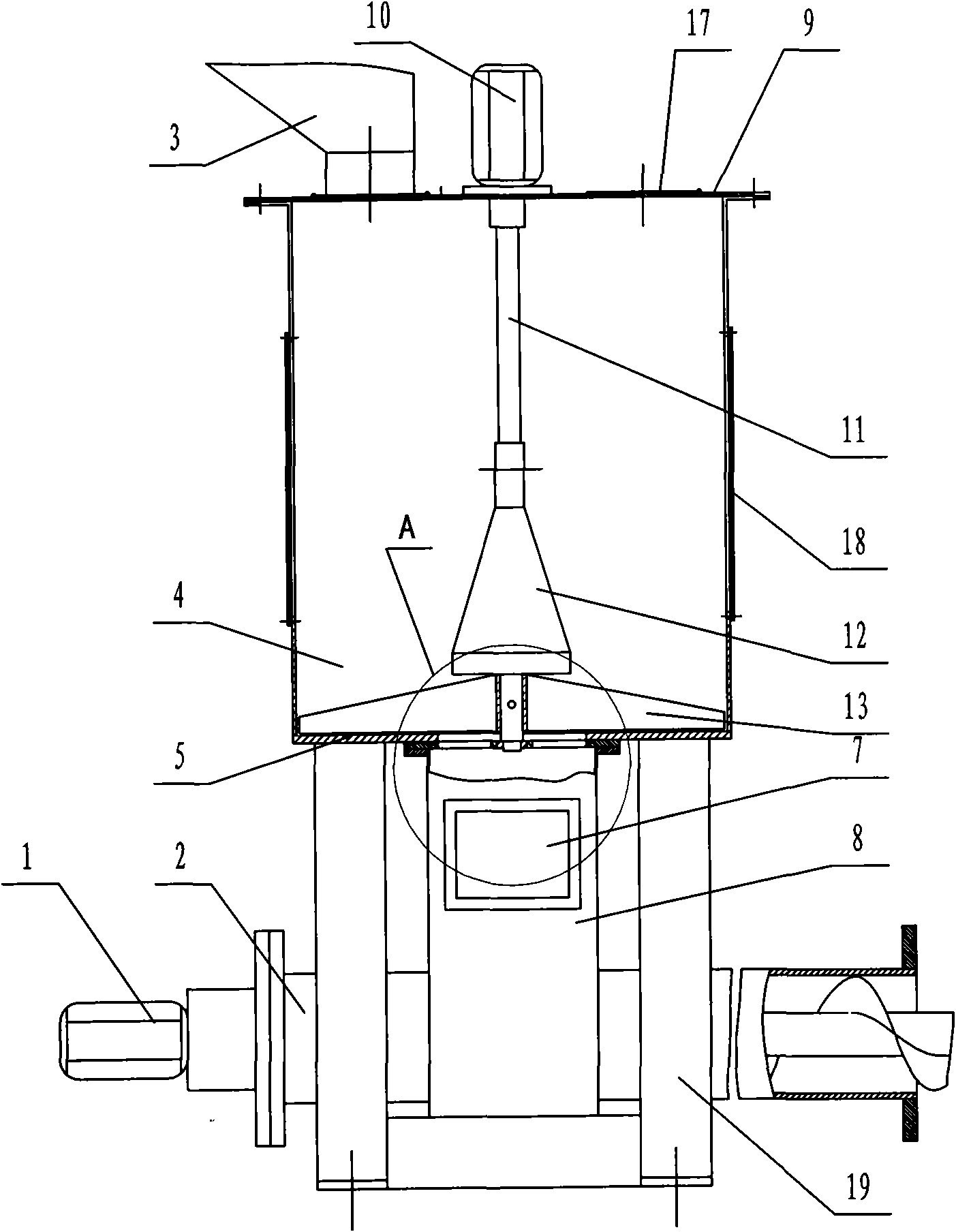

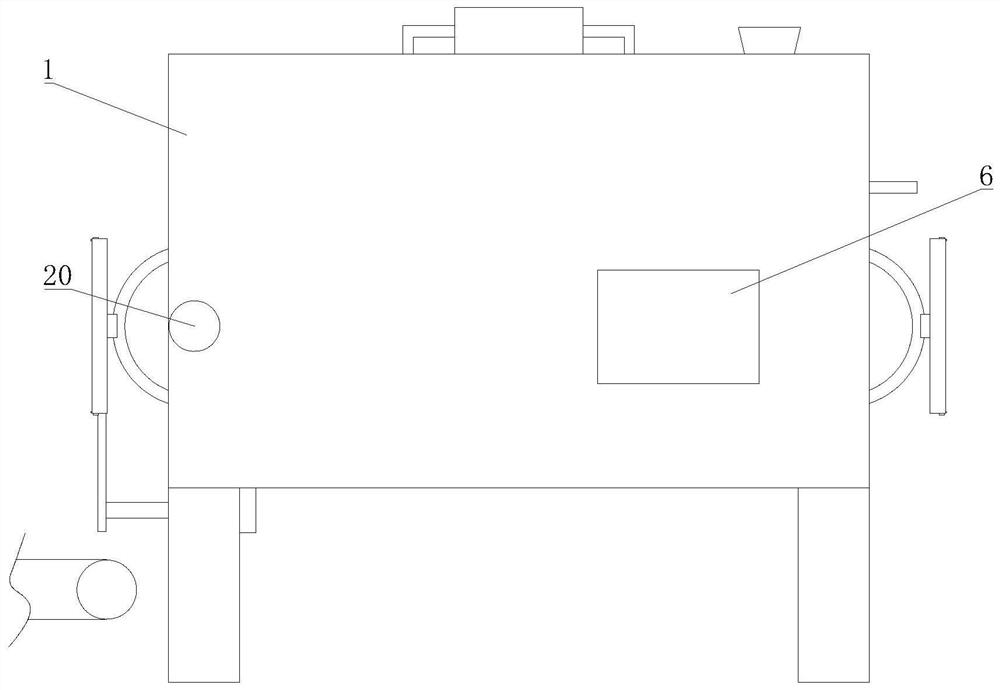

Biomass powder feeder

ActiveCN102275748AThe amount of material is uniform and stableNot easy to overheadLoading/unloadingEngineeringMechanical engineering

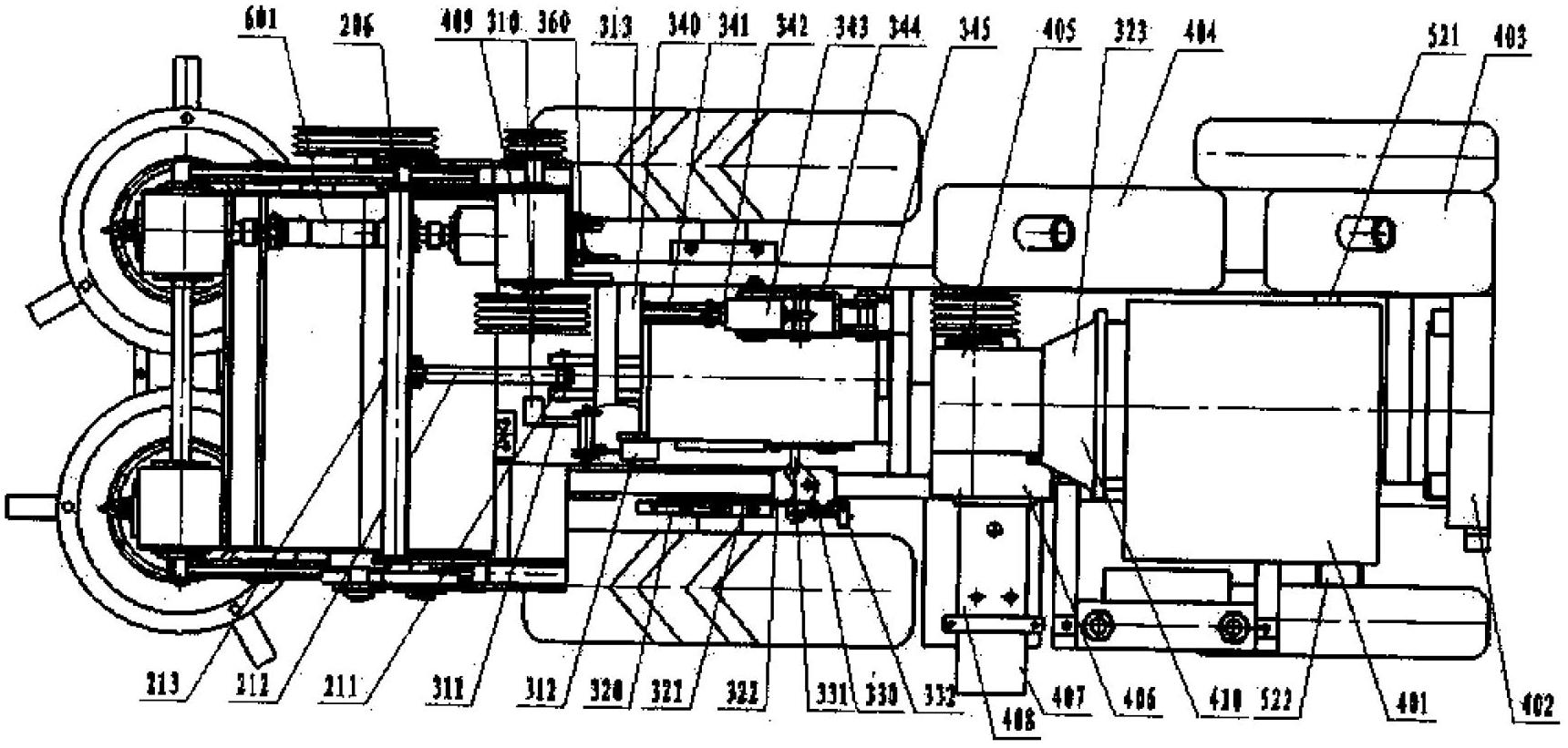

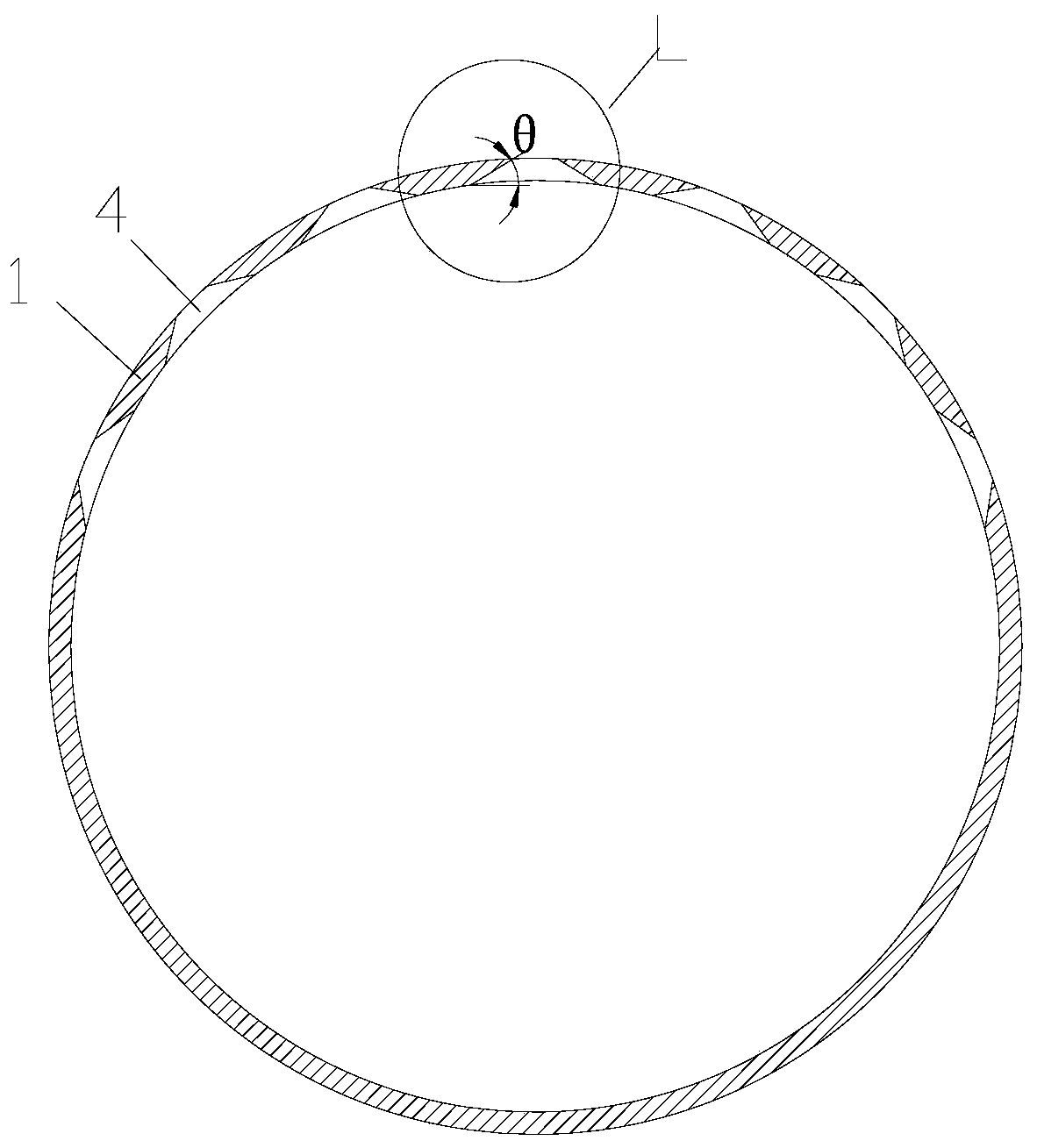

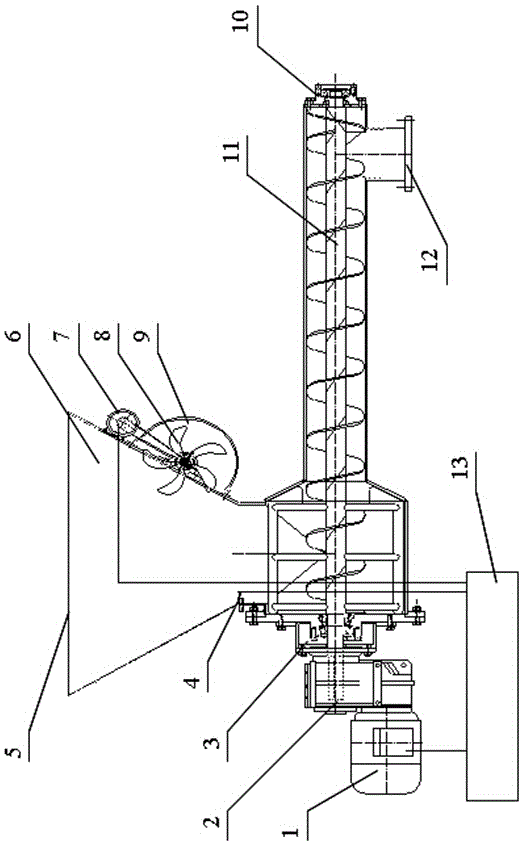

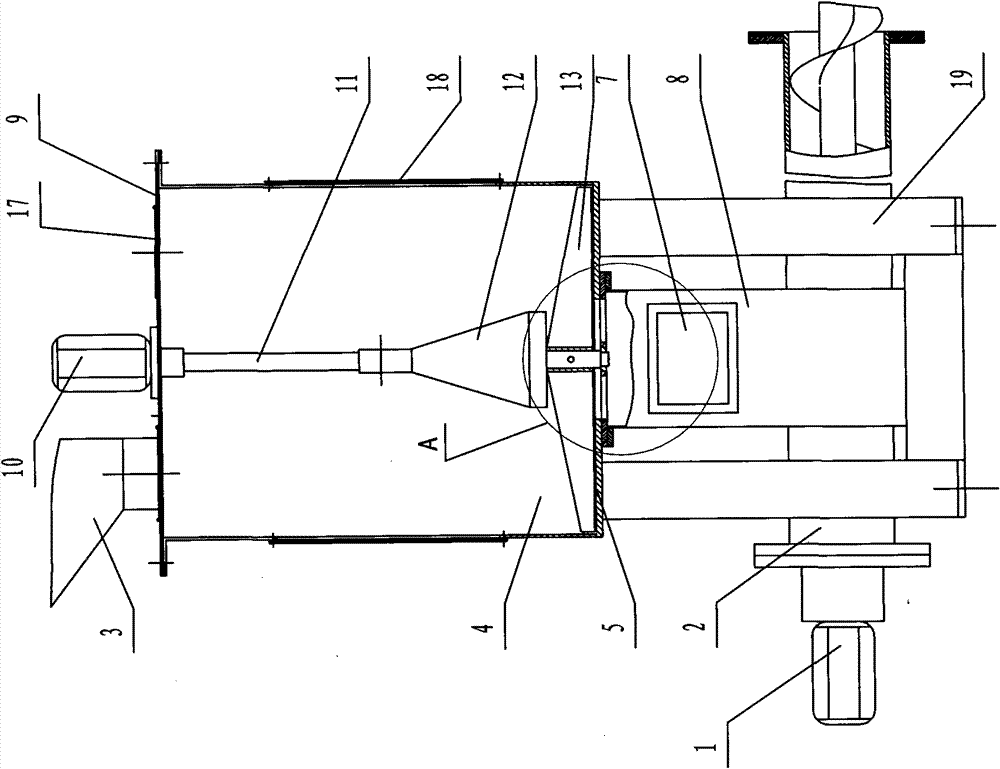

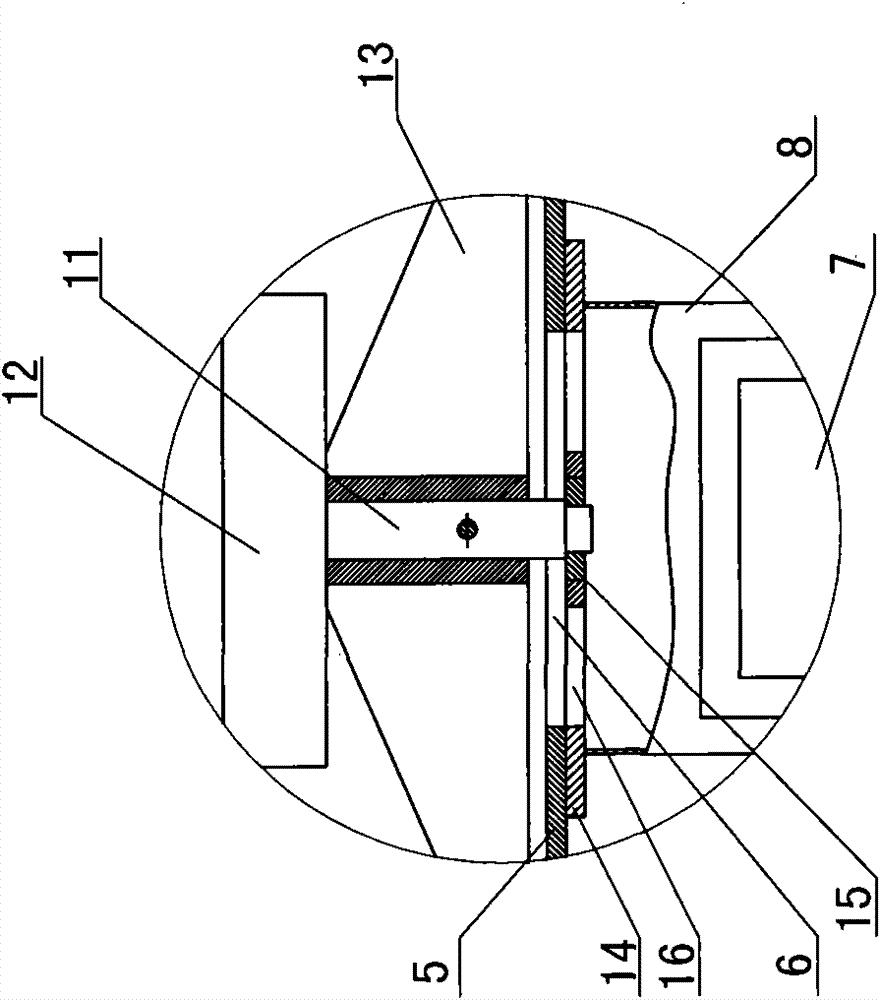

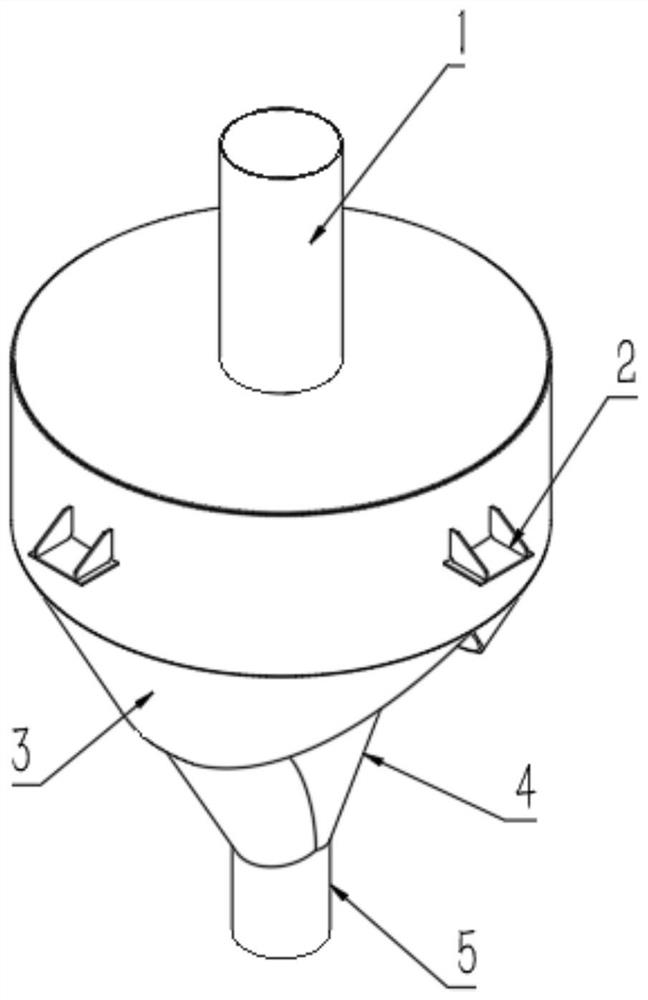

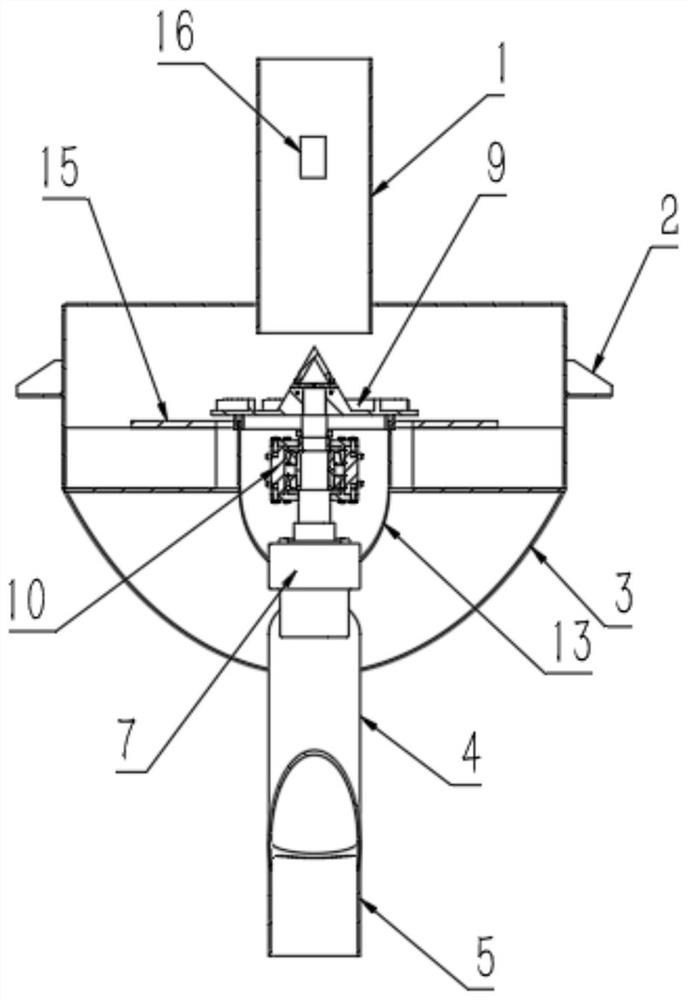

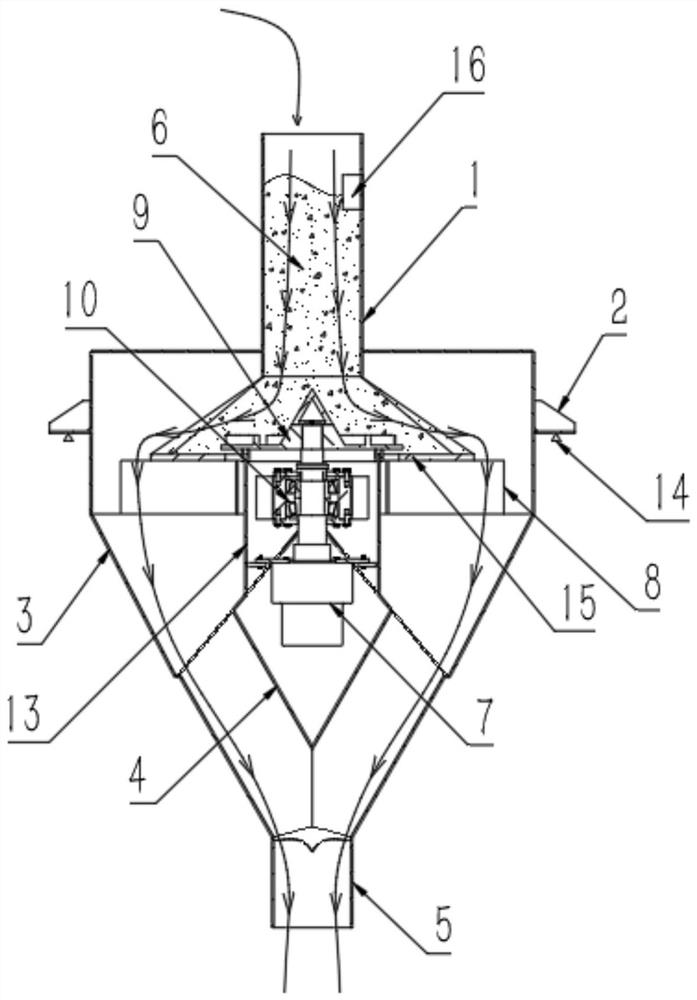

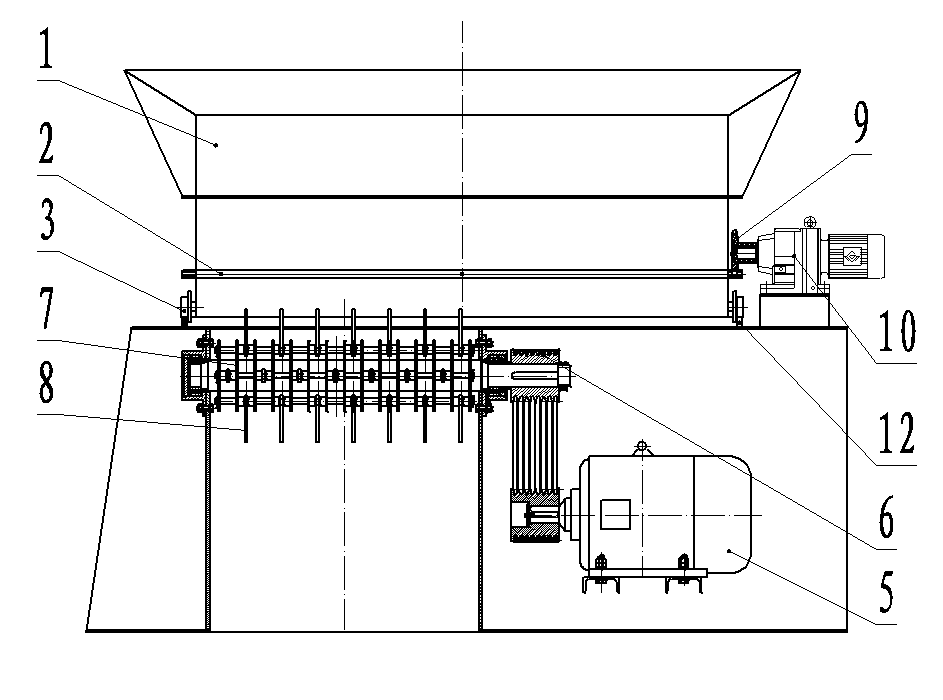

The invention provides a biomass powder feeder. A conveying device drives a screw auger through a speed reducing motor in a direct connection mode. The biomass powder feeder is characterized in that: a round hole is formed at the center of the bottom of a material cylinder; a connecting cylinder is vertical to the screw auger, and the bottom of the connecting cylinder is communicated with the screw auger; a bearing sleeve is arranged at the center of a support disc which is fixedly mounted at the top end of the connecting cylinder; the support disc is located on the baring sleeve, and blanking holes are uniformly distributed around the bearing sleeve; the upper end of a rotary shaft is fixedly connected with the output end of a speed regulating motor, and the lower end of the rotary shaftpasses through the round hole to be inserted into the bearing sleeve; the rotary shaft is provided with a conical material blocking cylinder above the round hole; the diameter of the bottom surface of the conical material blocking cylinder is greater than the diameter of the round hole; multiple scraping plates are fixedly mounted on the rotary shaft below the conical material blocking cylinder; the rotation diameter of each scraping plate is slightly less than the diameter of the material cylinder, and a certain clearance is reserved between the bottom side and the cylinder bottom; and the rated output of the screw auger is greater than the quantity of feed entering the connecting cylinder from the blanking holes. The biomass powder feeder provided by the invention takes biomass as a feeding object, realizes uniform and stable feeding, and has the advantages of simple structure, small volume and excellent working performance.

Owner:SHANDONG UNIV OF TECH

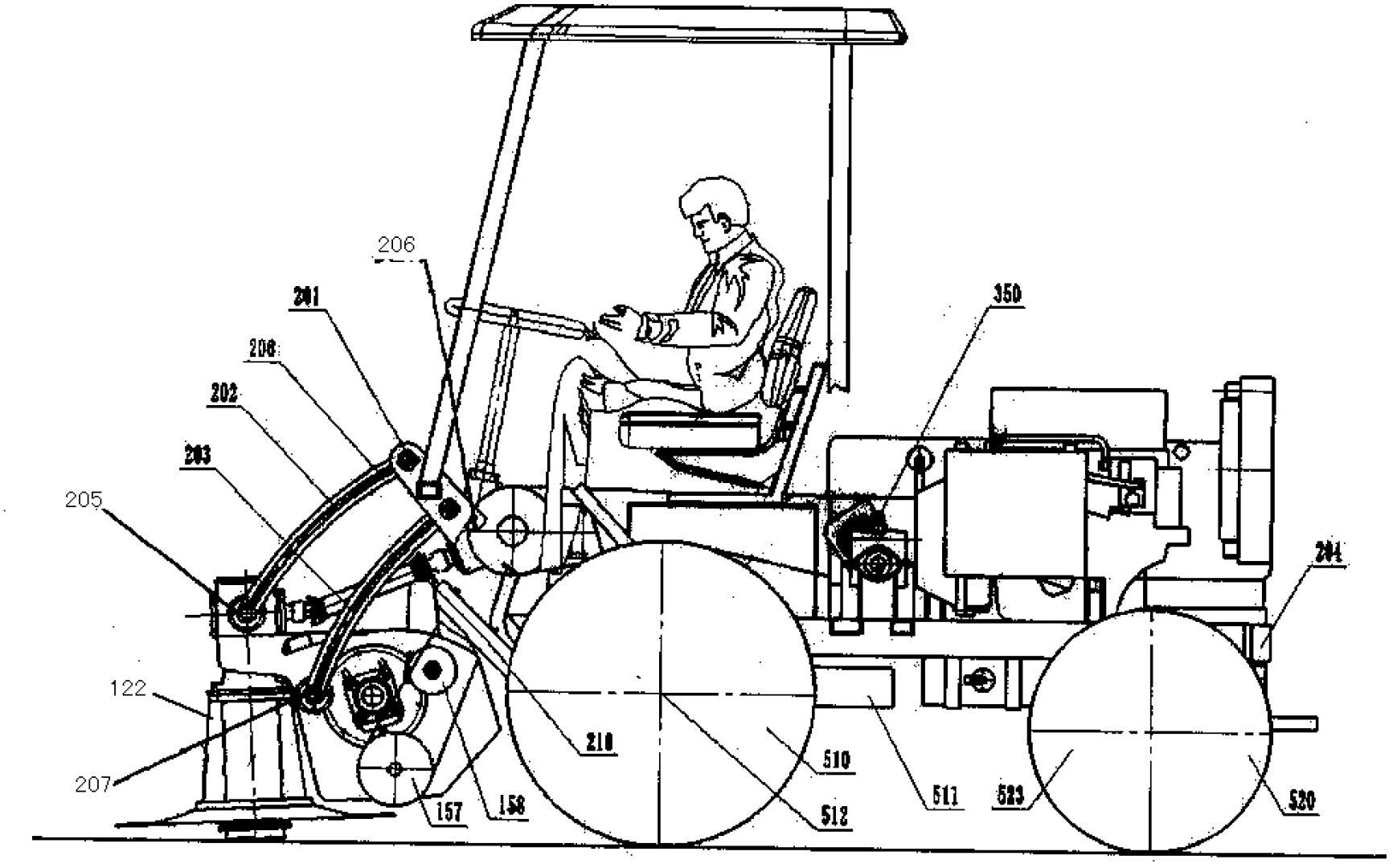

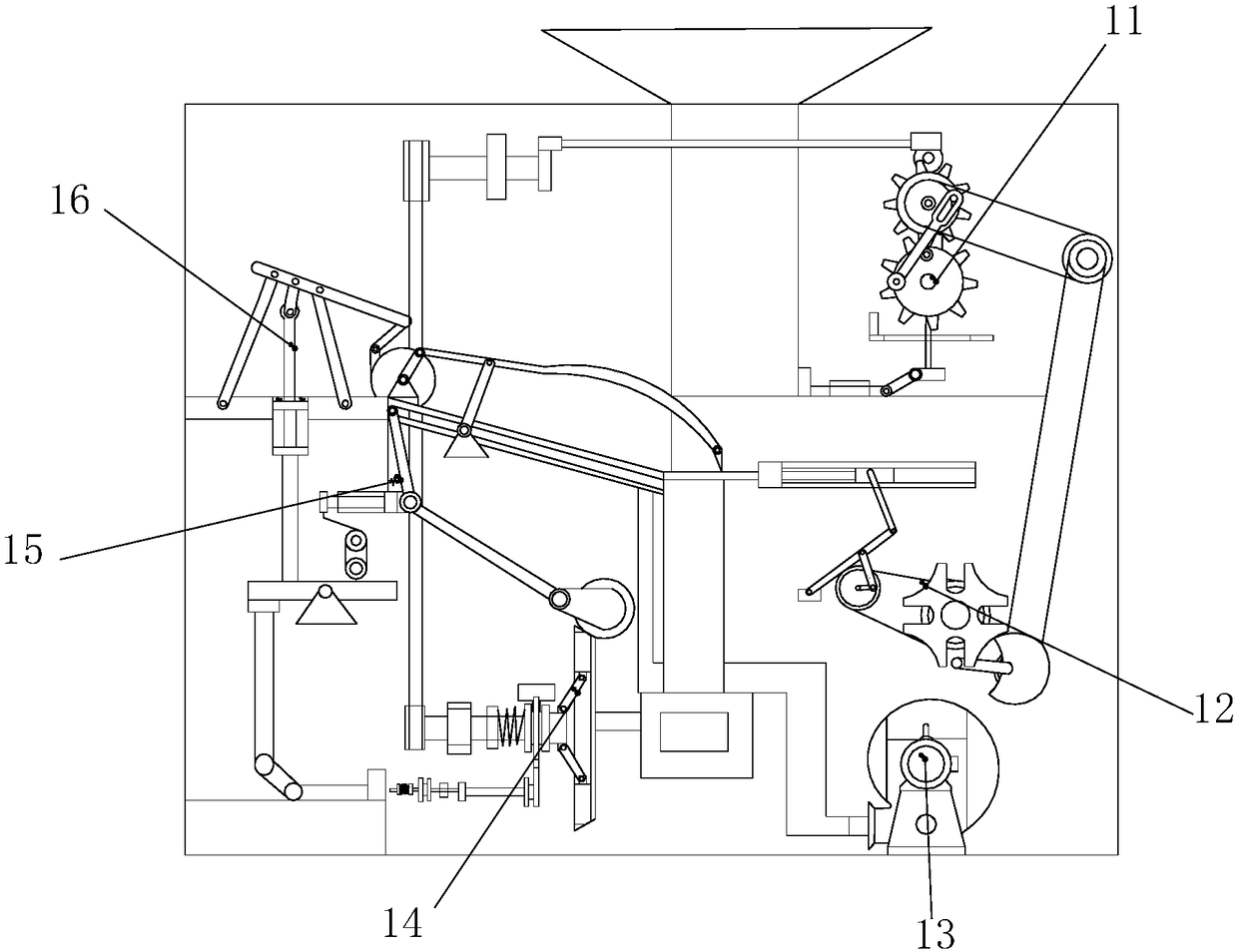

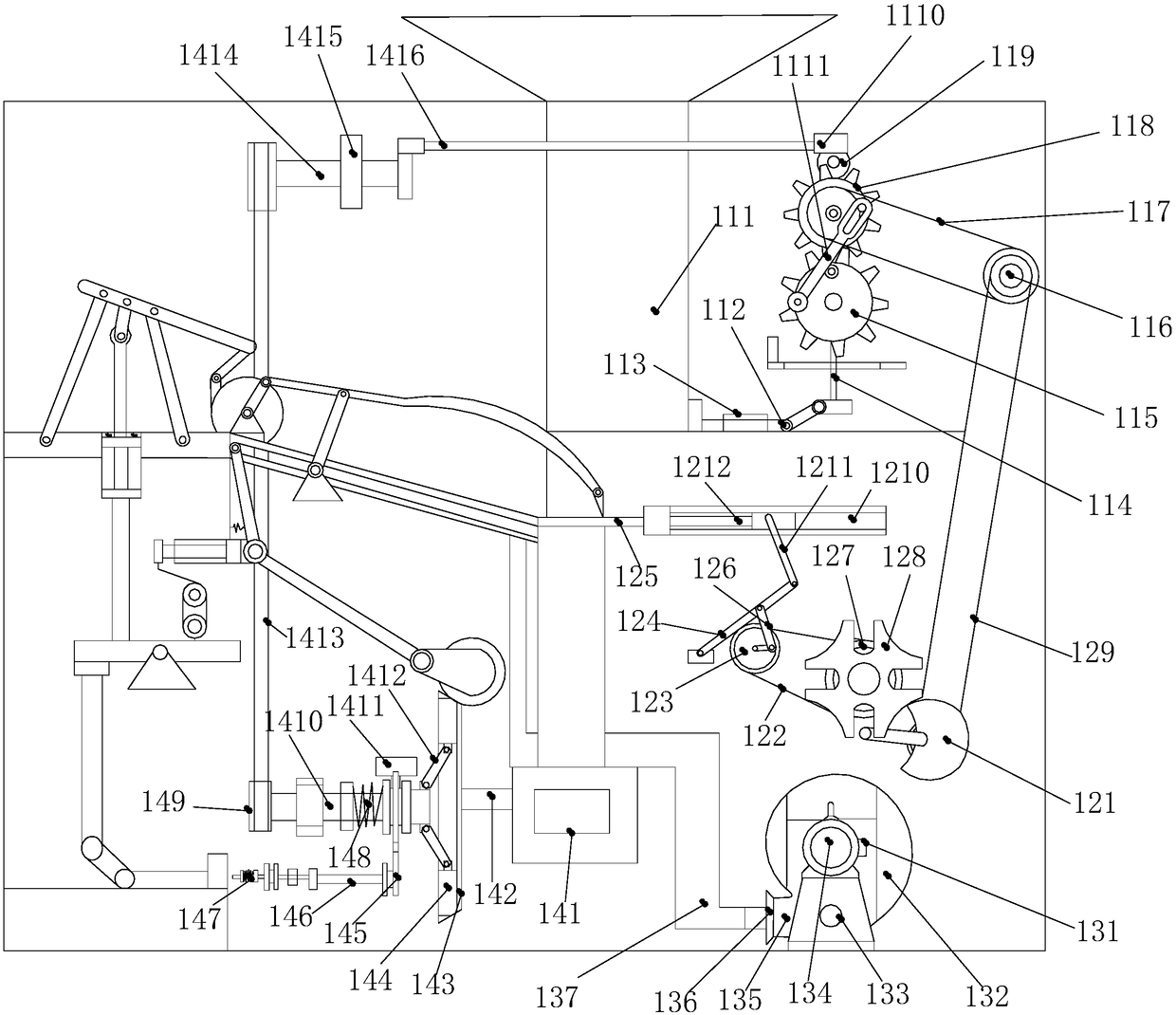

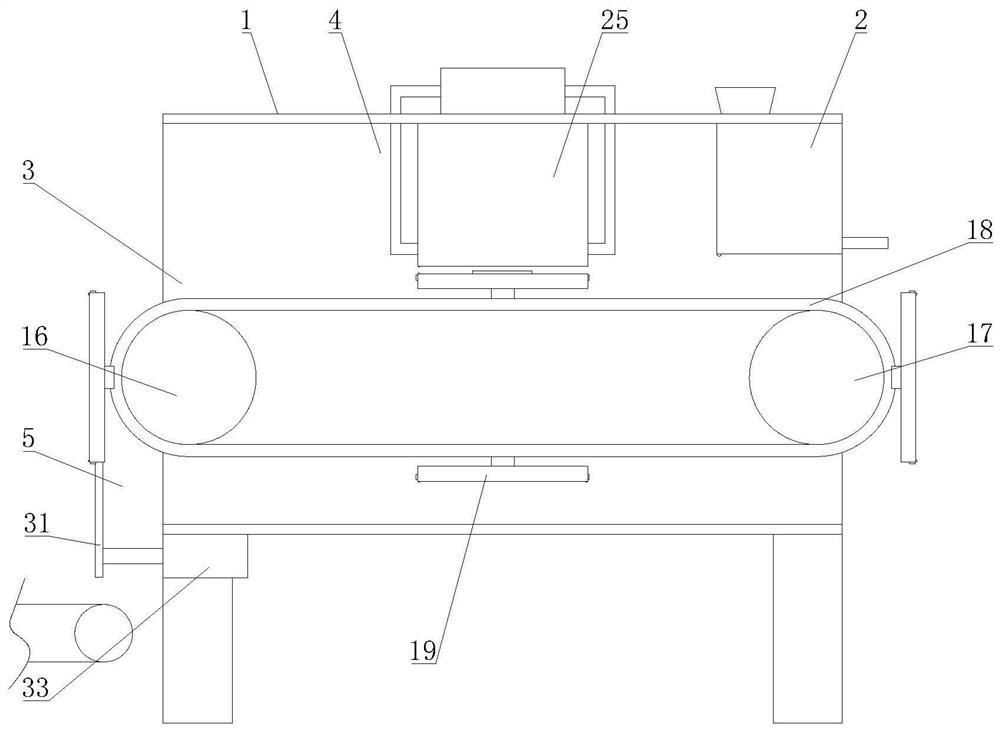

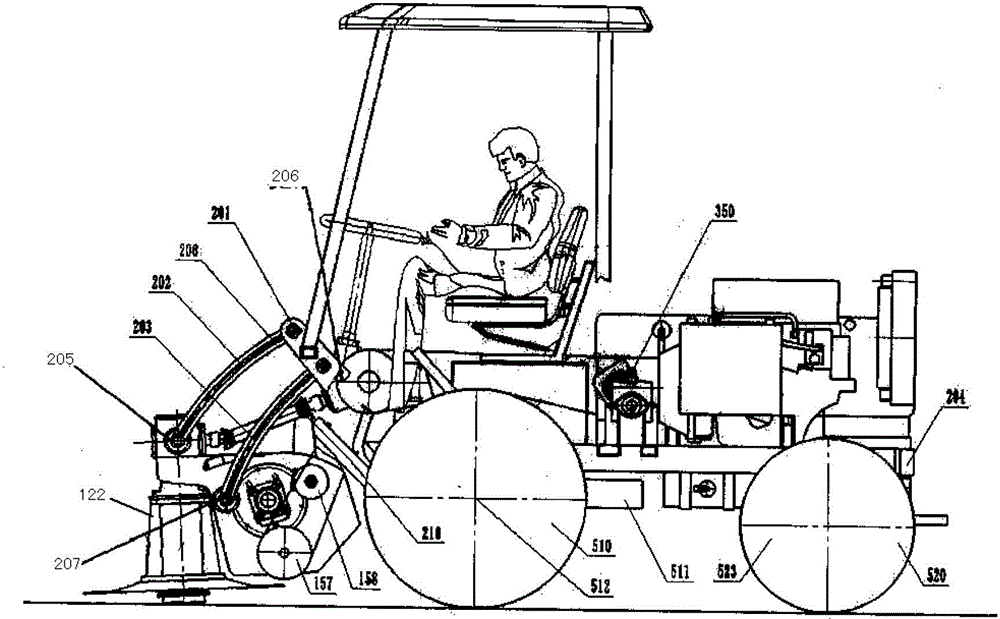

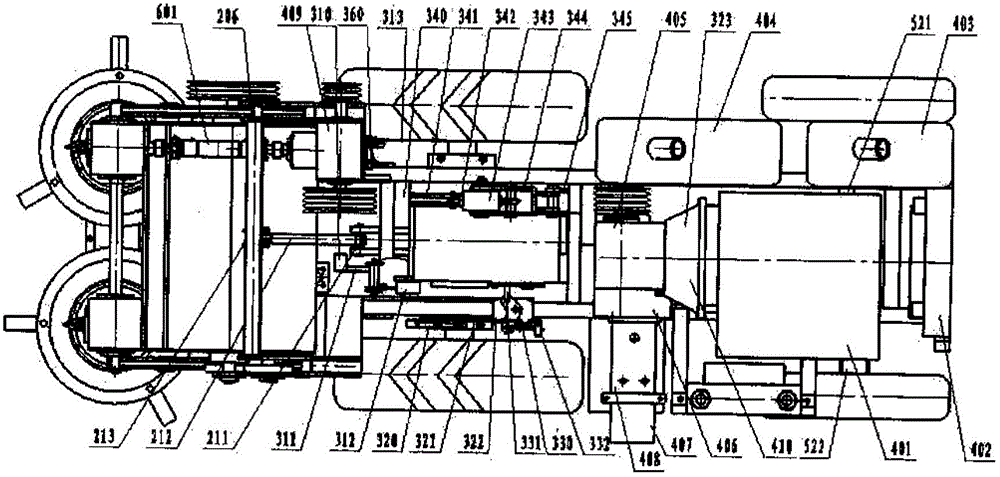

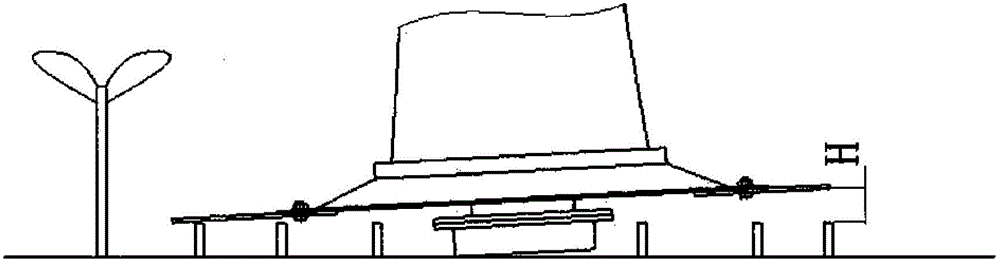

Small self-propelled alfalfa cradling and flattening machine

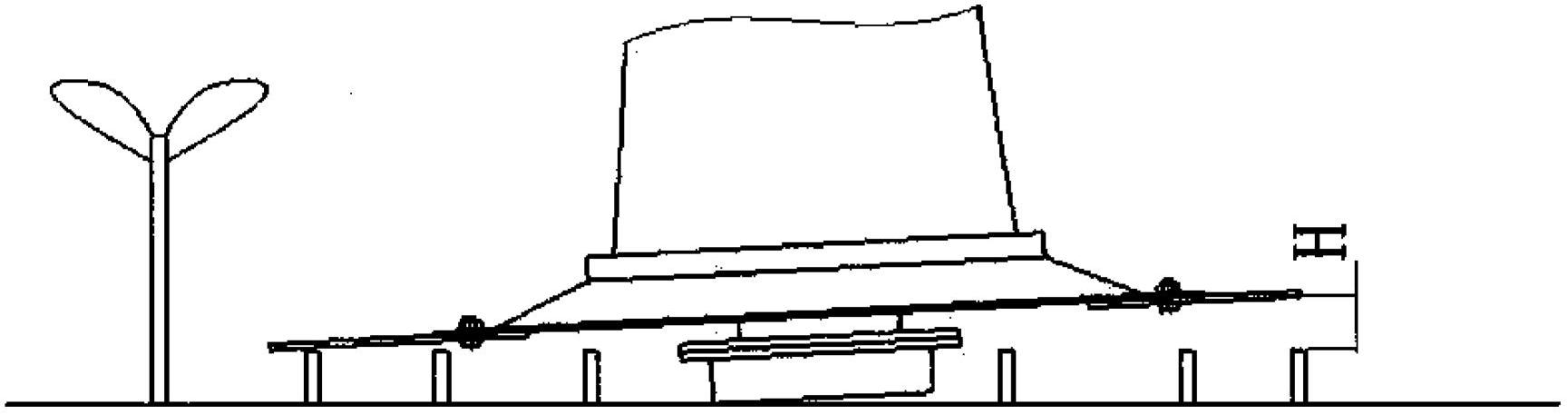

The invention discloses a small self-propelled alfalfa cradling and flattening machine, belonging to the technical field of agricultural machinery. The small self-propelled alfalfa cradling and flattening machine is mainly composed of a working device, a hydraulic lifting device, an operation system, a power and transmission system and a travelling system; the working device, the hydraulic lifting device and the operation system are arranged at the front part of the machine; the power and transmission system and the travelling system are arranged at the middle rear part of the machine; one end of the hydraulic lifting device is connected with the working device, and the other end of the hydraulic lifting device is connected with the machine frame; and the power and transmission system is connected with the operation system and the travelling system through the hydraulic device, gear transmission and a transmission part. The small self-propelled alfalfa cradling and flattening machine is designed for flattening and paving alfalfas into fluffy swathes while cradling alfalfas aiming at alfalfa obtaining works in small lands, such as hills, mountainous regions and the like; a cradling table device and a flattening device are connected by adopting a frame type structure, unparallel four-connecting-rod lifting mechanisms are adopted, and when the machine climbs, a cradling table can be lifted without influencing stability of the whole machine, so that operation is safer and more stable; stepless speed regulation can be realized by driving a front axle through a hydraulic motor; the working efficiency is increased; and simultaneously, the small self-propelled alfalfa cradling and flattening machine has wider practicability.

Owner:CHINA AGRI UNIV

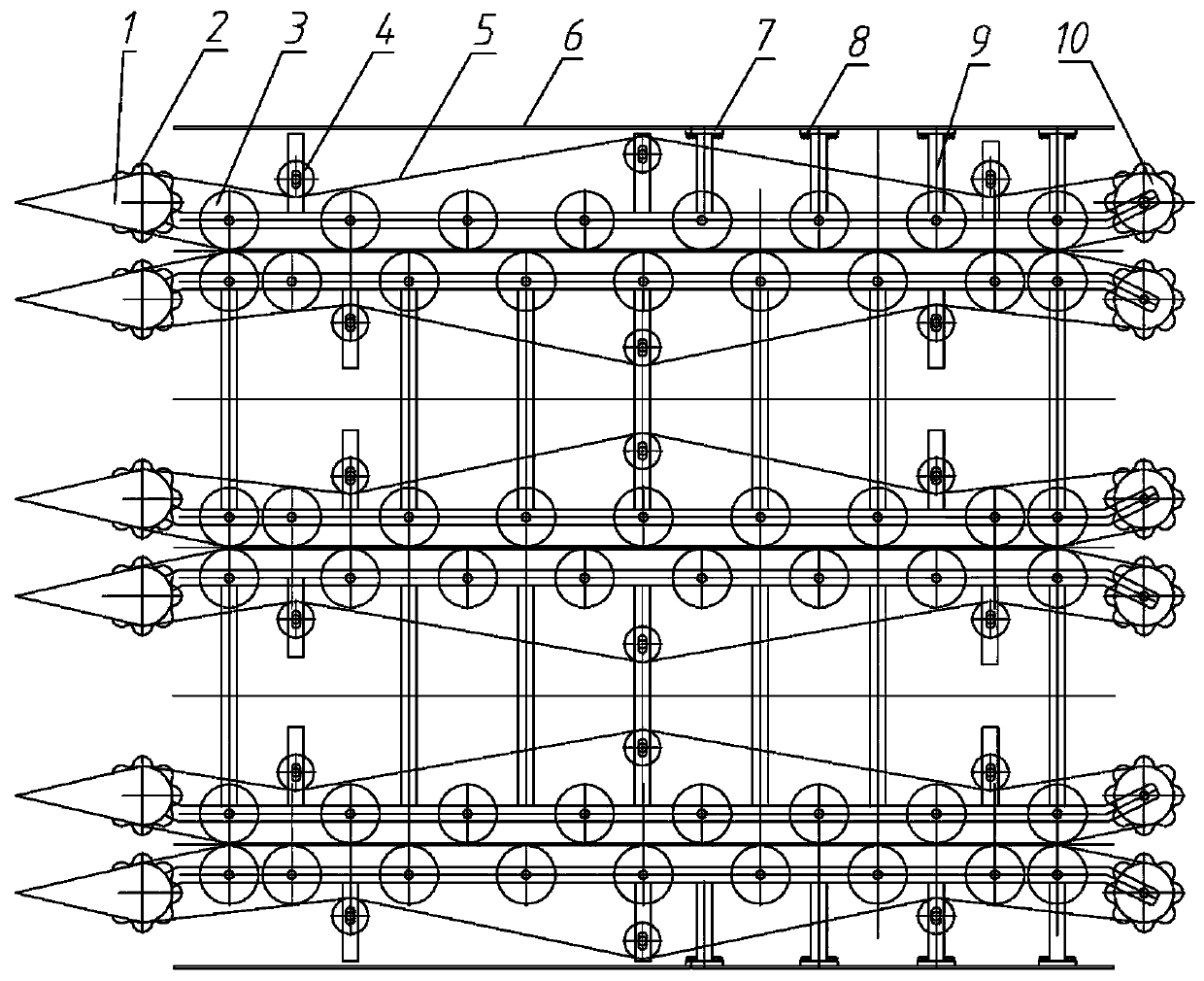

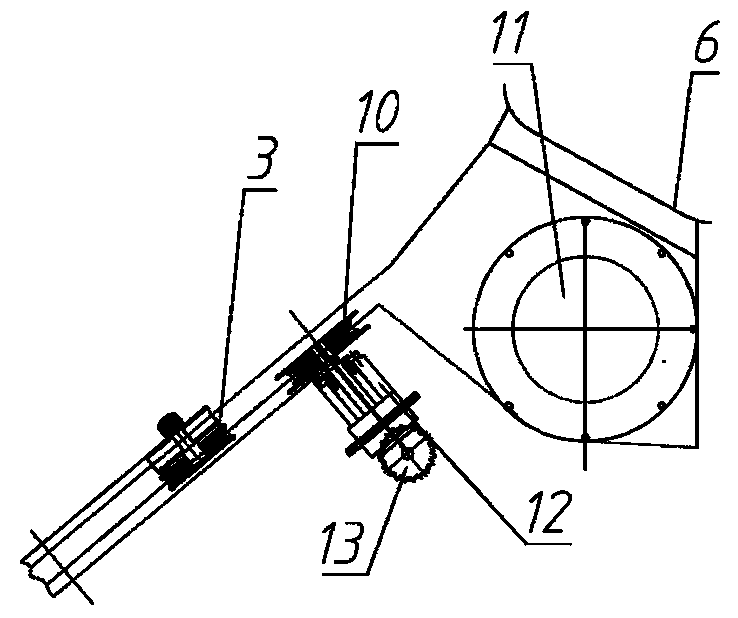

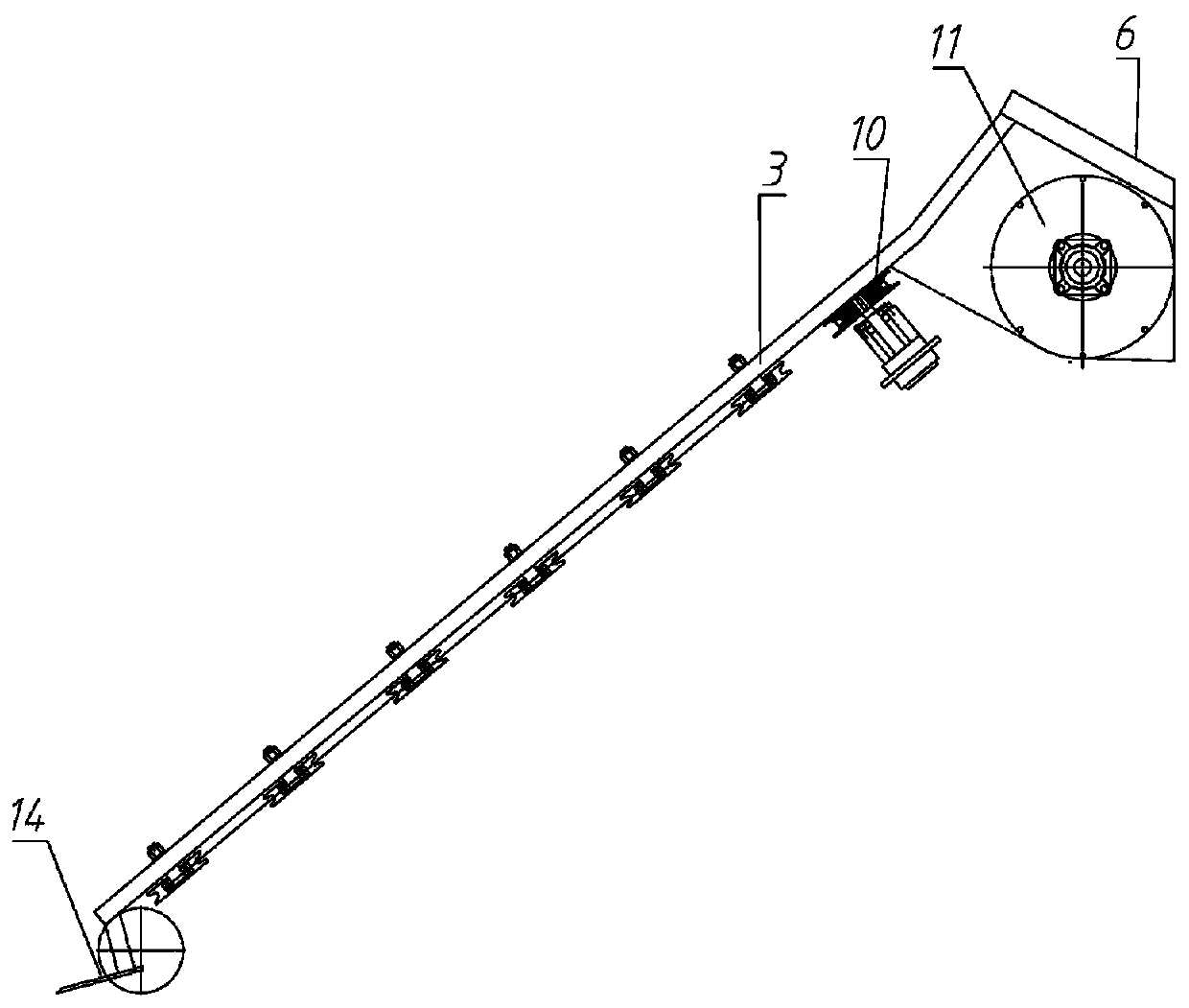

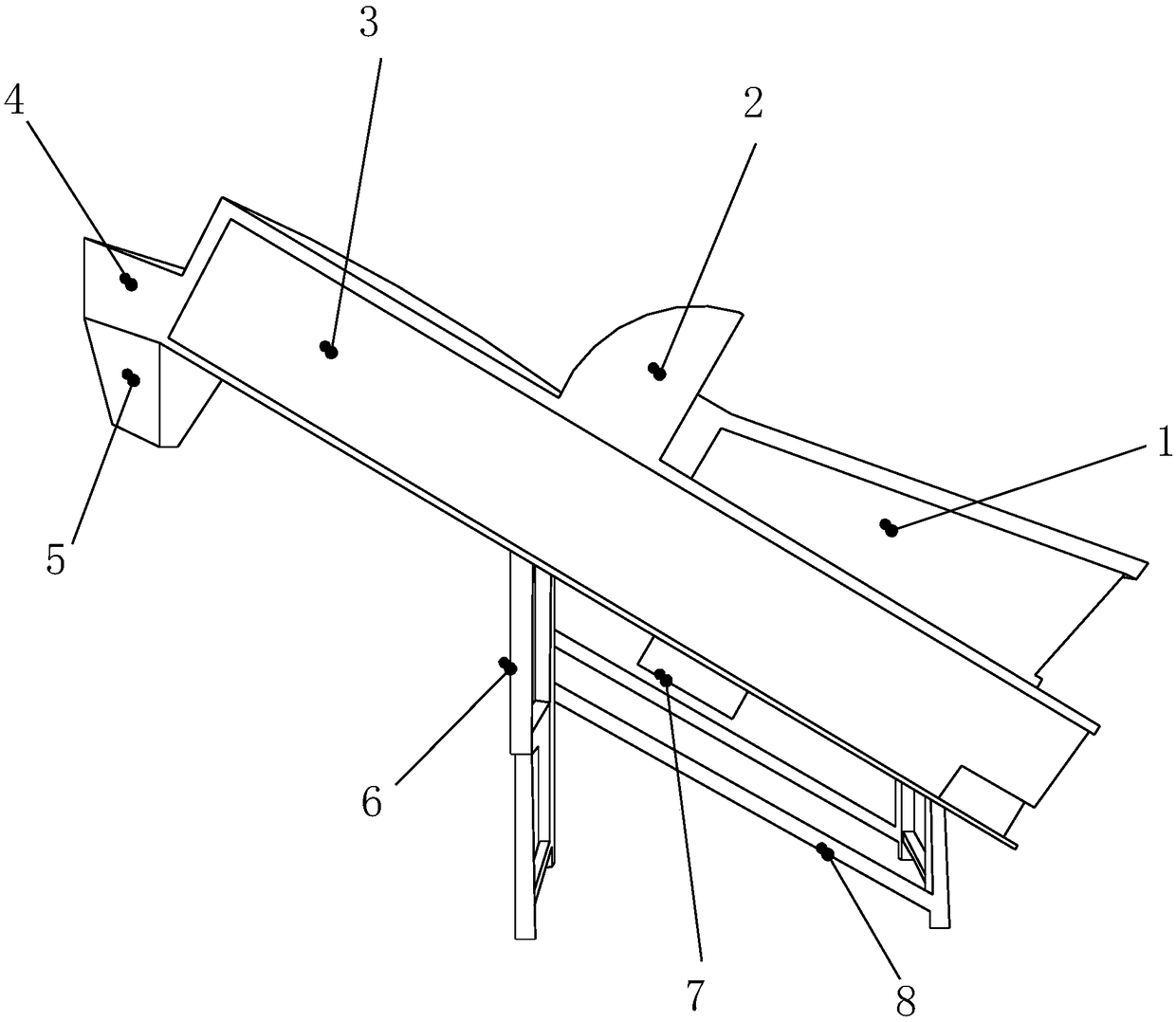

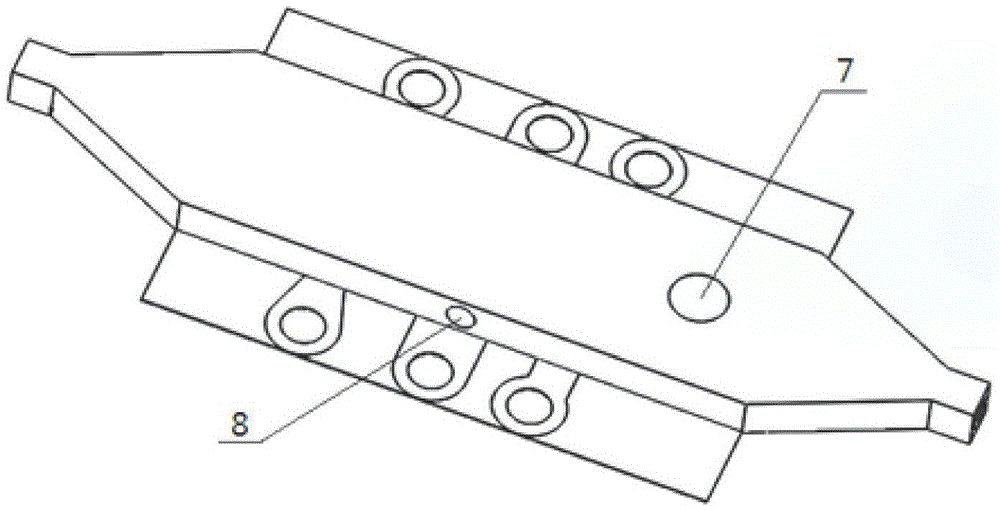

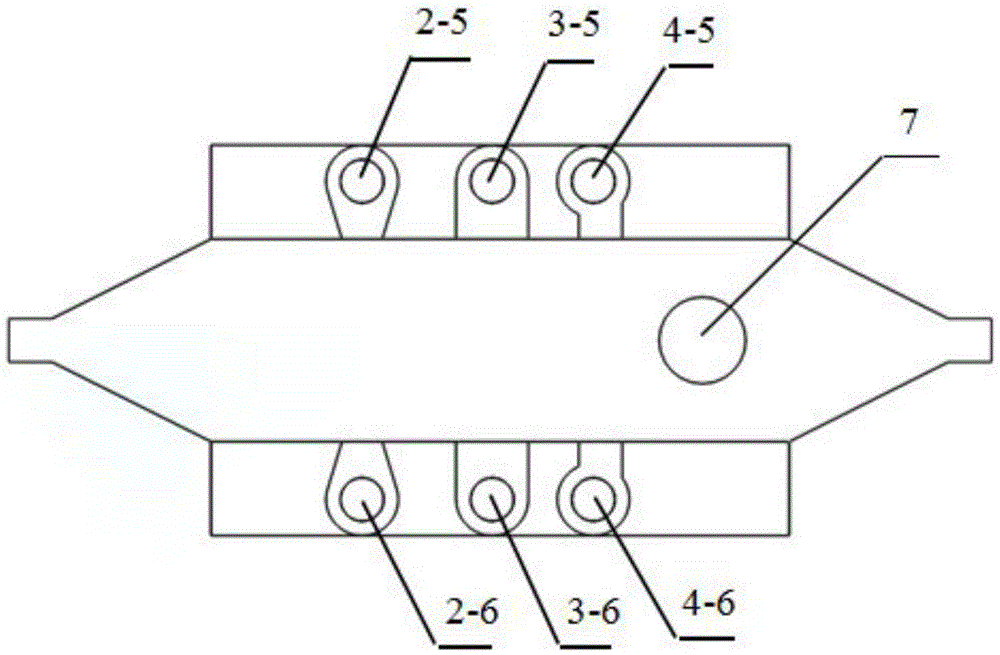

Stalk pulling and clamping conveying device of cotton stalk pulling crusher

The invention discloses a stalk pulling and clamping conveying device of a cotton stalk pulling crusher. The device comprises a rack which is obliquely arranged, wherein a film lifting shovel is arranged at the lower end of the rack, front clamping and conveying mechanisms are arranged on the rack at intervals side by side, and each clamping and conveying mechanism comprises seedling dividers, bottom guiding wheels, belt wheels, tensioning wheels, V-shaped belts and top guiding wheels positioned at the upper part of the rack; the top of the rack is provided with auger conveying rollers, a transmission box and a transmission chain wheel are arranged below rotating shafts of the top guiding wheels respectively, the transmission chain wheel is connected with an external power input mechanism,and the bottom guiding wheels, the belt wheels and the top guiding wheels are all driven to rotate by the transmission box and the V-shaped belts; the belt wheels are mounted on a belt wheel bracketthrough connecting shafts, the tension wheels are mounted on the belt wheel bracket through connecting shafts, the belt wheel bracket is fixed to the rack through connecting bolts used for connectingplates, and the connecting plates are welded to the rack. The device has the advantages of reliable work and excellent conveying capacity, and the capacity of grabbing stems can be improved.

Owner:XINJIANG AGRI UNIV

Method for ensuring stability of convection in tank furnace during replacement of batch feeder

ActiveCN110563311AWill not adjust the feeding amountFeed amount is stableCharging furnaceTank furnacesStopped workIndustrial engineering

The invention discloses a method for ensuring the stability of convection in a tank furnace during replacement of a batch feeder. At least two batch feeders are arranged in the tank furnace. The method comprises the following steps: 1, replacing a to-be-replaced batch feeder, stopping work of the to-be-replaced batch feeder, keeping regular work and stayed opening of a batch feeder which is not replaced during replacement; 2, opening the replaced batch feeder and performing feeding after the to-be-replaced batch feeder is replaced; 3, comparing the batch of the replaced batch feeder with thatof the batch feeder which is not replaced after the batch is stabilized, and the batch difference of each batch feeder is ensured to be within 5Kg; synchronously increasing the batch of all batch feeders, restoring the liquid level in a range of 0.5-1.5mm / 4h; and 4, restoring all batch feeders to normal working batch after the liquid level is restored to a required height. According to the method,unstable convection of the tank furnace caused be great batch adjustment can be reduced by slightly reducing the height of liquid level.

Owner:CAIHONG GRP SHAOYANG SPECIAL GLASS CO LTD

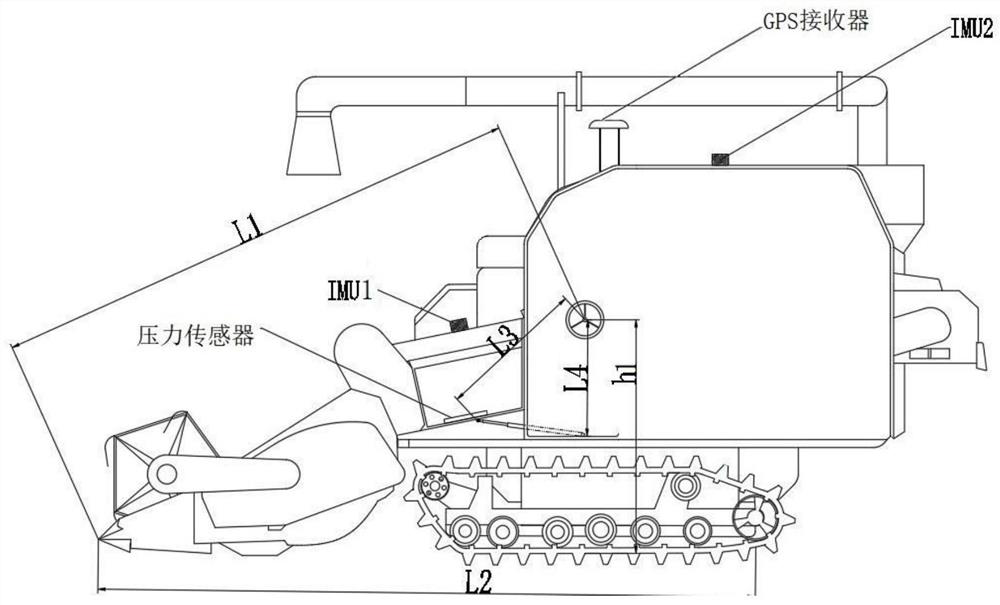

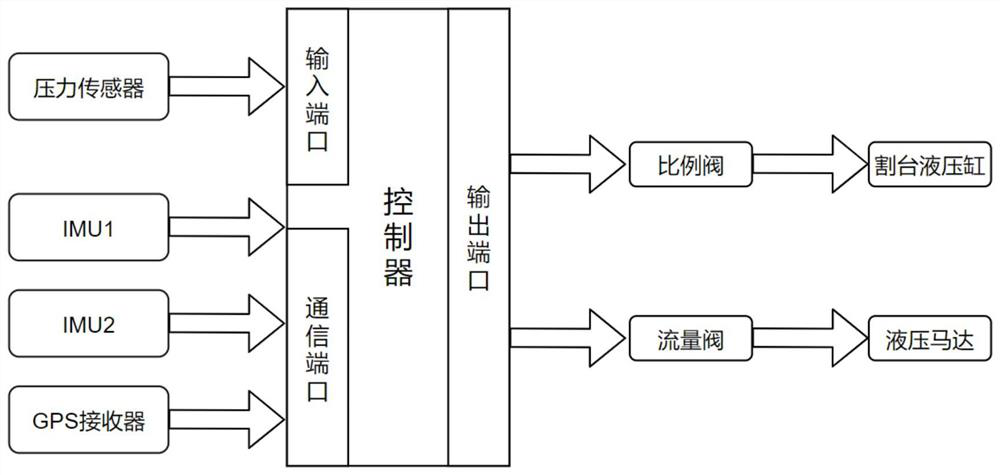

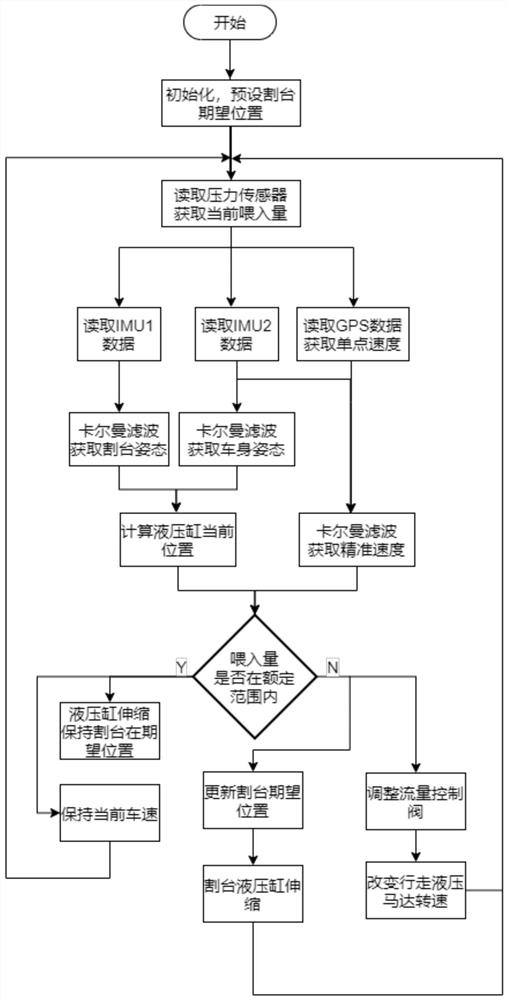

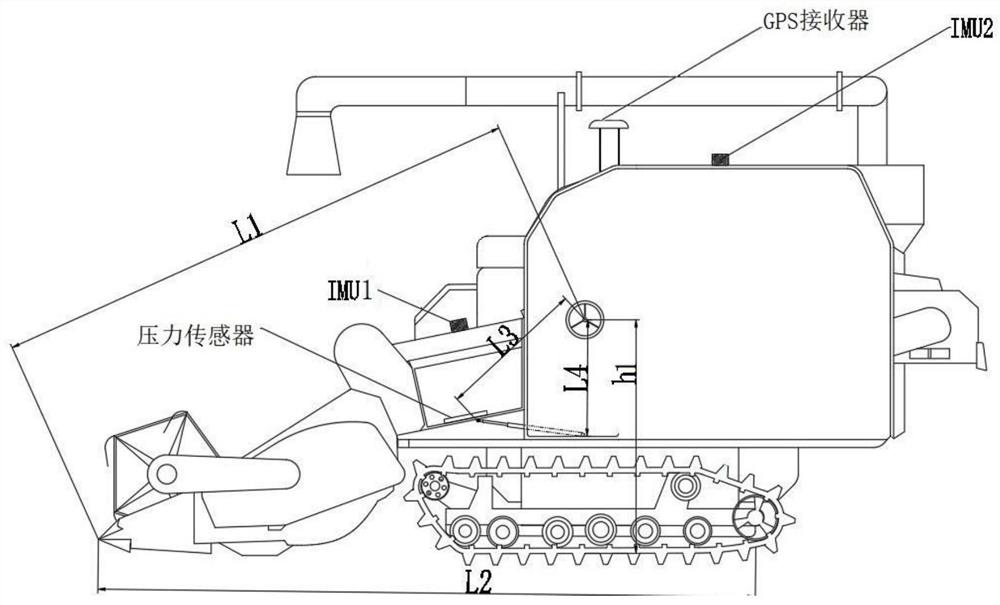

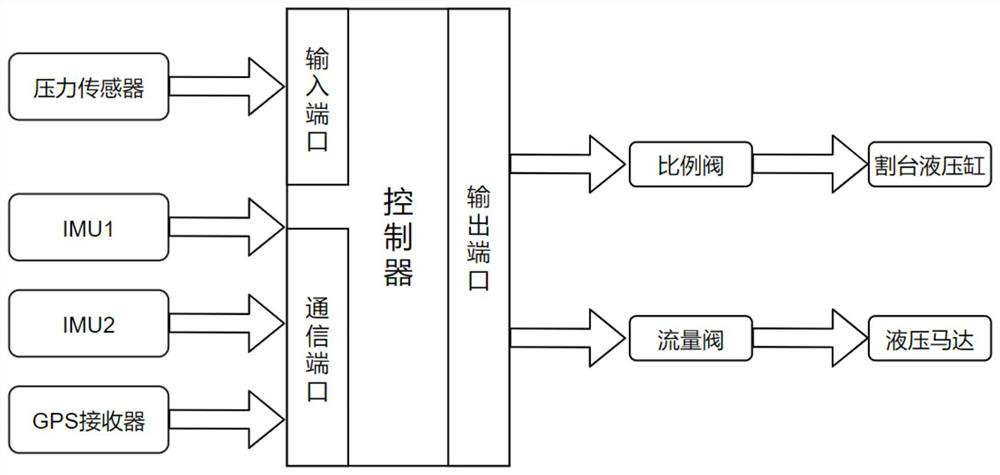

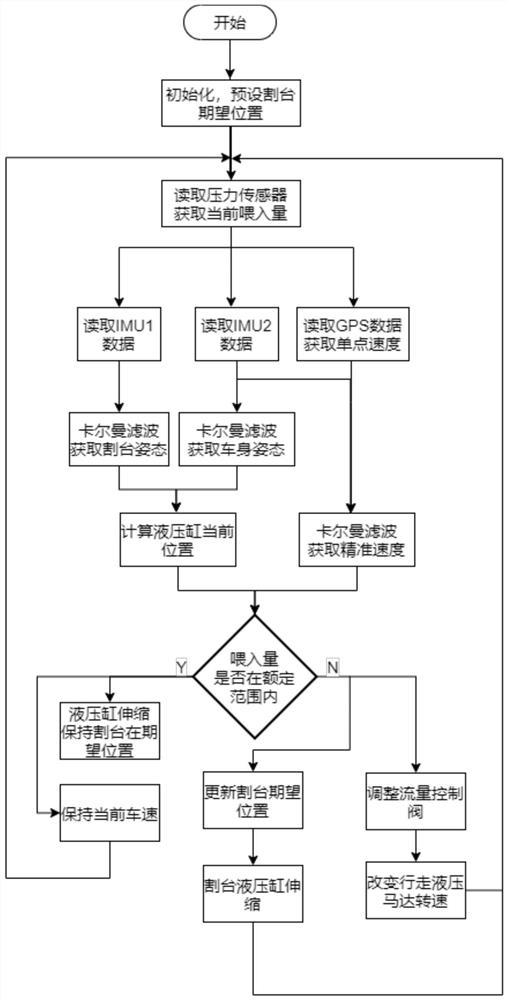

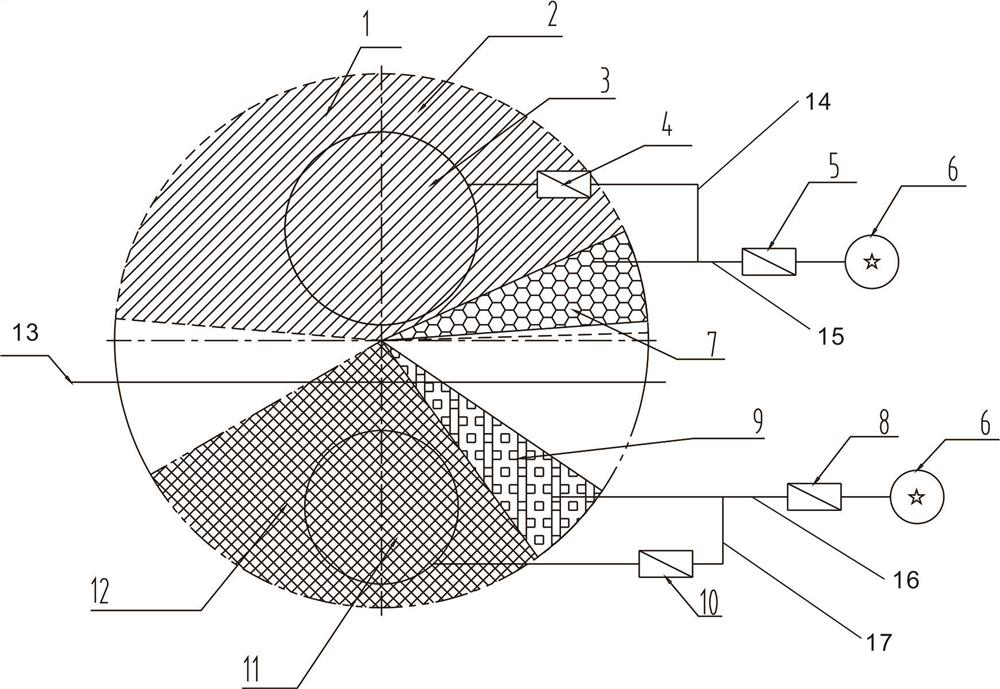

Feeding quantity regulation and control system and method for combine harvester

The invention provides a feeding quantity regulation and control system and method for a combine harvester. The regulation and control system comprises an IMU1, an IMU2, a pressure sensor, a GPS receiver and a controller, when the current feeding quantity is within the rated range, the height of a header and the operation speed of the harvester are kept unchanged, when the feeding quantity is not within the rated range, the IMU detects the posture of a vehicle body and the posture of a header inclined conveyor, the header height and a current hydraulic cylinder position corresponding to the header height are obtained through combination, the expected header height is preset, the expected header hydraulic cylinder position is obtained, the error between the expected header hydraulic cylinder position and the current hydraulic cylinder position is obtained, then the controller adjusts a proportional valve to drive the hydraulic cylinder to stretch out and draw back, and the header height is controlled to be stabilized at the expected position. Based on the speed variation, the controller controls the rotating speed of a hydraulic motor by adjusting a flow valve, and then the numerical value of the changed vehicle speed is stabilized. The height and the forward speed of the header are combined, the stable feeding amount is kept, and the efficient operation efficiency is kept.

Owner:JIANGSU UNIV

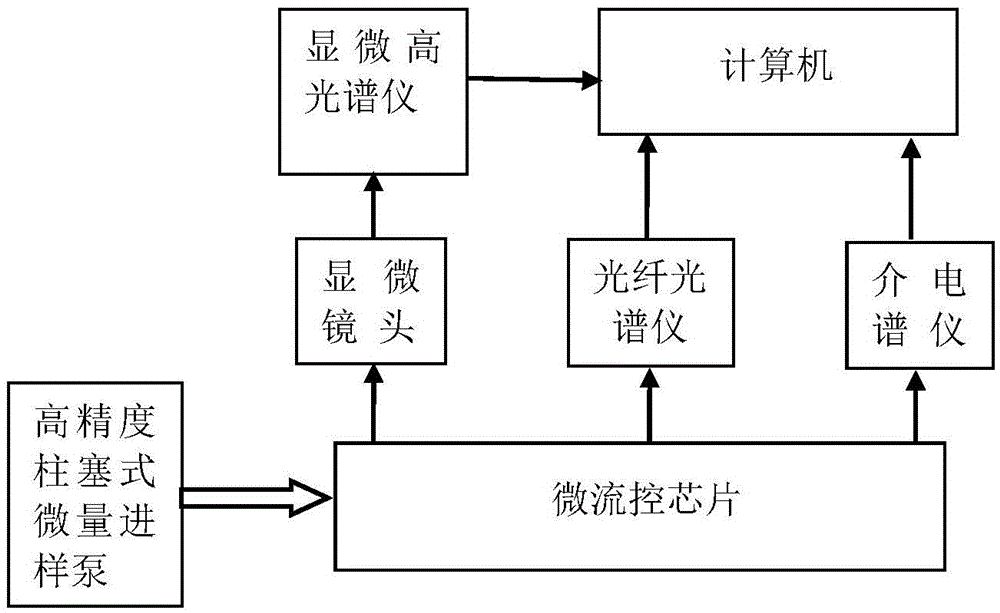

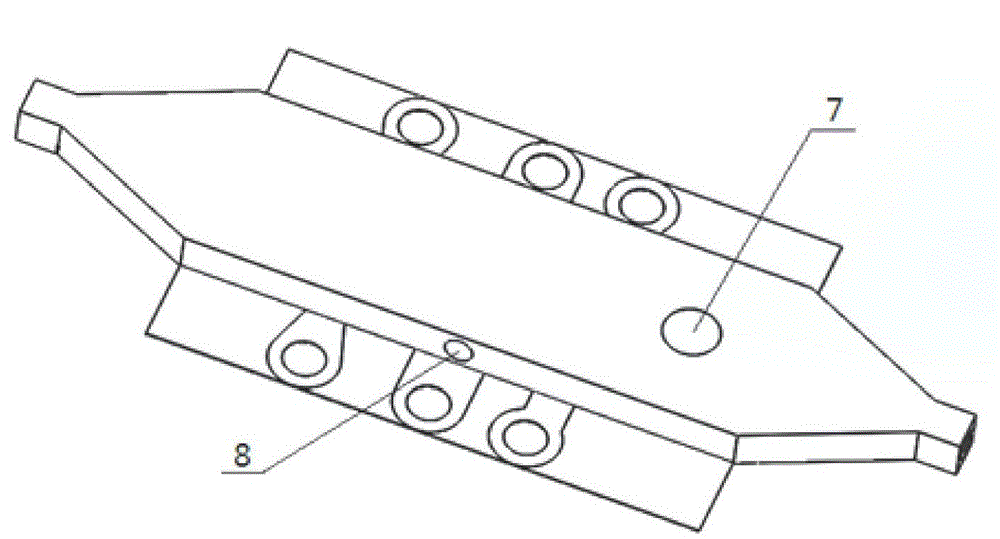

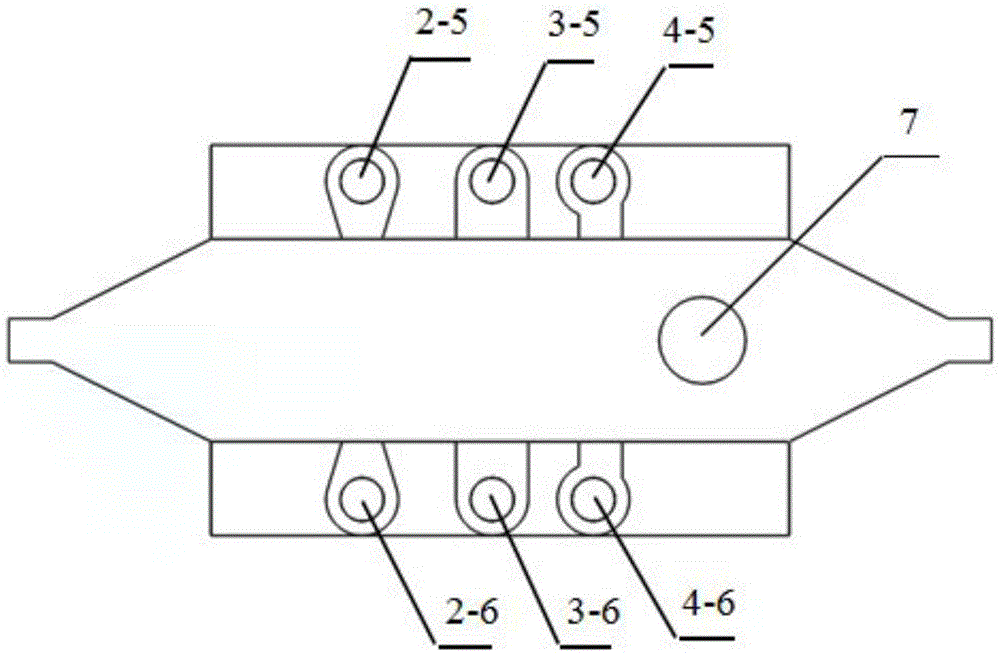

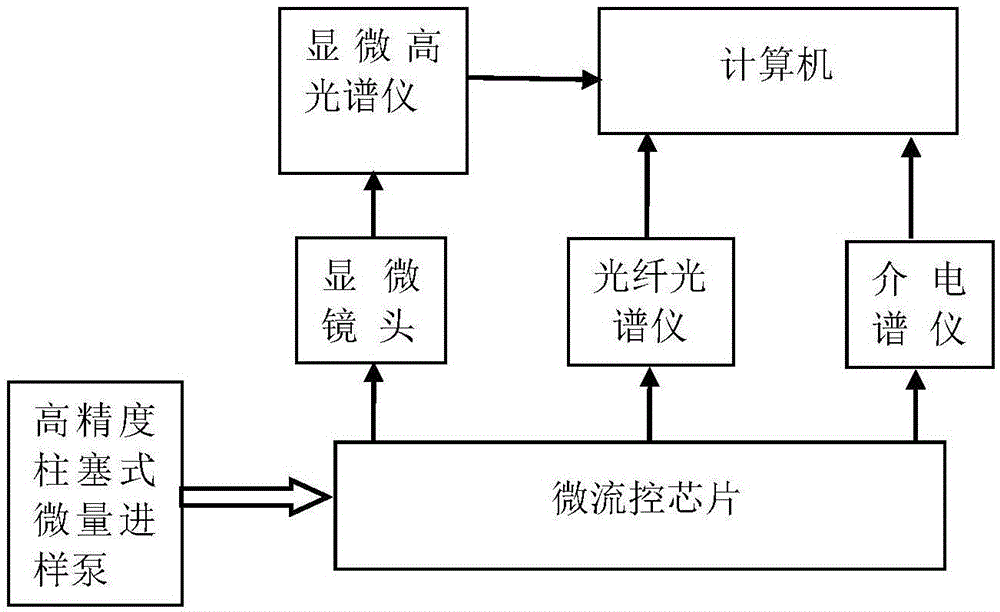

Integrated multi-parameter test platform for microbes

InactiveCN104593254ARealize acquisitionRealize synchronous acquisitionBioreactor/fermenter combinationsBiological substance pretreatmentsMicroscopic imageEngineering

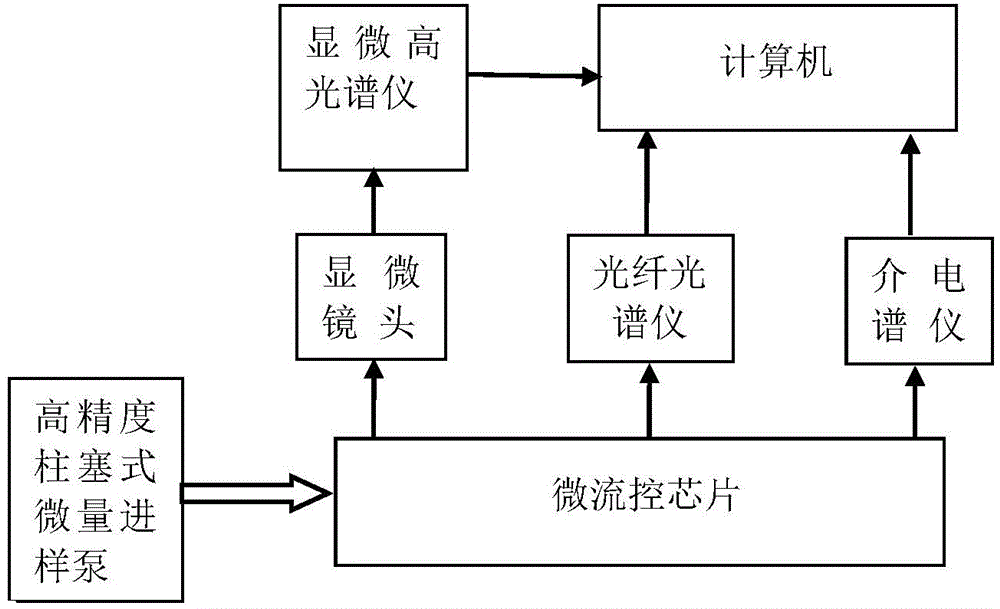

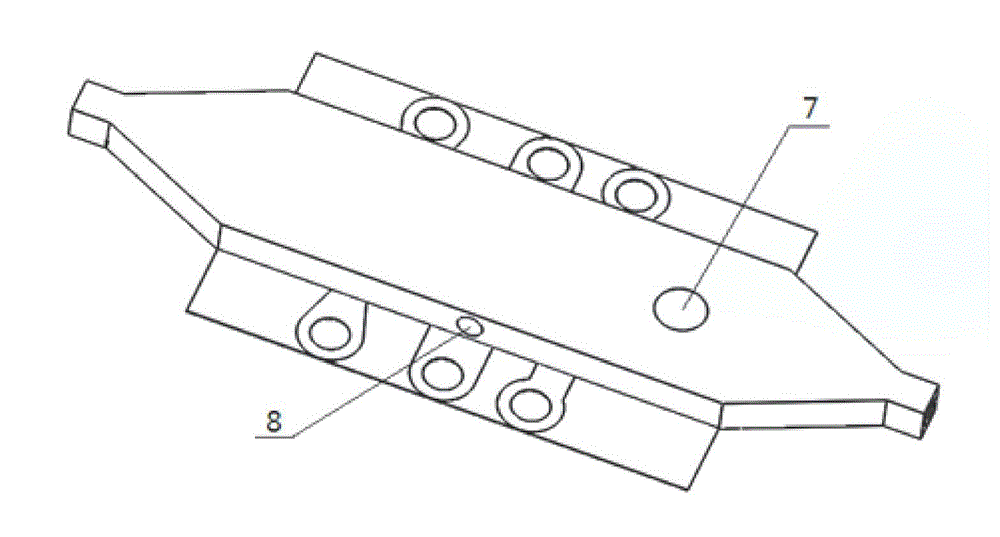

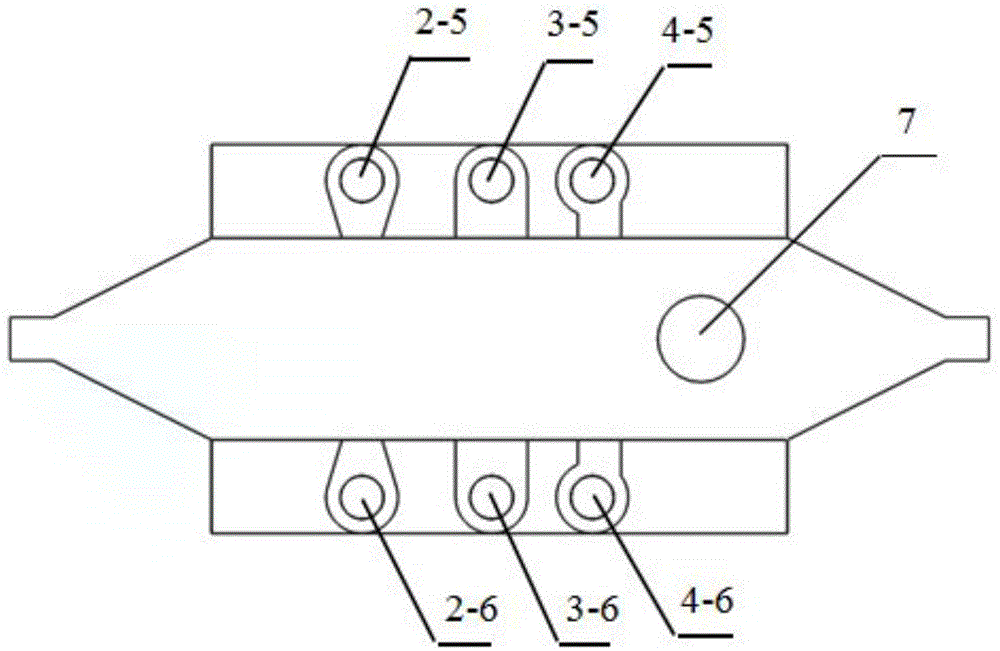

The invention discloses an integrated multi-parameter test platform for microbes. The integrated multi-parameter test platform is mainly applied to the qualitative and quantitative detection on the microbes in a liquid. The test platform comprises a high-accuracy plunger type trace sampling pump, a microfluidic chip, a microscopic lens, a microscopic high spectrometer, a computer, a fiber spectrometer and a dielectric spectrometer, wherein the high-accuracy plunger type trace sampling pump can be used for accurately controlling the sampling of a microbial test solution. According to the platform, information acquisition of microscopic images of the microbes in the liquid can be realized, meanwhile, spectral characteristic information and dielectric property information on the microbes can be acquired, and the synchronous acquisition of multivariate information on the microbes is realized, so that the synchronous acquisition of the multivariate information on the microbes is realized, the efficiency of detection is increased, and the accuracy of detection is improved.

Owner:TIANJIN AGRICULTURE COLLEGE

Dust prevention and removal device for agricultural equipment

InactiveCN108380597AAvoid enteringPerfect dust removalAgricultural machinesCleaning processes and apparatusElectricityPower controller

The invention discloses a dust prevention and removal device for agricultural equipment. The dust prevention and removal device structurally comprises an intelligent dust cleaning and prevention transmission device, a gear position plate, a device shell, a fixing frame, a discharging device, a movable support, a power source controller and reinforcing ribs. The movable support is located on the lower surface of the device shell, and meanwhile, the movable support and the device shell are connected together in a welded manner. The reinforcing ribs are arranged below the inner side surface of the movable support and are perpendicular in pairs. The power source controller is perpendicularly connected to the center of the lower surface of the device shell, penetrates the lower surface of the device shell and is electrically connected with an internal intelligent dust cleaning and prevention transmission device. The intelligent dust cleaning and prevention transmission device is fixedly mounted at the right side of the upper surface of the device shell. By means of the dust prevention and removal device, when an agricultural machine works, dust on crops can be thoroughly cleaned throughcertain transmission; in addition, the dust can be prevented from entering the equipment; and meanwhile, the feeding amount of the equipment can be stable, and thus the purpose that the device is perfected to a greater extent is achieved.

Owner:柴哲民

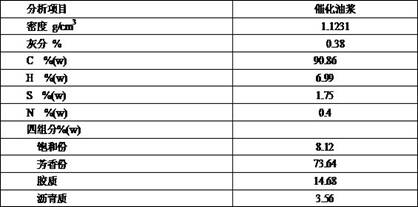

Method of producing carbon material

ActiveCN111892952AGood application effectHigh yieldThermal non-catalytic crackingTreatment with hydrotreatment processesDistillationCoke

Owner:CHINA PETROLEUM & CHEM CORP +1

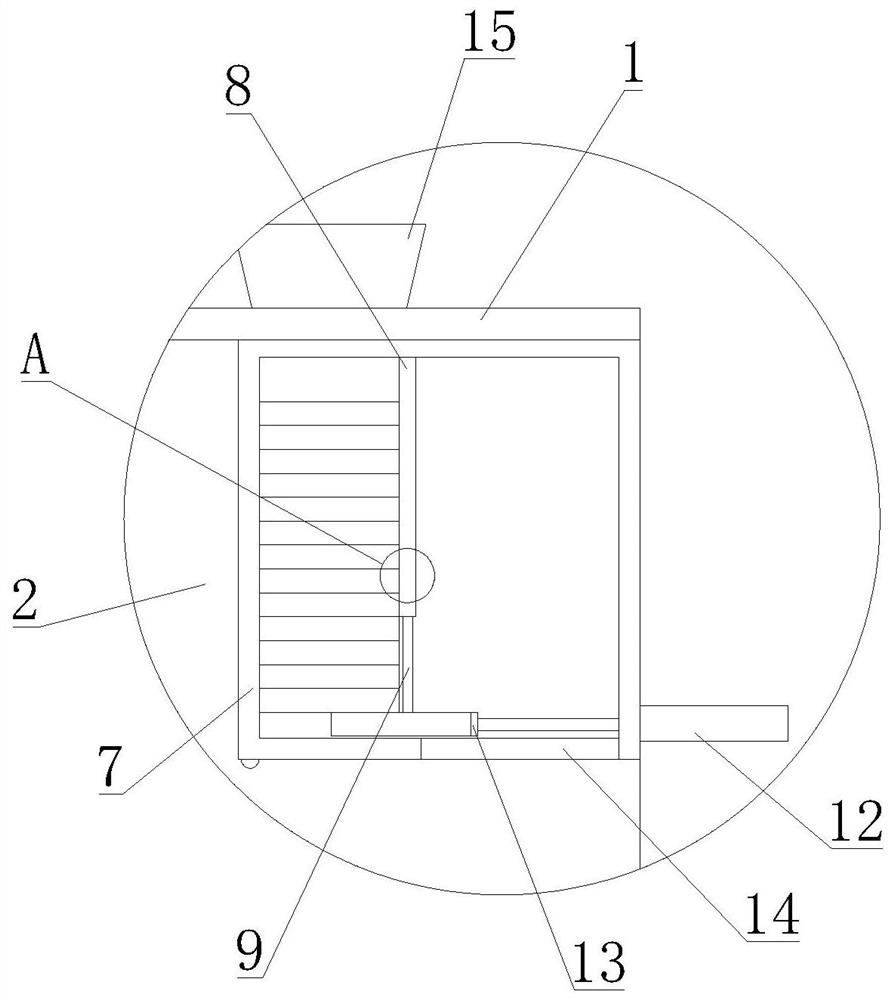

Battery core flattening equipment for lithium battery production process

ActiveCN112421120AAccurate cutting amountFeed amount is stableFinal product manufactureElectrolyte accumulators manufacturePhysicsCold air

Battery cell flattening equipment for a lithium battery production process comprises a working cabin, a discharging assembly, a conveying assembly, a flattening assembly, an unloading assembly, a laser positioner assembly and a controller. The conveying assembly is arranged in the working cabin; the discharging assembly is arranged above the feeding end of the conveying assembly; the flattening assembly is arranged in the working cabin; and the discharging assembly is arranged below the discharging end of the conveying assembly. Efficient circulation of discharging, flattening and dischargingis achieved, and automation performance is high; a die and an extrusion plate are convenient to mount and dismount; a battery cell is softened in a heating mode, the difficulty of a flattening processis reduced, cold air is supplied to the flattened battery cell to help the flattened battery cell to be cooled, the purpose of rapid shaping is achieved, and the stability of a flattening effect is guaranteed; the central position of the battery cell is extruded by the extrusion plate, and the edge of the battery cell is rotatably extruded by an extrusion roller so that the battery cell is uniformly stressed, and the flattened battery cell is uniform in thickness; and the fixed seat is rotatably matched and knocked so that the stress is uniform, and a discharging speed is increased.

Owner:安徽新品源电池技术有限公司

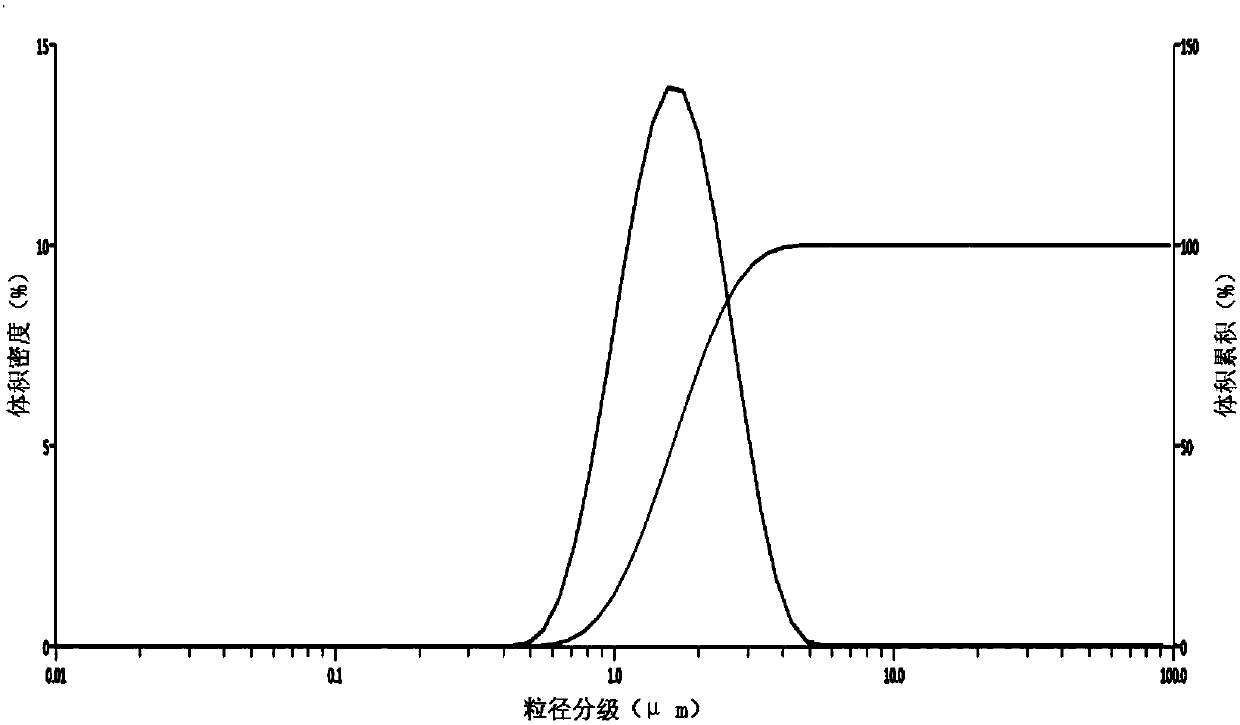

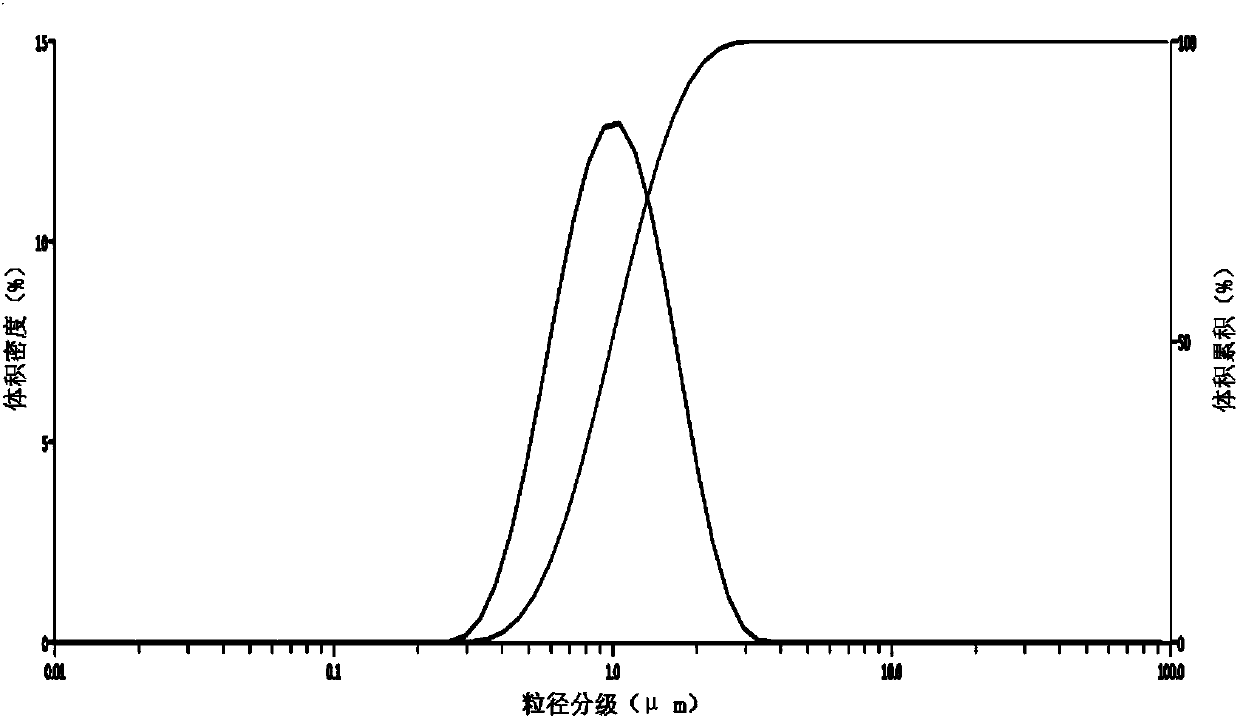

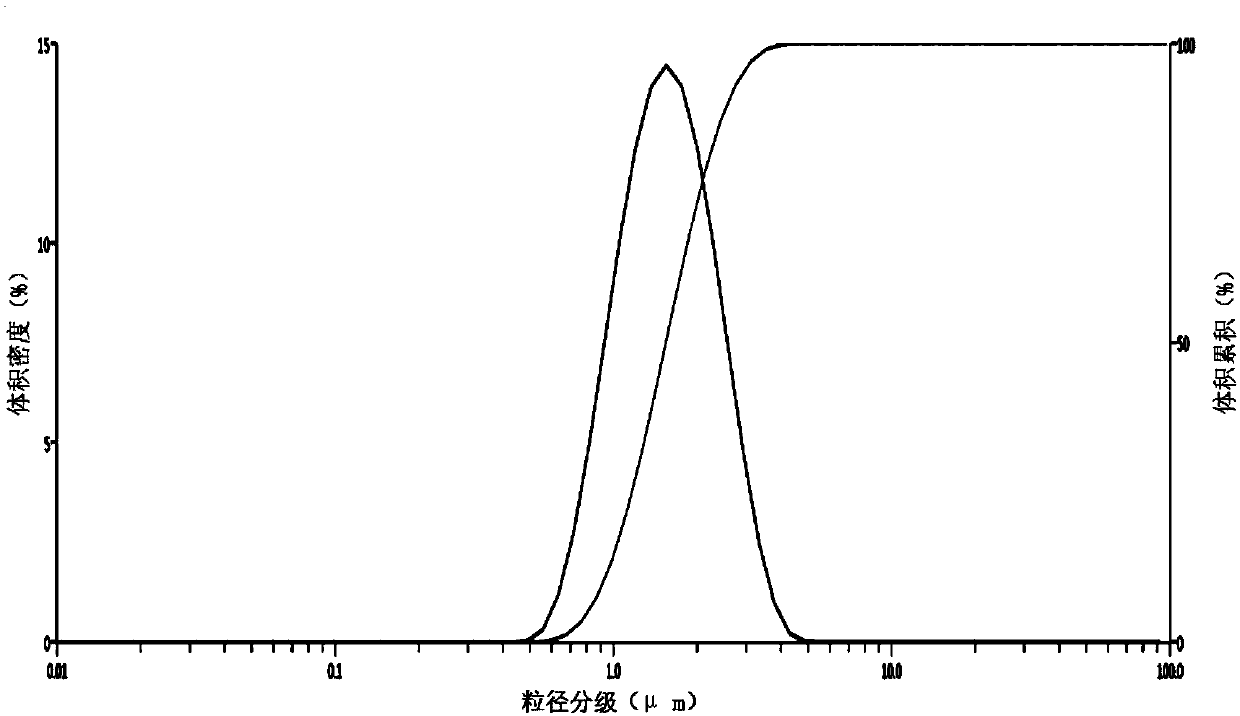

Metal powder grading method

ActiveCN108031649AImproved particle size distributionGood dispersionGas current separationDispersitySlurry

The invention provides a method adopting air flow grading for spherical and spheroid micro-order-particle-diameter metal powder so as to achieve the effect that particle dispersity is high, the particle diameter distribution consistency is high, and secondary pollution is avoided. The method mainly comprises the following main steps that 1, a selective high-pressure gas source is utilized to accelerate materials; and 2, air flow grading and collecting are conducted. According to the crushing and dispersing method, the dispersity and particle-diameter consistency of different metal particle products can be greatly improved, ultra-micro-fine (the average particle diameter is smaller than 0.1 [mu]m) and ultra-large irregular metal particles (the average particle diameter is larger than 10 [mu]m) are effectively removed, particularly the high-pressure gas source is utilized to serve as material conveying power and used for air flow returning in a grading system, secondary pollution of an equipment body and the environment in the treatment process to the products can be effectively avoided, and thus the metal powder products completely meet production of high-end conductive slurry and 3D printing materials.

Owner:SUZHOU SMART ADVANCED COATING TECH CO LTD

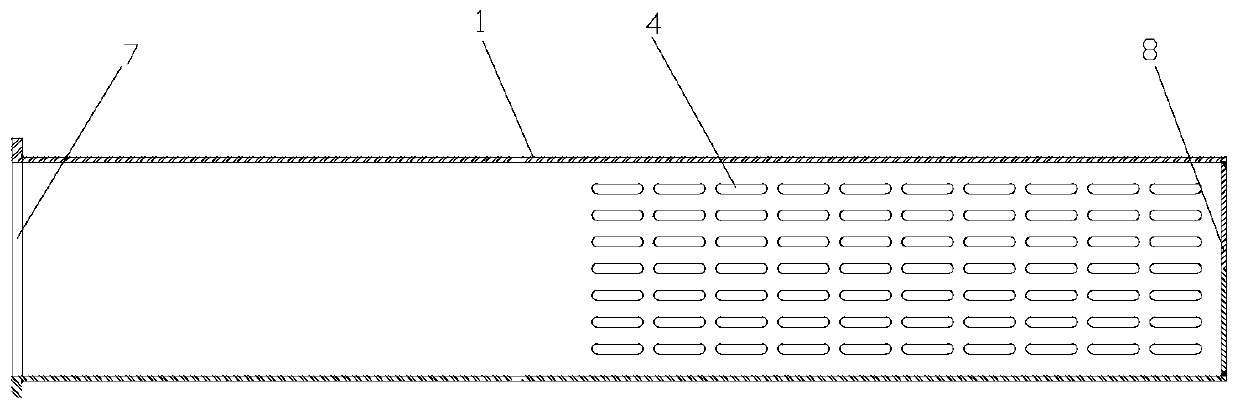

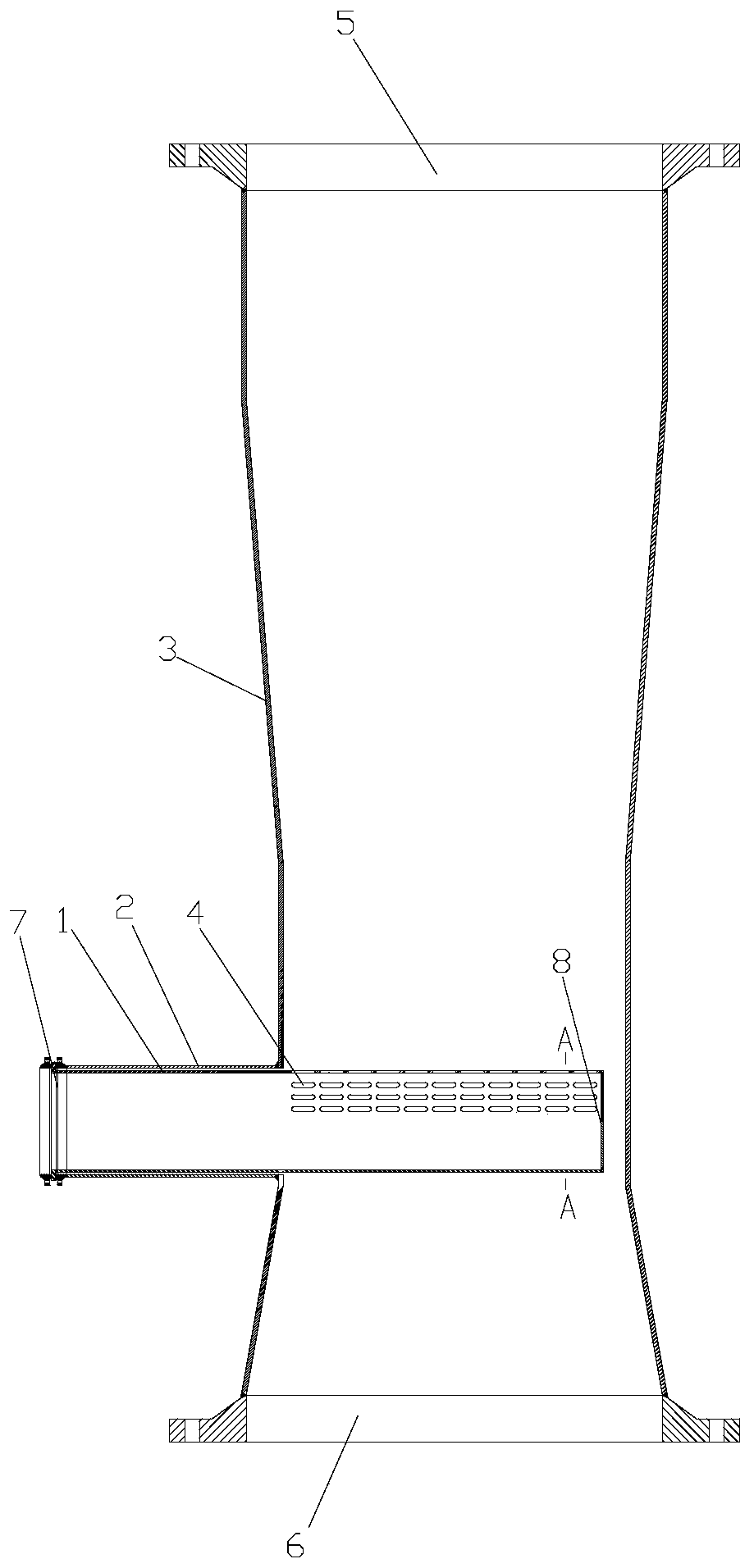

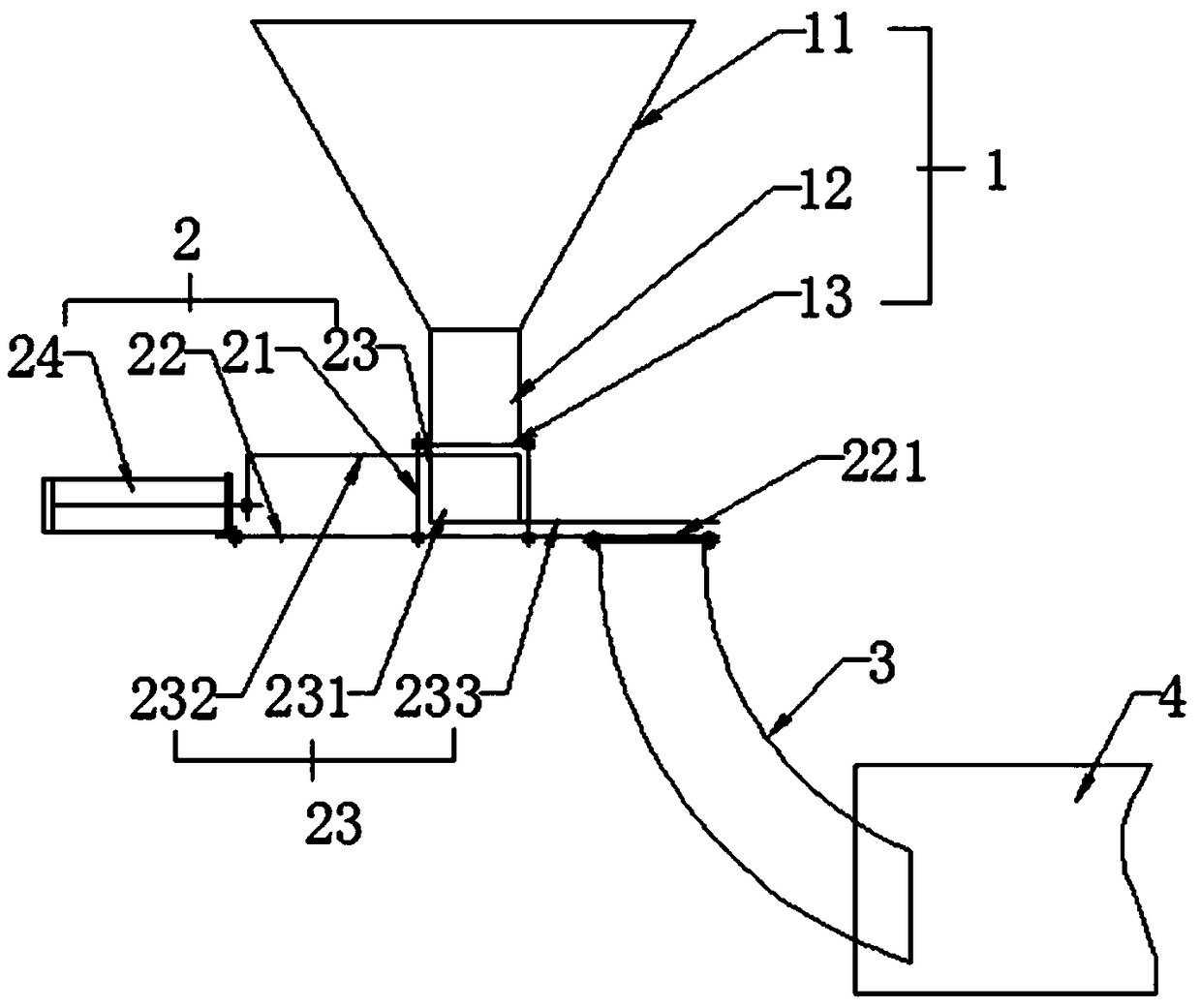

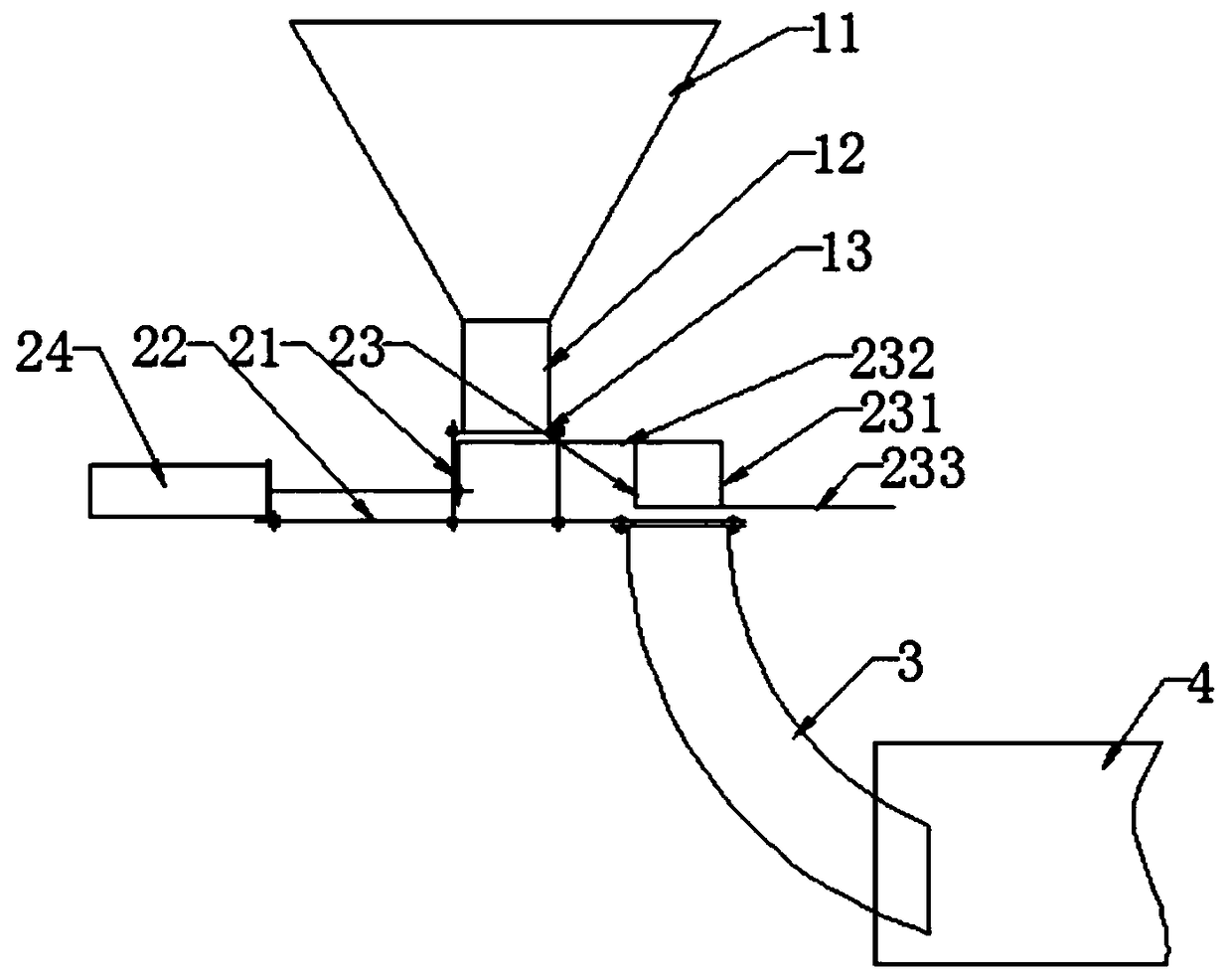

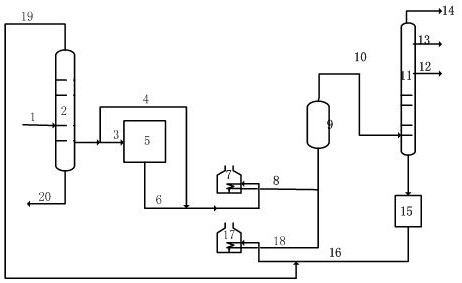

Gas-phase naphthalene feeder of phthalic anhydride device

The invention provides a gas-phase naphthalene feeder of a phthalic anhydride device. The gas-phase naphthalene feeder of the phthalic anhydride device comprises a feeding pipe (1), an outer sleeve (2) and a Venturi mixer (3); the outer sleeve (2) is fixedly connected onto the outer wall of the Venturi mixer (3); the feeding pipe (1) is sleeved in the outer sleeve (2), and one end the feeding pipe(1) stretches out of the outer sleeve (2) and enters the Venturi mixer (3); the end portion of one end, located in the Venturi mixer (3), of the feeding pipe (1) is sealed; long-strip holes (4) are formed in a part, located in the Venturi mixer (3), of the feeding pipe (1); the openings of the long-strip holes (4) face towards the low-pressure area of the Venturi mixer (3). According to the gas-phase naphthalene feeder of the phthalic anhydride device, uniform mixing of gas-phase naphthalene and air can be ensured; the reaction efficiency can be improved while the stability and safety of an oxidation reaction are improved; the product quality is improved; the oxidation yield is improved.

Owner:邢台旭阳化工有限公司

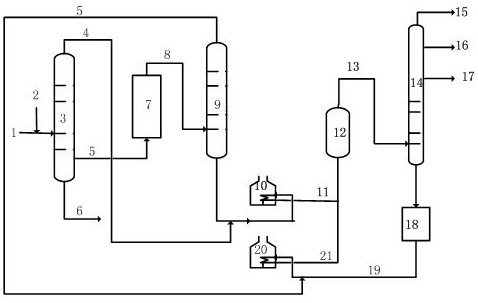

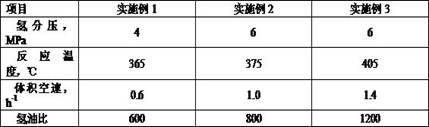

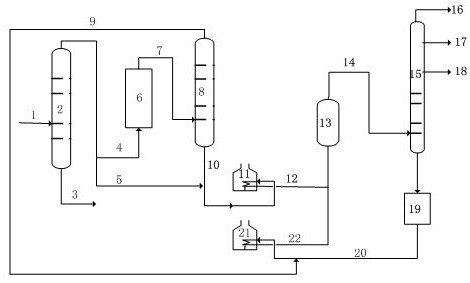

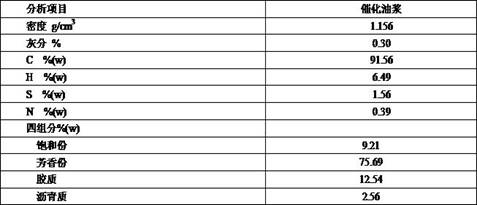

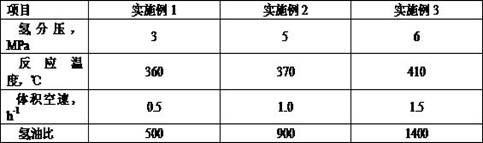

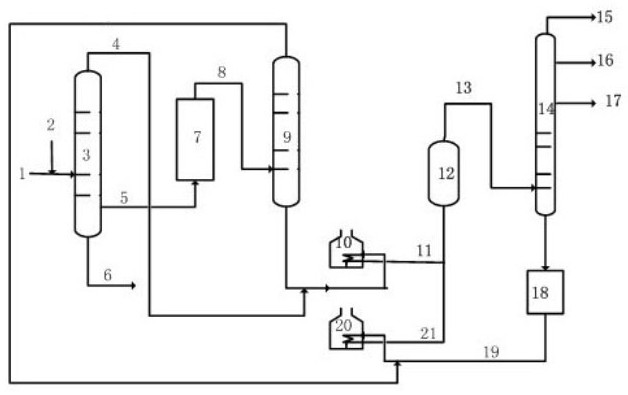

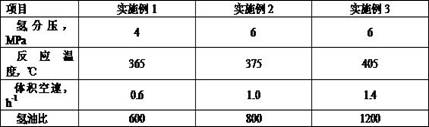

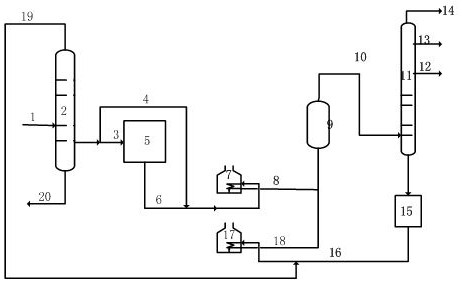

A method for producing needle coke with combined process

ActiveCN111892950BReduce coke sulfur contentLower coke thermal expansion coefficientTreatment with hydrotreatment processesFluid phaseCoke

The invention discloses a method for producing needle coke with a combined process. The content of the method is as follows: light distillate oil and heavy distillate oil are fractionated from raw oil through a vacuum distillation device, and the heavy distillate oil goes out of the device. Hydrogen treatment device, the liquid phase product obtained after hydroprocessing passes through the fractionation device to at least separate hydrogenated light distillate oil and hydrogenated heavy distillate oil, and the hydrogenated heavy distillate oil is used as the material for forming the mesophase to be heated by the heating furnace a and then enters the coke tower , the coking gas generated by the coke tower passes through the coking fractionation tower to obtain coker wax oil, which is mixed with hydrogenated light distillate oil as a coke pulling material, heated by heating furnace b, and then enters the coke tower, and the coke tower completes the stages of mesophase formation and Needle focus is obtained after the focus pull stage. The method can continuously produce high-quality needle coke with stable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

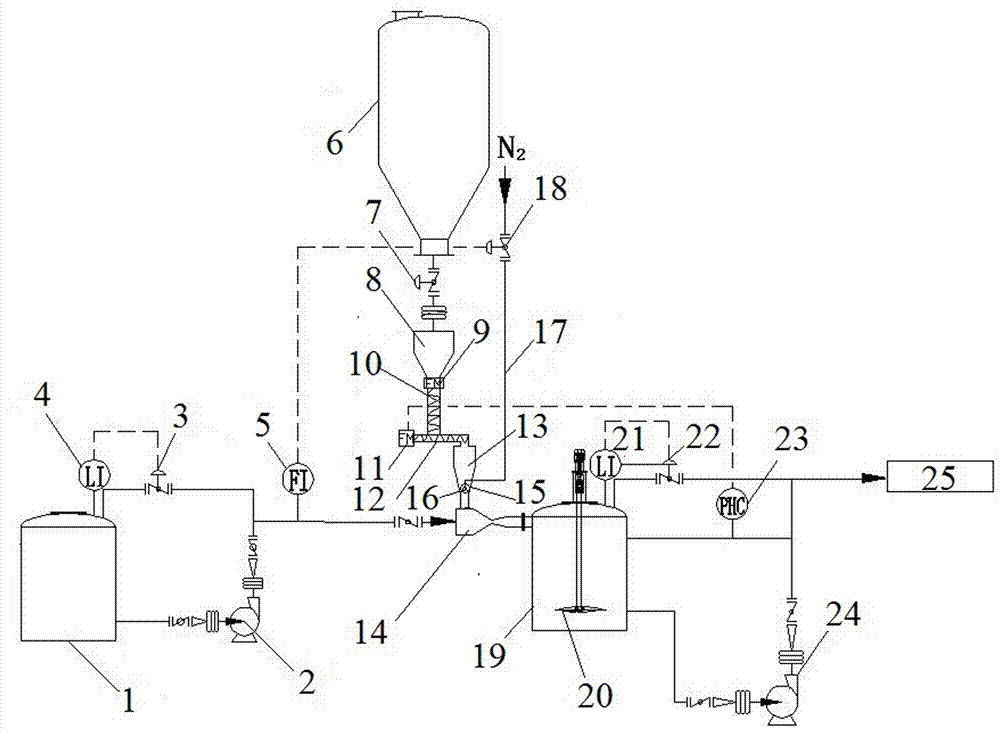

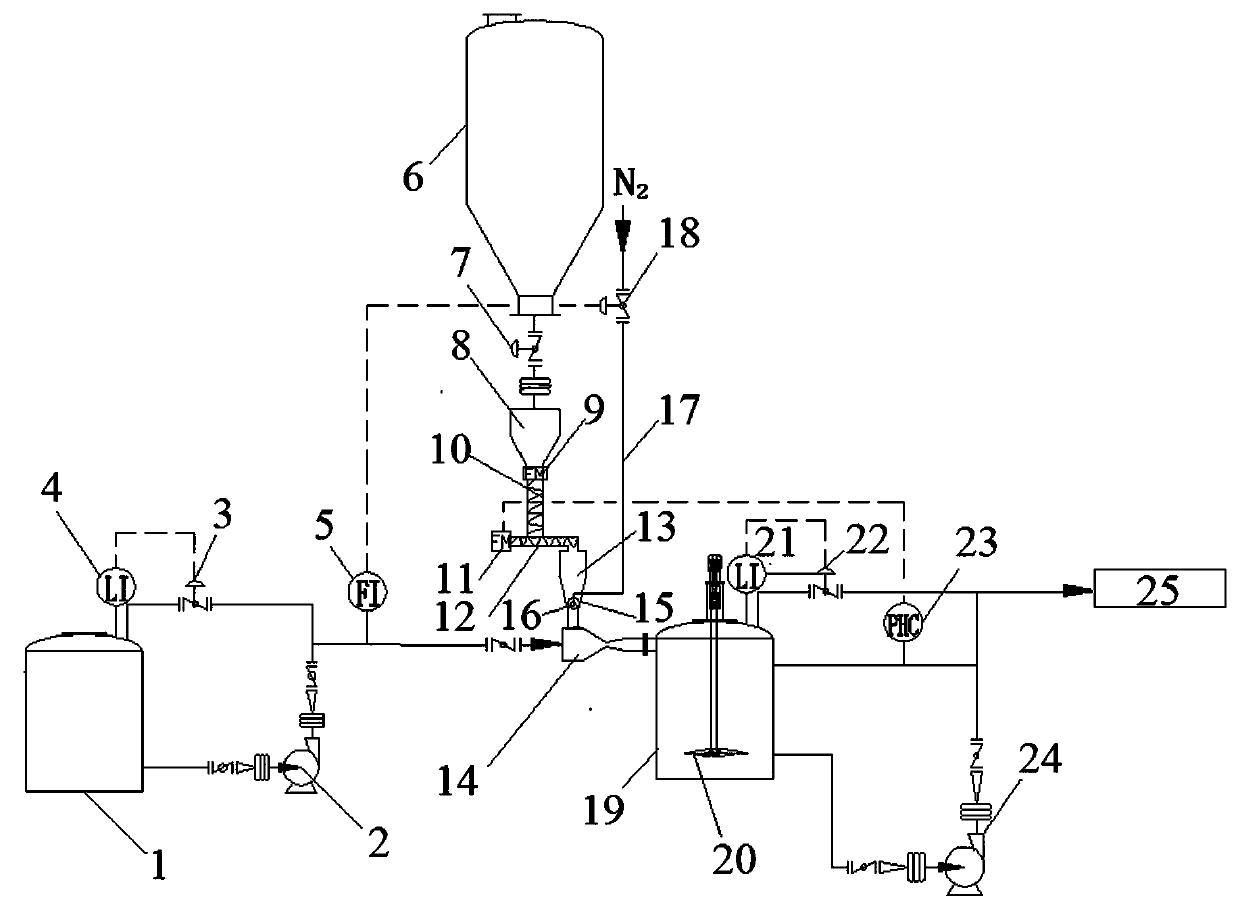

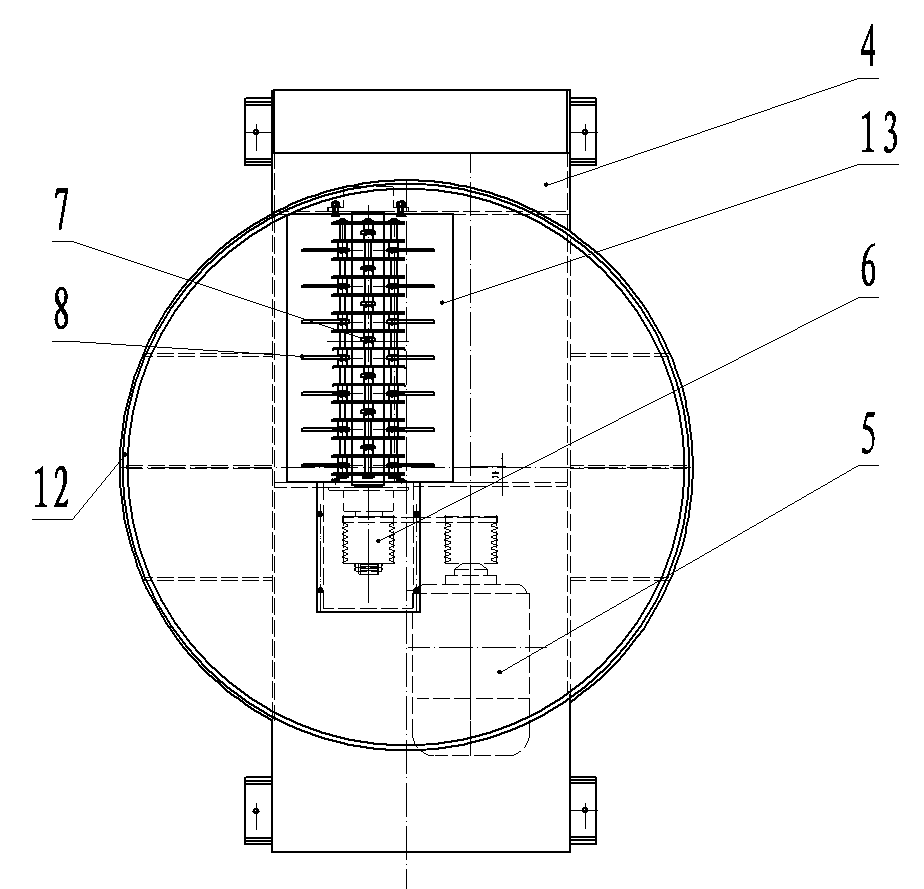

Magnesium oxide neutralization system and method for acid-making acid wastewater of smelting flue gas

ActiveCN107540074AAvoid cloggingWell mixedWaste water treatment from metallurgical processWater/sewage treatment by neutralisationNitrogen gasTreatment system

The invention discloses a magnesium oxide neutralization system and method for the acid-making acid wastewater of smelting flue gas, and belongs to the technical field of chemical engineering. The system mainly includes an acid water buffer tank, a magnesium oxide storage tank, a charging storage tank, a vertical spiral conveyor, a horizontal spiral conveyor, a hopper, a nitrogen purging device, an ejector and an acid water reaction tank; through the boosting function of the vertical and horizontal spiral conveyors, the nitrogen purging function, and the negative pressure absorbing function ofthe ejector, magnesium oxide powder is conveyed into the ejector, is mixed with the acid wastewater fully, and then enters into the acid water reaction tank. According to the magnesium oxide neutralization system and method, magnesium oxide solid powder is separated at the front end of the ejector, and it is avoided that the acid wastewater enters into the hopper to cause the magnesium oxide powder to be damped to cause blocking; therefore, the continuous and stable operation of the acid wastewater treatment system is ensured.

Owner:JINCHUAN GROUP LIMITED

Small self-propelled alfalfa cradling and flattening machine

The invention discloses a small self-propelled alfalfa cradling and flattening machine, belonging to the technical field of agricultural machinery. The small self-propelled alfalfa cradling and flattening machine is mainly composed of a working device, a hydraulic lifting device, an operation system, a power and transmission system and a travelling system; the working device, the hydraulic lifting device and the operation system are arranged at the front part of the machine; the power and transmission system and the travelling system are arranged at the middle rear part of the machine; one end of the hydraulic lifting device is connected with the working device, and the other end of the hydraulic lifting device is connected with the machine frame; and the power and transmission system is connected with the operation system and the travelling system through the hydraulic device, gear transmission and a transmission part. The small self-propelled alfalfa cradling and flattening machine is designed for flattening and paving alfalfas into fluffy swathes while cradling alfalfas aiming at alfalfa obtaining works in small lands, such as hills, mountainous regions and the like; a cradling table device and a flattening device are connected by adopting a frame type structure, unparallel four-connecting-rod lifting mechanisms are adopted, and when the machine climbs, a cradling table can be lifted without influencing stability of the whole machine, so that operation is safer and more stable; stepless speed regulation can be realized by driving a front axle through a hydraulic motor; the working efficiency is increased; and simultaneously, the small self-propelled alfalfa cradling and flattening machine has wider practicability.

Owner:CHINA AGRI UNIV

Microbial multi-parameter comprehensive testing platform

InactiveCN104593254BDetection of dielectric propertiesRealize acquisitionBioreactor/fermenter combinationsBiological substance pretreatmentsMicroscopic imageEngineering

Owner:TIANJIN AGRICULTURE COLLEGE

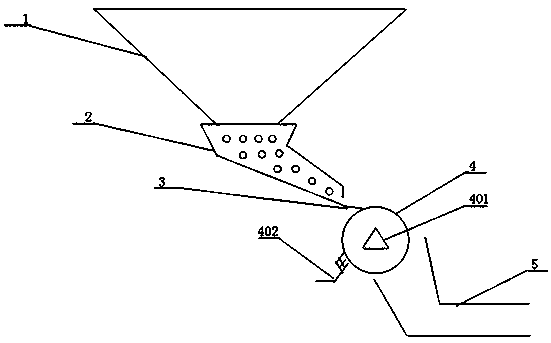

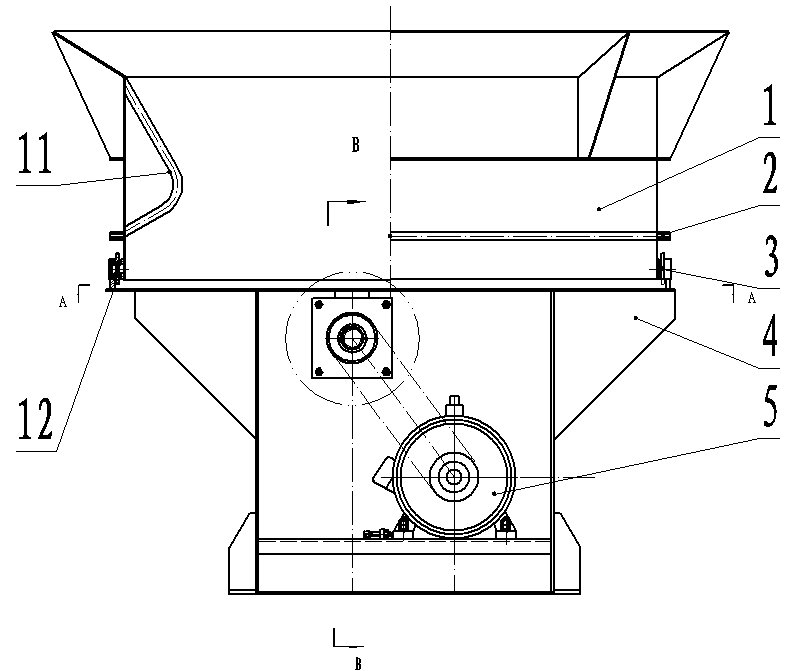

Straw briquetting automatic feeding buffer apparatus

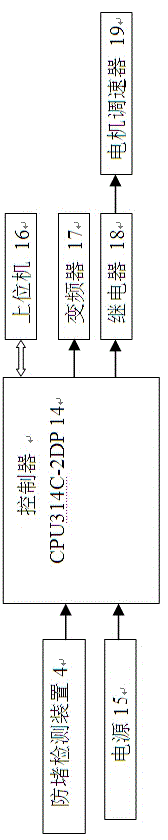

InactiveCN104865886AAvoid cloggingContinuous feedPIc system structureProgramme control in sequence/logic controllersAgricultural scienceReduction drive

The invention discloses a straw briquetting automatic feeding buffer apparatus. The feeding buffer apparatus is composed of a spiral feeder driving motor, a decelerator assembly, a bearing A, an anti-blocking detection device, a feeding port, a surge bin, a grass poking claw driving motor, a grass poking claw, a grass poking claw protection cover, a bearing B, a spiral feeder, a discharge port and a control unit. Under the action of the control unit, straw can be continuously, uniformly and quantitively output through the discharge port of the spiral feeder, and a blocking problem due to a condition that the straw is hung above the spiral feeder in the surge bin is solved through directional rotation of the grass poking claw. By employing the feeding buffer apparatus, a straw blocking problem caused by a condition that the manual feeding quantity does not match the briquetting equipment straw feeding quantity is solved through the buffer action of the surge bin, and shortcomings that manual feeding for the briquetting equipment is nonuniform and unstable are overcome. The feeding buffer apparatus is simple in structure, high in practicality and wide in applicable range, can be combined with most straw briquetting equipment, and can quantitively, continuously, uniformly and stably feed the straw to the straw briquetting equipment.

Owner:JIANGSU UNIV

A method of producing carbon material

ActiveCN111892952BGood application effectHigh yieldThermal non-catalytic crackingTreatment with hydrotreatment processesWaxThermodynamics

The invention discloses a method for producing carbon materials. The content of the method is as follows: a raw material oil is mixed with a certain proportion of vacuum residue oil, and then light distillate oil, middle distillate oil and tower bottom tail oil are separated through a vacuum distillation device. The tail oil goes out of the device, and the decompressed middle distillate oil enters the hydrotreating device, and the liquid phase product obtained after hydrotreating passes through the fractionating device to separate at least hydrogenated light distillate oil and hydrogenated heavy distillate oil, and hydrogenated heavy distillate oil After being mixed with the vacuum distillation light distillate oil, it is used as an intermediate phase material to be heated by the heating furnace a and then enters the coke tower, and the coking gas generated by the coke tower passes through the coking fractionation tower to obtain coked wax oil, and the coked wax oil is combined with the hydrogenation The light distillate oil is mixed as the coke pulling material, heated by the heating furnace b, and then enters the coke tower, and the coke tower completes the mesophase formation stage and the coke pulling stage in turn to obtain needle coke. The method can continuously produce high-quality high-end carbon materials with stable performance.

Owner:CHINA PETROLEUM & CHEM CORP +1

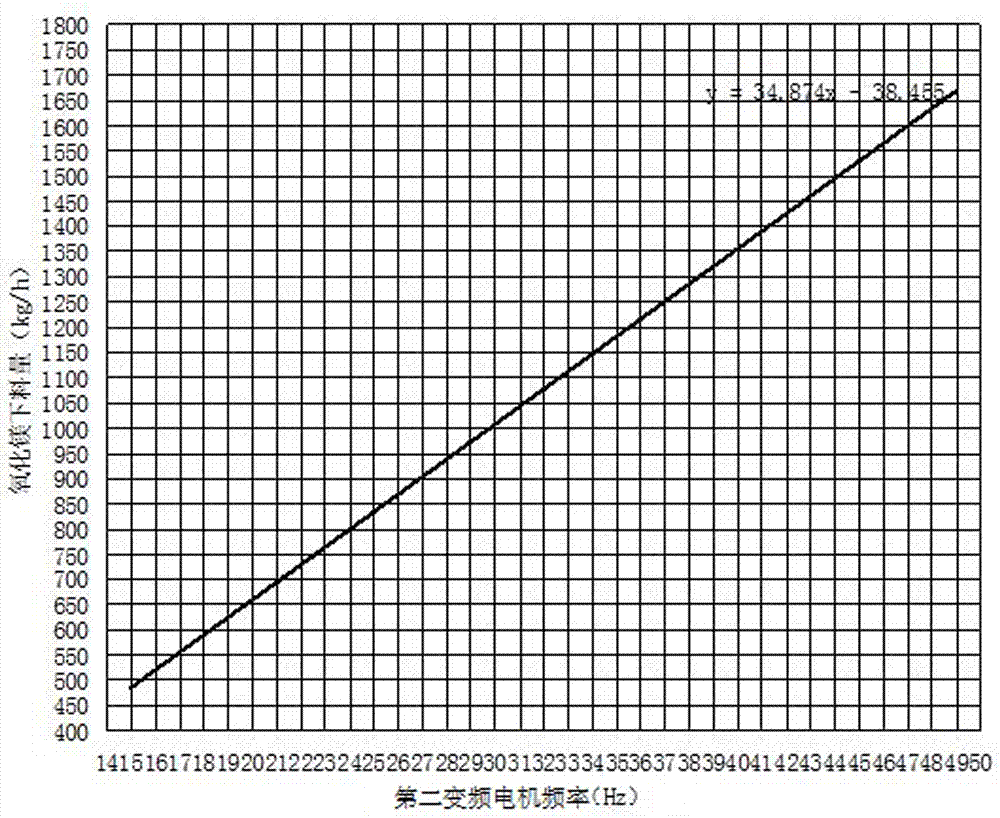

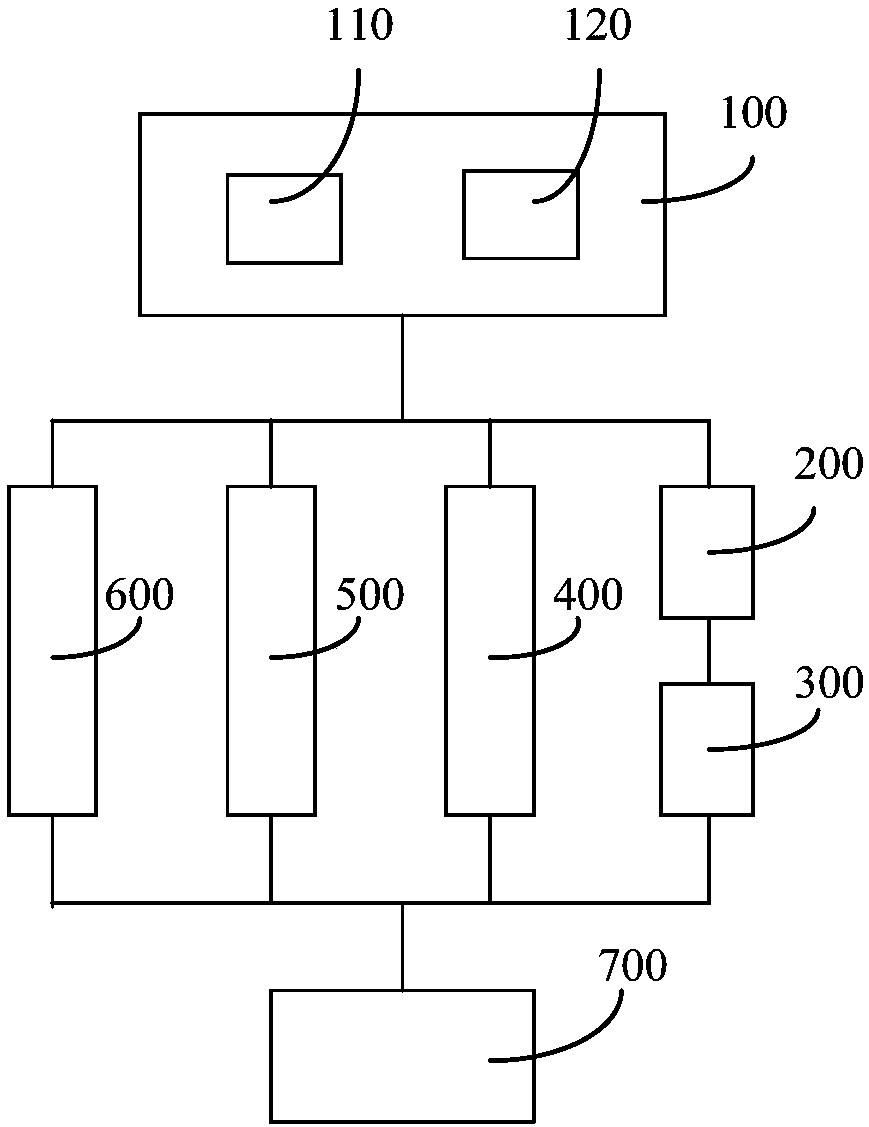

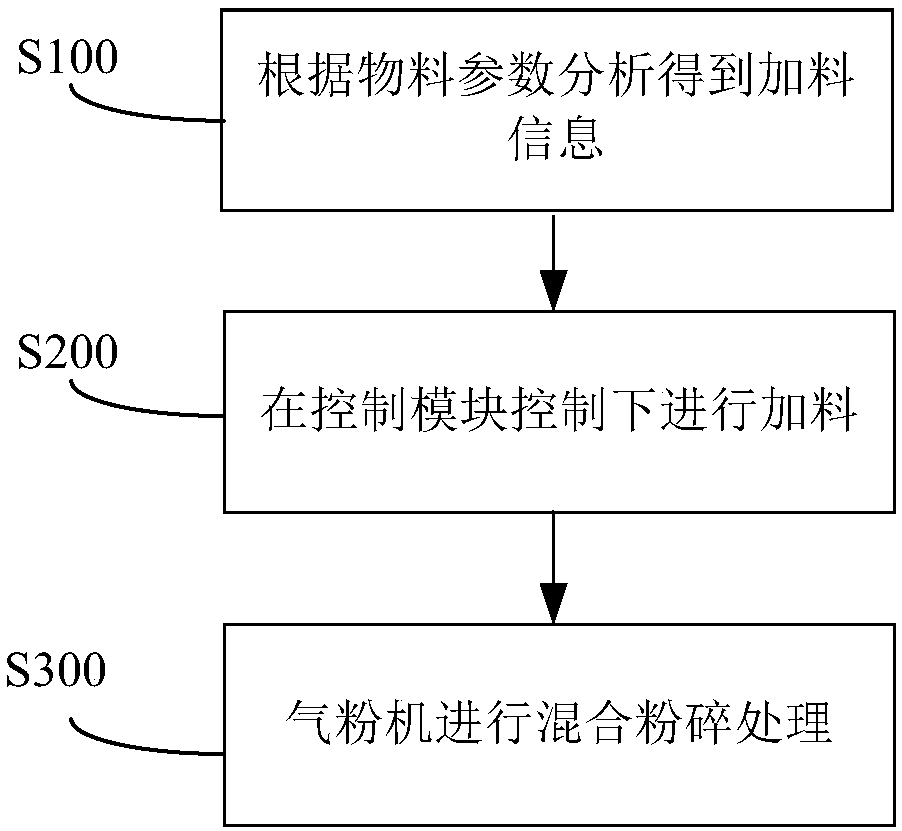

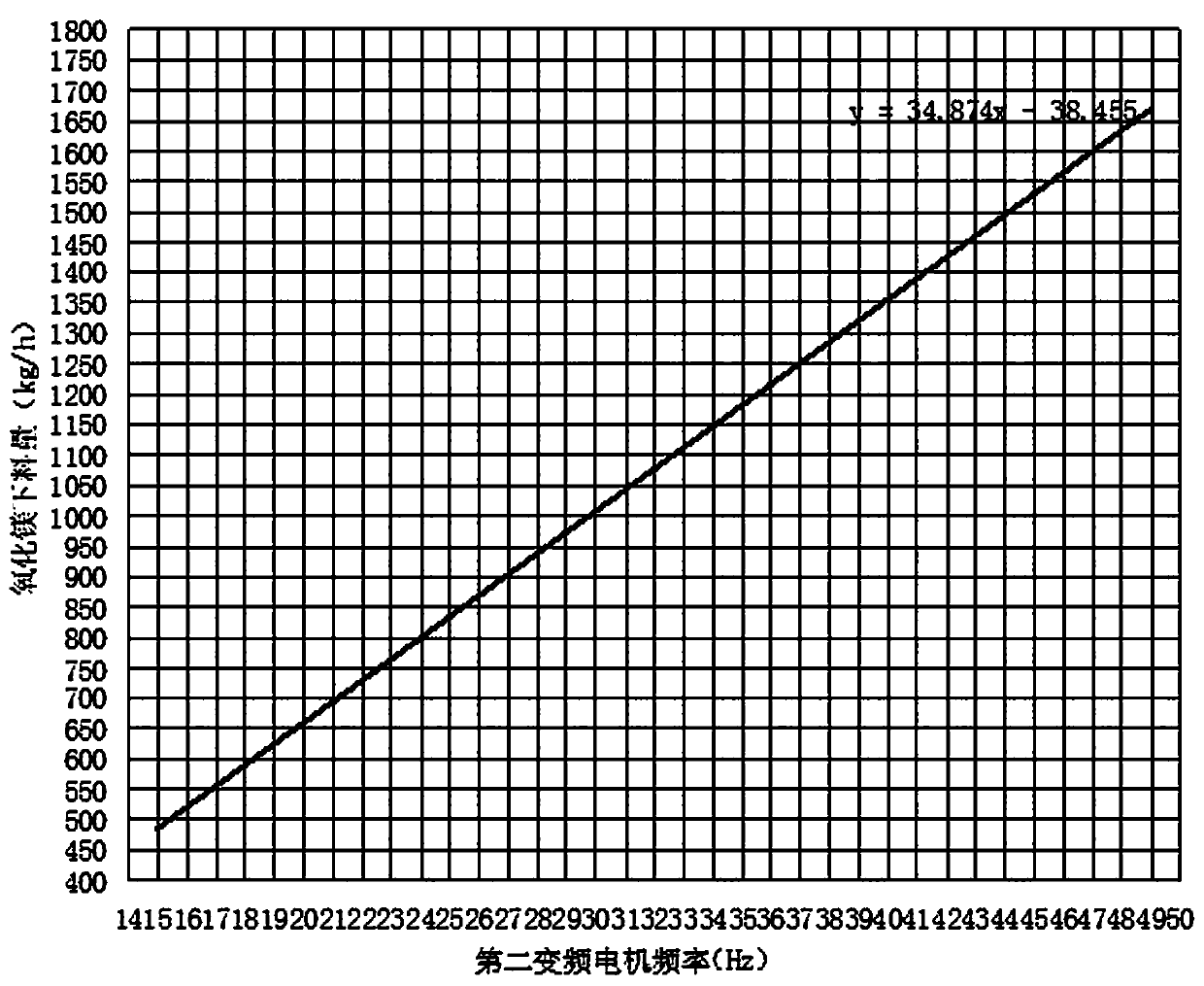

Systems and methods for powder comminution

The invention discloses a system and a method for pulverizing powder. Among them, the powder crushing system includes: a control device, a silo, a powder conveying device, a feeding steam conveying device, a pulverizing steam conveying device, an organic coating agent conveying device and an air powder machine. The system inputs the feeding amount, the mass ratio of the feeding steam to the powder feeding amount, the mass ratio of the organic coating agent to the powder feeding amount, and the quality difference between the feeding steam and the pulverizing steam through the input module. The amount of powder feeding automatically adjusts the feeding flow of feeding steam, pulverizing steam and organic coating agent, thus realizing automatic feeding of the air powder machine, the feeding amount of the air powder machine is stable, and the pressure difference of the silo is low. Therefore, the gas powder machine of the system has good feeding stability and long service life, and the fine powder material prepared has high output, good quality and low production cost.

Owner:YUNNAN METALLURGICAL XINLI TITANIUM IND CO LTD

Ball material feeding device of ferrite pre-sintering rotary kiln

PendingCN109341329AFeed amount is stableAvoid breakingRotary drum furnacesAutomatic controlEngineering

The invention discloses a ball material feeding device of a ferrite pre-sintering rotary kiln. A ball material storing mechanism, a material receiving mechanism, a discharging pipeline and a feeding controller are included; the material receiving mechanism comprises a connection screw, a bottom plate and a feeding cylinder; the upper end of the discharging pipeline is connected with a discharginghole formed in the bottom plate, and the lower end of the discharging pipeline stretches into a rotary heating pipe of the rotary kiln; and the feeding controller comprises a cycle timer and an electromagnetic valve, and the feeding controller is electrically connected with the feeding cylinder. Due to the above manner, the ball material feeding device of the ferrite pre-sintering rotary kiln is reasonable and compact in overall structure; a full-automatic control manner is achieved through the feeding controller; and the feeding process is not affected by the ball diameter or the ball type, and ball materials are not extruded or broken, either.

Owner:苏州天源磁业股份有限公司

Magnesium oxide neutralization system and method for acid waste water from smelting flue gas

ActiveCN107540074BFeed amount is stableReduce the amount of cuttingWaste water treatment from metallurgical processWater/sewage treatment by neutralisationNitrogen gasTreatment system

The invention discloses a magnesium oxide neutralization system and method for the acid-making acid wastewater of smelting flue gas, and belongs to the technical field of chemical engineering. The system mainly includes an acid water buffer tank, a magnesium oxide storage tank, a charging storage tank, a vertical spiral conveyor, a horizontal spiral conveyor, a hopper, a nitrogen purging device, an ejector and an acid water reaction tank; through the boosting function of the vertical and horizontal spiral conveyors, the nitrogen purging function, and the negative pressure absorbing function ofthe ejector, magnesium oxide powder is conveyed into the ejector, is mixed with the acid wastewater fully, and then enters into the acid water reaction tank. According to the magnesium oxide neutralization system and method, magnesium oxide solid powder is separated at the front end of the ejector, and it is avoided that the acid wastewater enters into the hopper to cause the magnesium oxide powder to be damped to cause blocking; therefore, the continuous and stable operation of the acid wastewater treatment system is ensured.

Owner:JINCHUAN GROUP LIMITED

Combined process for producing high-end graphite material

ActiveCN111892951AGuarantee product qualitySimple structureThermal non-catalytic crackingCarbon compoundsGraphite electrodeCoke

The invention discloses a combined process for producing a high-end graphite material. The process comprises the following steps: fractionating raw oil with a reduced-pressure distillation device to obtain light distillate oil, middle distillate oil and heavy distillate oil; allowing the middle distillate oil to enter a hydrotreating device; heating a liquid-phase product which is obtained after hydrotreatment and is used as a material for forming an intermediate phase by using a heating furnace a and then allowing the liquid-phase product to enter a coke tower; allowing coking gas generated by the coke tower to pass through a coking fractionating tower to obtain coker gas oil; mixing the coker gas oil and the light distillate oil separated from the raw oil by the reduced-pressure distillation device to obtain a mixture serving as a coke drawing material; and sequentially completing an intermediate phase forming stage and a coke drawing stage in the coke tower so as to obtain the high-end graphite material. The high-end graphite material continuously produced by the method has the advantages of stable streamline texture, low thermal expansion coefficient and the like, and is suitable for producing an ultrahigh-power graphite electrode.

Owner:CHINA PETROLEUM & CHEM CORP +1

System and method for controlling feed amount of combine harvester

The present invention provides a system and method for regulating the feeding amount of a combine harvester. The regulating system includes IMU1, IMU2, a pressure sensor, a GPS receiver and a controller. The current feeding amount is within the rated range to maintain the header height and harvest The operating speed of the machine remains unchanged. When the feeding amount is not within the rated range, the IMU detects the posture of the vehicle body and the tilting conveyor of the header, and combines it to obtain the height of the header and the corresponding current hydraulic cylinder position at this height. By presetting the expected header Height, the obtained expected header hydraulic cylinder position, based on the error between the expected header hydraulic cylinder position and the current hydraulic cylinder position, and then through the controller to adjust the proportional valve to drive the hydraulic cylinder to expand and contract, to control the header height to stabilize at the expected position; based on the speed change , the controller controls the hydraulic motor speed by adjusting the flow valve, and then stabilizes the value of the vehicle speed after the change. The height and forward speed of the combined harvesting unit of the present invention maintain a stable feeding amount and high operating efficiency.

Owner:JIANGSU UNIV

Application method of microorganism multi-parameter comprehensive test platform

InactiveCN105647790ARealize acquisitionRealize synchronous acquisitionBioreactor/fermenter combinationsBiological substance pretreatmentsTest platformWaveguide

The invention discloses an application method of a microorganism multi-parameter comprehensive test platform. A high-precision plunger type micro-scale sample feeding pump is used to precisely control the sample feeding of a microorganism test solution so as to stabilize the feeding quantity of the microorganism test solution during the whole test process and allow the microorganism test solution to enter from a liquid inlet, pass a micro-flow channel and discharge from a liquid outlet. A lens hole is connected with a microscopy hyper-spectrometer, and a background light source is turned on to provide background light for the microscopy hyper-spectrometer through a background light hole so as to collect microscopy hyper-spectrometer image information of microorganisms. Capacitive dielectric electrodes, planar waveguide and comb type electrodes and parallel electrodes are respectively connected with dielectric spectrum test equipment to detect the dielectric characteristics and number of microorganisms. An optical fiber through hole is connected with an optical fiber spectrometer to detect the spectral characteristics of the microorganisms. The microorganism multi-parameter comprehensive test platform is applicable to qualitative and quantitative detection of microorganisms in liquid, multi-information of the microorganisms can be synchronously collected, and detection efficiency and precision are increased.

Owner:TIANJIN AGRICULTURE COLLEGE

Tapioca flour iron removal machine

The invention discloses a tapioca flour iron removal machine, and belongs to the field of fuel ethanol production. The tapioca flour iron removal machine comprises a material cabin, a vibration feeder, a flexible connector, a rolling tube and a material collecting hopper, wherein a strong magnet is built at the axle center part of the rolling tube; a scrapping brush is arranged at the left lower part of the excircle of the rolling tube; the bottom of the material cabin is fixedly connected with the top of the vibration feeder; a plurality of vibration rods are arranged inside the vibration feeder; the flexible connector is arranged at a discharging opening of the vibration feeder; the front end of the flexible connector is connected with the discharging opening of the vibration feeder; theback end of the flexible connector is arranged at the top of the rolling tube; the material collecting hopper is arranged below the rolling tube; the fixed connection of the material cabin and the vibration feeder is screw bolt connection; the rolling tube clockwise rotates, and the rotation speed is 8 to 10 turns / minute; the magnetic field intensity of the strong magnet in the rolling tube is 0.5 Tesla; the scrapping brush is in a hairbrush shape; the sharp end of the hairbrush is in contact with the excircle of the rolling tube.

Owner:宿迁沂醇生物科技有限公司

Double-blowing system for distribution head of vacuum disc filter

ActiveCN114028865AReduce moistureClean thoroughlyMoving filtering element filtersCircular discEngineering

A double-blowing system for a distribution head of a vacuum disc filter comprises a distribution head; the upper portion of the distribution head is provided with a suction-dry area and a liquid level upper blowing area; the suction-dry area is provided with a suction-dry area liquid discharge pipe, the liquid level upper blowing area is provided with a first pipeline and a second pipeline, the first pipeline is provided with a first valve and is connected with the suction-dry area liquid discharge pipe, and the second pipeline is provided with a second valve and is connected with a compressed air system; the lower part of the distribution head is provided with a liquid suction area and a liquid level lower blowing area; and the liquid suction area is provided with a liquid suction area liquid discharge pipe, the liquid level lower blowing area is provided with a third pipeline and a fourth pipeline, the fourth pipeline is provided with a fourth valve and is connected with the liquid suction area liquid discharge pipe, and the third pipeline is provided with a third valve and is connected with the compressed air system. The adaptability of the vacuum disc filter to various materials is greatly improved, the use bottleneck of a vacuum disc dehydrator is overcome, and the disc filter has a better market prospect.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

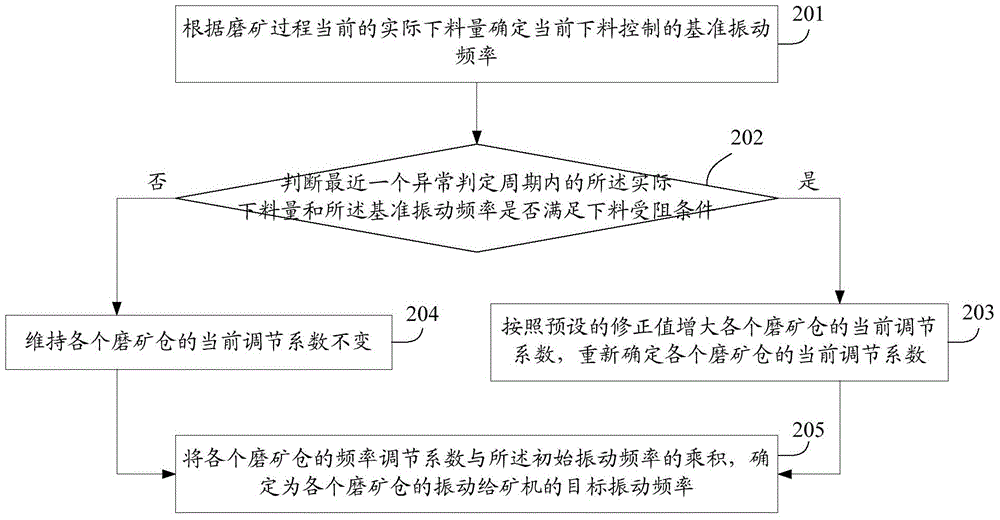

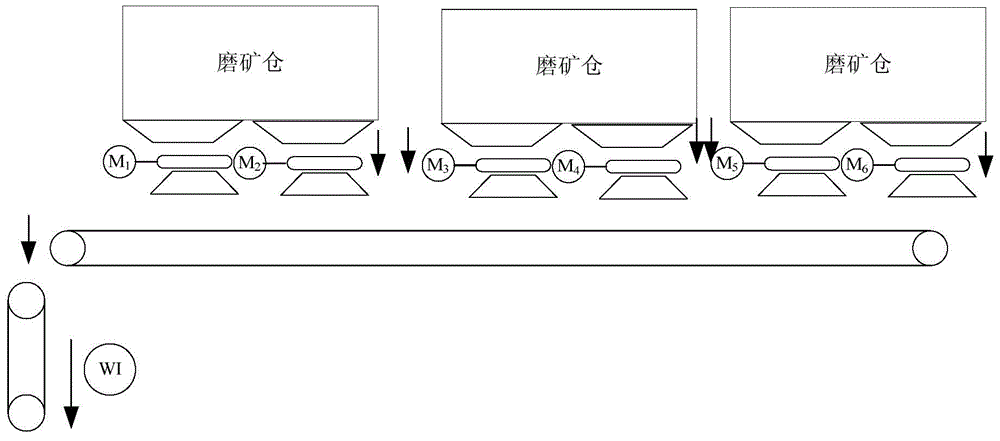

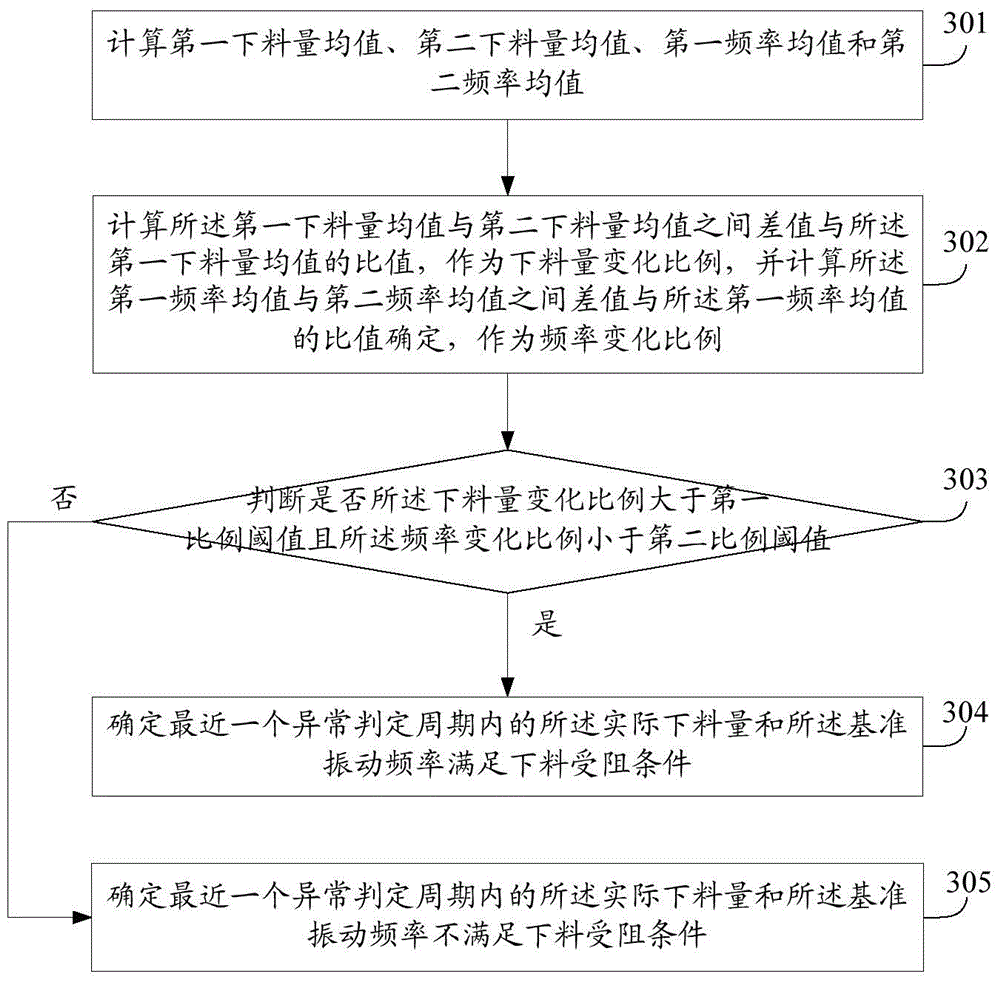

A method and device for controlling the blockage of feeding in the grinding bin during the grinding process

ActiveCN103439992BStable particle sizeStable deliveryMechanical oscillations controlTotal factory controlGranularityEngineering

The invention discloses a method and device for controlling feeding blocking of an ore grinding chamber in the ore grinding process. The method comprises the steps that the controlled standard vibration frequency of current feeding is determined according to the current actual feeding quantity in the ore grinding process; whether the actual feeding quantity and the standard vibration frequency in the last abnormal judging period satisfy the feeding blocking condition or not is judged, if the answer is positive, a current adjusting coefficient of each ore grinding chamber is increased according to a preset correcting value and the current adjusting coefficient of each ore grinding chamber is determined again, and if the answer is negative, the current adjusting coefficient of each ore grinding chamber remains unchanged; the arithmetic product of the current adjusting coefficient of each ore grinding chamber and the standard vibration frequency is determined to serve as the target vibrating frequency of a vibrating ore feeder of each ore grinding chamber. According to the technical scheme, the actual feeding quantity can be rapidly adjusted to the control feeding quantity, so that the feeding quantity of each ore grinding chamber is even and accurate and granularity of ground ore is indirectly made to be stable.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Biomass powder feeder

ActiveCN102275748BThe amount of material is uniform and stableNot easy to overheadLoading/unloadingRotational axisElectric machinery

The invention provides a biomass powder feeder. A conveying device drives a screw auger through a speed reducing motor in a direct connection mode. The biomass powder feeder is characterized in that: a round hole is formed at the center of the bottom of a material cylinder; a connecting cylinder is vertical to the screw auger, and the bottom of the connecting cylinder is communicated with the screw auger; a bearing sleeve is arranged at the center of a support disc which is fixedly mounted at the top end of the connecting cylinder; the support disc is located on the baring sleeve, and blanking holes are uniformly distributed around the bearing sleeve; the upper end of a rotary shaft is fixedly connected with the output end of a speed regulating motor, and the lower end of the rotary shaftpasses through the round hole to be inserted into the bearing sleeve; the rotary shaft is provided with a conical material blocking cylinder above the round hole; the diameter of the bottom surface of the conical material blocking cylinder is greater than the diameter of the round hole; multiple scraping plates are fixedly mounted on the rotary shaft below the conical material blocking cylinder; the rotation diameter of each scraping plate is slightly less than the diameter of the material cylinder, and a certain clearance is reserved between the bottom side and the cylinder bottom; and the rated output of the screw auger is greater than the quantity of feed entering the connecting cylinder from the blanking holes. The biomass powder feeder provided by the invention takes biomass as a feeding object, realizes uniform and stable feeding, and has the advantages of simple structure, small volume and excellent working performance.

Owner:SHANDONG UNIV OF TECH

A uniform feeding device

ActiveCN111889217BRealize the wind lock effectSmooth feedingGrain treatmentsMotor speedProximity sensor

The invention discloses a uniform feeding device, which comprises a feed pipe, a casing, a discharge pipe, a feeder, a driving mechanism, and a support plate. A proximity sensor is arranged on the upper part of the inner wall of the feed pipe, and the side of the casing is provided with Support, the lower part of the support is equipped with a pressure sensor, the discharge pipe and the inside of the shell are connected through a plurality of shunt pipes, the feeder includes a pusher arc plate, a bottom plate, an inner seal ring, and an outer seal ring. The drive mechanism includes a deceleration A motor, a bearing assembly, and a drive shaft. The geared motor is installed on the inner lower part of the fixed sleeve, and the geared motor is connected to drive the drive shaft to rotate. The middle part of the transmission shaft is connected with the bearing inner hole of the bearing assembly, the bearing assembly is installed in the fixed sleeve, the top of the transmission shaft is fixedly connected with the feeder and drives the feeder to rotate; the speed of the geared motor is controlled by the controller, and the The support plate is ring-shaped, and the vertical support is internally connected with the fixed sleeve and externally connected with the housing. The invention can not only realize the wind-locking effect of materials, but also can evenly feed materials.

Owner:YANCHENG INST OF TECH

A combined process method for producing high-end graphite materials

ActiveCN111892951BGuarantee product qualitySimple structureThermal non-catalytic crackingCarbon compoundsThermodynamicsGraphite electrode

The invention discloses a combined process method for producing high-end graphite materials. Light distillate oil, middle distillate oil and heavy distillate oil are fractionated from raw oil through a raw material oil fractionation tower, and the middle distillate oil enters a hydrotreating device for hydrogenation treatment. The obtained liquid phase product is used as the material for forming the mesophase to be heated by the heating furnace a and then enters the coke tower. The coking gas generated by the coke tower passes through the coking fractionation tower to obtain coker wax oil, which is the light distillate separated from the coke gas oil and the raw oil fractionation tower Mixed as the coke pulling material, it is heated by the heating furnace b and then enters the coke tower, and the coke tower completes the mesophase formation stage and the coke pulling stage in turn to obtain high-end graphite materials. The high-end graphite material produced continuously by the method has the advantages of stable streamlined texture, low thermal expansion coefficient, etc., and is suitable for producing ultra-high power graphite electrodes.

Owner:CHINA PETROLEUM & CHEM CORP +1

Straw chopper

The invention discloses a straw chopper. The straw chopper is characterized by comprising a frame (4), a crushing motor (5) is arranged below the frame (4) and drives a movable cutter (7) to rotate through a belt pulley (6), movable cutter heads (8) are arranged on the movable cutter (7), a rotating speed reducer (10) is arranged on the frame (4) and drives a rotary hopper (1) to rotate through a sprocket (9) and a rack (2), an inner port of the rotary hopper (1) serves as a feed inlet (13), rollers (3) are arranged at the outer bottom end of the rotary hopper (1) and rotate on a round rail (12) on the frame (4), and a shifting shaft (11) is arranged on the rotary hopper (1) and corresponds to the feed inlet (13) which corresponds to the movable cutter heads (8) in position. Crushed straw fibers are separated by the aid of a hammering crushing technology and are uniform in particle size and more beneficial to growth of funguses, straw crushing efficiency is improved greatly, and the straw chopper is applicable and efficient.

Owner:SHANDONG FENGYU EDIBLE FUNGUS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com