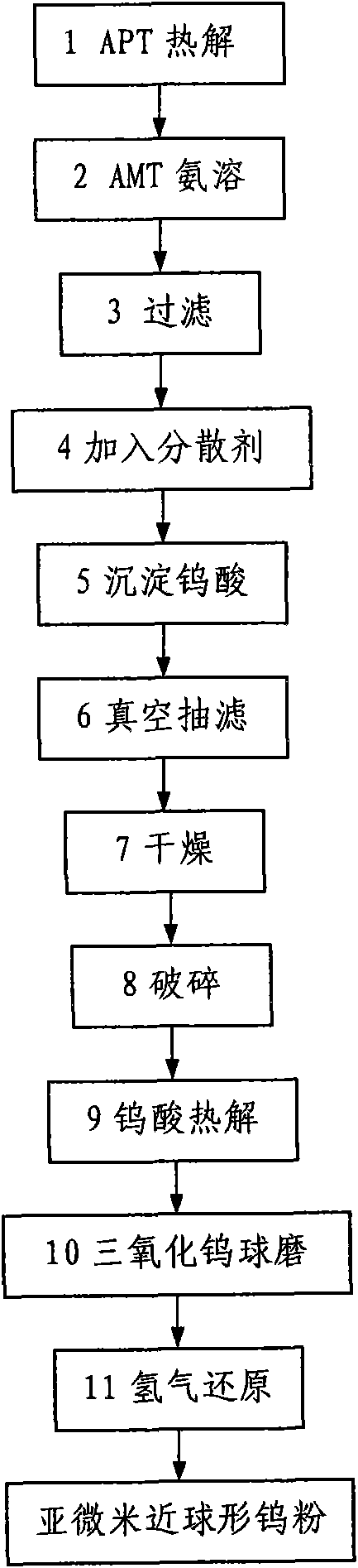

Preparation method of submicron nearly spherical tungsten powder

A near-spherical, sub-micron technology, applied in the field of powder metallurgy powder making, can solve the problems of high cost and coarse tungsten powder particles, and achieve the effects of low cost, elimination of agglomeration and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

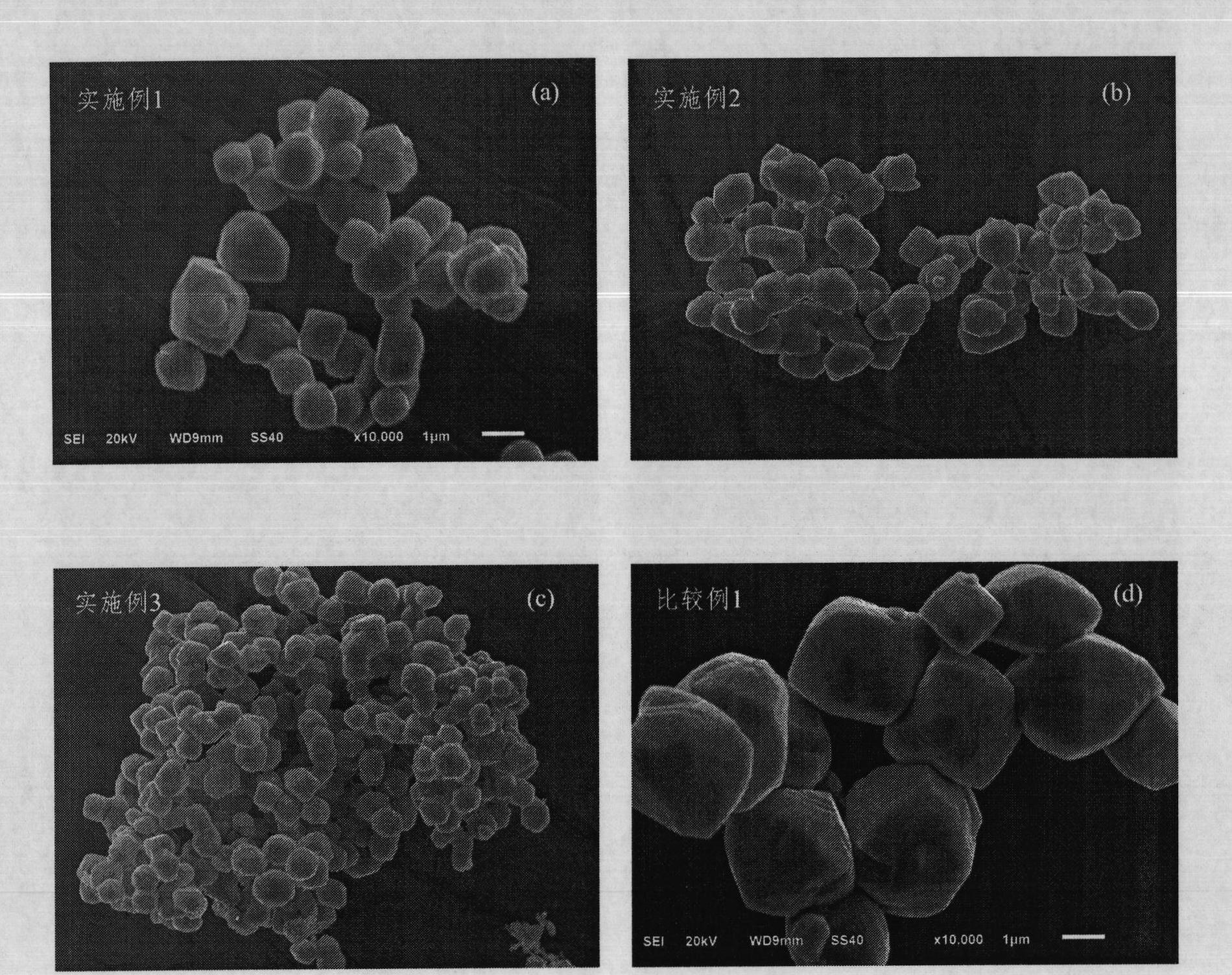

[0039] Accurately weigh 1000g of ammonium paratungstate (APT), place it in a porcelain boat, and pyrolyze it in a muffle furnace at 310°C for 1.5h to obtain 925g of amorphous ammonium metatungstate (AMT) with a weight loss rate of 7.5%; The obtained AMT was dissolved in an aqueous ammonia solution, the dosages of deionized water and ammonia water were 925ml and 1220ml respectively, stirred for 4h, and allowed to stand for 30min; the supernatant and the undissolved material were subjected to vacuum filtration to obtain 2100ml of ammonium tungstate solution with a density of 1.255 g / cm 3 , wherein the effective W content is 525g; based on the effective W content of 5% by weight, add 23ml of low molecular weight polyacrylate (PAANH) of an aqueous system to the ammonium tungstate solution 4 , diluted 10 times) as a dispersant, stir for 10 minutes and mix well; add 1100ml of concentrated nitric acid as a precipitant under strong mechanical stirring, first generate scheelonic acid, ...

Embodiment 2

[0042] Add 10 weight ‰ of methoxy polyethylene glycol (MPEG) and polyvinyl alcohol (PVA) as dispersant, add 1100ml concentrated hydrochloric acid as precipitant; in addition, vacuum filtration to obtain tungstic acid gel and place it in a quartz boat , dried at -60°C for 20h in a vacuum freeze dryer; the same as in Example 1, except that the type and amount of dispersant, the type of precipitant, and the drying method of tungstic acid gel are different from those in Example 1.

[0043] Observed by field emission scanning electron microscope (FESEM), the particle morphology of the prepared tungsten powder is nearly spherical, and the diameter of most particles is between 0.5 and 0.9 μm, such as figure 2 (b).

Embodiment 3

[0045] Add 15% by weight of polyvinylpyrrolidone (PVP) as a dispersing agent, and add 1100 ml of concentrated hydrochloric acid as a precipitating agent.

[0046] Observed by field emission scanning electron microscope (FESEM), the particle morphology of the prepared tungsten powder is nearly spherical, and the diameter of most particles is between 0.3 and 0.7 μm, such as figure 2 (c).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com