Method for determining sinter mixture granularity

A sinter mixture and particle size technology, which is applied in particle size analysis, measuring devices, particle and sedimentation analysis, etc., can solve the problem of inability to evaluate the effect of technical measures for strengthening sinter mixture granulation, and the measurement method cannot objectively reflect the particle size composition and measurement results Problems such as poor repeatability and comparability, to achieve objective and true measurement results, less human interference factors, and no potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

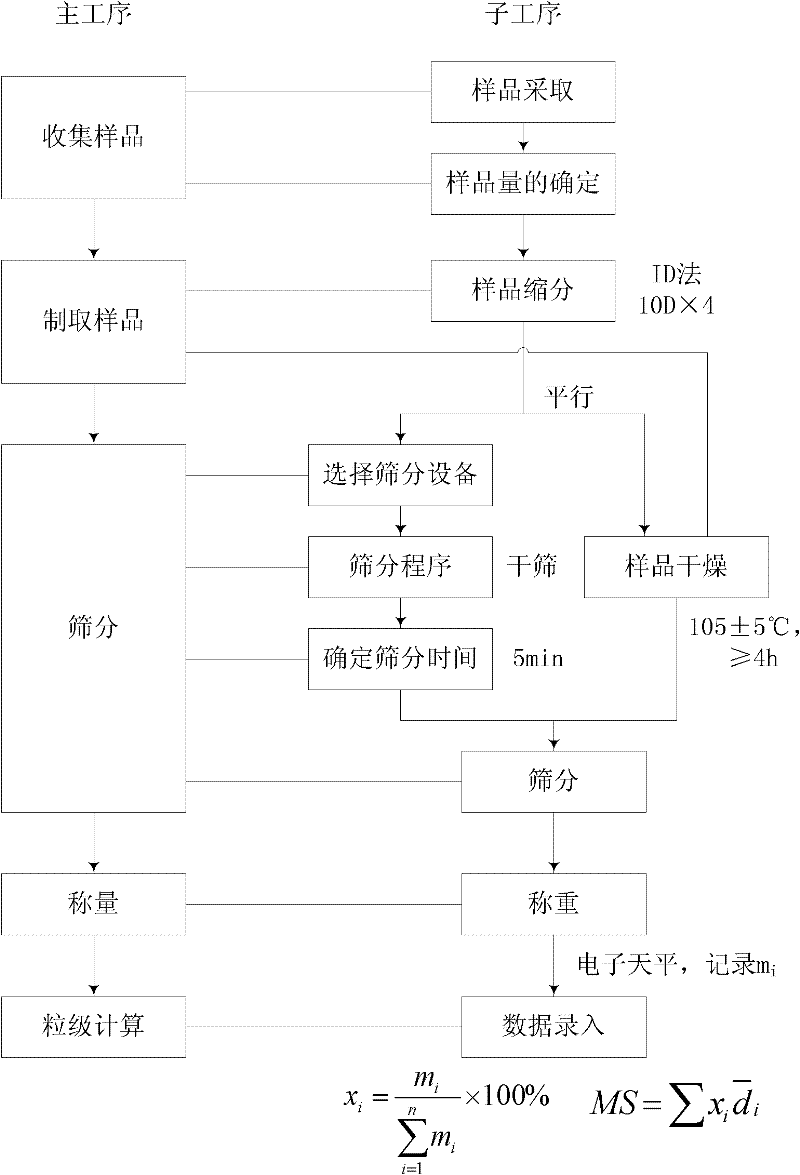

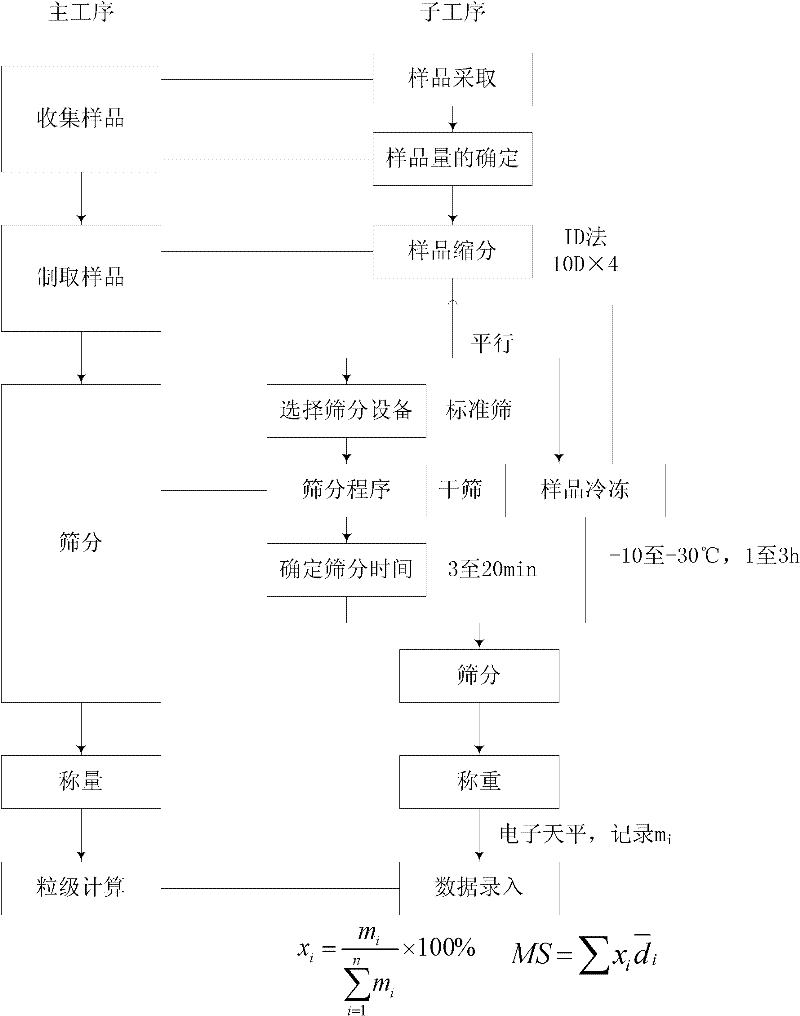

Method used

Image

Examples

Embodiment

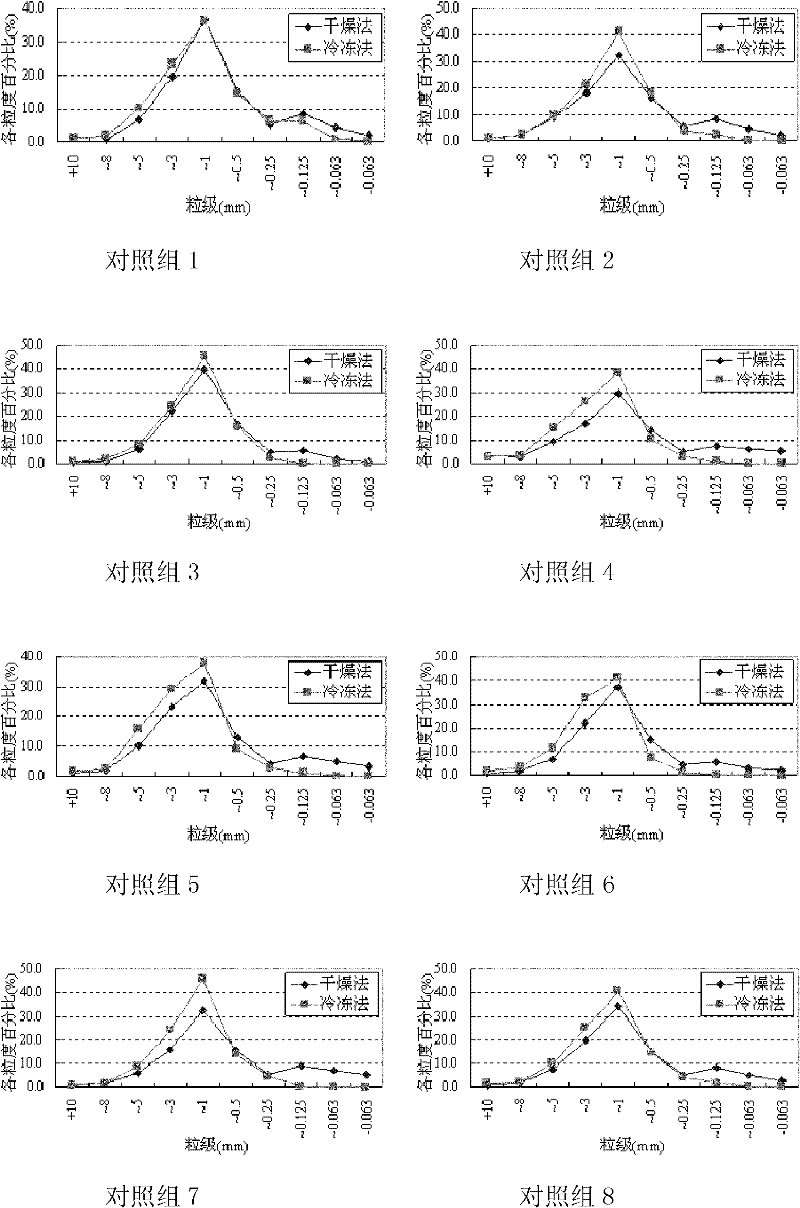

[0041] The freezing method of the present invention and the existing drying method are used to measure the particle size of the same sintered mixture sample, and its performance comparison is shown in Table 2, and the particle size composition comparison of the two methods is shown in Table 2. image 3 , the average particle size comparison see Figure 4 .

[0042] Table 2 Comparison of the performance of the freezing method and the drying method in the determination of the particle size of the sintered mixture

[0043]

[0044]

[0045] Note: (1) MS is the mean size (Mean Size), and the calculation formula is as described above.

[0046] (2) MS calculation example, calculated according to the data of each particle size of the freezing method in the control group 1, where the average particle size of the +10mm particle size powder is calculated as 12.5mm.

[0047] MS=12.5×1.1%+(10+8)÷2×1.7%+(8+5)÷2×10.1%+(5+3)÷2×23.2%+(3+1)÷2×36.3% +(1+0.5)÷2×14.4%+(0.5+0.25)÷2×6.1%+(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com