Method for preparing single crystal dispersed nanometer attapulgite through ion liquid synergetic high-pressure homogenizing treatment

A nano attapulgite, ionic liquid technology, applied in nanotechnology, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as changing the affinity and hydrophobic properties, and achieve the effects of stable quality, simple and easy process, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

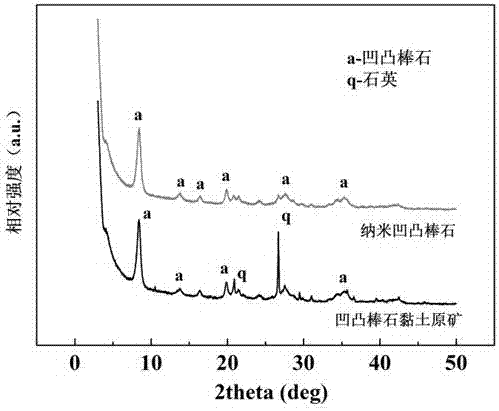

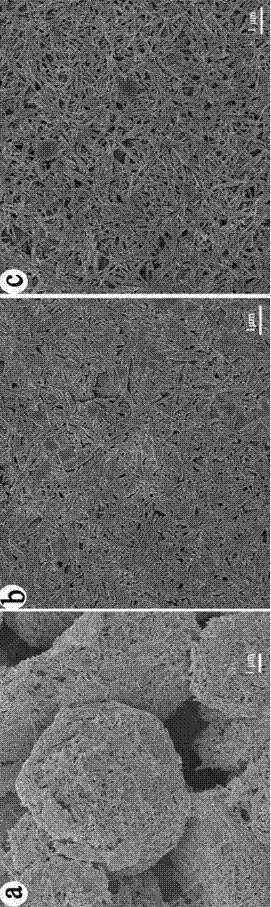

[0019] After crushing 50 kg of attapulgite ore, add 19.5 kg of ethanol / methanol containing 1.25 kg of 1-ethyl-3-methylimidazolium bromide ( v / v =1:1) in the solution, after mixing evenly, it is first processed by double rollers and pressed into tablets, and then transferred to a closed container for 24 hours, so that the ionic liquid and attapulgite can fully interact; then the mixture of attapulgite and ionic liquid is directly Disperse in 980kg of water, fully stir to form a suspension of about 5%, pass through a 400-mesh sieve, carry out high-pressure homogenization treatment at 5 MPa, and obtain the suspension hydraulic filtration treatment. The obtained filter cake has a power of 5 KW and a frequency of Under the action of 2450 Hz microwave, it was dried and pulverized to obtain off-white nano attapulgite. Its scanning electron microscope picture is shown in figure 2 c.

Embodiment 2

[0021] After crushing 50 kg of attapulgite ore, add 15 kg of ethanol / methanol containing 5 kg of 1,2-dimethyl-3-ethylimidazolium tetrafluoroborate ( v / v =1:1) solution, mixed evenly, processed by double rollers and pressed into tablets, then transferred to an airtight container and placed for 6 hours, so that the ionic liquid and attapulgite could fully interact; then the attapulgite and ionic liquid mixture was directly dispersed into 250 kg of water, fully stirred to form a 20% suspension, passed through a 400-mesh sieve, and subjected to high-pressure homogeneous treatment at 30 MPa, and the obtained suspension was hydraulically filtered, and the obtained filter cake had a power of 10 KW and a frequency of 2450 Under the action of Hz microwave, it is dried and pulverized to obtain off-white nano attapulgite. Its scanning electron microscope picture is shown in figure 2 c.

Embodiment 3

[0023] After crushing 50 kg of attapulgite ore, add 18 kg of ethanol / methanol containing 2 kg of 1,2-dimethyl-3-ethylimidazolium chloride ( v / v =1:1) solution, mixed evenly, processed by double rollers and pressed into tablets, then put in a closed container for 12 hours, so that the ionic liquid and attapulgite can fully interact; then directly disperse the attapulgite and ionic liquid mixture into 500 kg of water, fully stirred to form a 10% suspension, passed through a 400-mesh sieve, and subjected to high-pressure homogeneous treatment at 40 MPa, and the obtained suspension was hydraulically filtered, and the obtained filter cake had a power of 8 KW and a frequency of 2450 Under the action of Hz microwave, it is dried and pulverized to obtain off-white nano attapulgite. Its scanning electron microscope picture is the same as 2c.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com