Straw chopper

A technology of grass shredders and racks, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of affecting the growth and development of mycelia, uneven grain size of grass, and easy blockage of feed inlet, etc., to achieve Guarantee the effect of growth and development, uniform particle size and stable feeding amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

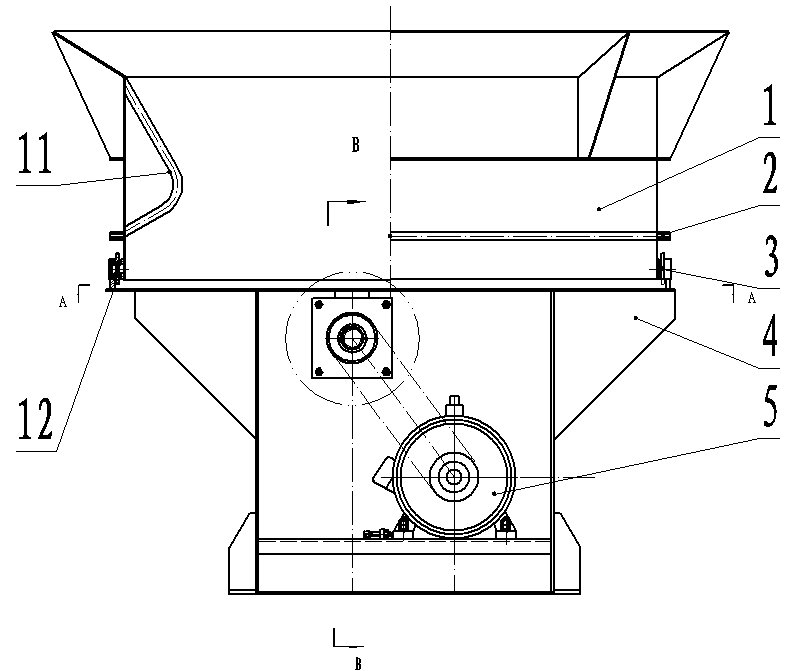

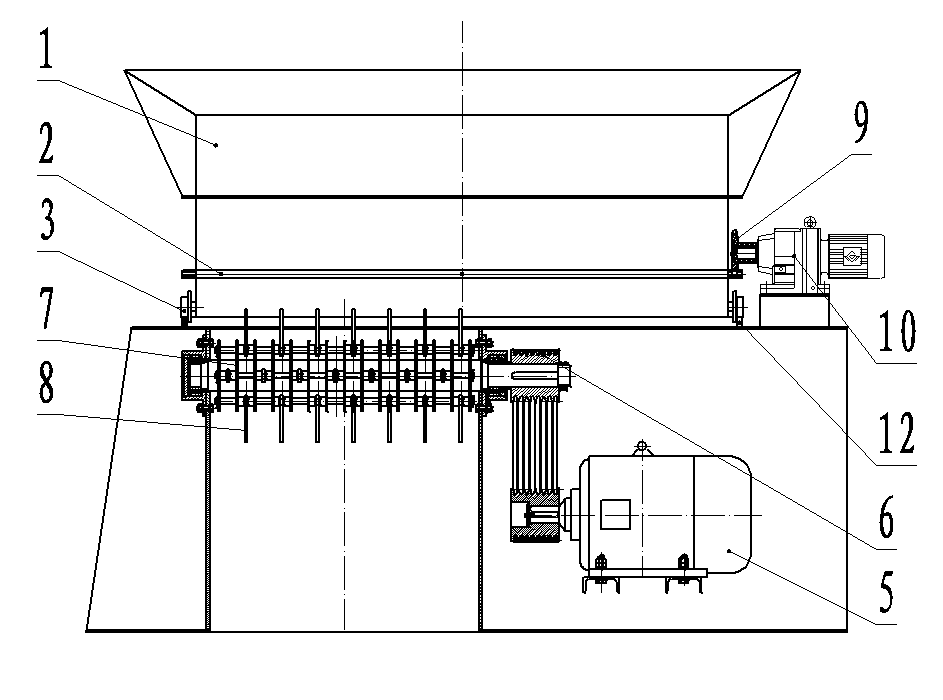

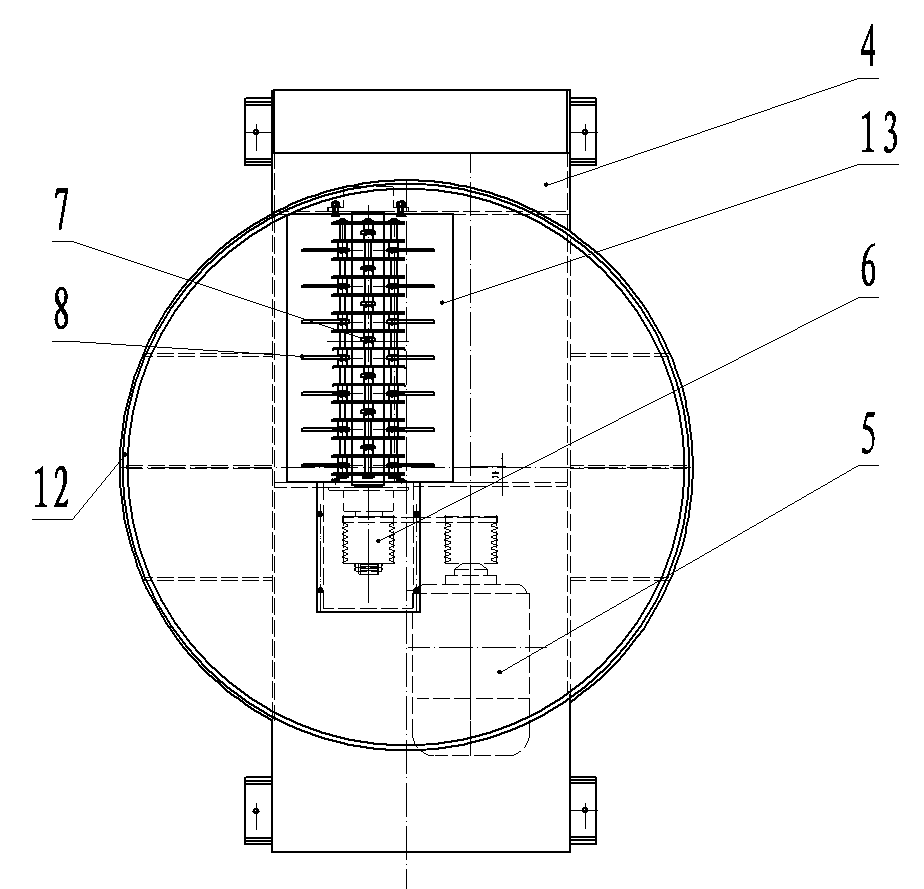

[0013] Example 1, see figure 1 , 2 , 3, process and make frame 4, install crushing motor 5 under frame 4, crushing motor 5 connects the shaft of movable cutterhead 7 through belt pulley 6, drives movable cutterhead 7 to rotate, installs 4 rows on movable cutterhead 7 Movable cutter head 8; a rotary reducer 10 is installed on the frame 4, and the rotary reducer 10 is connected to the rotary hopper 1 through the sprocket 9 and the rack 2, and the sprocket 9 and the rack 2 are meshed to drive the rotary hopper 1 to rotate, and the rotary hopper The inner port of 1 is the material inlet 13, and the center of the rotary hopper 1 and the material inlet 13 are not in the same circle center, and are set eccentrically; the roller 3 is installed on the outer bottom of the rotary hopper 1, and the circular shape of the roller 3 on the frame 4 Rotate on the track 12, on the revolving hopper 1, a dial shaft 11 is installed, the dial shaft 11 corresponds to the feed port 13, and the feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com