Air flow pulverizer

A jet mill and pulverized material technology, applied in grain processing and other directions, can solve the problems of time-consuming and laborious, foreign matter mixed in adjustment operations, deviation of the interval between the front cover and the discharge side rotor, and achieve the effect of stable particle size and restraining quality deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

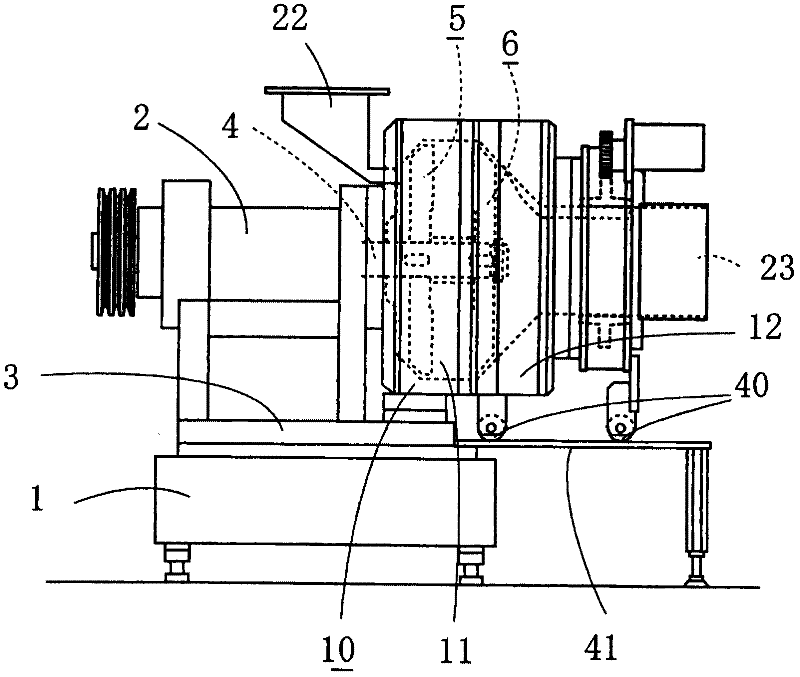

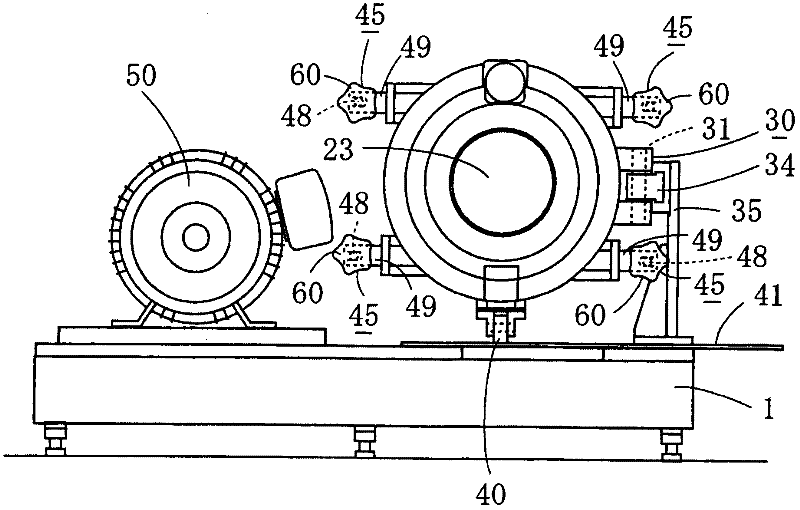

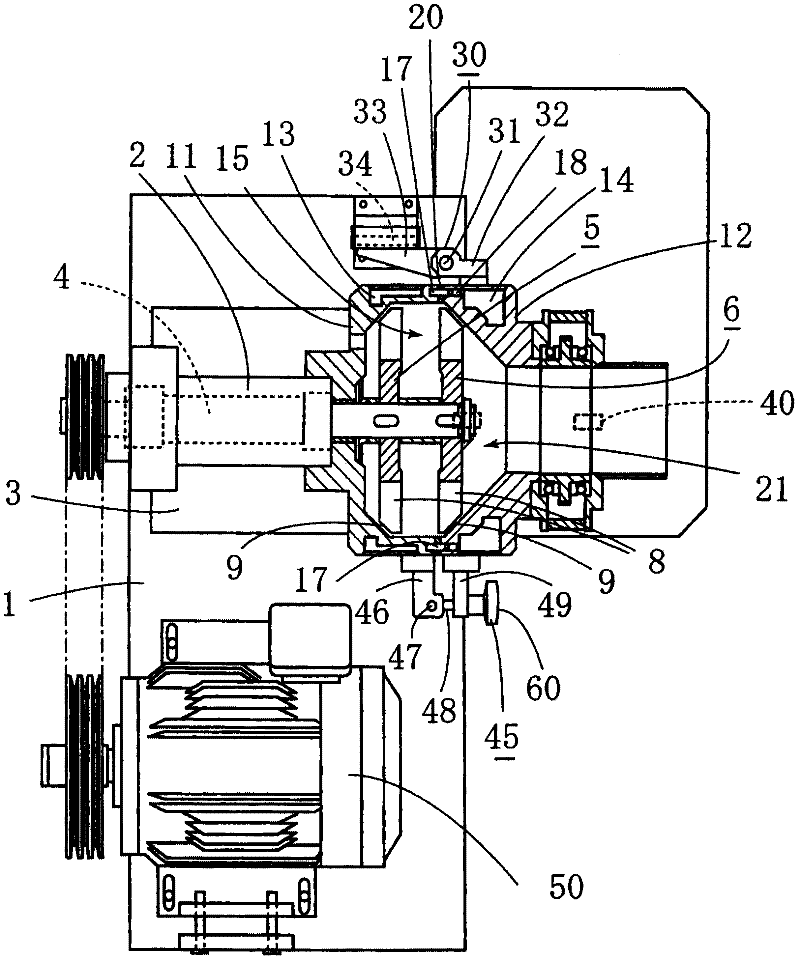

[0062] exist Figure 1 to Figure 3 Among them, 1 is a base, 2 is a bearing horizontally supported by a frame 3 on the base 1 , and 4 is a rotating shaft supported by the bearing 2 . As shown in the figure, the rotating shaft 4 protrudes in a cantilever form from the bearing 2 , and the inlet-side rotor blade 5 and the discharge-side rotor blade 6 are fixed at a certain interval by spacer sleeves or the like, and can be rotated at high speed by a motor (motor) 50 . The shape of the inlet side rotor 5 and the outlet side rotor 6 is substantially the same, as image 3 , Figure 4 As shown, a plurality of blades 8 protrude from the outer periphery of the disc-shaped portion 7 on the central side. The tip portion of the blade 8 is formed as a tapered portion 9 . and, if figure 1 As shown, the inlet-side rotary blade 5 forms a tapered portion 9 on the inlet side, and on the discharge-side rotary blade, a tapered portion 9 is formed on the discharge side opposite to the inlet sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com