Lithium iron phosphate positive plate and environment-friendly low-temperature-resistant lithium battery comprising same

A technology of lithium iron phosphate and positive electrode, which is applied in the field of environment-friendly low-temperature resistant lithium batteries, can solve the problems that limit the wide application of lithium iron phosphate batteries, low energy density of lithium-ion batteries, low tap density and compaction density, and achieve Conducive to conduction and diffusion, improve electrical and thermal conductivity, and high compaction density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The above-mentioned positive electrode sheet is prepared by the following methods, including:

[0043] 1) Add the formulated amount of aqueous positive electrode slurry and deionized water to the double planetary beater, and stir for 2 hours at a revolution speed of 40-50 revolutions / min and a rotation speed of 1300-1500 revolutions / min to make the first Aqueous cathode slurry;

[0044] 2) Add the above-mentioned first aqueous positive electrode slurry to a high-speed disperser, and disperse it to a viscosity of 5000-8000 mPa.s under the conditions of 3500-4500 revolutions / min to obtain the aqueous positive electrode slurry;

[0045] 3) Coat the water-based positive electrode slurry on aluminum foil with a thickness of 12-16μm, dry it until the moisture content is ≤1%, then roll compaction, and cut according to the width required by the process to obtain the positive electrode sheet;

[0046] An environmentally friendly low-temperature resistant lithium battery, comprising the ...

Embodiment 1-4

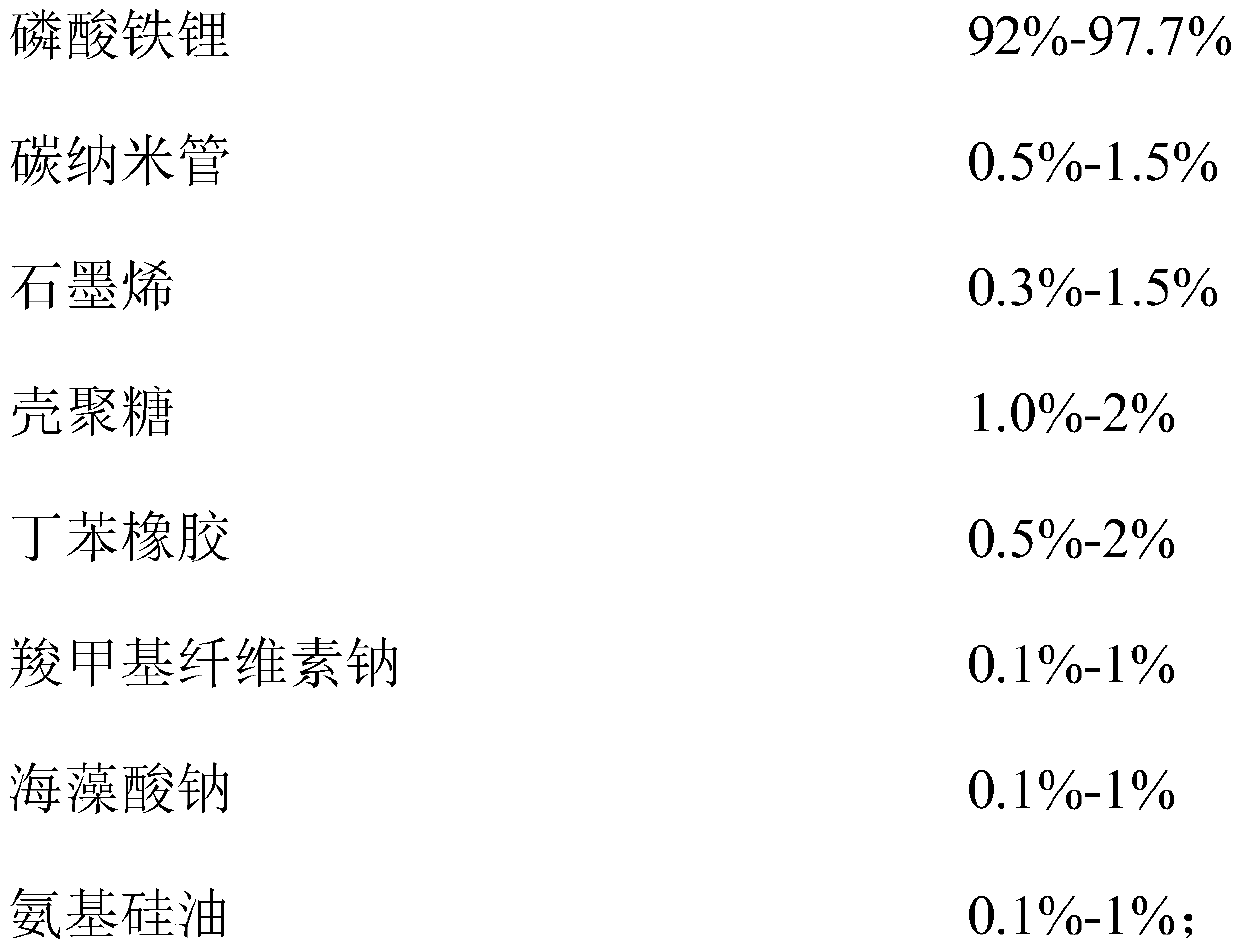

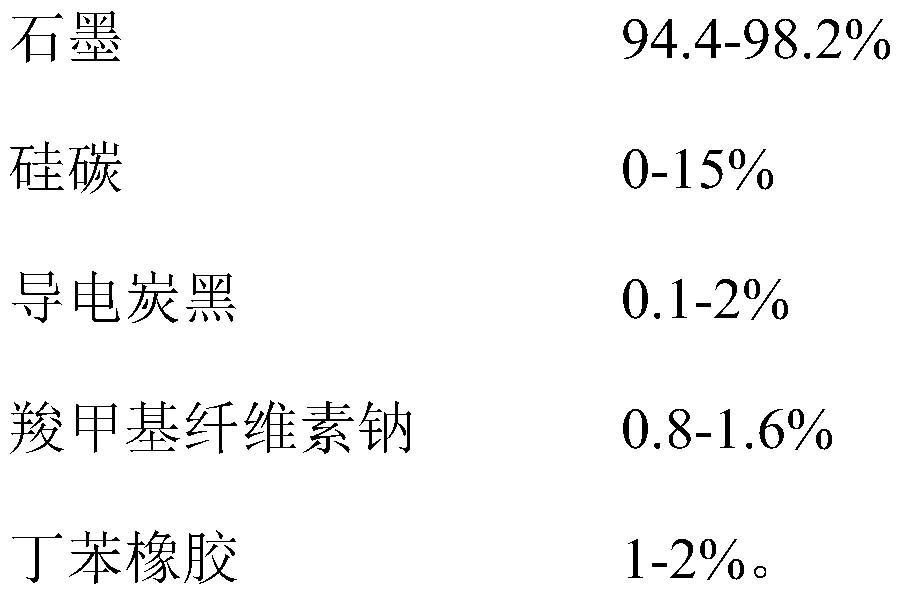

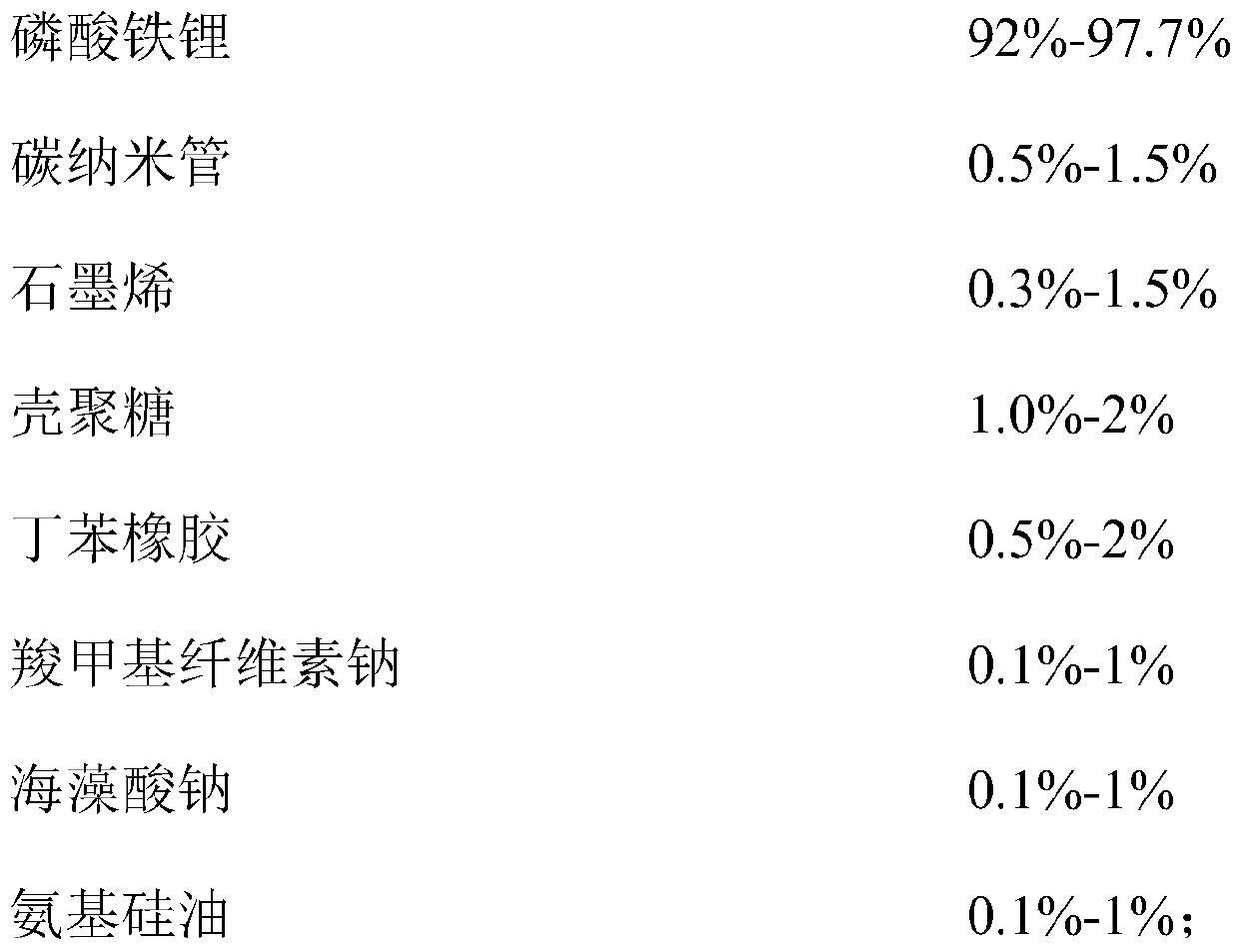

[0065] The components were weighed according to the proportions in Table 1, and the positive electrode plates were prepared according to the preparation methods of Examples 1-4.

[0066] Table 1 Example 1-4 Positive electrode composition

[0067]

[0068] Among them, the particle size of lithium iron phosphate is 4-10 μm, and the average particle size is 6 μm.

Embodiment 1

[0071] 1) Add the aqueous cathode slurry and deionized water of the formula in Table 1 into the double planetary beater, and stir for 2 hours under the conditions of revolution speed of 48 revolutions / min and rotation speed of 1400 revolutions / min to make the first aqueous cathode Slurry

[0072] 2) Add the above-mentioned first aqueous positive electrode slurry to a high-speed disperser, and disperse it to a viscosity of 5000 mPa.s under the condition of 3500 revolutions / min to obtain the aqueous positive electrode slurry;

[0073] 3) Coat the water-based positive electrode slurry on a 14μm thick aluminum foil according to the areal density of 300g / ㎡, and dry it until the water content is ≤1%, and then the active material is 2.6g / mm 3 The compaction density is rolled and finally cut into 57mm wide positive electrode sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com