Preparation method of universal titanium dioxide water slurry

A titanium dioxide, general-purpose technology, applied in the field of preparation of general-purpose titanium dioxide water slurry, can solve the problems of slurry layering, viscosity increase, waste of materials, etc., to avoid viscosity increase or serious layering, ensure performance and normal use , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

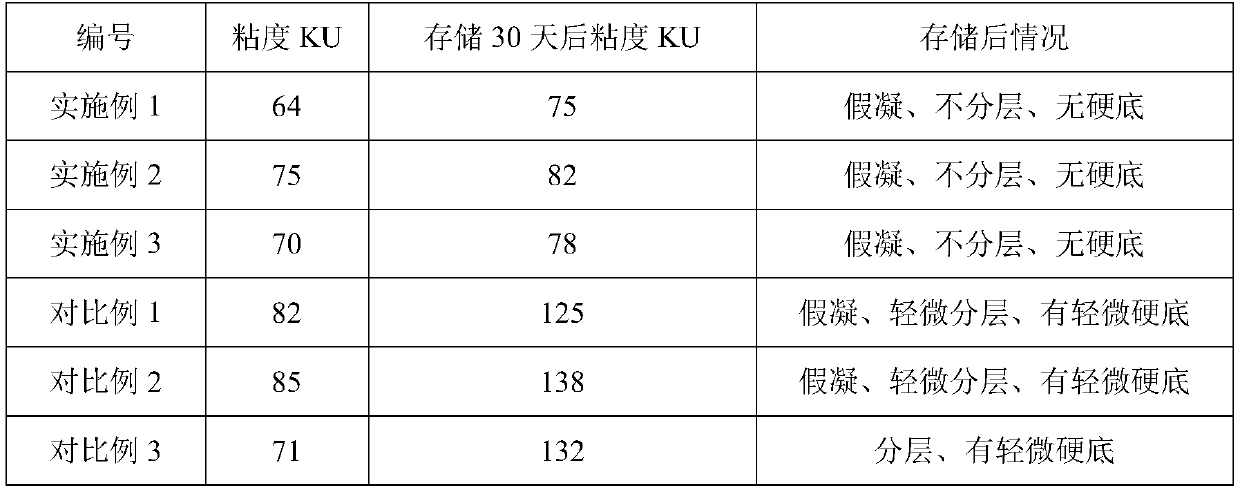

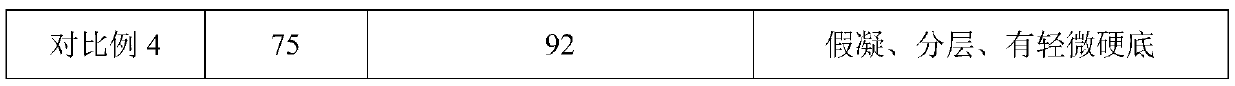

Examples

Embodiment 1

[0030] 1.1, take by weighing 400g of the primary rutile titanium dioxide powder prepared by the chlorination method, add deionized water to be mixed with a slurry with a mass concentration of 20%, adjust the pH of the slurry to 9.5 with sodium hydroxide solution, add 0.2% (in the form of SiO 2 accounted for TiO 2 by weight) sodium silicate solution, the concentration of sodium silicate solution is SiO 2 Calculated as 100g / L, aging for 20min.

[0031] 1.2. Heat the ground slurry to 60°C and maintain this temperature throughout the coating process.

[0032] 1.3, add 1.0% at one time (as SiO 2 accounted for TiO 2 by weight) sodium silicate solution, its concentration is SiO 2 Calculated at 100g / L, matured for 10 minutes, uniformly adjusted the pH of the slurry to 6.0 with a mass concentration of 5% sulfuric acid solution within 1 hour, and matured for 30 minutes.

[0033] 1.4. Add 1.0% sodium metaaluminate solution (with Al in sodium metaaluminate) at 0.5h 2 o 3 accounted ...

Embodiment 2

[0039] 1.1, take by weighing 400g of the primary rutile titanium dioxide powder prepared by the sulfuric acid method, add deionized water to be mixed with a slurry with a mass concentration of 30%, adjust the pH of the slurry to 11.0 with sodium hydroxide solution, add 0.5% (as SiO 2 accounted for TiO 2 by weight) sodium silicate solution, the concentration of sodium silicate solution is SiO 2 Calculated as 200g / L, aging for 40min.

[0040] 1.2. Heat the ground slurry to 90°C and maintain this temperature throughout the coating process.

[0041] 1.3, add 4.0% at one time (as SiO 2 accounted for TiO 2 by weight) sodium silicate solution, its concentration is SiO 2 Calculated at 200g / L, matured for 30 minutes, uniformly adjusted the pH of the slurry to 7.0 with a mass concentration of 10% hydrochloric acid solution within 3 hours, and matured for 60 minutes.

[0042] 1.4. Add 4.0% potassium metaaluminate solution (as Al in potassium metaaluminate) in 2h 2 o 3 accounted fo...

Embodiment 3

[0048] 1.1, take by weighing 400g of the primary rutile titanium dioxide powder prepared by the chlorination method, add deionized water to be mixed with a slurry with a mass concentration of 25%, adjust the pH of the slurry to 9.5 with sodium hydroxide solution, add 0.3% (in the form of SiO 2 accounted for TiO 2 by weight) sodium silicate solution, the concentration of sodium silicate solution is SiO 2 Calculated as 150g / L, aging for 30min.

[0049] 1.2. Heat the ground slurry to 80°C and maintain this temperature throughout the coating process.

[0050] 1.3, add 2.5% at one time (as SiO 2 accounted for TiO 2 by weight) sodium silicate solution, its concentration is SiO 2 Calculated at 150g / L, aging for 20min, adjusting the pH of the slurry to 6.5 with a nitric acid solution with a mass concentration of 10% within 2h, and aging for 50min.

[0051] 1.4. Add 3.0% sodium metaaluminate solution (with Al in sodium metaaluminate) in 1h 2 o 3 accounted for TiO 2 by weight), ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com