System for controlling grinding density and fineness as well as method for controlling grinding density and fineness

A control system, concentration and fineness technology, applied in the direction of grain processing, etc., can solve the problems of insufficient control accuracy, high labor intensity, slow response speed, etc., to achieve stable pulp concentration and particle size distribution, reduce labor intensity, and response speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present application, but not to limit the present application.

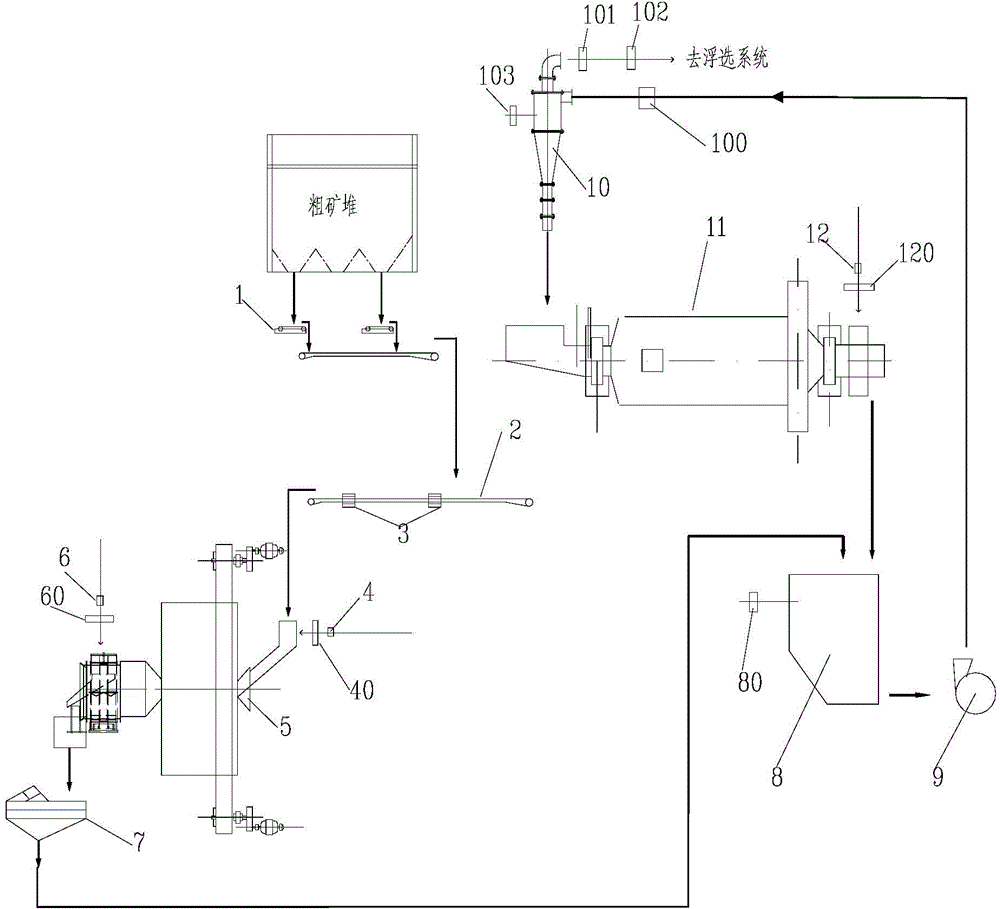

[0040] figure 1 It is a schematic diagram of the grinding process involved in the embodiment of the present invention.

[0041] like figure 1 As shown, in a preferred embodiment, the ore feeding device is a heavy plate type ore feeder 1 . The grinding process is roughly as follows:

[0042] The heavy-duty apron feeder 1 feeds the ore to the No. 3 belt 2, and the actual ore feeding amount is measured by the belt scale 3. The ore is transported into the semi-autogenous mill 5 through the No. 3 belt 2. The semi-autogenous mill 5 is provided with a semi-autogenous mill water adding valve 4 at the feed end. The actual water supply is measured by the semi-autogenous mill water adding valve flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com