Method and device for treating waste bread

The technology of a processing device and a processing method is applied in the directions of grain processing, preliminary processing to promote the drying of solid materials, removal of solid waste, etc., and can solve the problems of complicated processing procedures and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

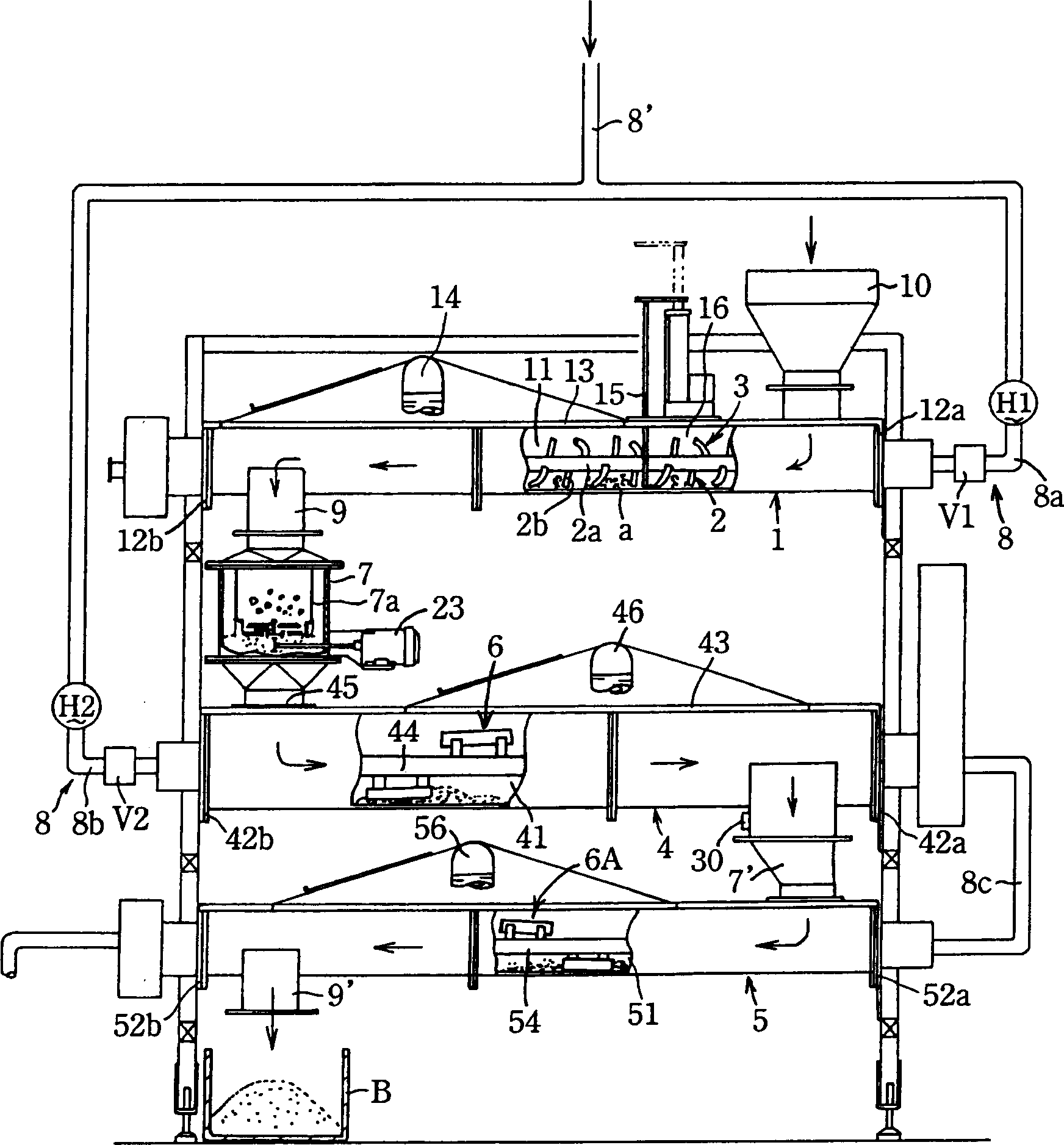

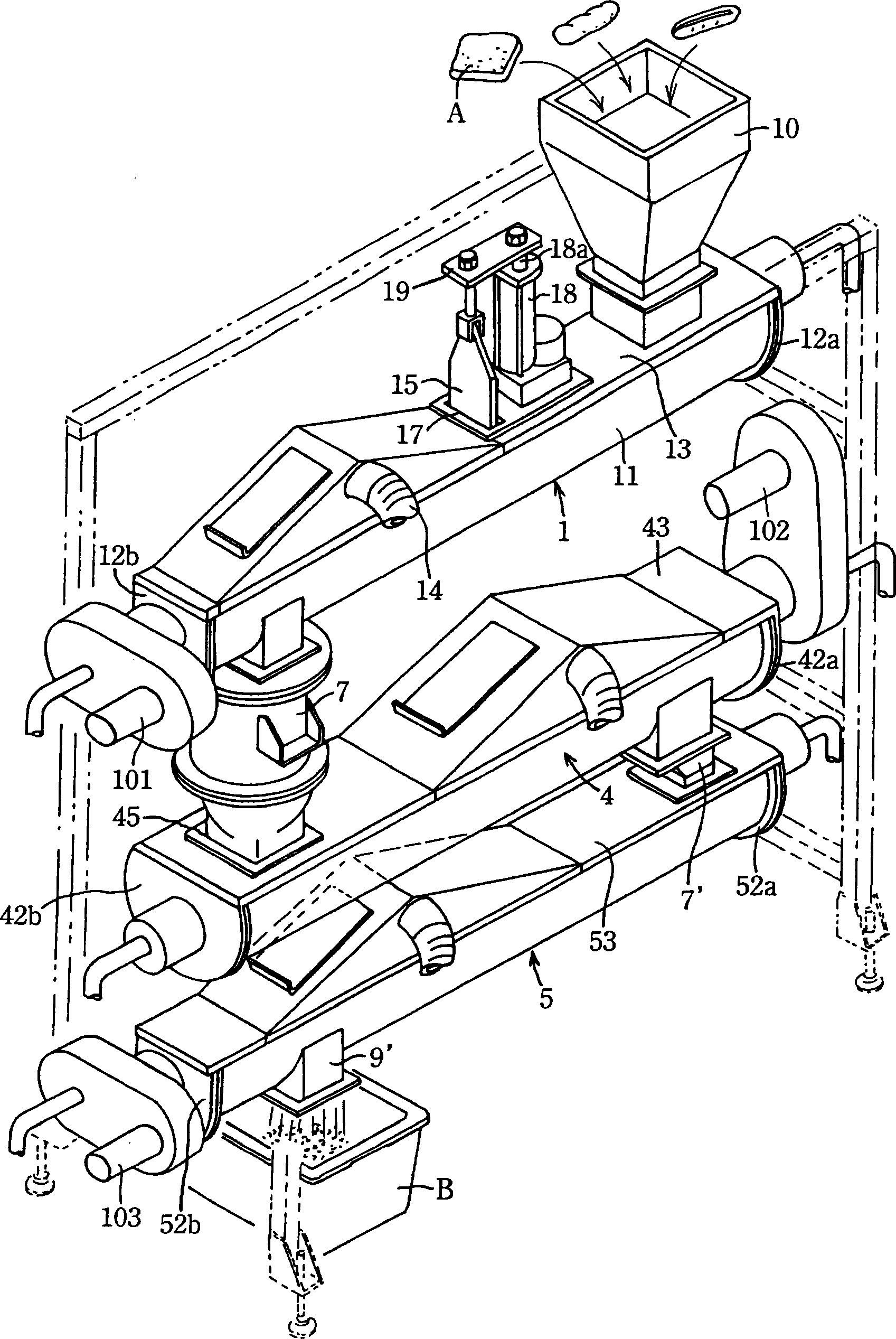

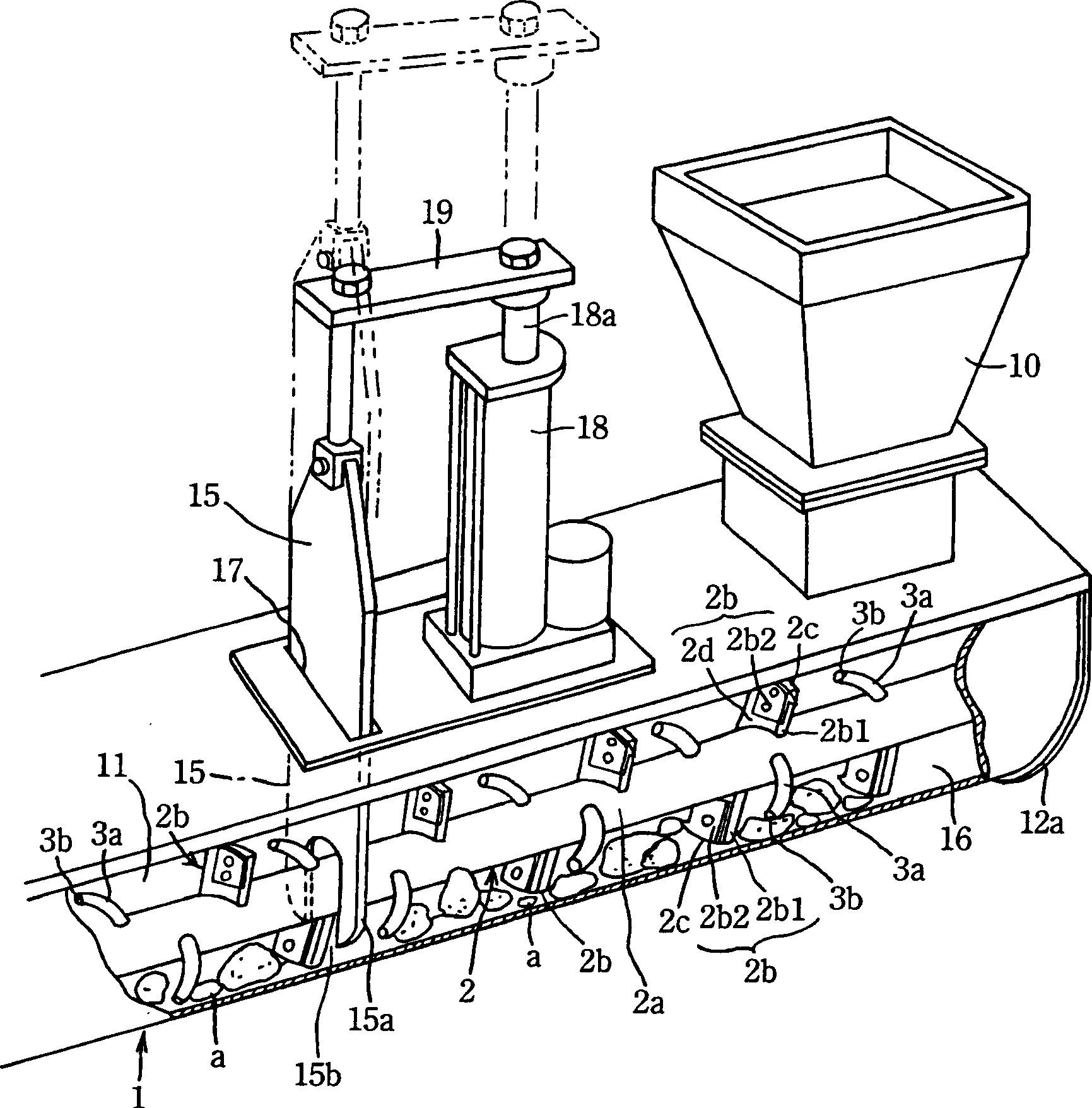

[0045] Next, the specific embodiment of the processing apparatus of the discarded bread of this invention is demonstrated based on drawing. figure 1 , figure 2 Among them, the processing device for discarded bread A consists of an airtight cylindrical primary drying passage 1 which is connected to the upper upper part of one end side, communicates with the opening lower end of the discarded bread input hopper 10, and is provided with a discarded bread pulverizing device 2 and a hot air injection device 3 inside. , arranged side by side under the primary drying passage 1, through the vertical cylindrical passage 7 to receive the discarded bread A powder a that is transported out from the outlet at the other end of the primary drying passage 1 and carry out secondary drying. The secondary drying passage 4 is arranged side by side under the secondary drying passage 4, and is in the shape of a closed cylinder that dries the dried powder a of the discarded bread A that is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com