Toner and image forming process

A technology of toner and colorant, applied in the field of toner, which can solve problems that have not yet been successful

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

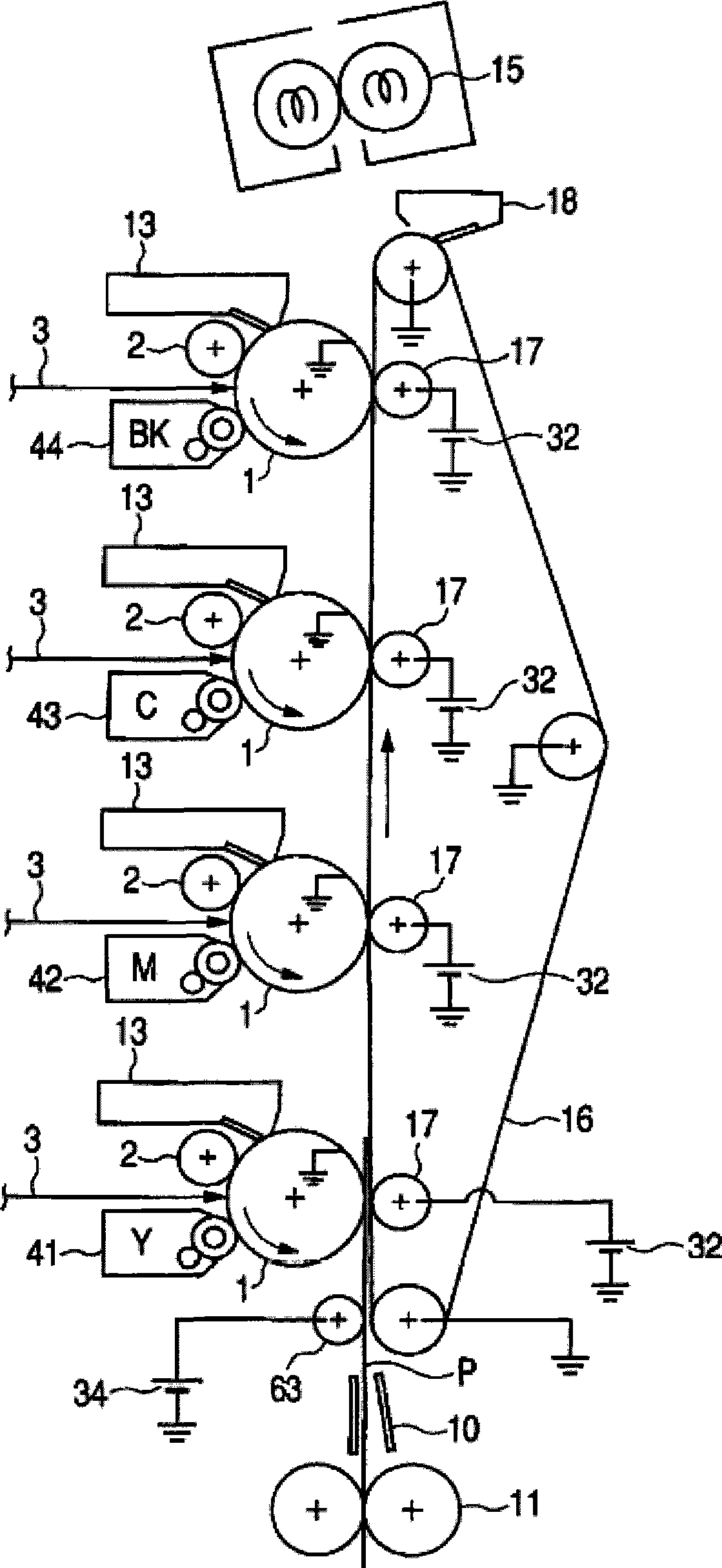

[0046] In the present invention, a fatty acid metal salt composition containing a nonionic surfactant is added to the toner mother particles as an external additive. This can improve the releasability of the toner and can prevent the toner from melting-adhering (toner filming) to the toner carrying member. Furthermore, due to its excellent releasability, it is possible to prevent fine powder having a relatively small particle diameter from remaining on the surface of the toner carrying member, and this makes it possible to maintain a stable particle size distribution throughout the operation.

[0047] In addition, as long as a fatty acid metal salt composition containing a nonionic surfactant is added as an external additive to toner base particles, the charging stability of the toner is improved, and the charge amount can be maintained at a suitable level throughout operation. within range. Therefore, this can well prevent any occurrence of halftone image unevenness and imag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

| Median diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com