Double-blowing system for distribution head of vacuum disc filter

A technology of distributing head and filter, applied in filtration separation, moving filter element filter, separation method, etc., can solve the problems of difficult control of liquid level in slurry tank, substandard production capacity, high moisture content of filter cake, and achieve normal feeding volume. Stabilizing, maintaining thorough cleaning, reducing cake moisture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

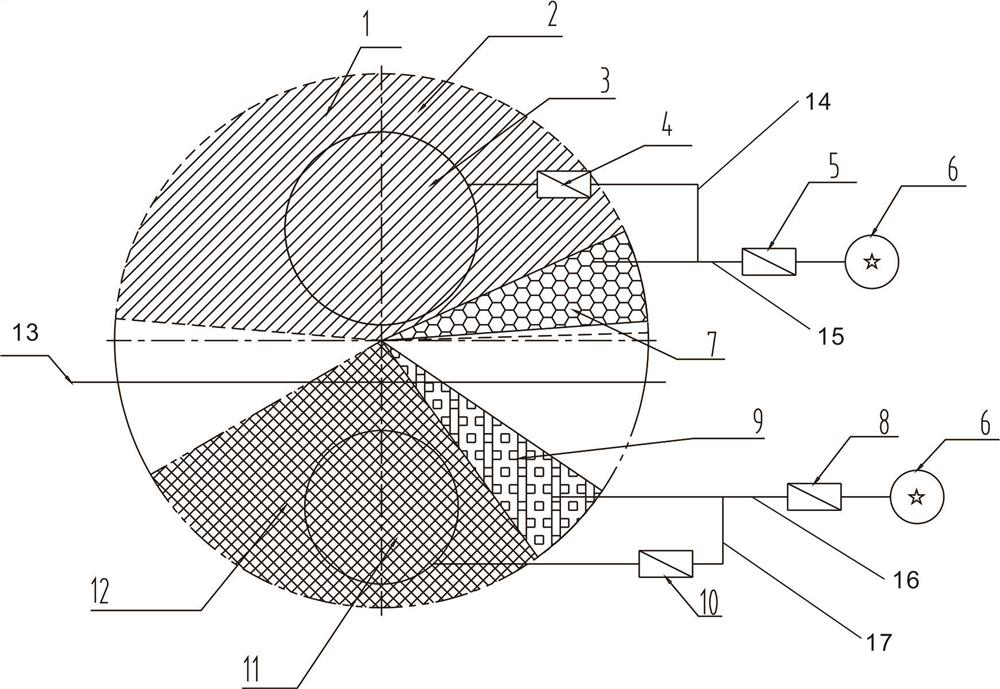

[0025] Example 1, the feed rate is normal and stable, and when the material properties are good, the filter cake on the filter cloth is thicker, and only scraper discharge can meet the production requirements, and only need to open the third valve 8 at intervals to make the liquid level fall into the blowing area 9 is connected to the compressed air system 6, providing partial regeneration of the filter cloth under the liquid level 13, which can not only maintain the high vacuum operation of the system, but also help to increase production capacity, reduce the moisture content of the filter cake, and keep the filter medium and filter cloth thoroughly clean. Extended service life.

Embodiment 2

[0026] Embodiment 2, under the normal operation of the vacuum disc filter, it is necessary to further increase the slurry processing capacity, increase the production capacity and require lower moisture in the filter cake, it is necessary to open the first valve 4 and close the second valve 5 to make the liquid level rise. The blowing area 7 is connected with the drying area 2, which increases the area of the drying area 7, prolongs the drying time of the filter cake, and greatly reduces the moisture content of the filter cake. The third valve 8 is opened and the fourth valve 10 is closed, and the blowing zone 9 under the liquid level blows continuously, and the filter cake adsorbed on the filter cloth falls off completely in the slurry tank under the liquid level 13, and the filter cake is allowed to flow again in the liquid suction zone 12. The cloth absorbs the thicker filter cake, and it is discharged at the scraper discharge place.

Embodiment 3

[0027] Embodiment 3, when the material properties are bad, the capacity of the vacuum disc filter is easily limited, and a large amount of overflow of the slurry tank is likely to occur. Only relying on scraper unloading can not meet the production capacity at all. Open the second valve 5 and the third valve 8 to connect the blowing zone 7 on the liquid level and the blowing zone 9 on the liquid level to the compressed air system 6 and blow air at the same time. Through the blowing zone 7 on the liquid level, the filter cake is completely dropped into the discharge bin to increase the production capacity. After passing through the blowing zone 9 under the liquid level, the filter cloth is thoroughly cleaned, and new filter cake is re-absorbed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com