A kind of silicon carbon negative electrode material slurry and preparation method thereof

A negative electrode material and slurry technology, applied in the field of silicon carbon negative electrode material slurry and its preparation, can solve the problems of silicon carbon particle damage, uneven dispersion, poor graphite wrapping, etc., to prevent secondary agglomeration and improve cycle life , Improve the effect of dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the silicon carbon negative electrode material slurry of the present invention comprises the following steps:

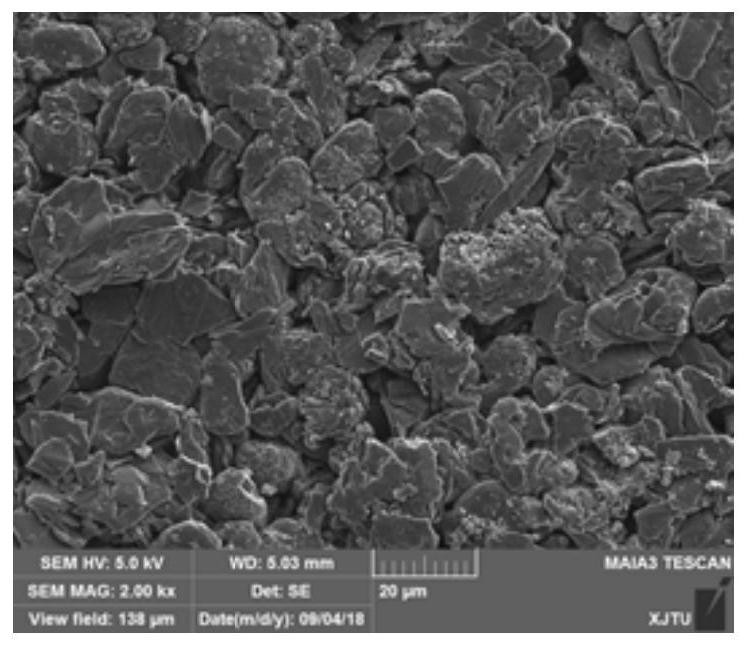

[0027] 1) According to the pulping ratio, add part of the CMC glue, all the conductive agent and all the silicon carbon particles, mix and wet at a low speed of 10-100 rpm for 10-100 minutes, and then disperse at a high speed of 2000-3000 rpm for 60- 180 minutes, obtain slurry 1;

[0028] 2) Add all the graphite materials to the slurry 1, mix and wet at a low speed of 10-100 rpm for 10-100 minutes, then disperse at a high speed of 2000-3000 rpm for 60-180 minutes to obtain slurry 2;

[0029] 3) Add the remaining CMC glue and part of the deionized water to the slurry 2, vacuumize, and disperse at a high speed of 2000-3000 rpm for 60-180 minutes to obtain the slurry 3;

[0030] 4) Add SBR binder with a solid content of 45% to the slurry 3, disperse at a high speed of 2000-3000 rpm for 20-90 minutes, add deionized water to adjust the vi...

Embodiment 1

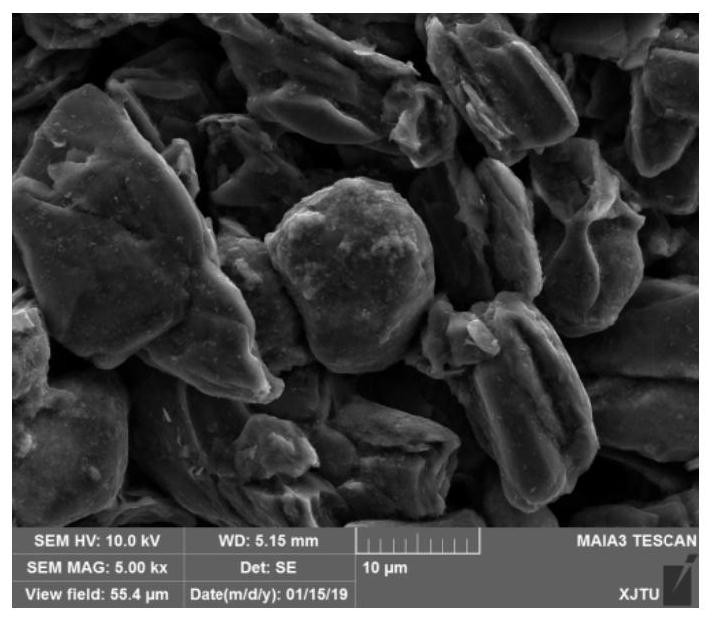

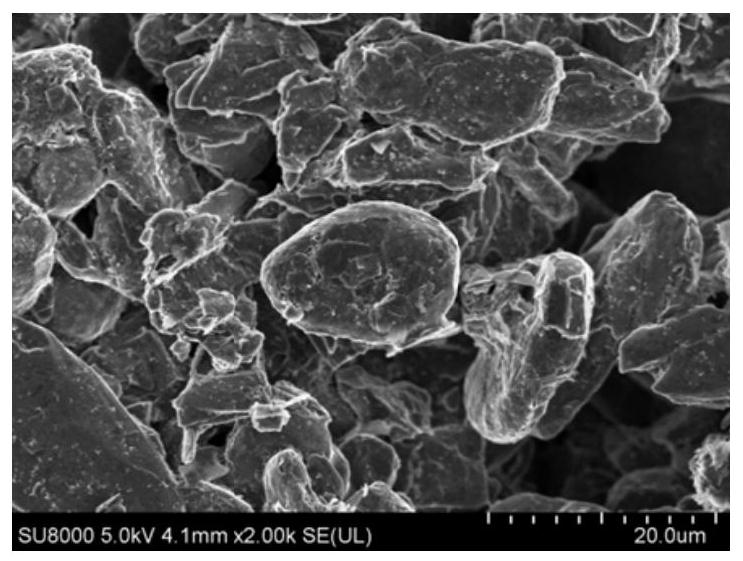

[0040] 1) According to the mass ratio of silicon carbon, graphite, conductive agent, sodium carboxymethyl cellulose (CMC), and SBR 10:85:1:1.5:2.5, add carboxymethyl with a solid content of 1% accounting for 30% of the total glue amount Base cellulose sodium (CMC) glue 720g, conductive agent SP16g and core-shell silicon carbon particles 160g (900mAh / g), wherein the silicon carbon particle D50 is 15μm, first mix and wet at low speed at 10 rpm for 10 minutes, and then 2000 rpm high-speed dispersion for 60 minutes to obtain slurry 1;

[0041] 2) Then add 1360g of all graphite materials to the slurry 1, wherein the graphite particle D50 is 10 μm, mix and wet at a low speed of 10 rpm for 10 minutes, and then disperse at a high speed of 2000 rpm for 60 minutes, slurry 2;

[0042] 3) Add 1680g of remaining glue and deionized water to slurry 2, vacuumize at 2000 rpm and disperse at high speed for 60 minutes, slurry 3;

[0043] 4) Add 88g of binder SBR to the slurry 3, disperse at a h...

Embodiment 2

[0045] 1) According to the mass ratio of silicon carbon, graphite, conductive agent, sodium carboxymethylcellulose (CMC), and SBR of 20:70:6:2:2, add carboxymethyl, which accounts for 35% of the total glue amount and has a solid content of 1.5%. Cellulose sodium (CMC) glue 778g, conductive agent Ketjen black 100g and embedded silicon carbon negative electrode material 333g (600mAh / g), in which the silicon carbon particle D50 is 19μm, mixed and wetted at low speed at 10 rpm for 30 minutes , and then dispersed at a high speed of 2200 rpm for 100 minutes, slurry 1;

[0046] 2) Then add 1166g of all graphite materials to the slurry 1, wherein the graphite particle D50 is 10 μm, mix and wet at a low speed of 10 rpm for 30 minutes, and then disperse at a high speed of 2200 rpm for 100 minutes, slurry 2;

[0047] 3) Add 1444g of remaining glue solution and deionized water to slurry 2, vacuumize at 2200 rpm and disperse at high speed for 100 minutes, slurry 3;

[0048] 4) Add 74.07g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com