Patents

Literature

128results about How to "Stable particle size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of submicron nearly spherical tungsten powder

ActiveCN102485380AParticle size and its distribution are stableEliminate reunionPowder metallurgyChemistry

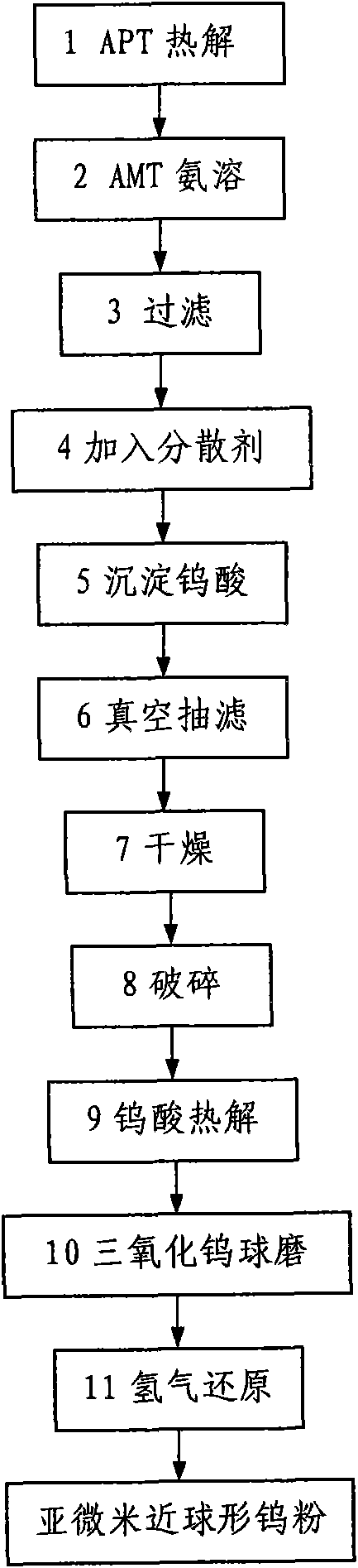

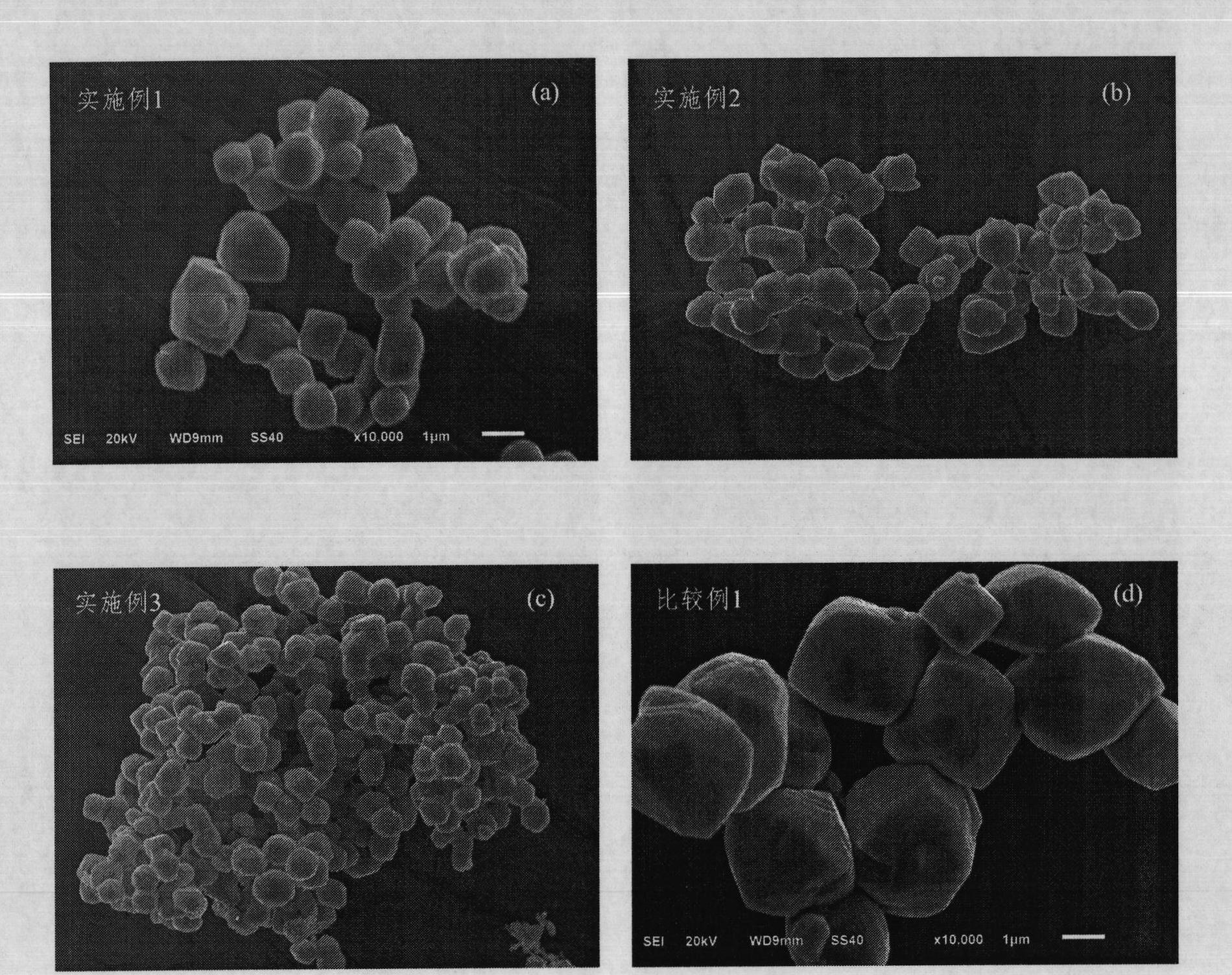

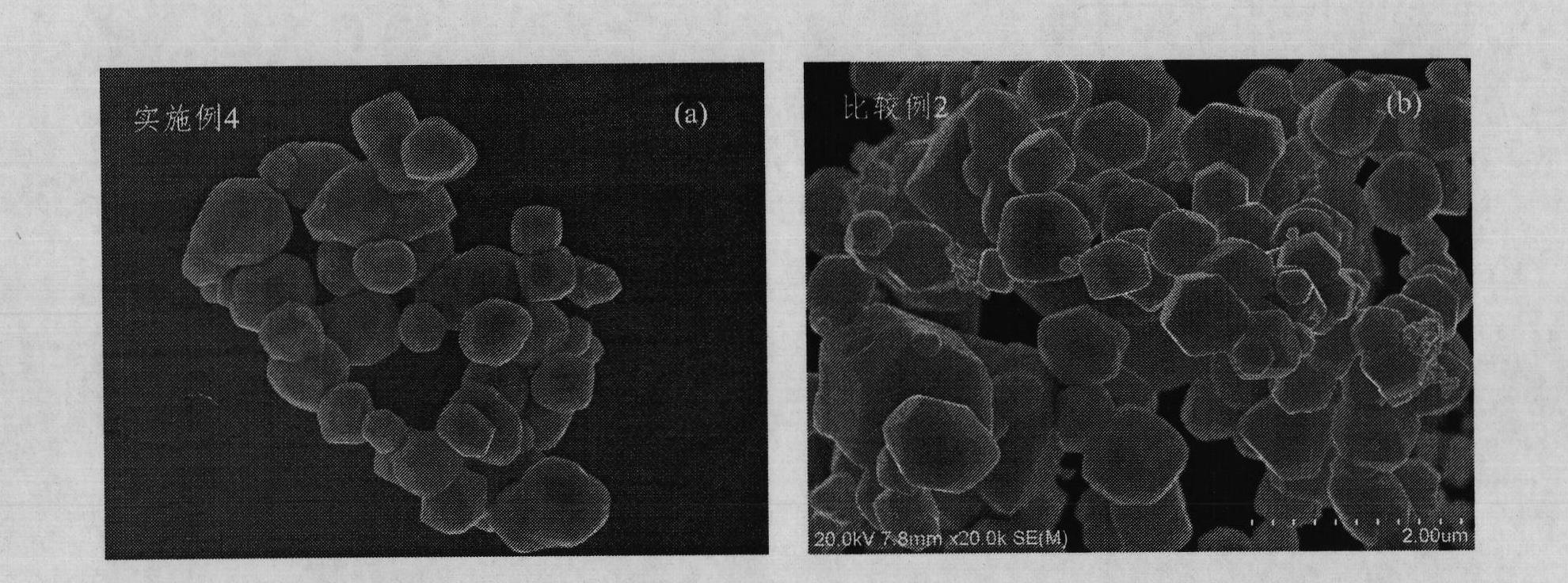

The invention belongs to the powder preparation field adopting powder metallurgy, and relates to a preparation method of submicron nearly spherical tungsten powder. The method comprises the following steps of: (1) pyrolyzing commercial ammonium paratungstate to obtain ammonium metatungsten; (2) dissolving the ammonium metatungsten in ammonia water; (3) filtering to obtain an ammonium tungstate solution; (4) adding a dispersant in the ammonium tungstate solution to mix evenly; (5) adding a precipitator while stirring to obtain tungstic acid sol; (6) performing vacuum filtration to obtain tungstic acid gel; (7) performing common drying or freeze drying; (8) crushing; (9) pyrolyzing to obtain tungsten trioxide; (10) performing ball milling; and (11) performing hydrogen reduction to obtain the submicron nearly spherical tungsten powder. By adopting the preparation method, the submicron nearly spherical tungsten powder can be prepared stably; and the technology is simple, the cost is lower, and mass production can be realized.

Owner:中国有研科技集团有限公司 +1

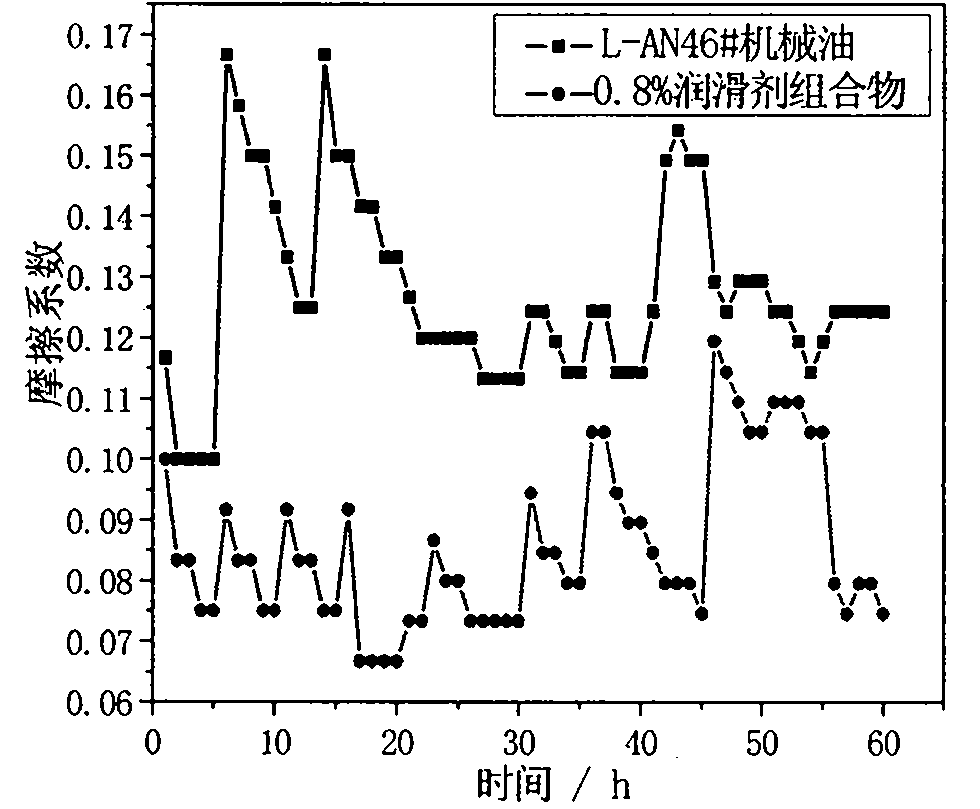

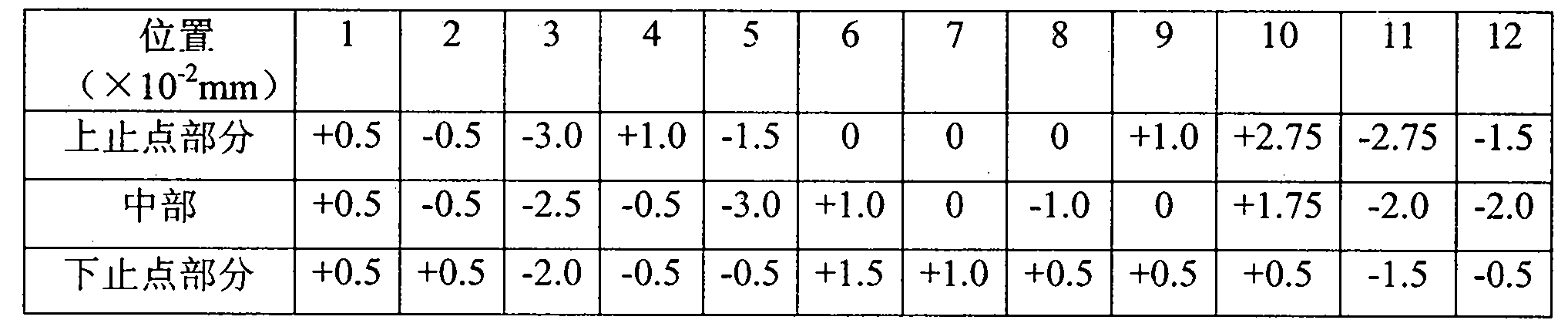

Wear repairing lubricating agent composition containing sheet silicate mineral substances and preparation method thereof

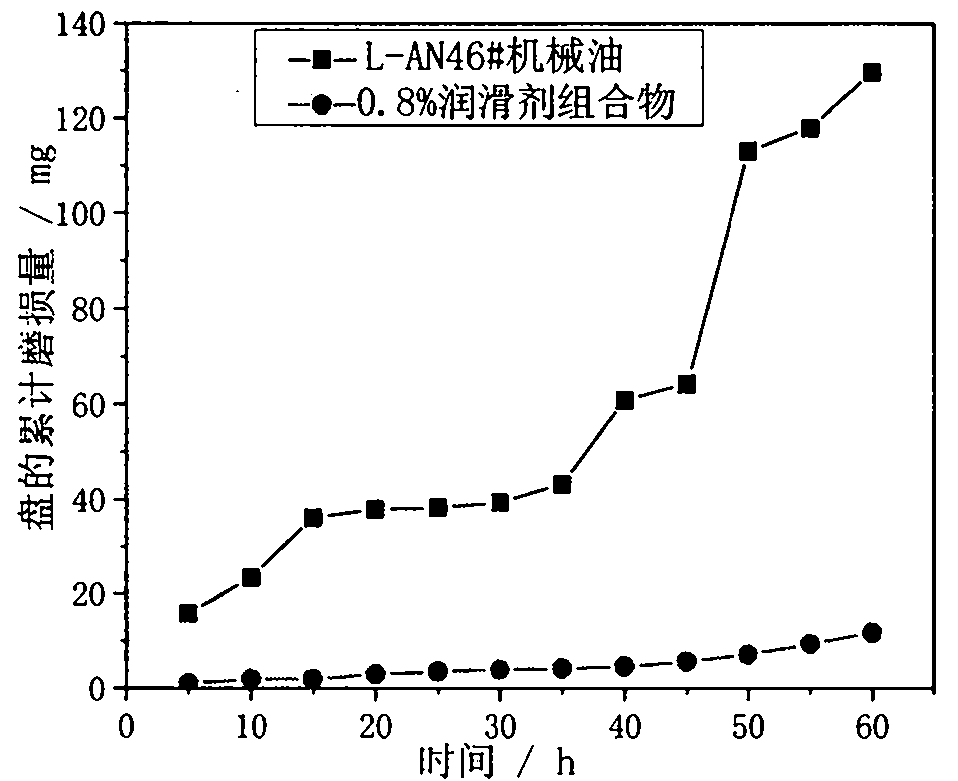

The invention relates to a wear repairing lubricating agent composition containing sheet silicate mineral substances and a preparation method thereof. The lubricating agent composition provided by the invention comprises the following components in percent by mass: 10-20 percent of sheet silicate mineral substances, 0.1-5 percent of surface modifying agent, 0.1-5 percent of metal catalytic object, 1-10 percent of performance regulating agent composition and 70-80 percent of base lubricating agent. The preparation method comprises the steps of: mixing and grinding the sheet silicate mineral substances according to the proportion, preferably, sheet silicate mineral substances with granularity D90 of not more than 3mu m; and then adding in a base lubricating agent prepared from a surfactant, the metal catalytic object and the performance regulating agent in different proportions, and grinding. The using method is as follows: 0.2-1 wt percent of the wear repairing lubricating agent composition is added in the traditional lubricating agent system of equipment. The lubricating agent composition provided by the invention has better self-repairing effect and remarkable energy-saving and consumption-reducing effect; and due to a repairing layer formed on the surface through friction, the hardness of a matrix is improved, and the roughness is lowered.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

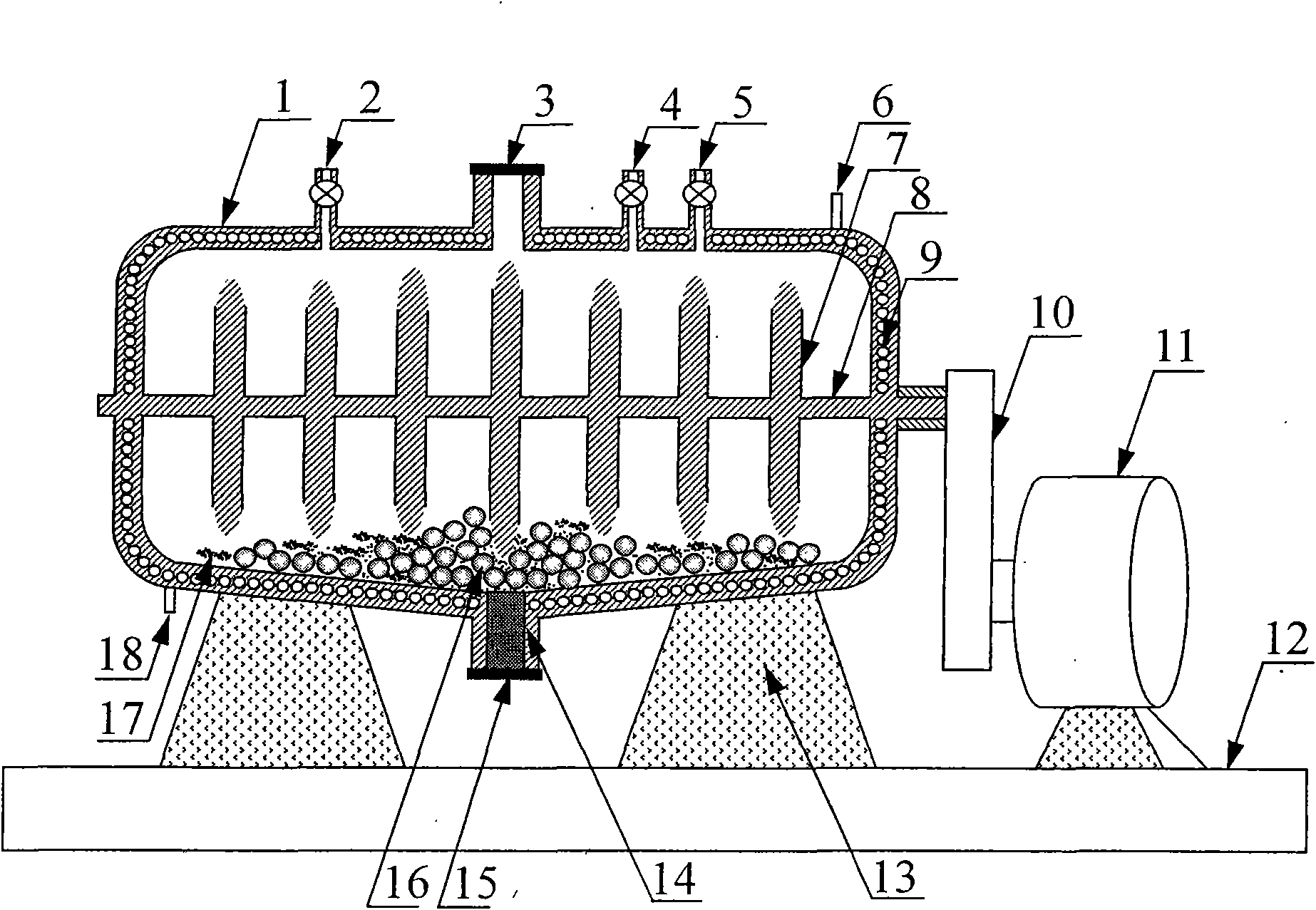

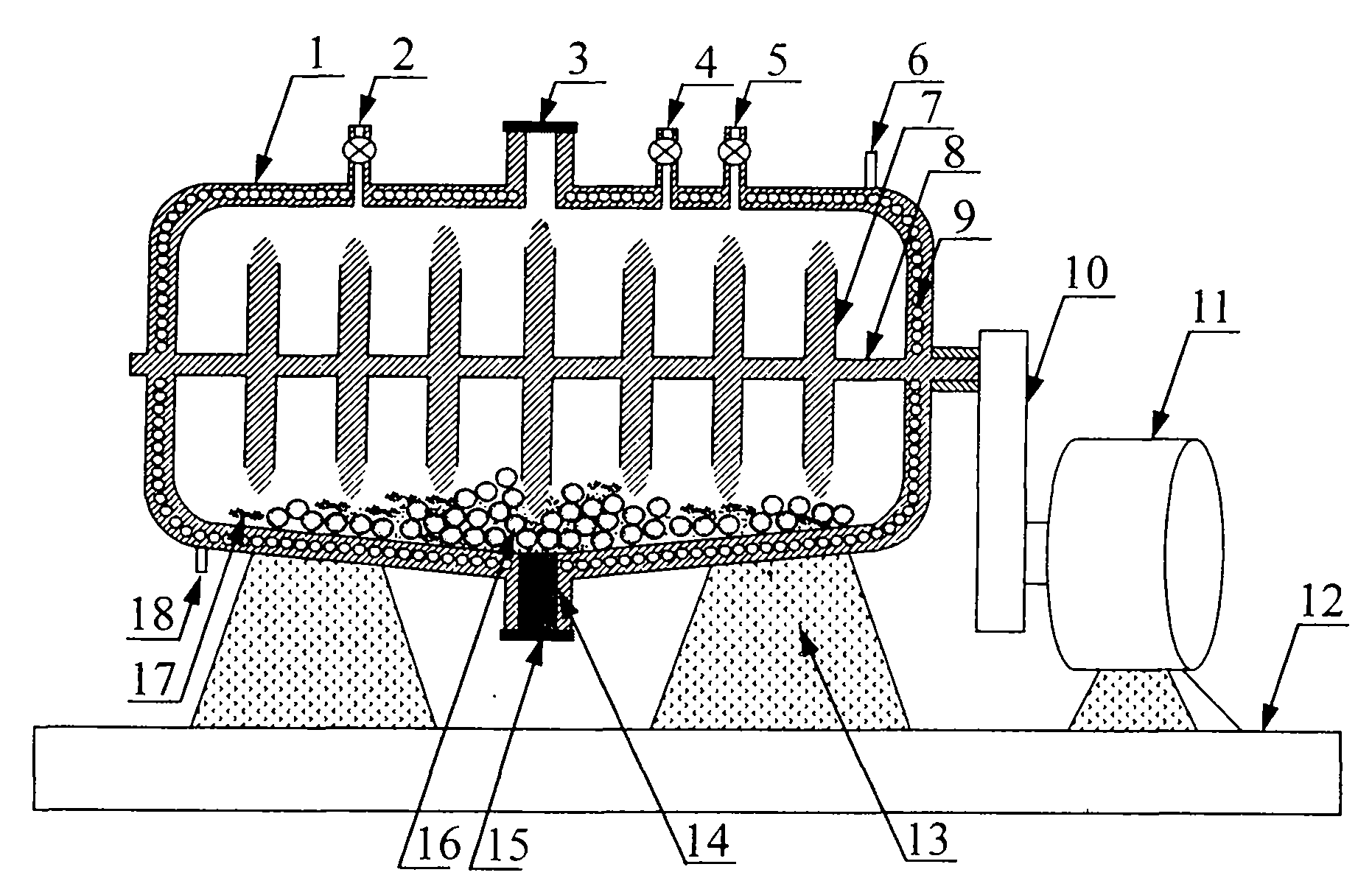

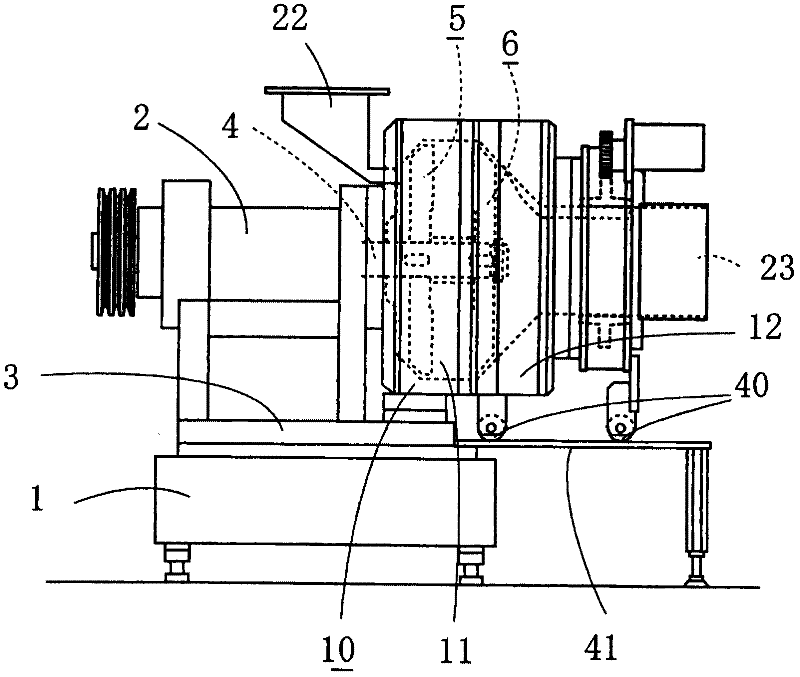

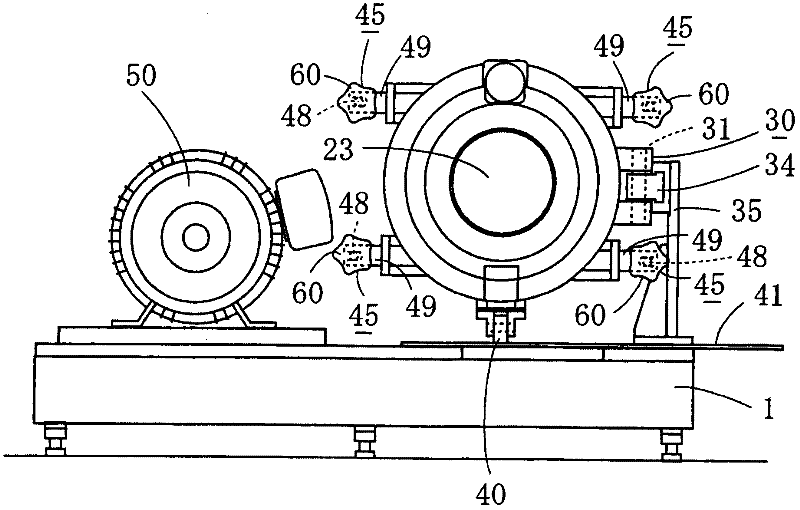

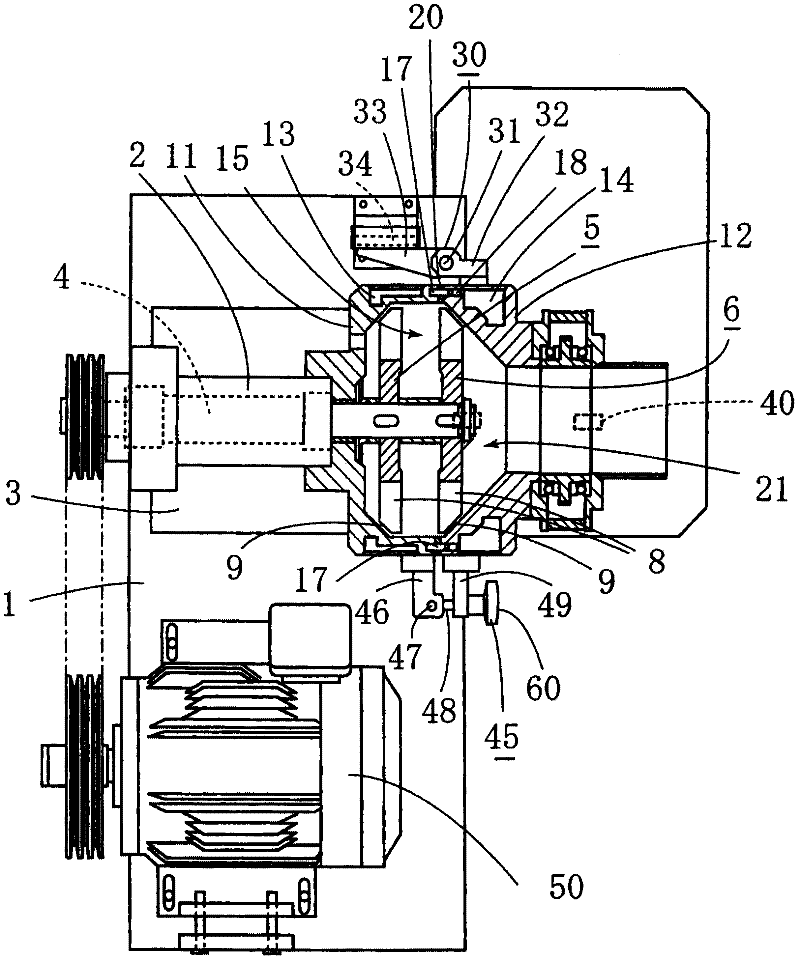

Ball grinder available for solid state reaction of powder

InactiveCN101823013AImprove mechanical energyMeeting the Energy Requirements of Solid-State Chemical ReactionsGrain treatmentsChemical reactionHigh energy

The invention relates to a ball grinder available for the solid state reaction of powder, which mainly comprises a ball grinding cylinder, an electromotor, a driving device, a grinding ball and a material inlet and outlet, wherein the horizontal type ball grinding cylinder is fixedly supported on a bracket; a jar is internally provided with the girding ball; the center of the ball grinding cylinder is provided with a rotatable main shaft; the main shaft is driven by the electromotor through the driving device to rotate; the main shaft is provided with a blade, wherein the rotating speed of the blade is 300-2000 r / min; the mechanical energy is transmitted to the grinding ball through the beating of the blade, so that the grinding ball can irregularly move with high speed; the bottom of theball grinding cylinder is in the shape of gradient with 0-30 degrees from the two ends to the center; the jar body of the ball grinding cylinder is provided with a cooling sleeve and an inlet and an outlet of cooling medium; and the jar body of the ball grinding cylinder is provided with an air exhausting opening and an air inlet. The ball grinder can lead the grinding ball to generate higher mechanical energy to provide high energy for inducing the solid state reaction among materials, thereby smashing, grinding and dispersing the materials and directly reacting to generate nanometer composite oxide.

Owner:BEIJING UNIV OF CHEM TECH

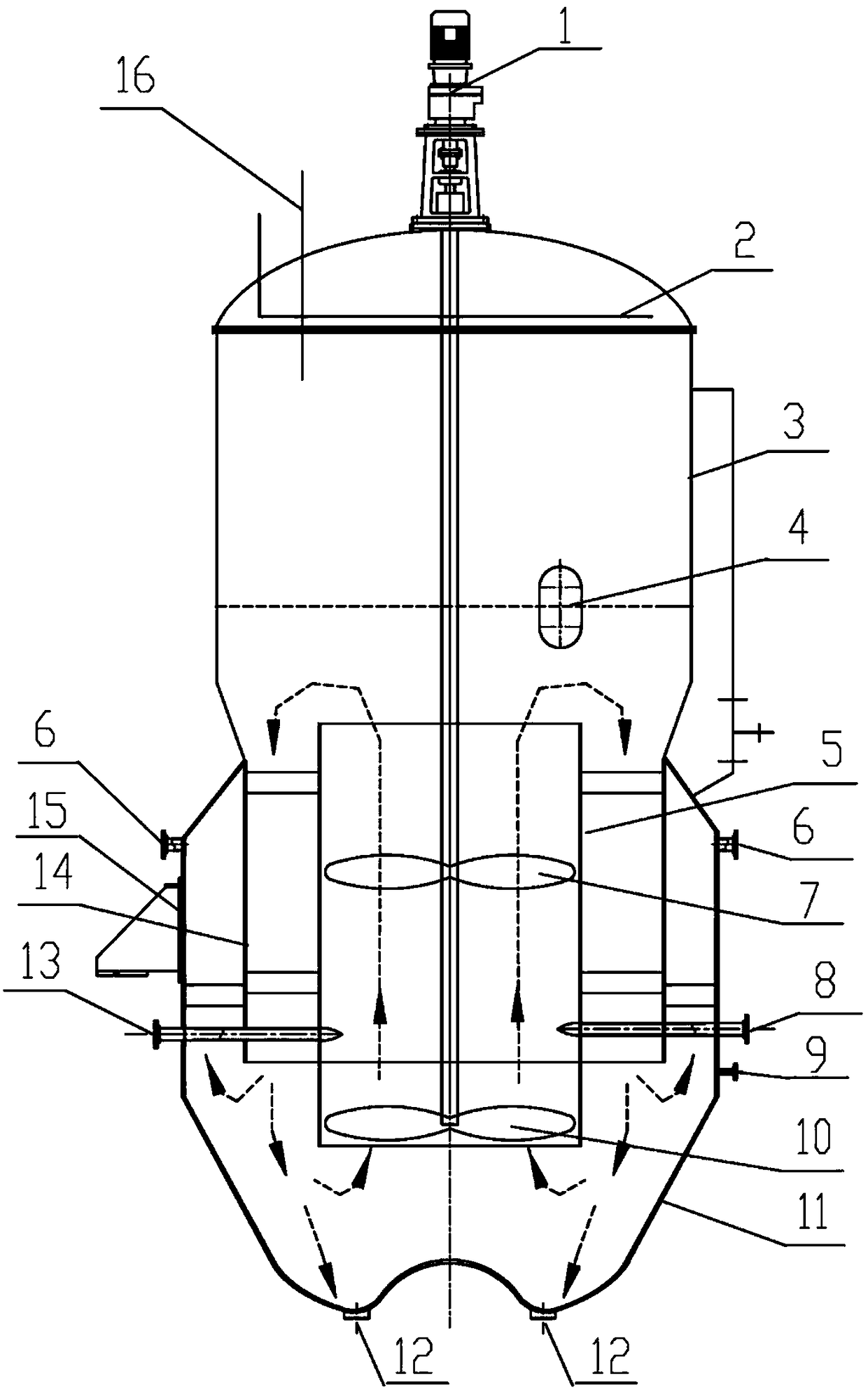

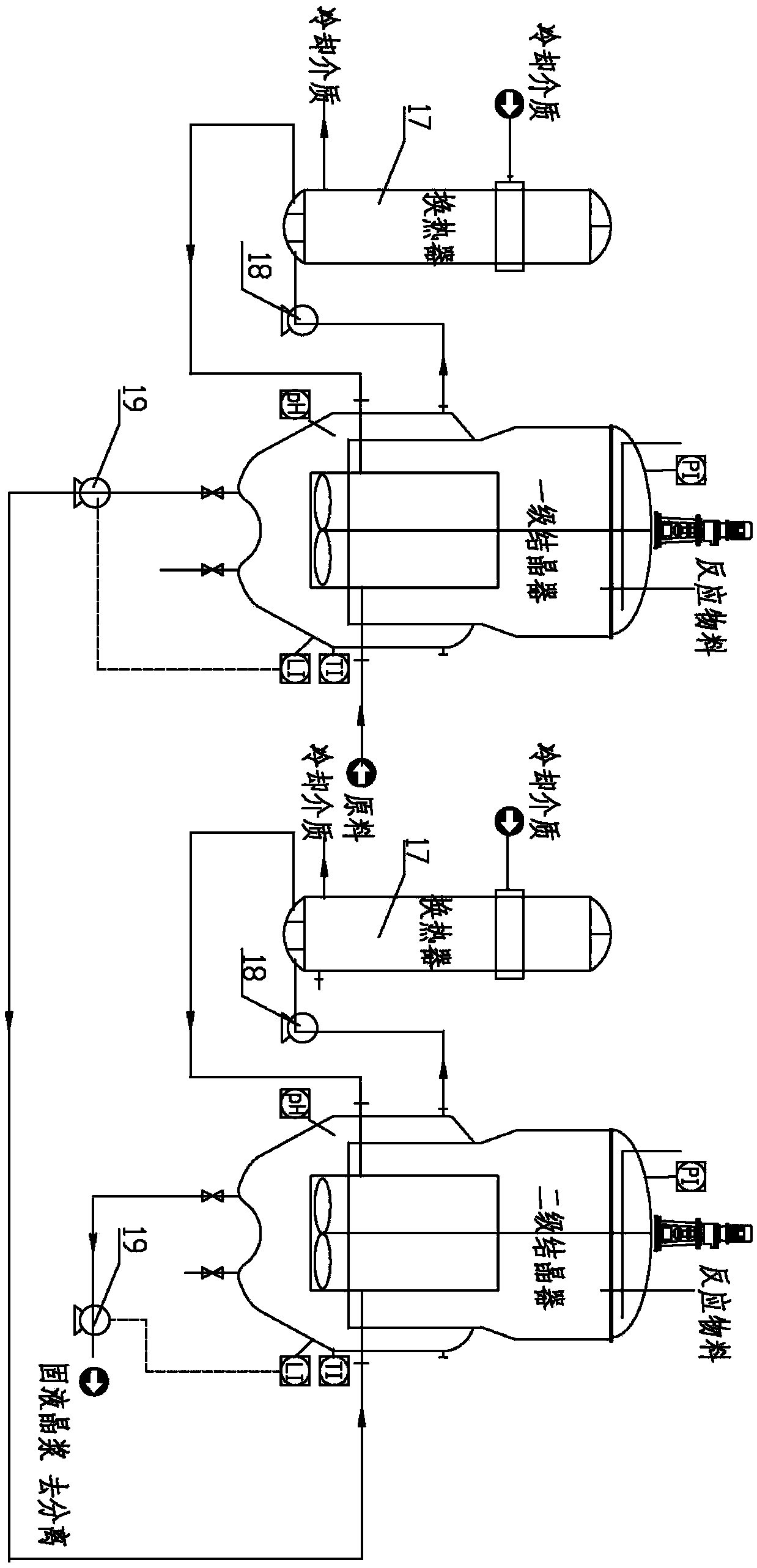

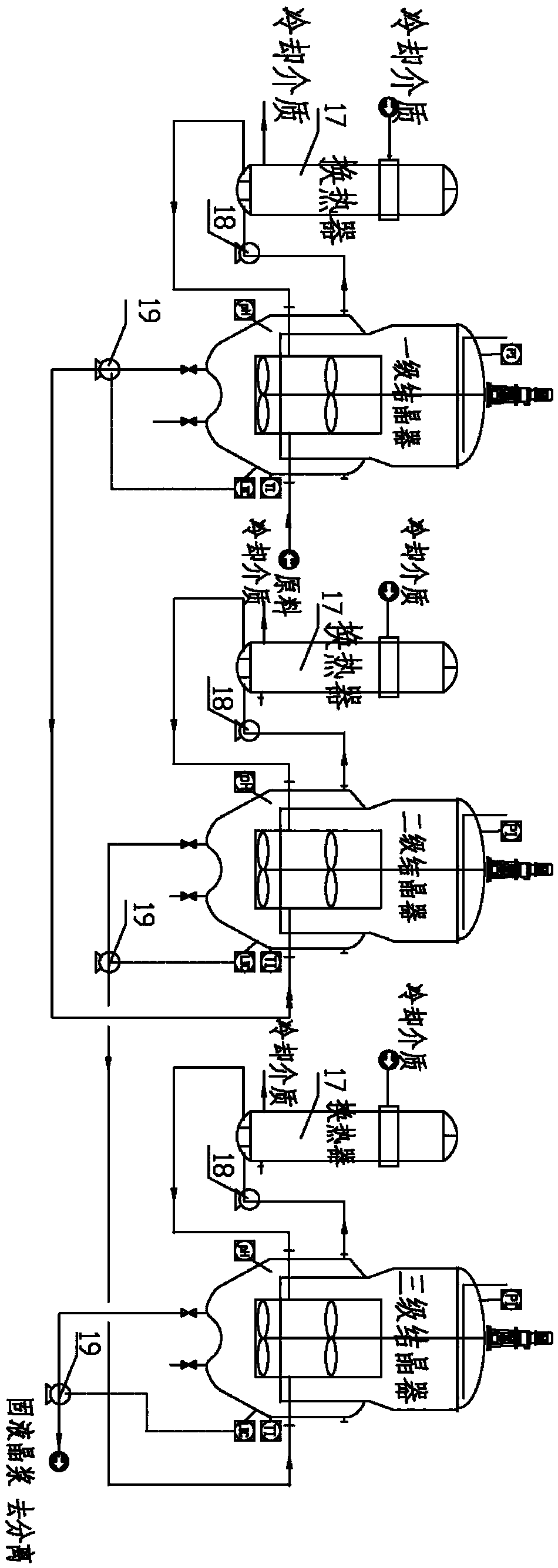

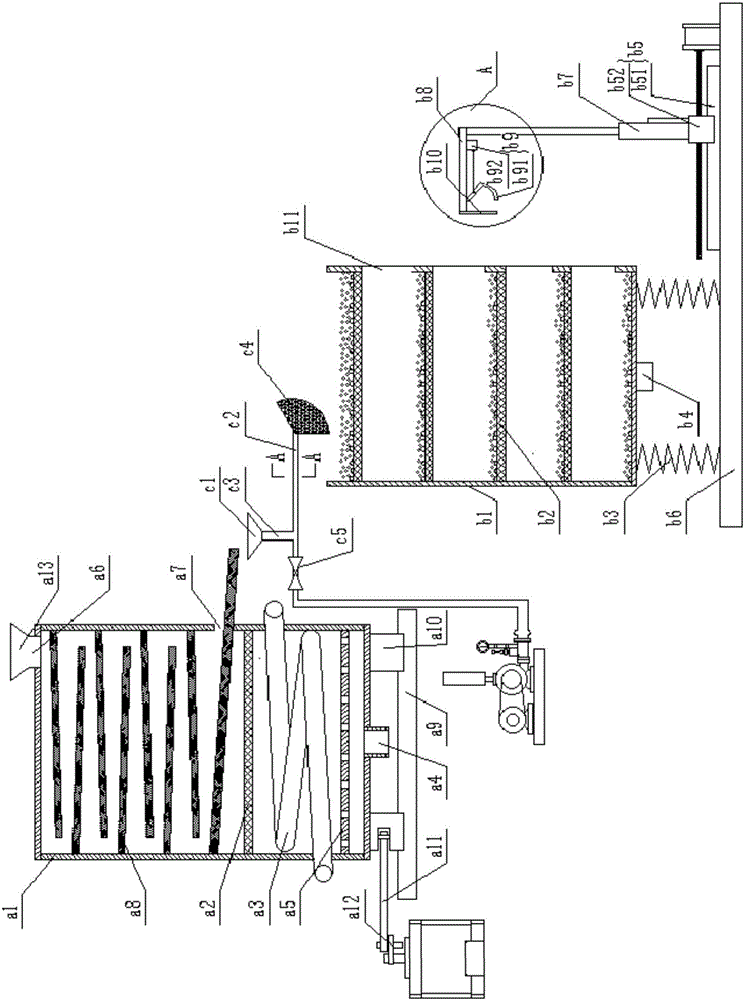

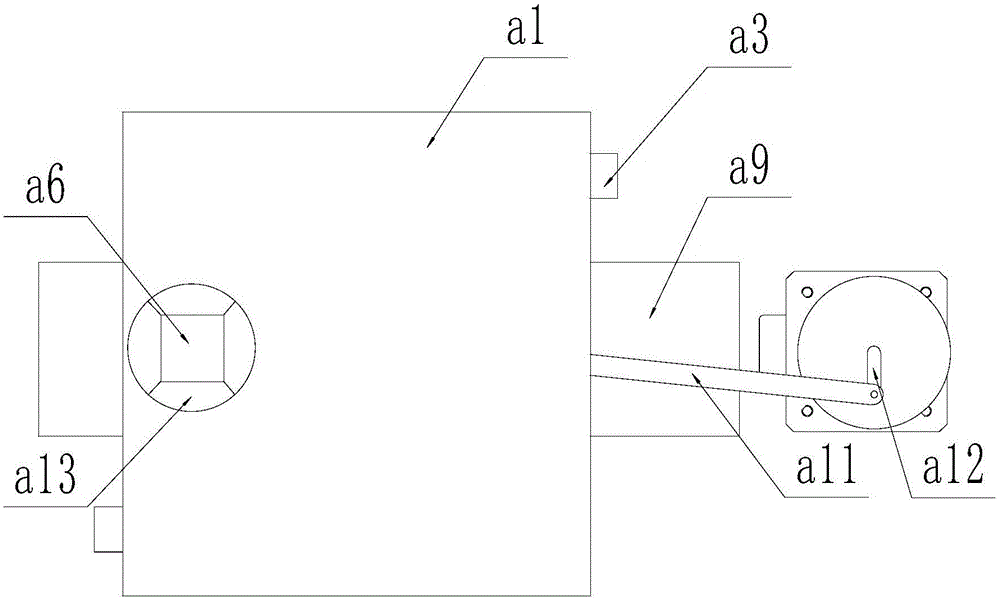

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

High-efficiency composite grinding sheet and manufacturing method thereof

ActiveCN103612217AHigh bonding strengthImprove acid resistanceAbrasion apparatusGrinding devicesFiberPost curing

The invention discloses a high-efficiency composite grinding sheet and a manufacturing method thereof. The high-efficiency composite grinding sheet comprises a base material, base gel, an abrasive material and composite gel. The abrasive material is attached to the base material through the base gel and the composite gel, the back of selected steel vulcanized fiber paper is coated with the base gel through at least one of the methods of roller painting, blade coating and flat coating; the selected abrasive material is ground into abrasive material particles which are evenly mixed with the composite gel, and then the back of the selected steel vulcanized fiber paper with the base gel is coated with the mixture; a semi-finished product coated with the base gel and the composite gel is detached and sequentially undergoes a post curing process, a flexure and water entrainment process, a laser cutting process, a steel vulcanized fiber paper anti-deformation processing process and a storing process so as to support a grinding sheet finished product. The grinding sheet is sharp, long in service life, resistant to high temperature after being ground, and good in moisture resistance. The manufacturing method can effectively prevent deformation, and the product is large in tensile strength, good in adhesion and strong in grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

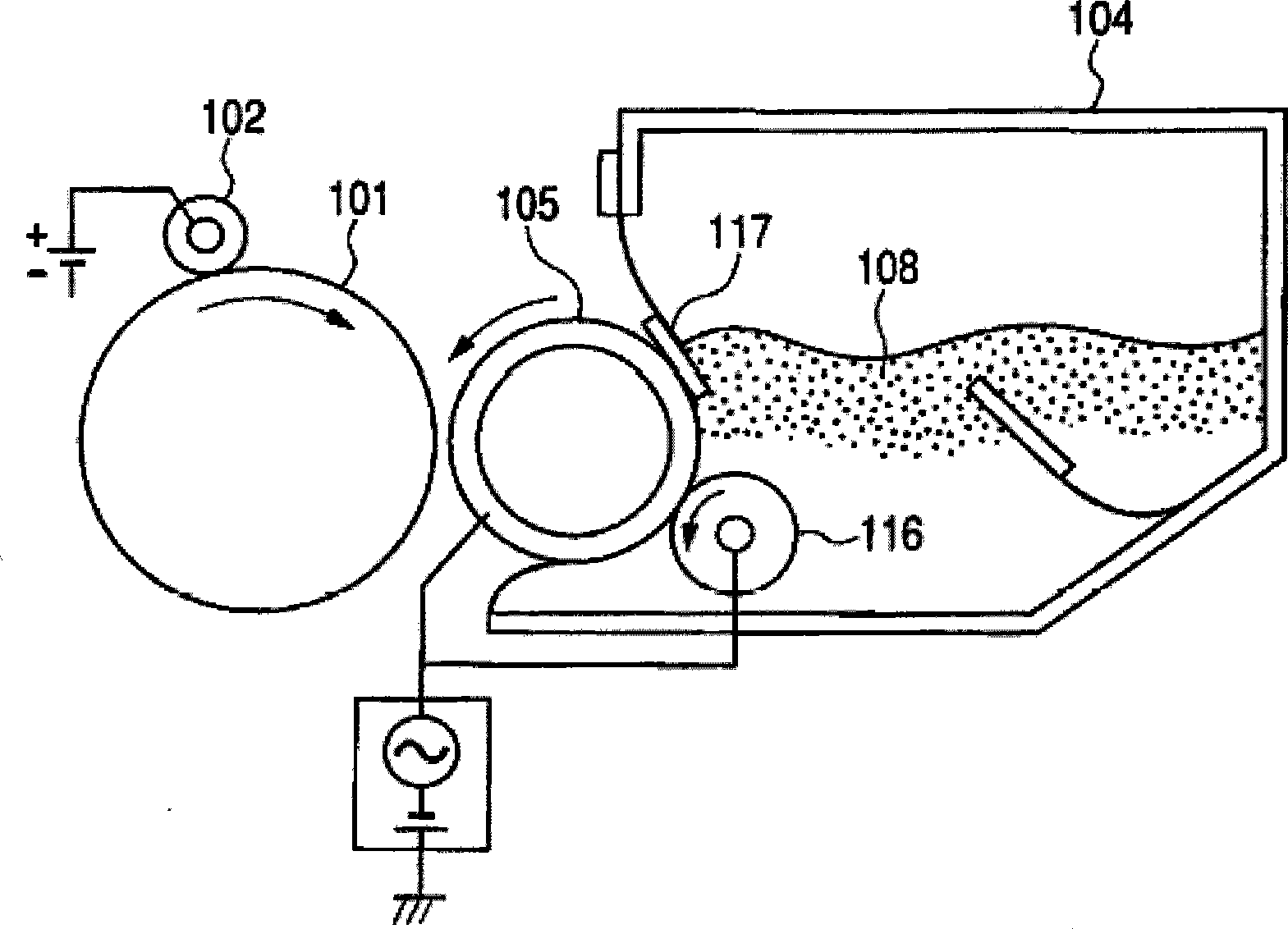

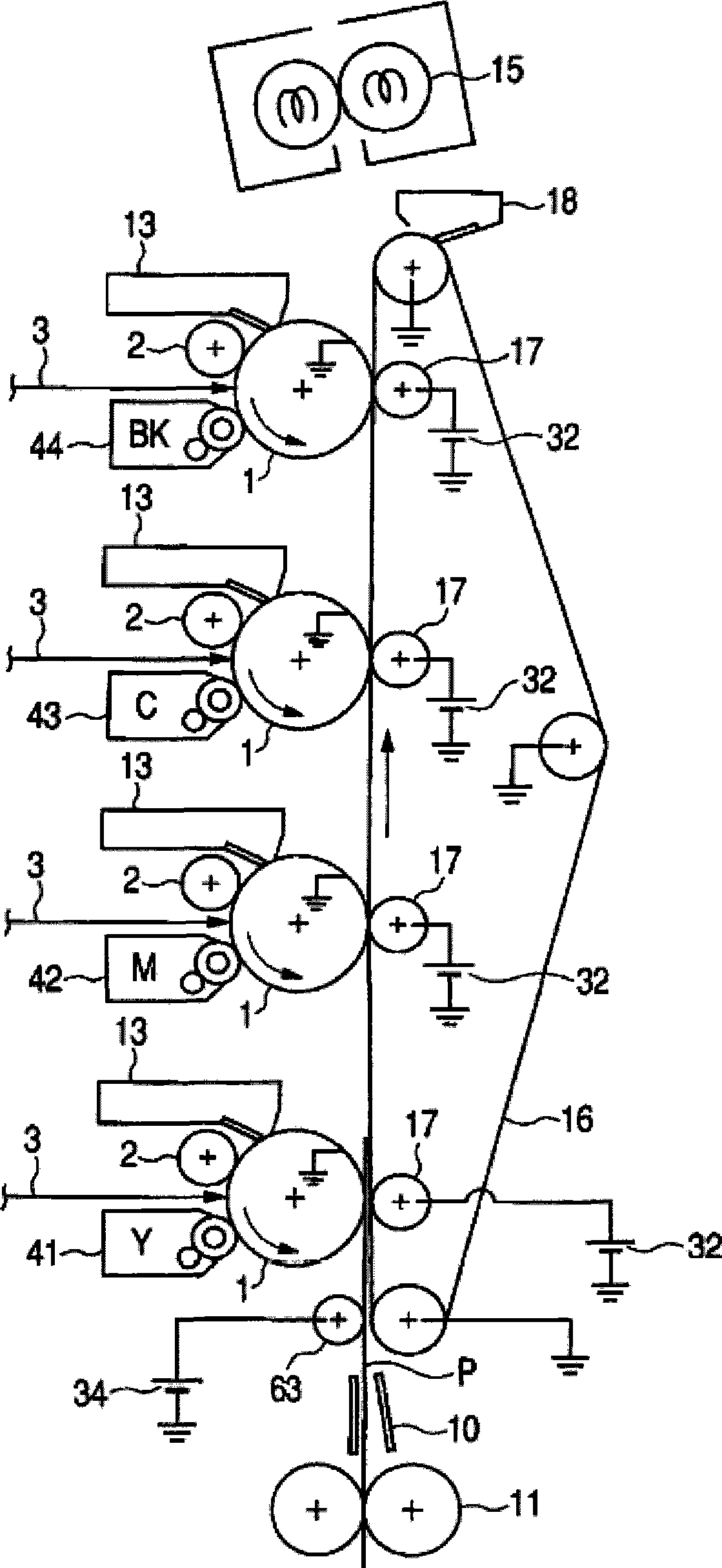

Toner and image forming process

ActiveCN101430513AGood release effectStable particle sizeDevelopersElectrographic processes using charge patternColor toneSurface-active agents

A toner which has i) toner base particles containing at least a binder resin and a colorant and ii) a fatty acid metal salt composition as an external additive. The fatty acid metal salt composition contains a nonionic surface-active agent and a fatty acid metal salt. This toner and an image forming process making use of the toner can keep the toner from adhering to a toner carrying member throughout running, promise a stable chargeability of the toner and can keep any deterioration of halftone image quality from being caused by excess charging of the toner and any image fog from being caused by insufficient charging of the toner.

Owner:CANON KK

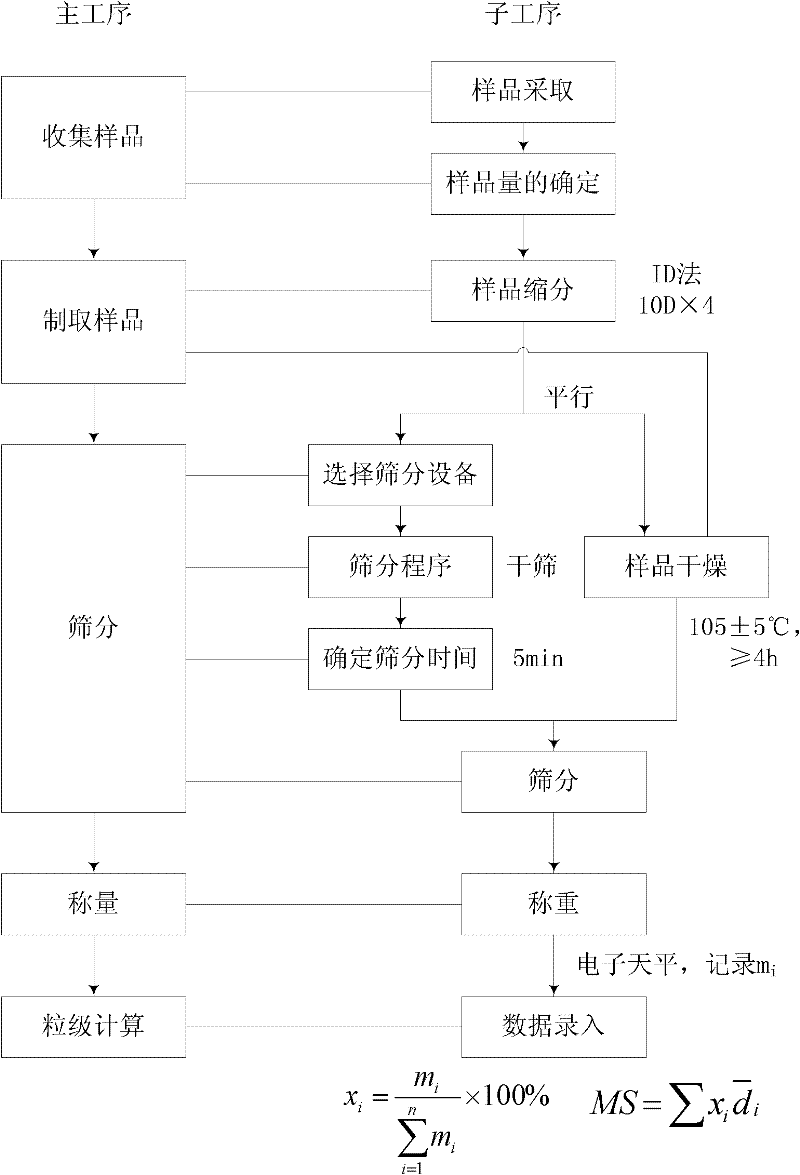

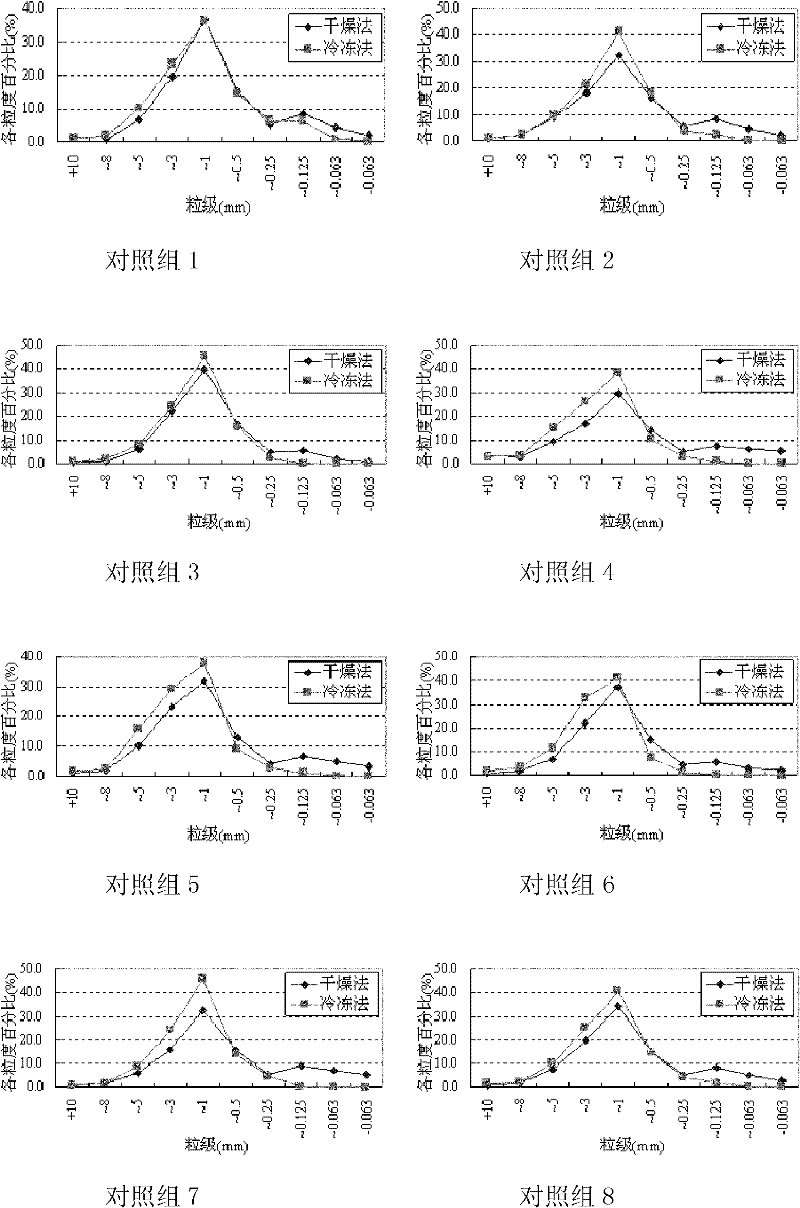

Method for determining sinter mixture granularity

InactiveCN102443695AObjectively reflect the composition of particle sizeThe measurement result is objectiveParticle size analysisScreening proceduresGranularity

The invention provides a method for determining the sinter mixture granularity, which comprises the following steps of: (1) sample collection: sampling samples and determining the sample quantity; (2) sample preparation: reducing, dividing and freezing the samples; (3) screening: selecting screening equipment, determining the screening procedure, determining the screening time and carrying out screening; (4) weighing: weighing the weight of screened materials in all size grades; and (5) size grade calculation: calculating the percentage corresponding to all size grades according to a formula after the weighing completion of the samples in all size grades, recording the percentages, and calculating the average granularity. The method is characterized in that in the second step, the samples are frozen by a refrigerator after reduction and division. When the method is used, the problems that in the existing granularity determining method, the mixture size grade composition under the actual production condition cannot be objectively reflected, the mixed pelletization effect enhancing measure cannot be reasonably evaluated, and the like can be solved. The method has positive effects of effectively improving the proportioning, stabilizing the sinter process and stabilizing and improving the sinter mineral quality on sinter work procedures.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Resource utilization method for combined production of biogas and cultivation matrix through utilizing tobacco stalk fermentation

InactiveCN102851318AModerate granularityQuality improvementBio-organic fraction processingInternal combustion piston enginesSocial benefitsResource utilization

The invention provides a resource utilization method for the combined production of a biogas and a cultivation matrix through utilizing tobacco stalk fermentation. The method comprises the following steps: carrying out anaerobic fermentation of a main fermentation raw material which is waste tobacco stalks generated in the tobacco threshing redrying line to produce the biogas; carrying out solid-liquid separation of a biogas slurry and the tobacco stalks to obtain a tobacco stalk biogas residue and a biogas slurry; purifying the biogas to prepare clean fuels or to be used for electricity generation to provide partial energy for a plant area; and decomposing the tobacco stalk biogas residue, and carrying out dry molding to prepare the cultivation matrix, wherein the biogas slurry returns to a fermentation system to be recycled or to be used as a liquid organic fertilizer. The method provided by the invention has the advantages of simple production operation, concentrated and stable raw material, scale production benefiting, low production cost, realization of no pollution, zero discharge and cycle utilization of waste tobacco stalk resources of a threshing redrying plant, and generation of good economic, ecological and social benefits.

Owner:ZHENGZHOU UNIV

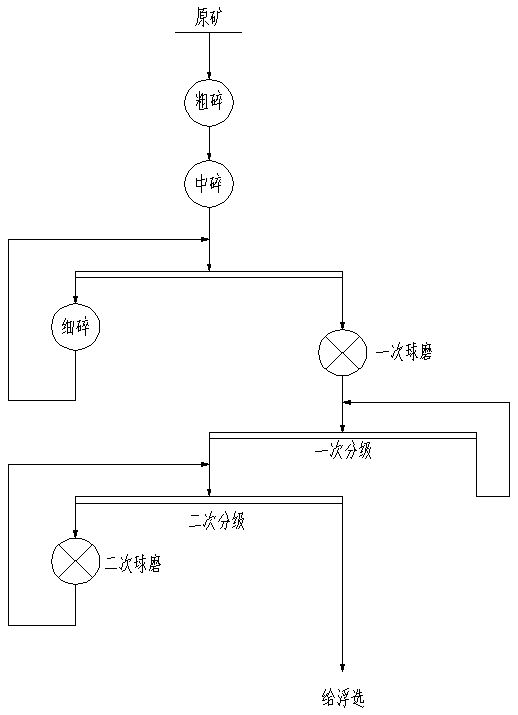

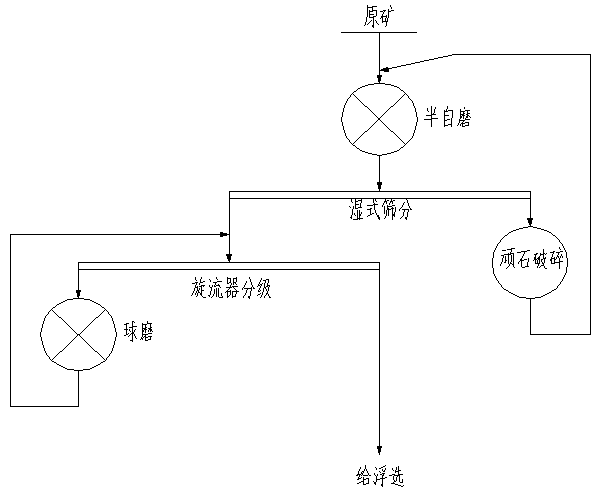

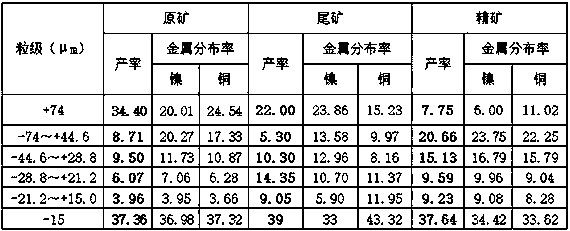

Crushing and grinding process for treating nickel copper sulfide ore

ActiveCN109569837AStable particle sizeReasonable particle size distributionGrain treatmentsMetallic NickelWorking environment

The invention discloses a crushing and grinding process for treating nickel copper sulfide ore, and belongs to the technical field of metal mineral processing. The crushing and grinding process comprises the specific process steps of semi-autogenous grinding, wet-type screening, insensate stone crushing, cyclone classification and ball-milling classification. According to the crushing and grindingprocess for treating the nickel copper sulfide ore, semi-autogenous grinding equipment is used for crushing, an original crushing way of ore is changed, the production process is simplified, comparedwith a conventional crushing and grinding process of nickel copper sulfide ore, the particle size of grinding products is stable, particle grade distribution is more reasonable, excessive crushing ofmetal minerals is reduced, pollution of iron to useful minerals is reduced, more powerful conditions for flotation are created, and the content of the particle grade being -74 to +10 [mu]m suitable for enrichment and recovery of the flotation process is increased by 14%, while the content of the particle grade being -10 [mu]m not suitable for flotation process treatment is decreased by about 5%;the number of equipment is less, and the production cost is low; and back-and-forth transport of the ore in a production link is reduced, dust pollution to the working environment of staff is avoided,and the risk of occupational disease of personnel is reduced.

Owner:JINCHUAN GROUP LIMITED

Preparation method of particle drainage agent

The invention provides a preparation method of a particle drainage agent, and relates to the technical field of metallurgical fire-refractory materials. The preparation method of the particle drainageagent comprises the following steps of selecting a composition of one or more than two of chrome ore, quartz sand, corundum, zircon sand and magnesium sand with granularity smaller than or equal to 100 meshes as a raw material, weighing the applicable weight of raw materials according to the formula of the drainage agent, and uniformly mixing, so as to obtain fine powder; adding a binder into thefine powder, and uniformly mixing; extruding, granulating into particles, and drying and curing the obtained particles, so as to obtain the particle drainage agent. The particle drainage sand prepared by the method has the advantages that the components are uniform and stable, the content deviation is controlled within + / -0.5%, and the segregation of components is avoided in the production, transportation and use process. The particle drainage agent has the advantages that the granularity is uniform and stable, and the controllability is larger; in the use process, the casting effect is stable, and the automatic casting rate is stabilized to 99.5% or above.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Preparation method of superfine titanium carbonitride powder

The invention discloses a preparation method of superfine titanium carbonitride powder and belongs to the technical field of nano ceramic powder preparation. The preparation method comprises the following steps: S1, grinding titanium dioxide and carbon black into absolute ethyl alcohol with paraffin and uniformly mixing the mixture to obtain a mixed material; S2, drying the mixed material to granulate to obtain mixed particles; S3, feeding the mixed particles to a continuous graphite carbon tube furnace for carbonitriding and controlling the reaction temperature and the reaction atmosphere toobtain a titanium carbonitride coarse product; and S4, removing free carbon and impurities from titanium carbonitride coarse product to obtain a titanium carbonitride product. The titanium carbonitride prepared by the invention has the advantages of being low in cost, high in yield and high in product purity.

Owner:CHENGDU MET CERAMIC ADVANCED MATERIALS

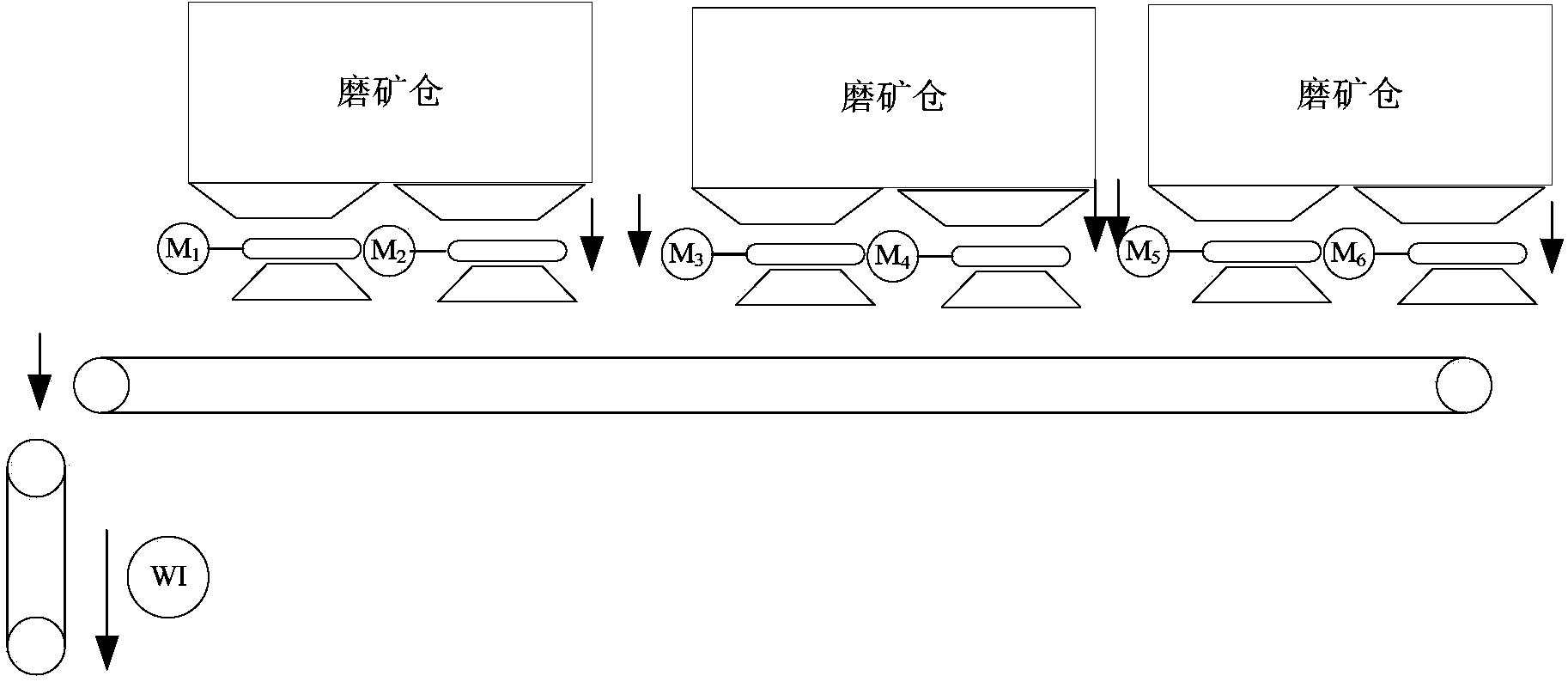

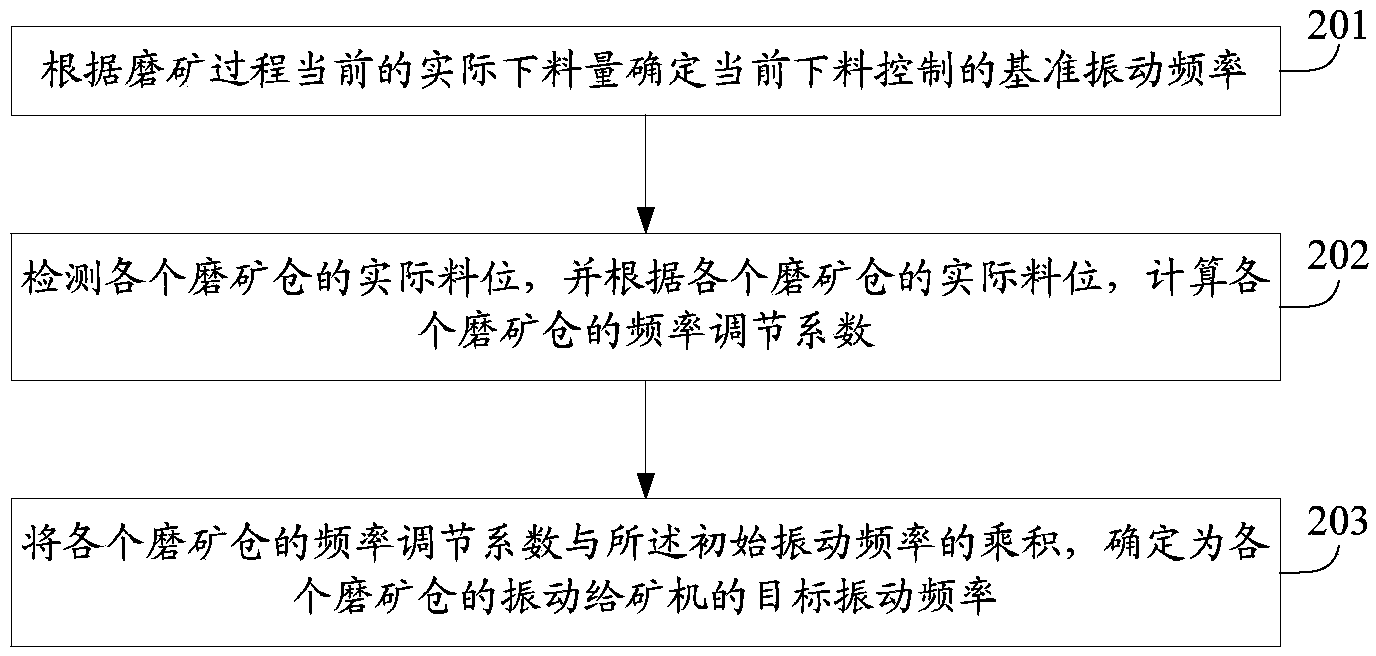

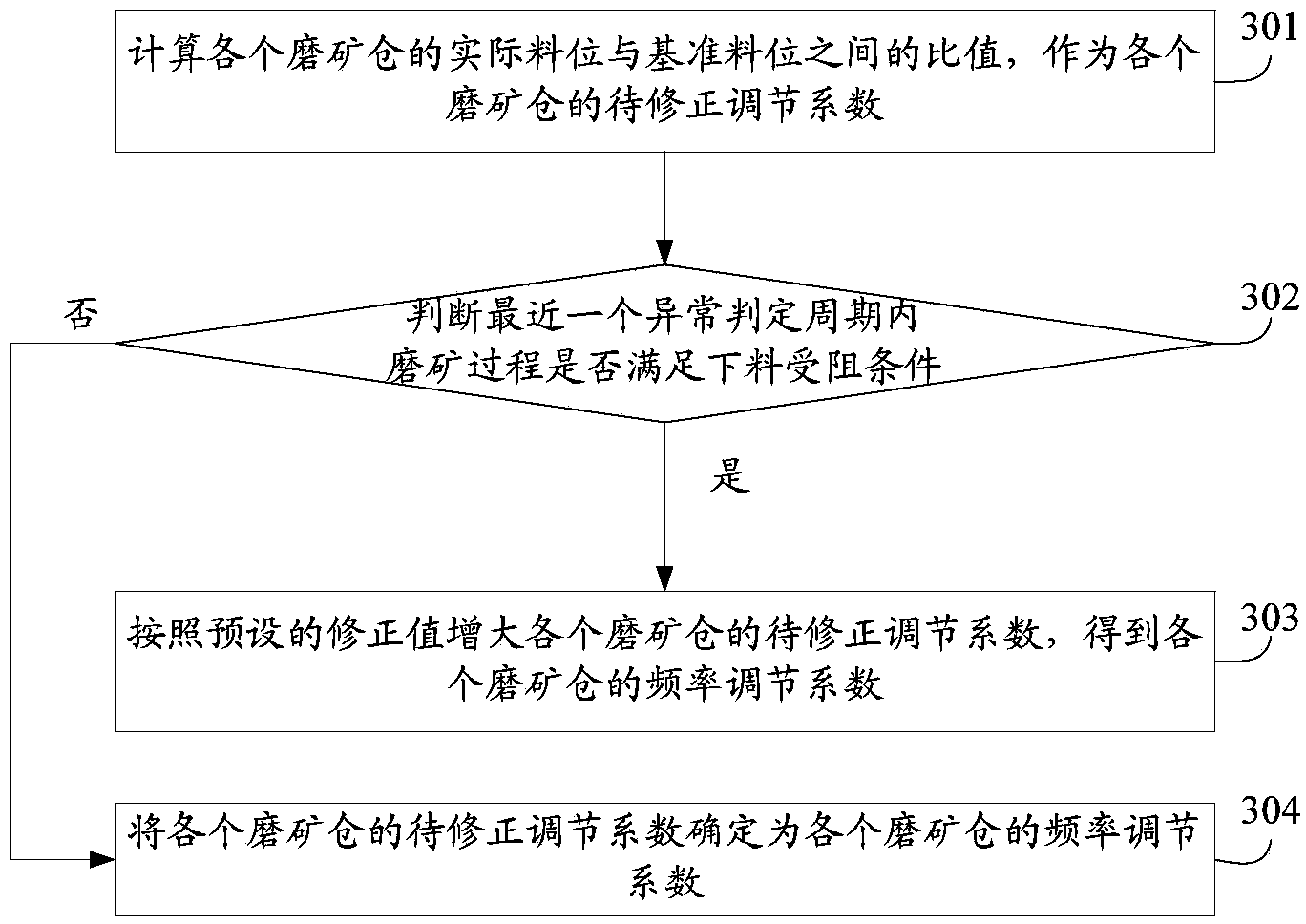

Method and device for controlling discharging of multiple ore grinding bins in ore grinding process

The invention discloses a method and device for controlling discharging of multiple ore grinding bins in an ore grinding process. The method comprises the steps: determining a fundamental vibrating frequency of current controlled discharging according to the current actual discharging amount in the ore grinding process; detecting an actual material level of each ore grinding bin, and calculating a frequency regulating coefficient of each ore grinding bin according to the actual material level of each ore grinding bin, wherein the lower the actual material level of the ore grinding bin is, the smaller the frequency regulating coefficient is; determining a product of the frequency regulating coefficient of each ore grinding bin and the fundamental vibrating frequency as a target vibrating frequency of a vibrating ore feeder of each ore grinding bin. According to the technical scheme of the invention, the condition of emptying of the ore grinding bin in a discharging process can be effectively avoided, the probability of ore-free operation of the vibrating ore feeder is reduced, and thus the condition that the actual discharging amount greatly deviates from the controlled discharging amount instantly due to emptying of the ore grinding bin is reduced so that the discharging amount of the ore grinding is uniform and accurate, and the granularity of ore ground products is stable.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

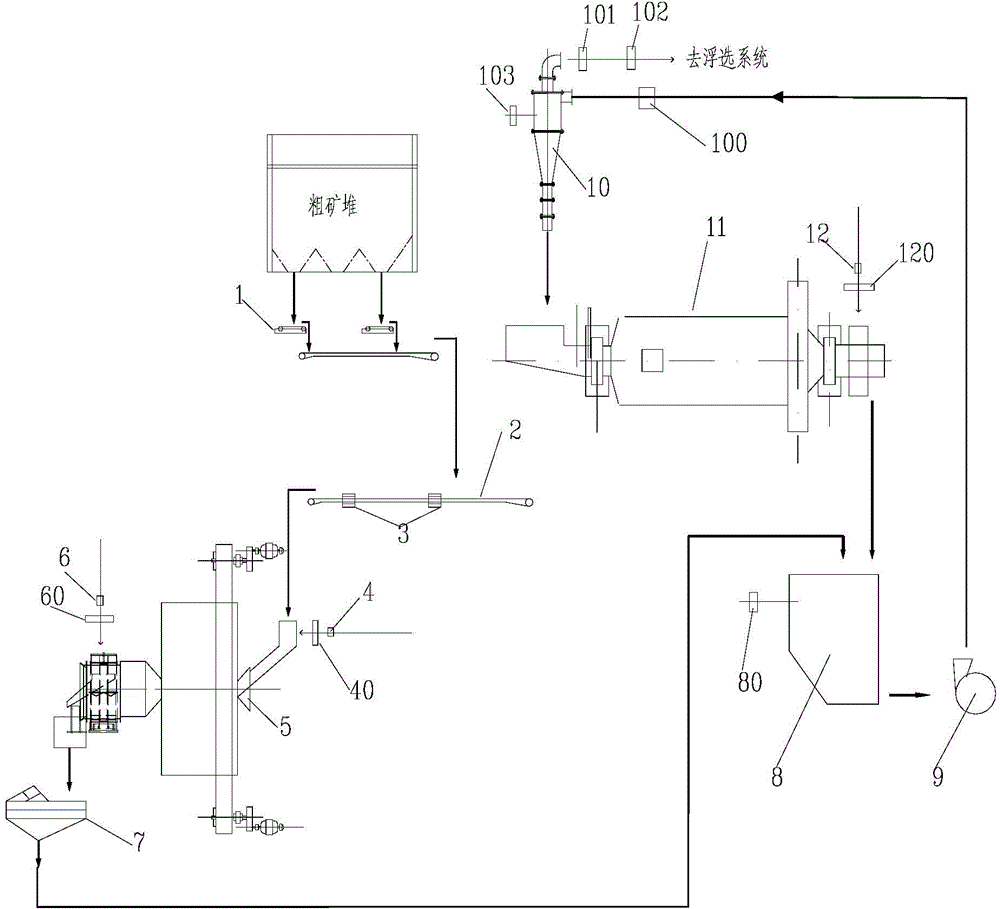

System for controlling grinding density and fineness as well as method for controlling grinding density and fineness

The invention provides a system for controlling grinding density and fineness as well as a method for controlling grinding density and fineness. The system for controlling grinding density and fineness comprises an interface operation unit, a detection unit, a central data processing unit and a PID control unit, according to a comparison result of the central data processing unit, ore-feeding amount of an ore-feeding apparatus, water supply volume of a water supply apparatus and frequency of a slurry pump at upstream of a cyclone can be controlled, so that actual overflow concentration and the actual overflow granularity is in a set overflow concentration set parameter and overflow granularity set parameter scope. The invention also provides a method for controlling grinding density and fineness, which comprises the following steps: preseting, detecting, processing, controlling grinding density and controlling the grinding granularity. By using the system for controlling grinding density and fineness as well as the method for controlling grinding density and fineness, concentration and granularity of pulp through grinding can be effectively controlled, effect is rapid, and operation is simple.

Owner:CHINA GOLD INNER MONGOLIA MINING

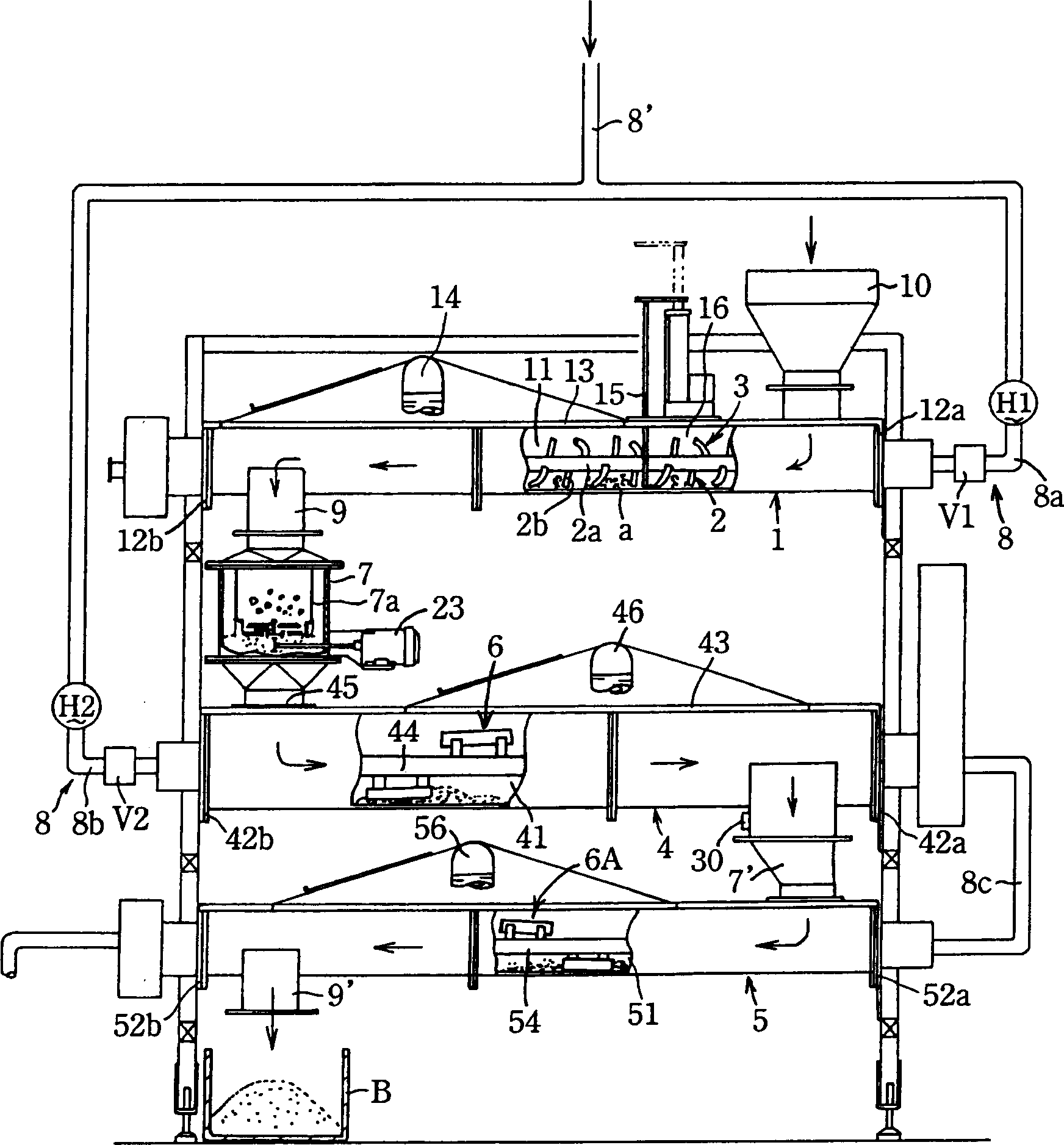

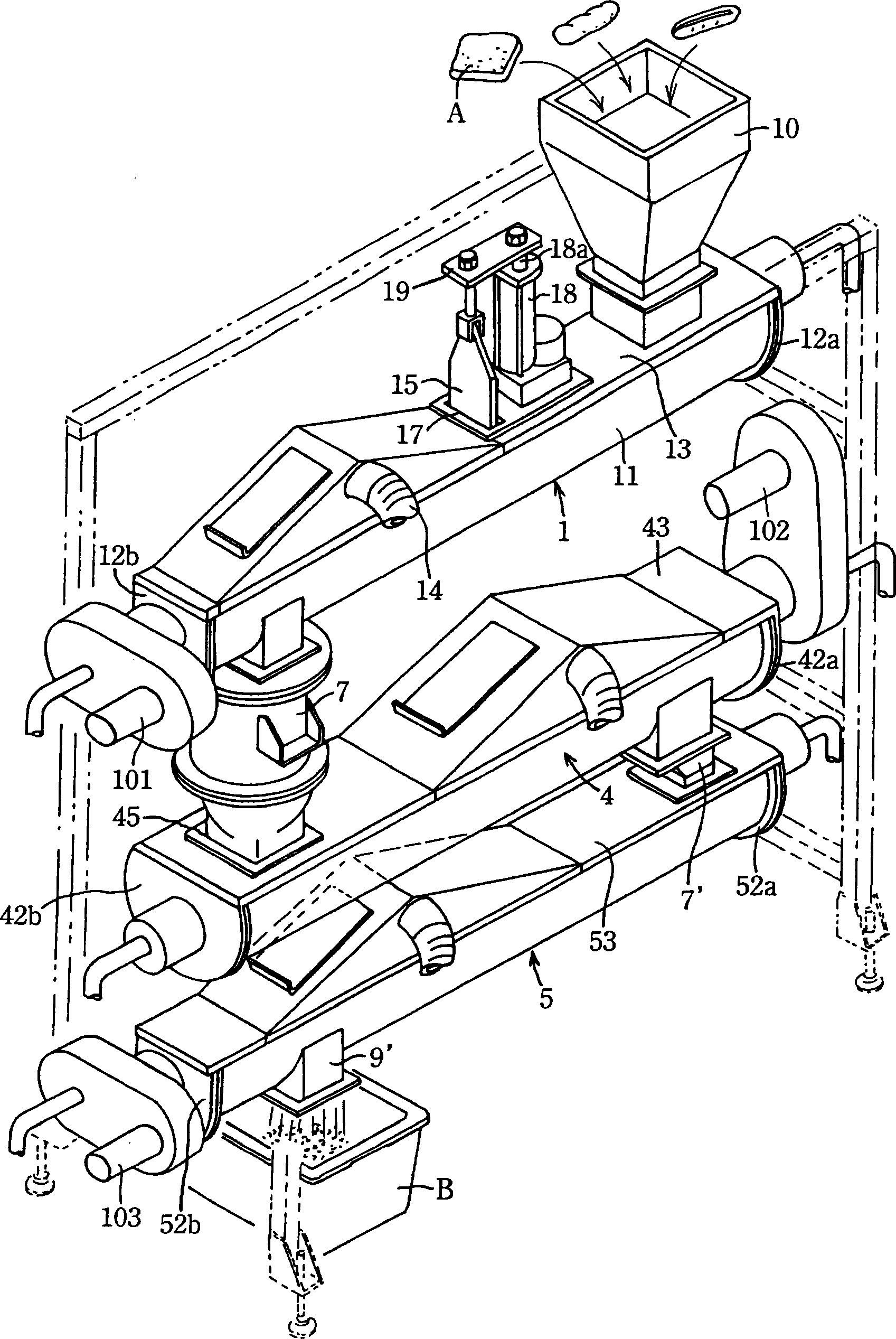

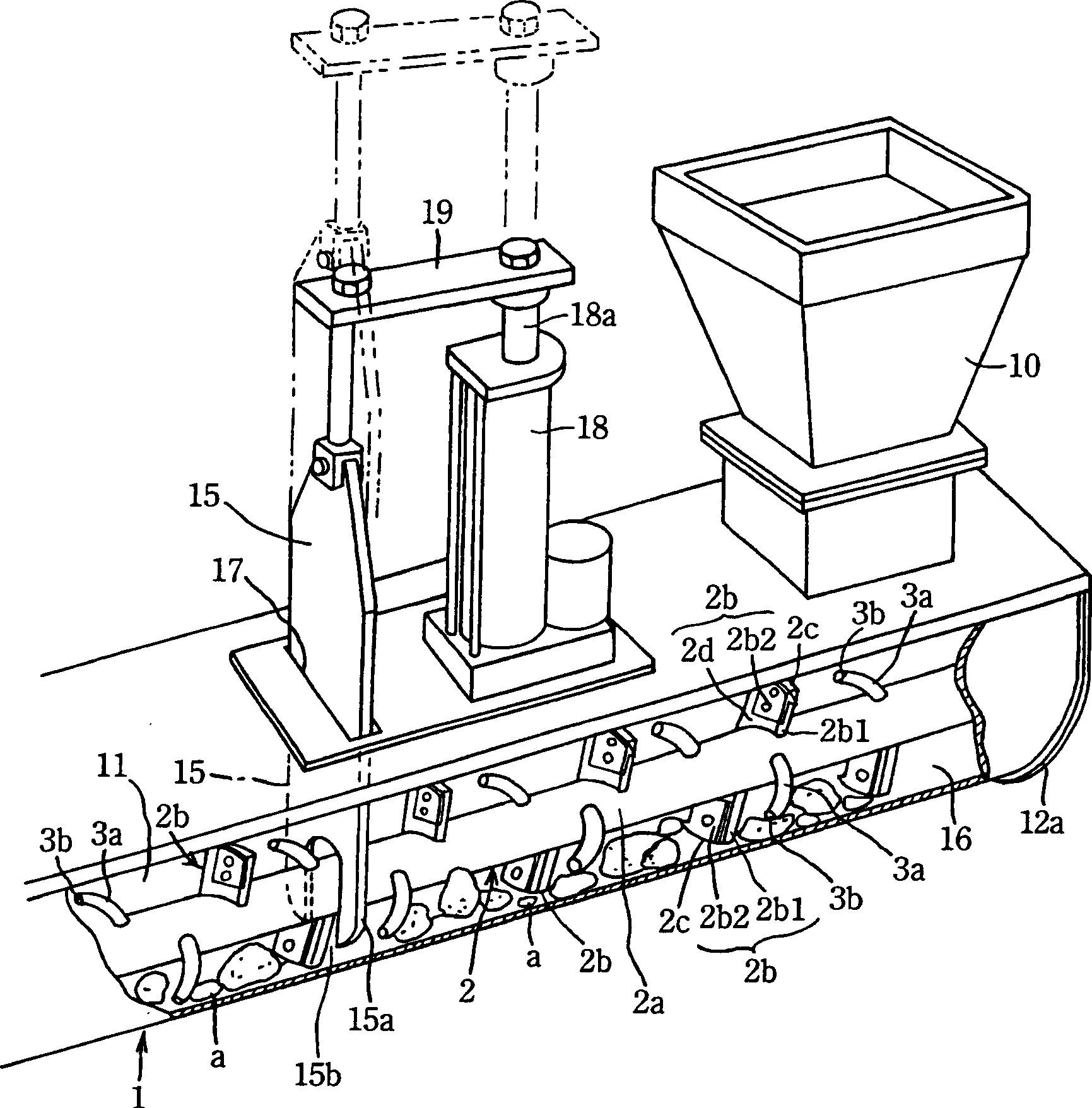

Method and device for treating waste bread

InactiveCN1787886AEfficient removalReduce moisture contentSolid waste disposalAnimal feeding stuffInjection portPulp and paper industry

Provided is a method and device that can efficiently crush and dry waste bread into fine powder particles with low moisture content so that they can be used as compound feed for livestock. The waste bread (A) is supplied into the primary drying passage (1) which has a rotary grinding blade (2b) and a hot air nozzle (3a) with an outlet facing the delivery direction, and is dried using the front end surface of the rotary grinding blade (2b) and the primary drying passage (3a). The inner bottom surface of the passage (1) grinds and pulverizes the waste bread (A). At the same time, the heated primary drying passage (1) and the hot air sprayed from the nozzle (3a) are used to evaporate and remove the moisture in the waste bread (A). It is then finely pulverized by the rotating blade (20) and supplied into the secondary drying passage (4) through the mesh body (7a), and then dried in the secondary drying passage (4).

Owner:NIPPON ZOKI PHARM CO LTD

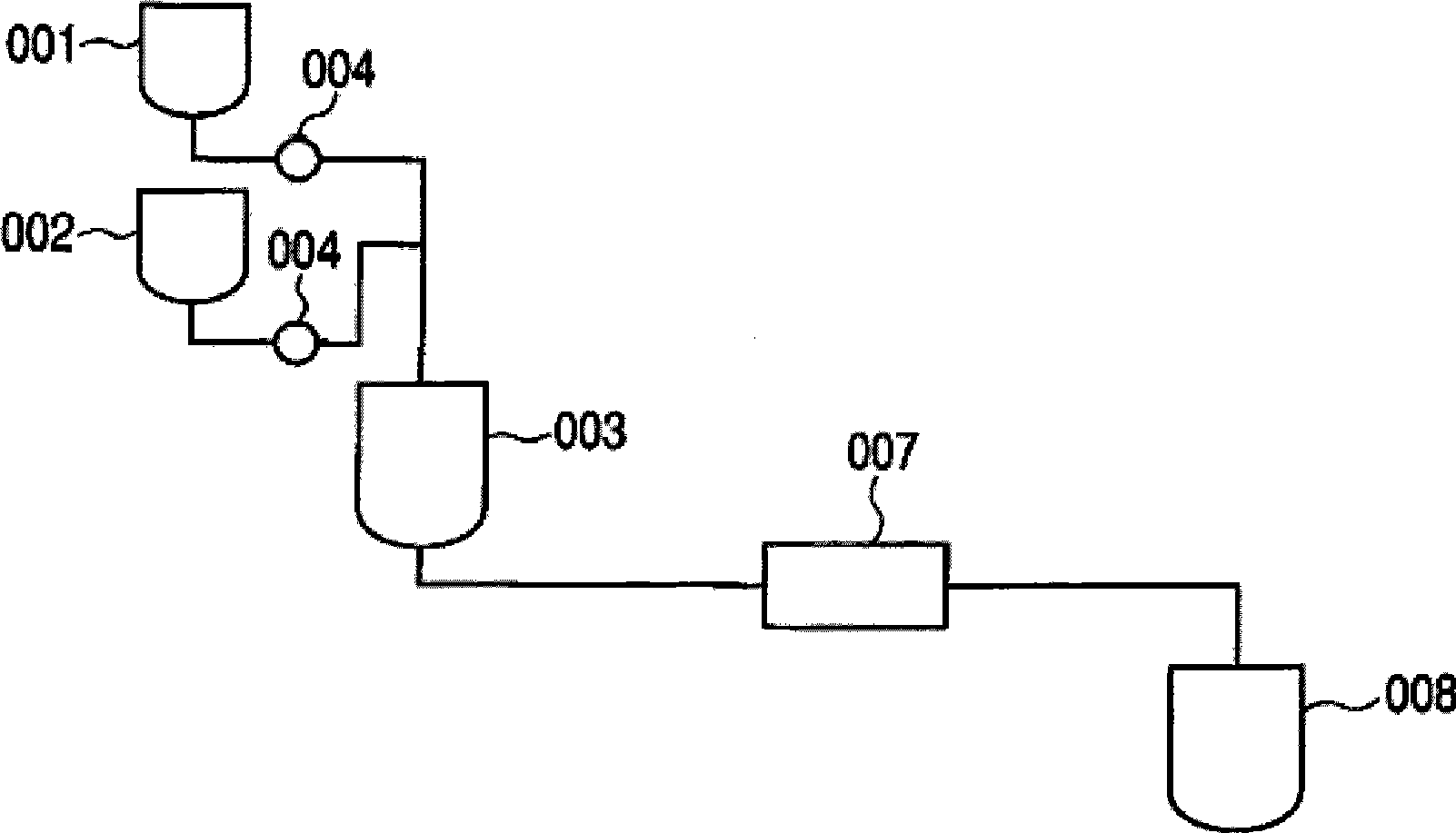

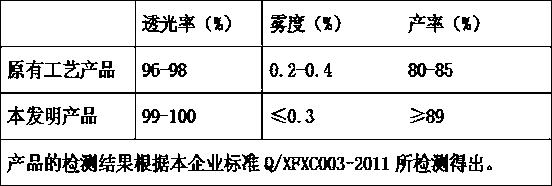

Emulsifying defoaming system and PVB (Polyvinyl Butyral) resin production method employing the same

ActiveCN103007587AGood emulsifying effectGood repeatabilityFilm/foil adhesivesFoam dispersion/preventionPlasticizerReaction system

The invention provides an emulsifying defoaming system and a PVB (Polyvinyl Butyral) resin production method employing the same and relates to an additive and application thereof in a resin production process, wherein the emulsifying defoaming system is composed of an emulsifier and a defoamer; the weight percentage of the emulsifier is 50-99.9%; and the emulsifier is the mixture of sodium hexadecyl sulfosuccinate or octyl phenyl polyoxyethylene ether and sodium alkyl sulfosuccinate. The emulsifying defoaming system is applied so that bubbles generated by stirring while the excellent emulsification effect of the reaction system is achieved; so that therefore, the generation of massive wastes can be reduced and the quality and yield of the product can be improved. Simultaneously, the defoamer applied in the emulsifying defoaming system provided by the invention is also advantages for improving the compatibility of a plasticizer with the resins. The formation of bubbles in the subsequent extrusion curtain coating processing procedure of the resins also can be eliminated in the presence of the defoamer; and the obtained membrane is free of defect apparently.

Owner:HUZHOU XINFU NEW MATERIALS CO LTD

Cement combination semi-finishing grinding optimization control system and cement combination semi-finishing grinding optimization control method

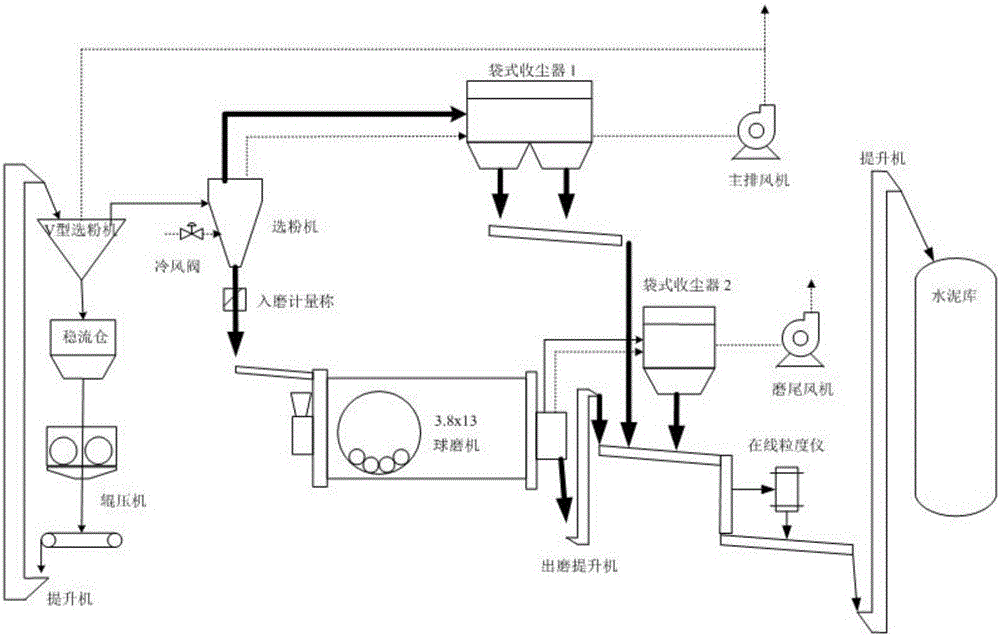

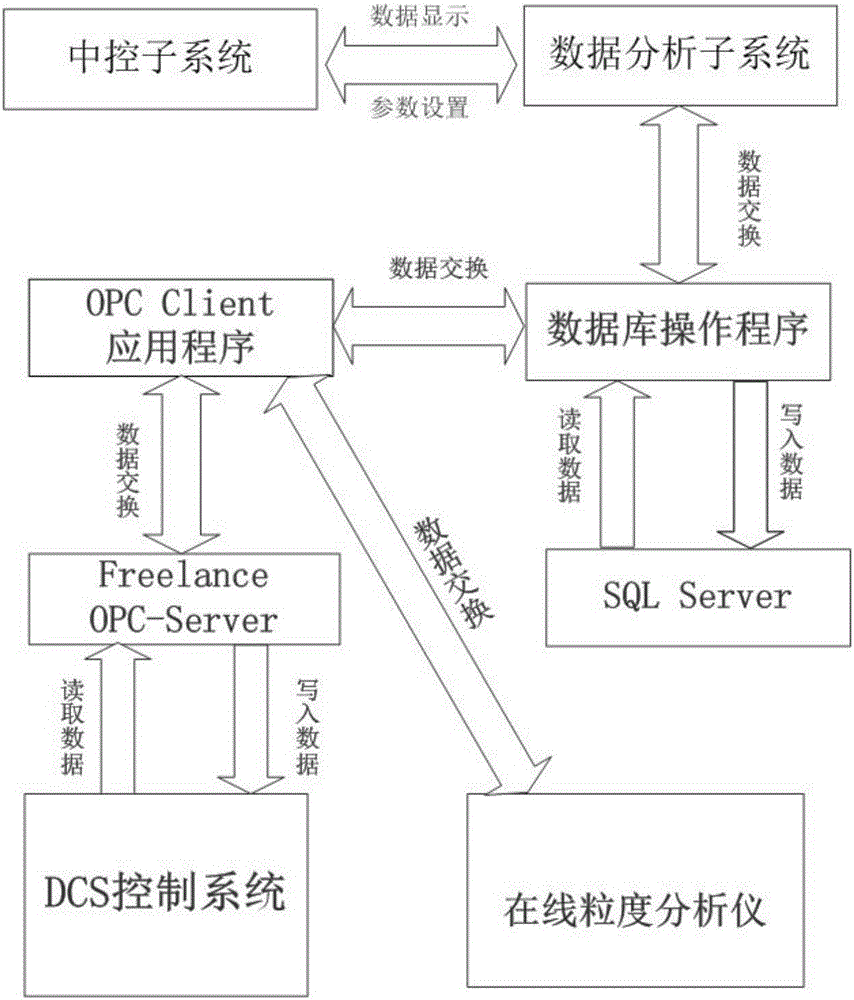

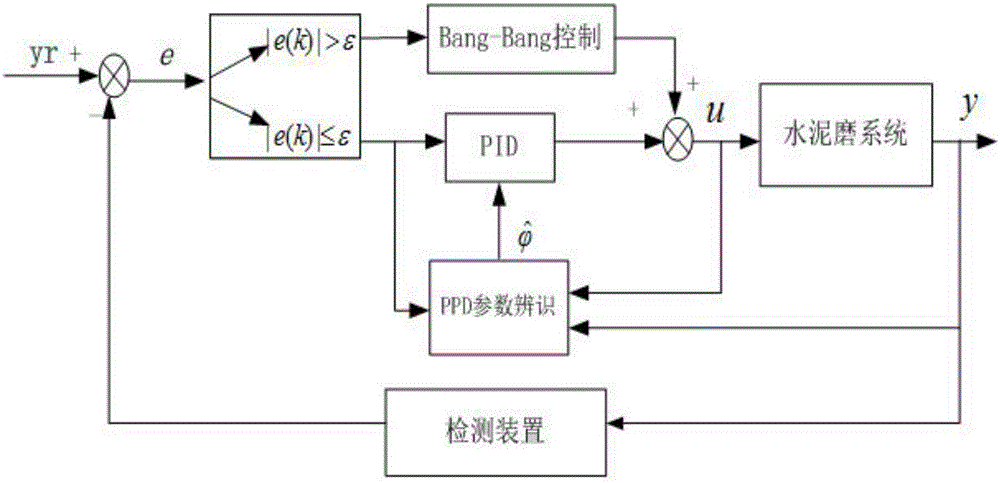

ActiveCN106814719AReasonable particle size distributionQuality improvementTotal factory controlProgramme total factory controlControl systemData acquisition

The invention discloses a cement combination semi-finishing grinding optimization control system. The cement combination semi-finishing grinding optimization control system comprises a data acquisition subsystem, a data analyzing subsystem, a DCS control subsystem, and a centralized control subsystem. The data acquisition subsystem is used to acquire parameters of cement production key equipment in DCS and particle size parameters analyzed and processed by a particle size analyzer. The data analyzing subsystem is used to determine whether cement particle size distribution is reasonable according to data acquired by the data acquisition subsystem, and according to the cement particle size distribution condition, the cement production key equipment is selected to be adjusted, so that the cement particle size tends to be normal, and by using the data analyzing subsystem, the adjusting amplitude of the cement production key equipment is provided. The cement key equipment is adjusted by the DCS control subsystem according to a result acquired by the data analyzing subsystem, and therefore objects of reasonable cement particle size distribution and stable quality are achieved. The invention also provides a cement combination semi-finishing grinding optimization control method.

Owner:UNIV OF JINAN +1

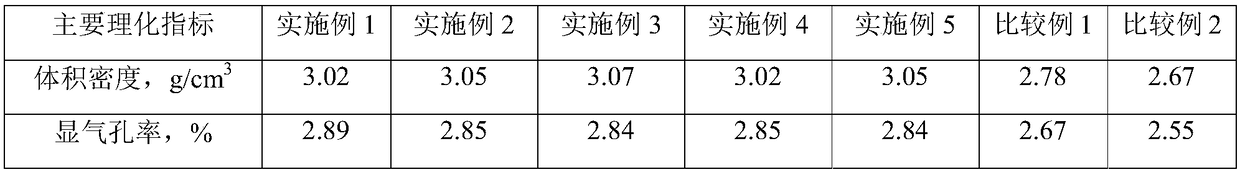

High-performance magnesia carbon brick and preparation method thereof

The invention provides a high-performance magnesia carbon brick and a preparation method thereof. The high-performance magnesia carbon brick is mainly prepared from the following raw materials in parts by mass: 60-75 parts of fused magnesite particles, 10-25 parts of 120-400-mesh fused magnesite fine powder, 1-5 parts of aluminum powder, 0.1-5 parts of a spinel-calcium aluminate multiphase material, 10-16 parts of crystalline flake graphite and 2-4 parts of a binding agent, wherein the fused magnesite particles are prepared by mixing three kinds of particles with the particle size of 3-5 mm, 1-3 mm and 0.075-1 mm according to the mass ratio of (3-5):(3-5):(2-4). According to the magnesia carbon brick, the spinel-calcium aluminate multiphase material is introduced, so that a low-melting-point substance is generated on the surface of the magnesia carbon brick at a high temperature, thermal stress is relieved, thermal shock damage and mechanical damage are reduced, and therefore the purpose of preventing the magnesia carbon brick from cracking is achieved.

Owner:上海新泰山高温工程材料有限公司

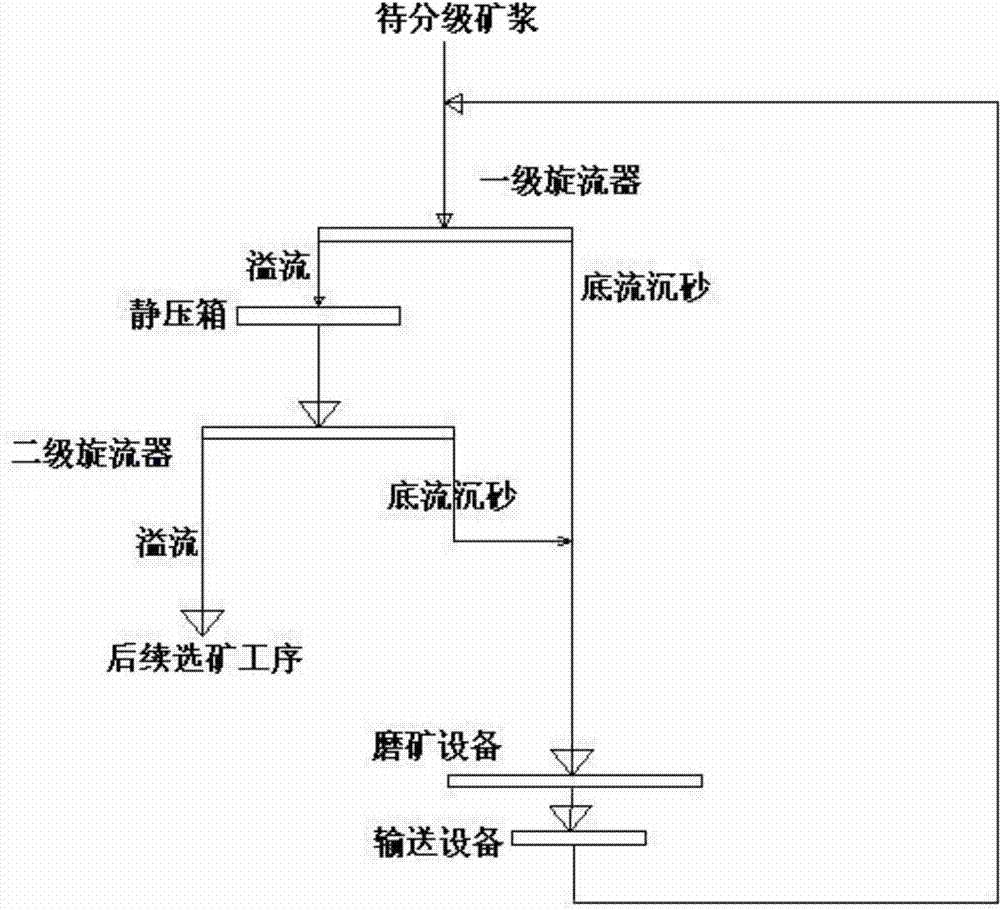

Grinding classification method

InactiveCN104492615ASlurry pressure remains stableGrading parameters remain stableReversed direction vortexHeight differenceClassification methods

The invention belongs to the field of ore pulp classification, relates to a grinding classification method, and concretely relates to a method for performing classification by utilizing a waterpower swirler. The to-be solved technological problem is that in order to guarantee the granularity of ore pulp subjected to grinding classification to reach product quality requirements, the grinding classification method comprises the following steps: A, inputting ore pulp needing classification operation into a first-stage swirler for classification; B, enabling classified overflow ore pulp in the first-stage swirler to enter a static-pressure box; C, enabling ore pulp in the static-pressure box to automatically flow into a second-stage swirler depending on the height difference with the second-stage swirler; D, collecting overflow ore pulp subjected to classification in the second-stage swirler, so as to obtain mineral with targeted grinded particle level; and E, regrinding underflow settled sand in the first-stage swireler and in the second-stage swireler, and then again sending into the first-stage swirler for classification. Finally, the mineral with the target particle level is obtained by utilizing the two stages of swirlers for classification.

Owner:四川安宁铁钛股份有限公司

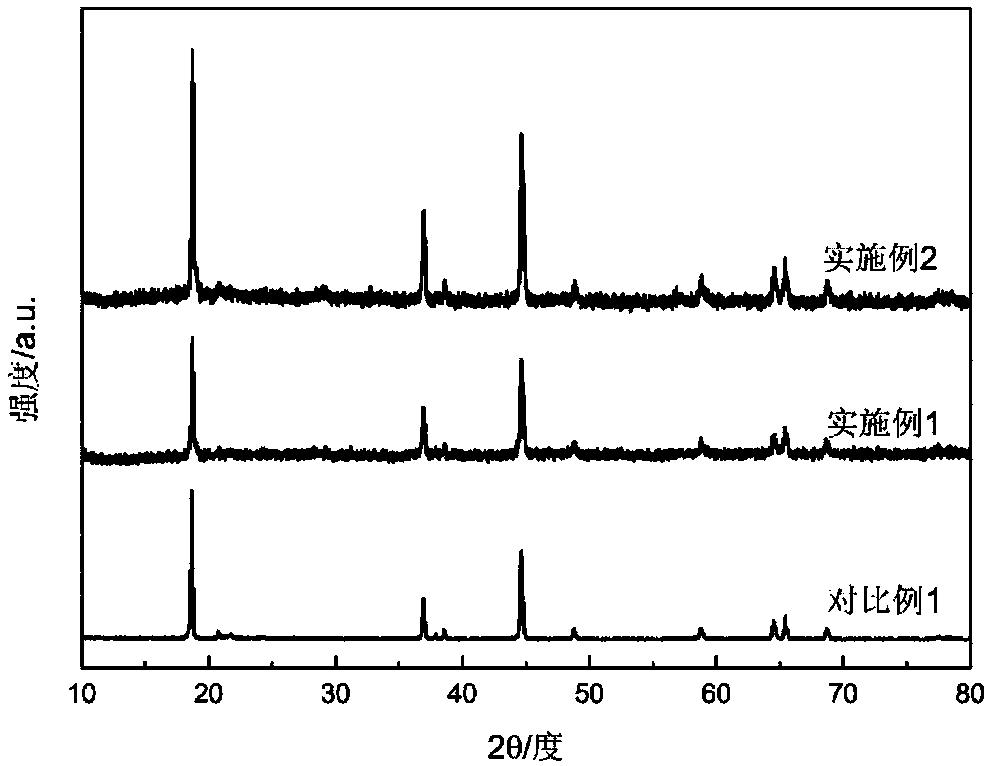

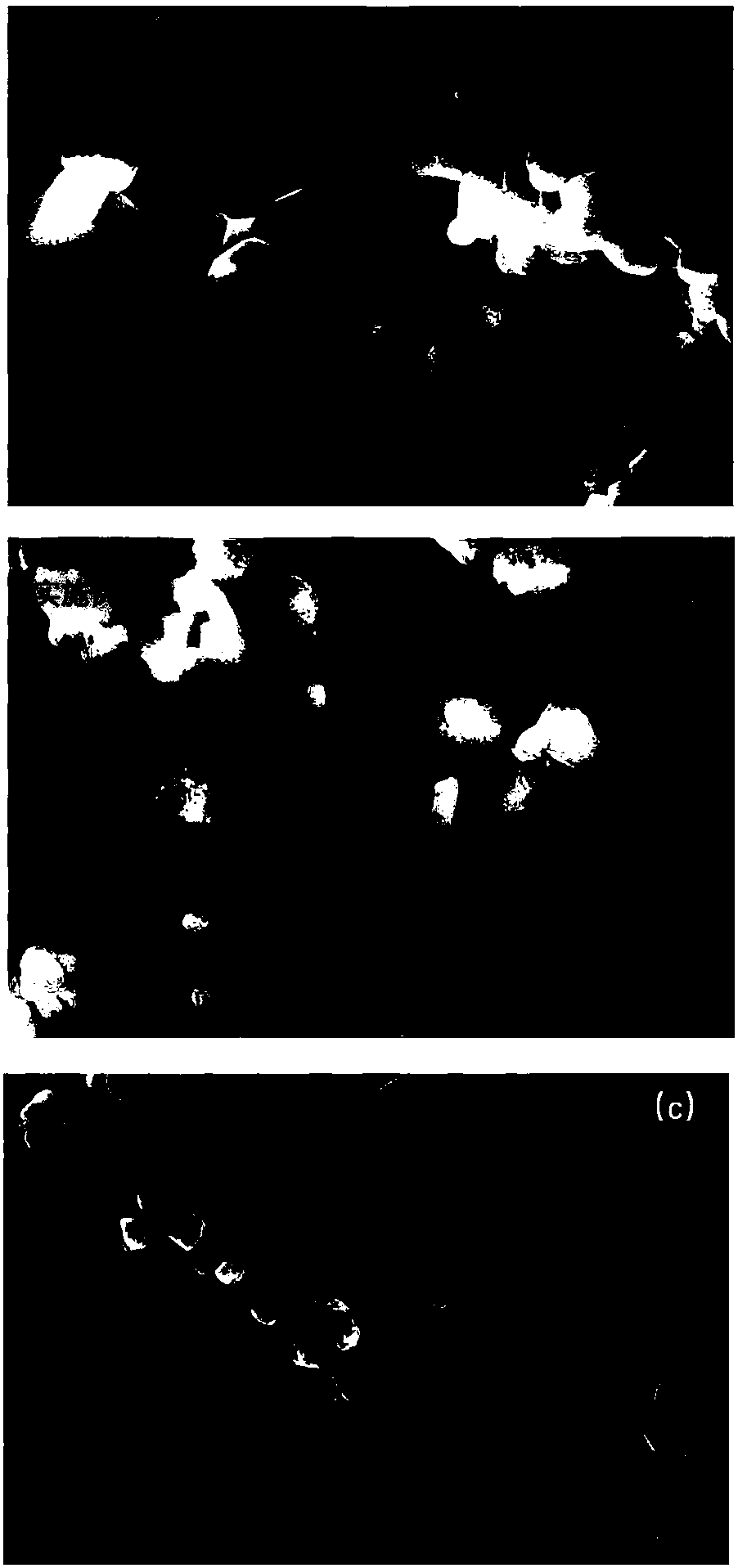

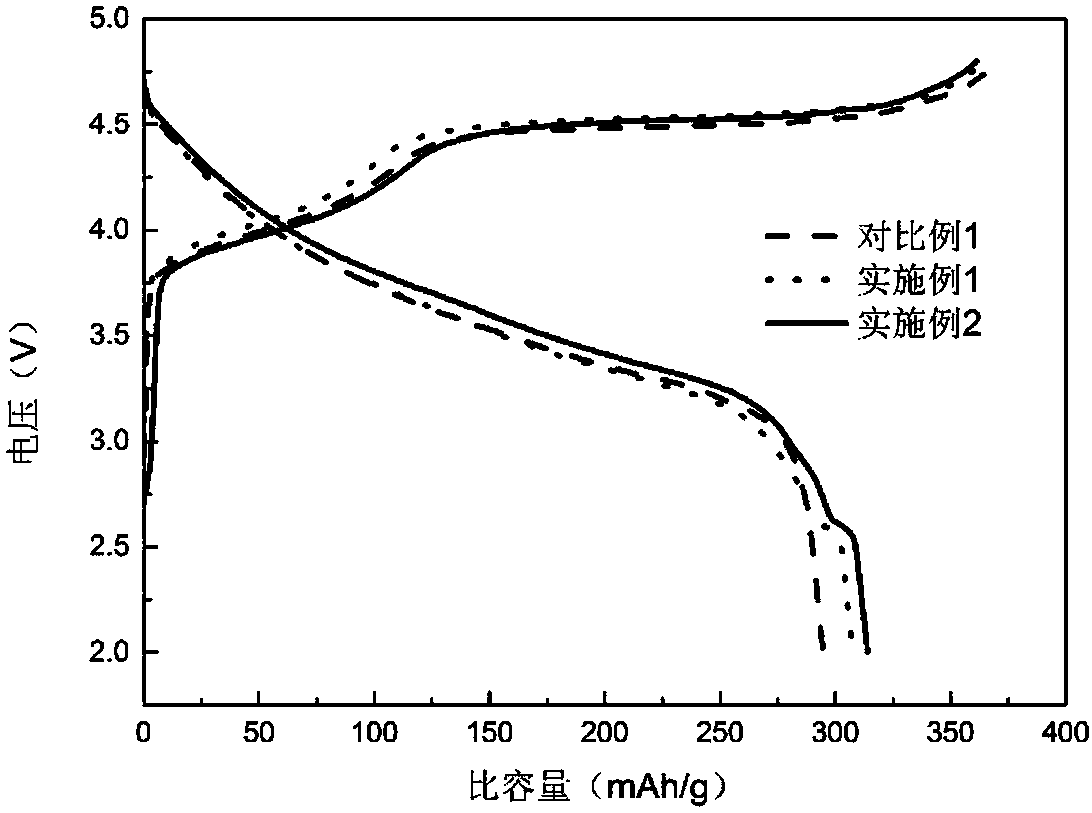

Modification method of cerium-tin compound oxide coated lithium-rich manganese-based positive material

ActiveCN108172808AThe synthesis method is simpleUniform product distributionMaterial nanotechnologySecondary cellsSolventUltrasonic oscillation

The invention discloses a modification method of a cerium-tin compound oxide coated lithium-rich manganese-based positive material. The body of the material is a lithium-rich manganese-based positivematerial, and the surface coated substance of the material is a cerium-tin compound oxide material containing rich oxygen defects. The modification method comprises the following preparation steps: (1) dispersing the lithium-rich manganese-based positive material into a secondary water solvent, and forming a uniform mixed solution through ultrasonic oscillation to be marked as an A solution; (2) dispersing a metal salt containing Sn and Ce elements into the secondary water solvent, adding an alkaline source to adjust the pH of the solution to be 12, and marking the solution to be a B solution;(3) after uniformly mixing the A solution and the B solution, putting the mixture into water at the temperature of 140 to 220 DEG C inside a reaction still for heat treatment for 12 to 36 h, and washing, filtering and drying to obtain a precursor material; and (4) after sufficiently grinding the precursor material, carrying out calcinations at the temperature of 450 to 650 DEG C for 3 to 10 h, and cooling to room temperature so as to obtain the cerium-tin compound oxide coated lithium-rich manganese-based positive material. According to the method, the surface coating for the lithium-rich manganese-based positive material is realized through hydro-thermal treatment, the preparation technology is simple, and the obtained material is high in degree of crystallinity, high in capacity and good in rate capability.

Owner:UNIV OF SCI & TECH BEIJING

Formula and production process of environment-friendly and pollution-free grass carp feed

InactiveCN110269161AReasonable ratioIncrease production capacityFood processingClimate change adaptationFish oilWater quality

The invention relates to the aspect of aquaculture, in particular to a formula and production process of an environment-friendly and pollution-free grass carp feed. The formula includes a component A, a component B and a component C. According to the mass parts, 1-40 parts of bean pulp, 1-30 parts of peanut meal, 5-15 parts of wheat meal, 5-15 parts of corn flour and 5-10 parts of fish oil are evenly mixed to form the component A, 15-30 parts of a fermented feed, 10-25 parts of clostridium alcohol protein, 10-30 parts of chicken meal, 5-10 parts of earthworm powder, 1-5 parts of a liver and bile protecting additive and 1-5 parts of a decavitamin additive are evenly mixed to form the component B, and 20-30 kg of pulverized corn straw is put into 100 kg of starch water to be heated until viscosity is realized to form the component C. The raw material ratio in the process conforms to the feeding habit characteristic of grass carps, the production process is environmentally friendly and free of pollution, and the prepared fish feed cannot contaminate water.

Owner:FRESHWATER FISHERIES RES CENT OF CHINESE ACAD OF FISHERY SCI

Spherical styrene-butadiene rubber for 3D printing and preparation method thereof

ActiveCN105504174AFulfil requirementsNarrow particle size distributionAdditive manufacturing apparatusRubber materialPolymer science

The invention relates to a spherical styrene-butadiene rubber material for 3D printing. The material is characterized in that a structural core is polystyrene microspheres; the material is prepared from, by weight, 5-20 parts of polystyrene microspheres, 60-80 parts of butadiene monomers, 20-30 parts of styrene monomers, 0.2-1 part of an emulsifying agent, 0.02-0.5 part of an initiator, 0.02-0.1 part of a terminating agent and 80-120 parts of a filling material. Styrene-butadiene rubber latex is prepared through a seeding emulsion polymerization method in which the polystyrene microspheres serve as the core and the polystyrene microspheres, the butadiene monomers and the styrene monomers are grafted and copolymerized, the styrene-butadiene rubber latex and the filling materials are coagulated into powder, the particle size is 10-100 micrometers, particle size distribution is narrow, performance is uniform and stable, and the spherical styrene-butadiene rubber material can be directly applied as a 3D printing material.

Owner:台州科金中高技术转移有限公司

Production process of black tea powder bread

InactiveCN102511529AEasy to dissolveUniform particle sizeDough treatmentBakery productsIntegrated technologyFood processing

The invention discloses a production process of black tea powder bread and belongs to the field of food processing. The double-screw extruding process is adopted to be combined with the ultramicro crushing integrated technology for preparing black tea powder. The black tea coarse powder is placed into a feeding groove of a double-screw extruding machine at a velocity being 25 to 30kg / h, simultaneously, water is used for humidifying the black tea coarse powder in a spraying form at an auxiliary material inlet part of the extruding machine, the rotating speed and the temperature of the extruding machine are respectively set into 100r / min to 140r / min and 130DEG C and 150 DEG C, and the humidification quantity is 2kg / h to 3kg / h. The double-screw extruding powder is subjected to the ultramicrocrushing under the conditions of the feeding quantity being 20kg to 30kg, the crushing machine rotating speed being 5000r / min to 5500r / min and the crushing time being 5min to 10min, and black tea ultramicro powder is obtained. The bread made from the black tea ultramicro powder has thick black tea fragrance, fine tissue and good eating quality.

Owner:FUJIAN BEICHILE FOOD

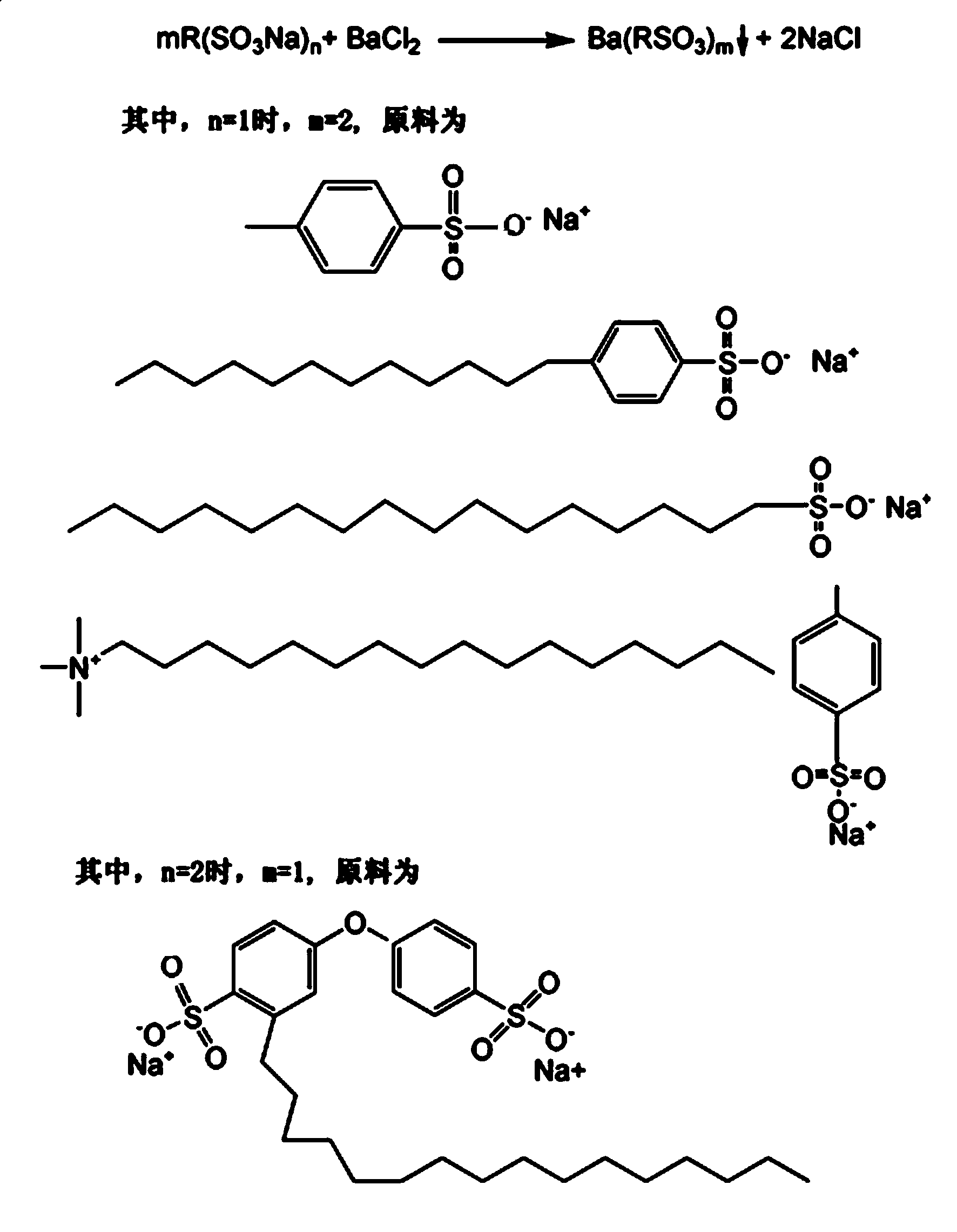

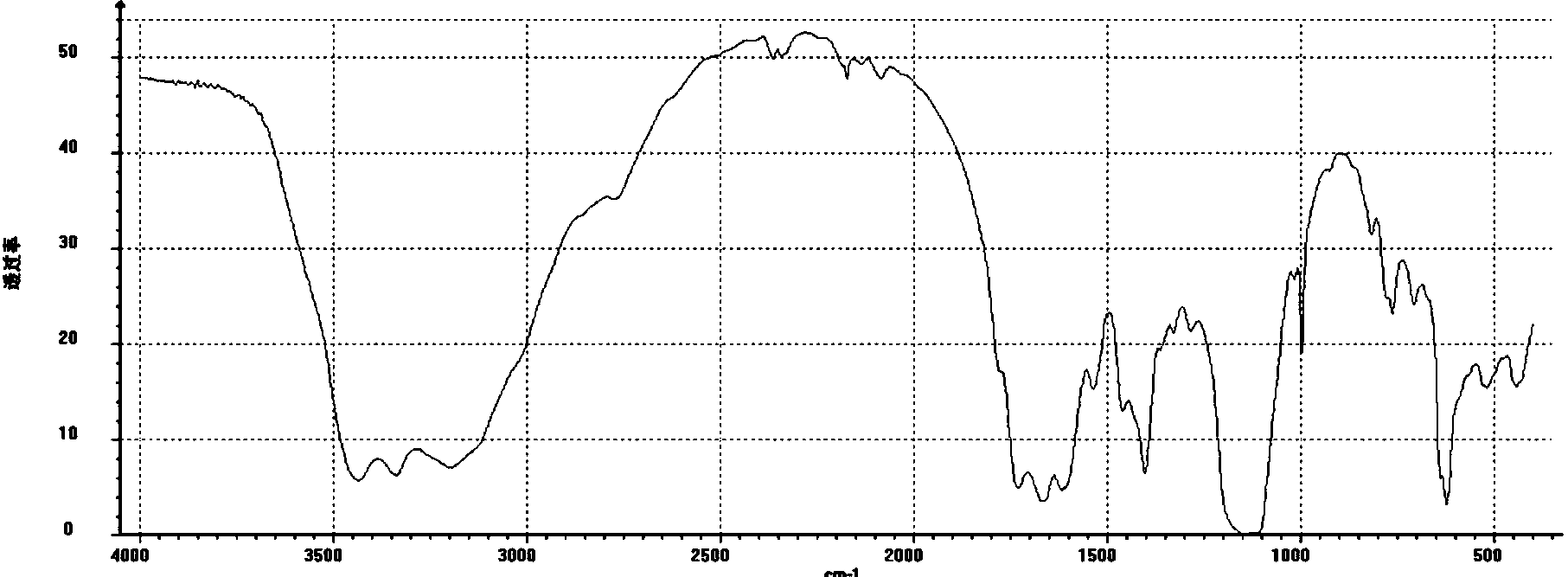

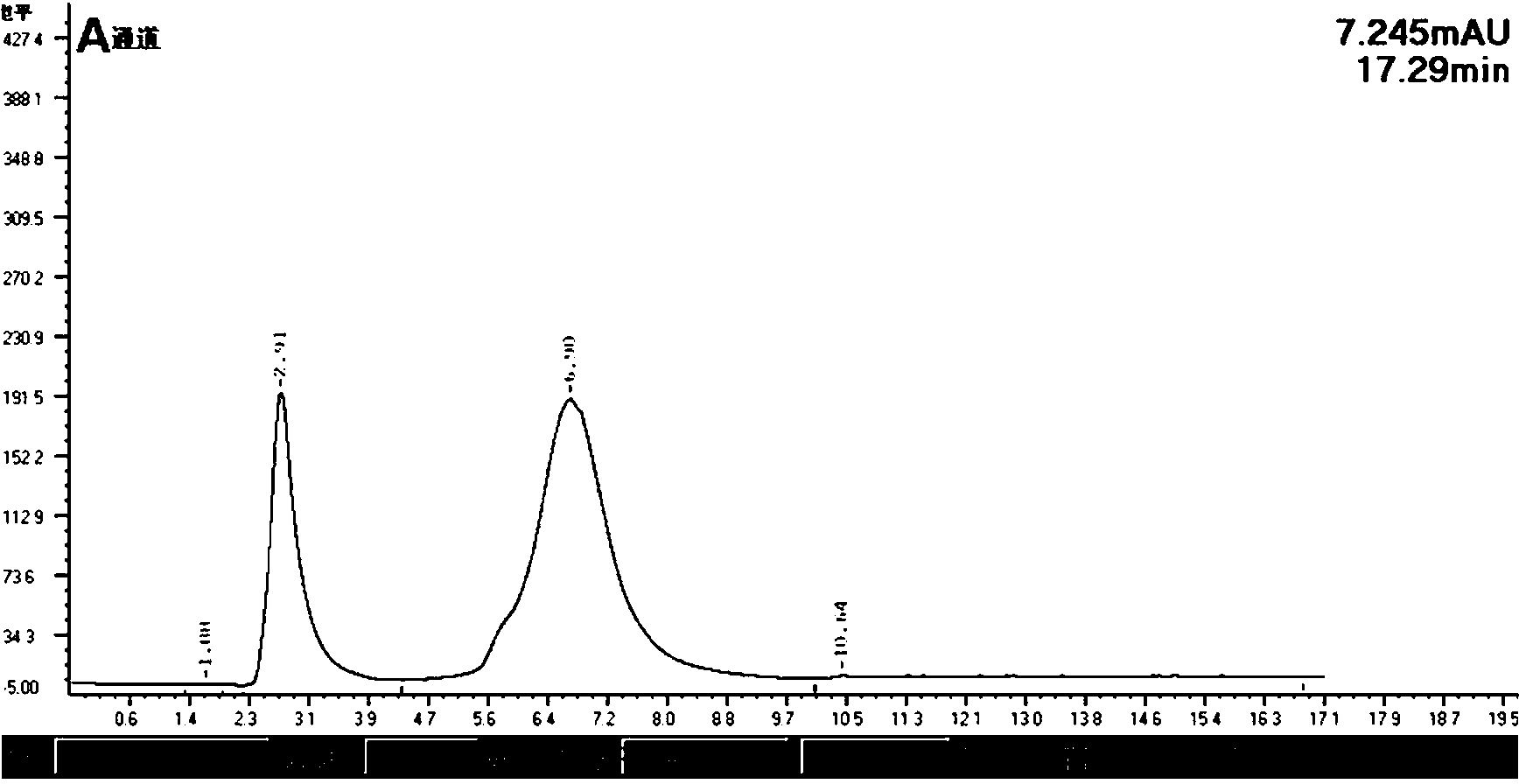

Barium sulfonate catalyst and application thereof in synthesis of D,L-P-hydroxyphenyl hydantoin

ActiveCN104174436AStable particle sizeHigh affinityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsSulfonateBarium dichloride

The invention discloses a barium sulfonate catalyst and application thereof in synthesis of D,L-P-hydroxyphenyl hydantoin, belonging to the technical field of catalysts. The barium sulfonate catalyst disclosed by the invention is prepared by comprising the following steps: mixing organic zwitter-ion sodium sulfonate with barium chloride, adding into an ultrasonic reaction kettle, reacting at 400 W for 3 h, centrifuging to collect precipitation after reacting, suspending the precipitation in water, adjusting the concentration to 0.1 mol / L, stirring, ageing, centrifuging, and drying at low temperature. The barium sulfonate catalyst disclosed by the invention is steady in granularity, low in corrosivity to reaction equipment, easy to recycle and reusable, and therefore, the yield of D,L-P-hydroxyphenyl hydantoin can be obviously increased.

Owner:LULIANG UNIV

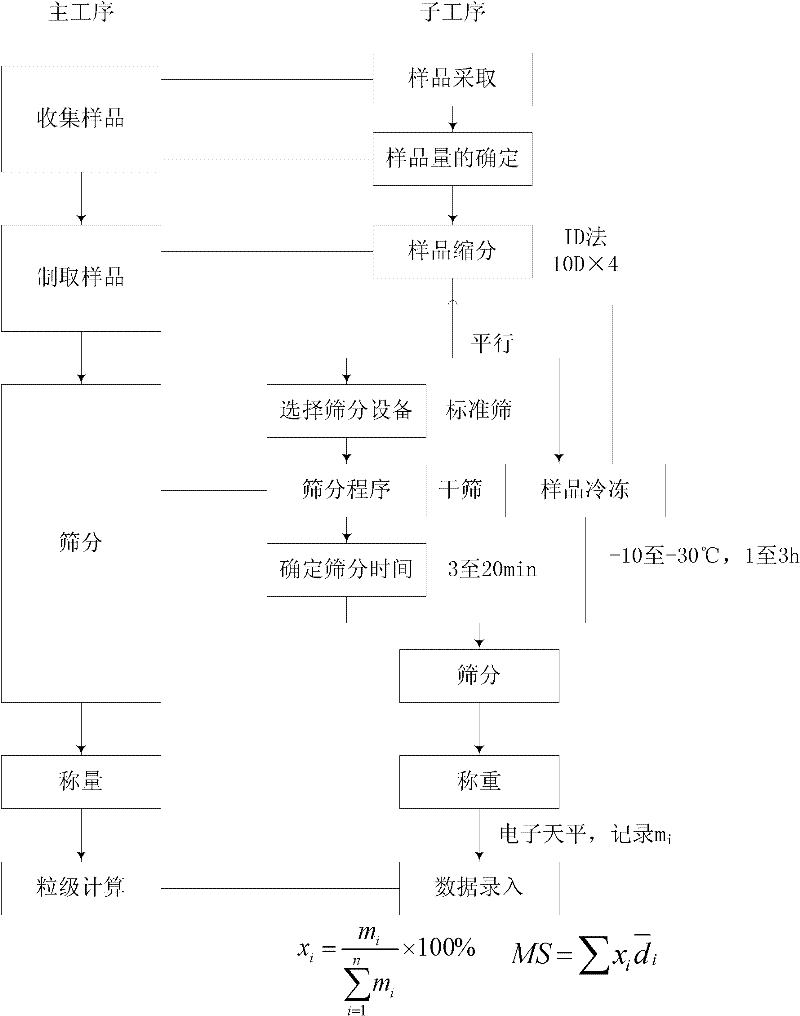

Determining system for original granularity of sintering mixture

PendingCN106404619AReduce labor intensityImprove the stability of analysis and detectionParticle size analysisGranularityUltimate tensile strength

The invention discloses a determining system for original granularity of a sintering mixture. The determining system comprises a cooling device, a detecting and sample sending device, a screening device and a microscope, wherein a discharging port of the cooling device communicates with a feeding port of the detecting and sample sending device, and the detecting and sample sending device is located between the cooling device and the screening device; the sintering mixture passes through the cooling device, the detecting and sample sending device and the screening device sequentially and is fed to the microscope for detection and observation. Compared with the prior art, the determining system has the advantages that the obtained mixture is not required to be classified during freezing of the sintering mixture, the granularity of the mixture is stable, manual stirring operation is not needed, and continuous feeding and recycling of a condensate can be realized; continuous and automatic sampling and feeding of mixture particles with different particle diameters are realized in a screening process, the stability, uniformity and reliability of sampling are improved, human unstable factors during sending are avoided, the labor intensity is reduced, the analysis and detection accuracy is improved, and the sample accuracy is effectively improved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

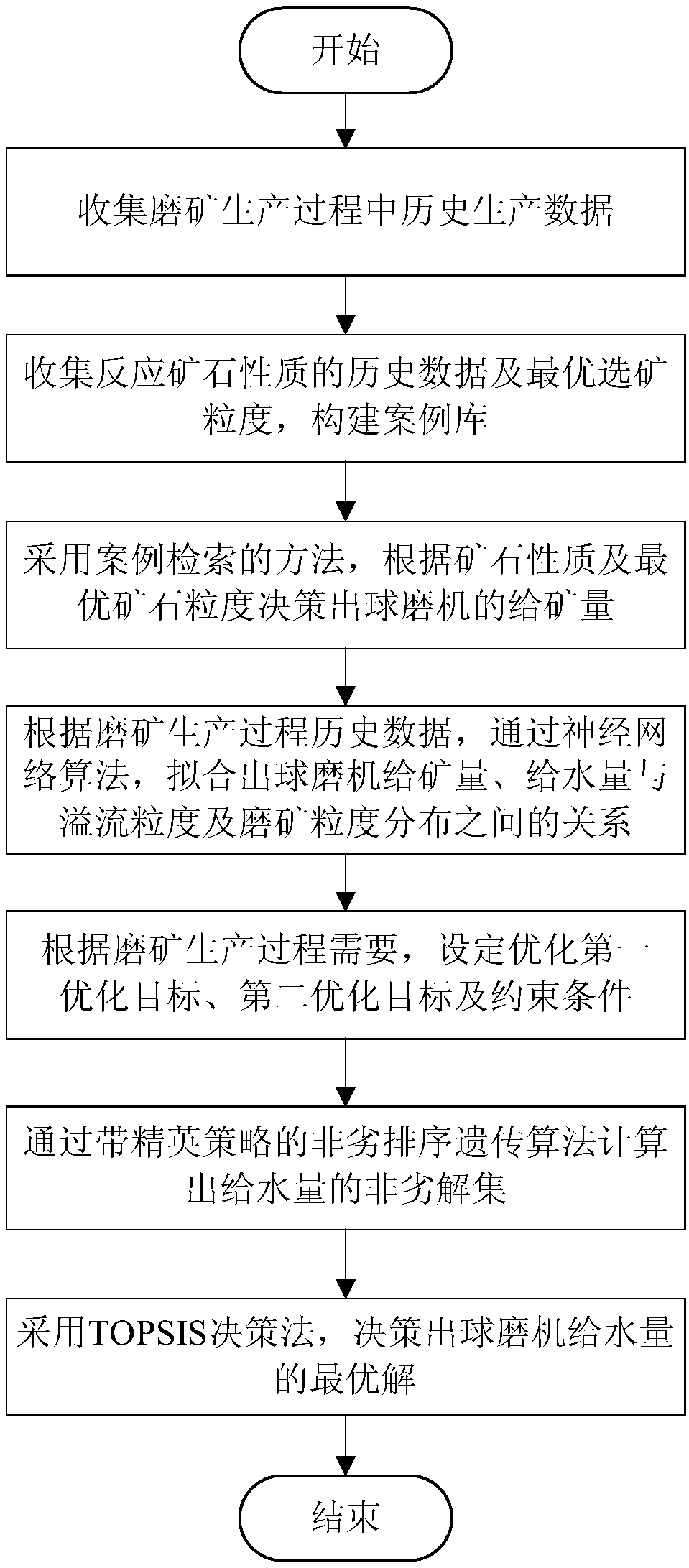

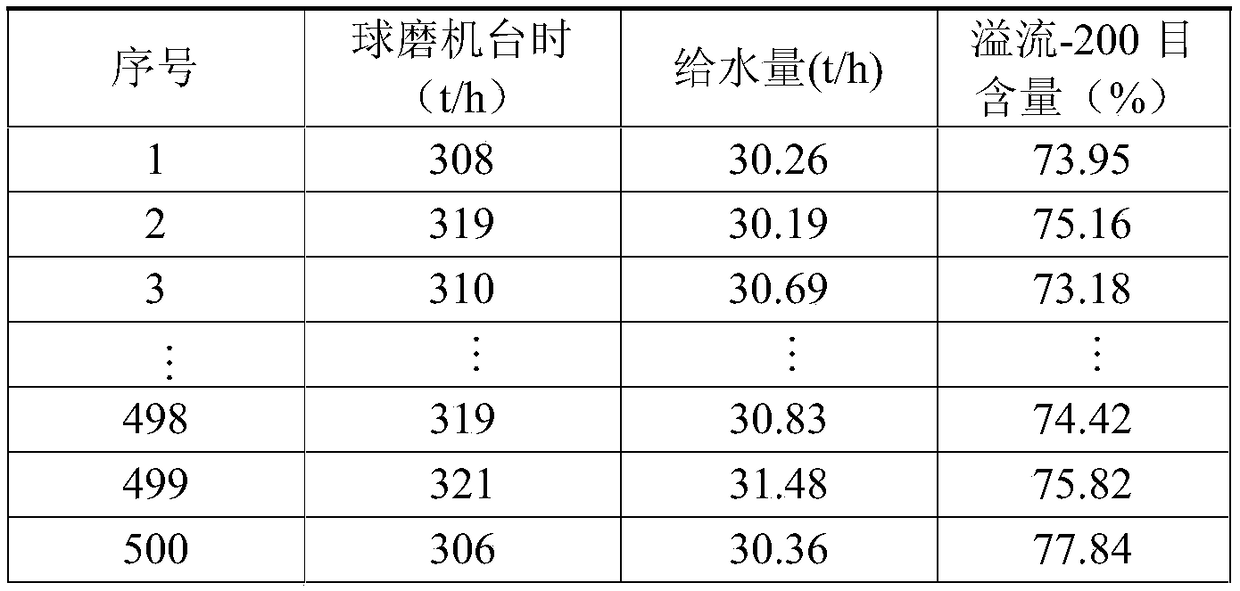

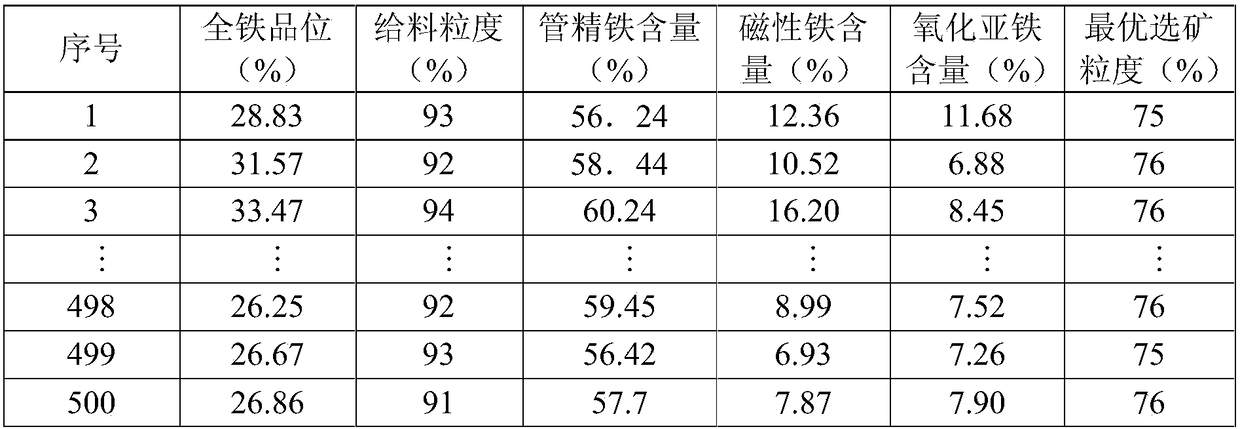

Ore grinding process modeling method based on neural network and evolutionary computation

ActiveCN108469797AStable particle sizeImprove real-time performanceTotal factory controlProgramme total factory controlProduction rateMathematical model

The invention provides an ore grinding process modeling method based on a neural network and evolutionary computation, and relates to the technical field of iron ore grinding. The method comprises thesteps that firstly, a case library is established, and the reasonable ore feeding quantity of a ball grinding mill is retrieved from the case library by adopting a case retrieval method; then througha neural network method, a mathematical model is established during the ore grinding of the ball grinding mill, and a relation among the ore feeding quantity, the water feeding quantity and the ore grinding effect is established; the maximum specific productivity of the ball grinding mill and the optimal size distribution of the grinded ore are taken as optimal objects, combined with actual working conditions, constraint conditions are determined, a group of noninferior solution set is obtained by a non-dominated sorting genetic algorithm with an elitist strategy, and an optimal solution is decided by adopting a TOPSIS algorithm. The provided ore grinding process modeling method based on the neural network and the evolutionary computation has the advantages that the reasonable ore feedingquantity and water feeding quantity are calculated, on the basis of ensuring the particle size of ore, the processing efficiency of the ball grinding mill is increased, and the stability, reliabilityand economy during the production of the ore grinding are improved.

Owner:NORTHEASTERN UNIV

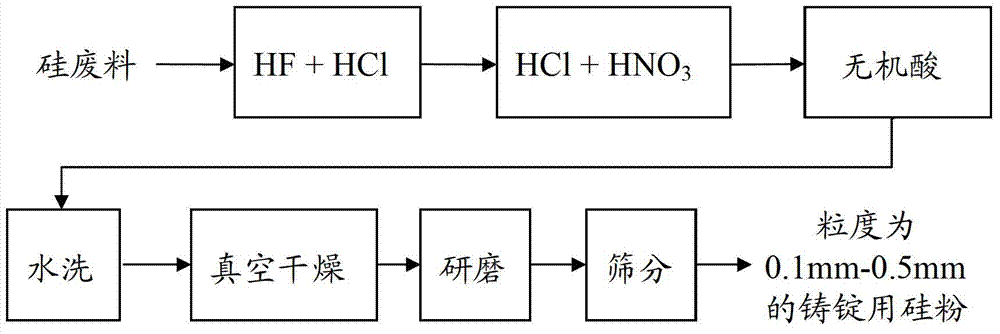

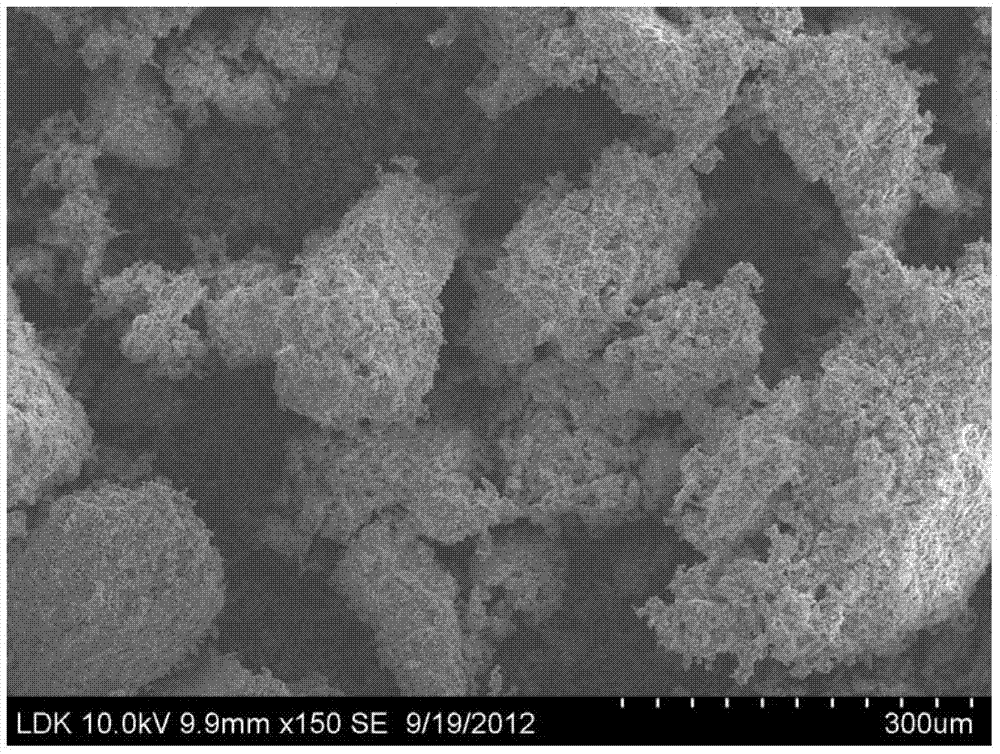

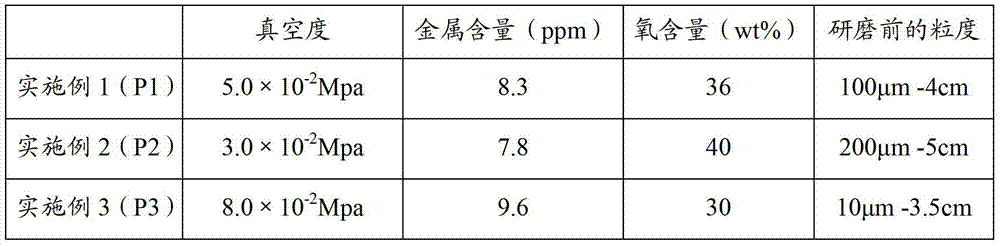

Ingot-casting silicon powder with controllable grain size as well as preparation method and application thereof

ActiveCN103395788AGranularity controllableModerate reunionSilicon compoundsHydrofluoric acidIngot casting

The invention provides a preparation method of ingot-casting silicon powder with controllable grain size. The preparation method comprises the following steps of: pickling silicon waste by using hydrofluoric acid and hydrochloric acid; pickling by using hydrochloric acid and nitric acid; pickling by using inorganic acid; carrying out solid-liquid separation and washing until the pH value is neutral, so as to obtain primary silicon powder; placing the primary silicon powder in a dryer with the temperature of 30-120 DEG C, setting the vacuum degree of the dryer as3.0*10<-2>-8.0*10<-2>MPa, and drying for 2-24 hours, so as to obtain the silicon powder with the grain size of 10 microns to 5 centimeters; grinding the obtained silicon powder, and screening by using a non-metal screen, so as to obtain the ingot-casting silicon powder with the grain size of 0.1-0.5mm. The preparation method can be used for solving a problem that the silicon powder is easy to melt during an ingot-casting process due to the low surface oxidization degree or extremely low grain size of the silicon powder. The invention further provides ingot-casting silicon powder with controllable grain size and application of the ingot-casting silicon powder in the field of solar poly-crystal silicon ingot preparation.

Owner:JIANGXI SAI WEI LDK SOLAR HI TECH CO LTD

Air flow pulverizer

ActiveCN102205259AChange grading performanceAvoid the risk of foreign matterGrain treatmentsRotary wingFront cover

The invention provides an air flow pulverizer comprising a housing 10 having a cylindrical main body 11 and a conical front cover 12. Inside the housing, a suspension arm supports a rotary wing 5 at an inlet side and a rotary wing 6 at an outlet side, and a pulverizing area 15 with certain volume is defined by the rotary wings and the inner wall of the housing 10. The position of the conical front cover 12 is adjustable relative to the cylindrical main body 11 of the housing 10, so as to change the grading performance of a grading area formed by the conical front cover 12 and a conical portion 9 of the rotary wing 6 at the outlet side.

Owner:MINAMI SANGYO

Ecological fish-farming method

InactiveCN108617551AStable particle sizeImprove water stabilityClimate change adaptationAnimal feeding stuffDiseaseAquatic animal

The invention relates to an ecological fish-farming method. The method comprises the following steps: 1) fish pond construction; 2) fish pond treatment; 3) fry stocking; 4) water quality management; and 5) feeding management. The method provided by the invention adopts an ecological circulation mode of flowing water culture and a mode of imitating natural growth, and cultured fish have good quality of fish, a high yield, and a low incidence rate; through the flowing water culture, no chemical drugs are used for sterilization and disinfection, water quality is good, and the cultured fish have afast growth speed and strong disease resistance; and aquatic animals and plants and artificial biological feed are mainly used, so that the cultured fish have fresh and delicious fish and high quality, and breeding benefits and ecological benefits are increased.

Owner:长沙市开福区竹坡水产养殖有限公司

Production method of germinated brown rice tea bag

InactiveCN101385494AFit for drinkingStable particle sizeTea substituesFood preparationPenetration forceGamma-Aminobutyric acid

The invention relates to a production method of germinated brown rice teabag which is rich in gamma-aminobutyric acid and is convenient in drinking; wherein, the method takes the germinated brown rice which is rich in gamma-aminobutyric acid as raw material; after being parched at 120 DEG C, the germinated brown rice is crashed into 20-40 meshes in grain size, then is filled into a tea bag with less than 100 meshes in penetration force, therefore, the finished products is obtained after the tea bag is sealed. Before being bagged, the germinated brown rice can also be added with 25% of tea dust, essence and flavors or ethyl maltol and the like, to prepare the products with different flavors. The products produced by the method have the advantages of proper grain size, soak resistance, good flavor and convenient in drinking.

Owner:FUJIAN AGRI & FORESTRY UNIV

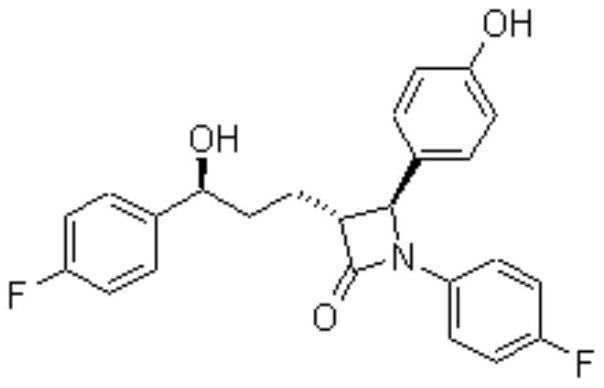

Ezetimibe medicinal preparation

ActiveCN111803458ASolve liquidity problemsImprove liquidityOrganic active ingredientsPowder deliveryProcess engineeringPharmaceutical formulation

The invention relates to an ezetimibe medicinal preparation. The medicinal preparation specifically comprises an ezetimibe solid dispersion, a filling agent, a disintegrating agent and an adhesive, wherein the ezetimibe solid dispersion comprises ezetimibe, microcrystalline cellulose and a dispersing agent; and the particle size d0.5 of the microcrystalline cellulose is less than or equal to 30 [mu] m. The ezetimibe medicinal preparation prepared by the invention has a relatively good dissolution rate, and has a dissolution effect consistent with that of an original researched sold product; the process is smooth in the preparation process; the quality of the obtained product meets the standard requirements; and the ezetimibe medicinal preparation is suitable for industrial large-scale production.

Owner:BEIJING WINSUNNY PHARMA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com